Head installation structure of a template sewing machine

An installation structure and technology for sewing machines, applied in the field of sewing machines, can solve problems such as vibration and noise of worktables and racks, and achieve the effects of improving sewing accuracy and reducing vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

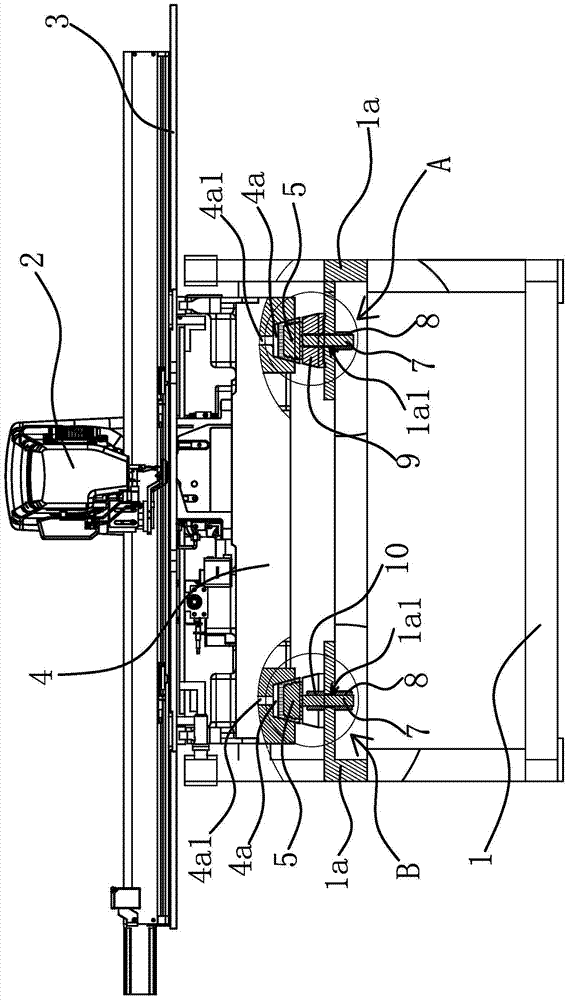

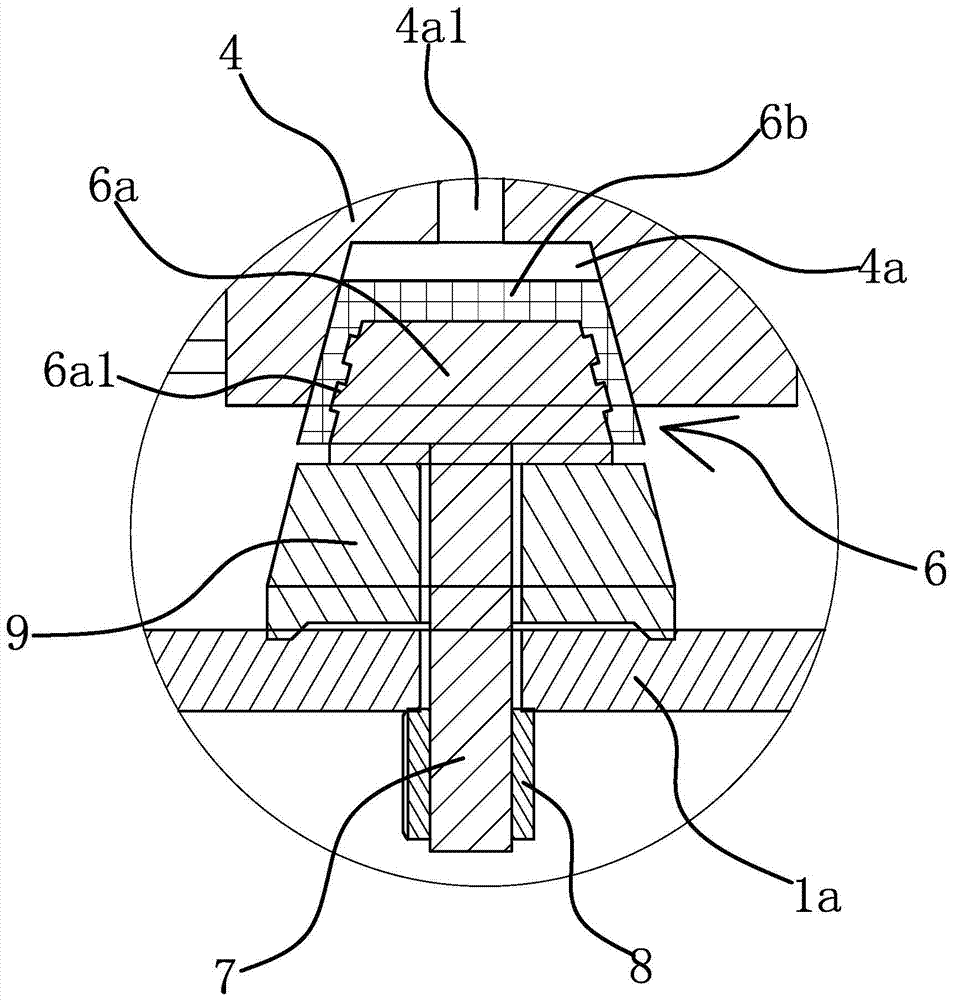

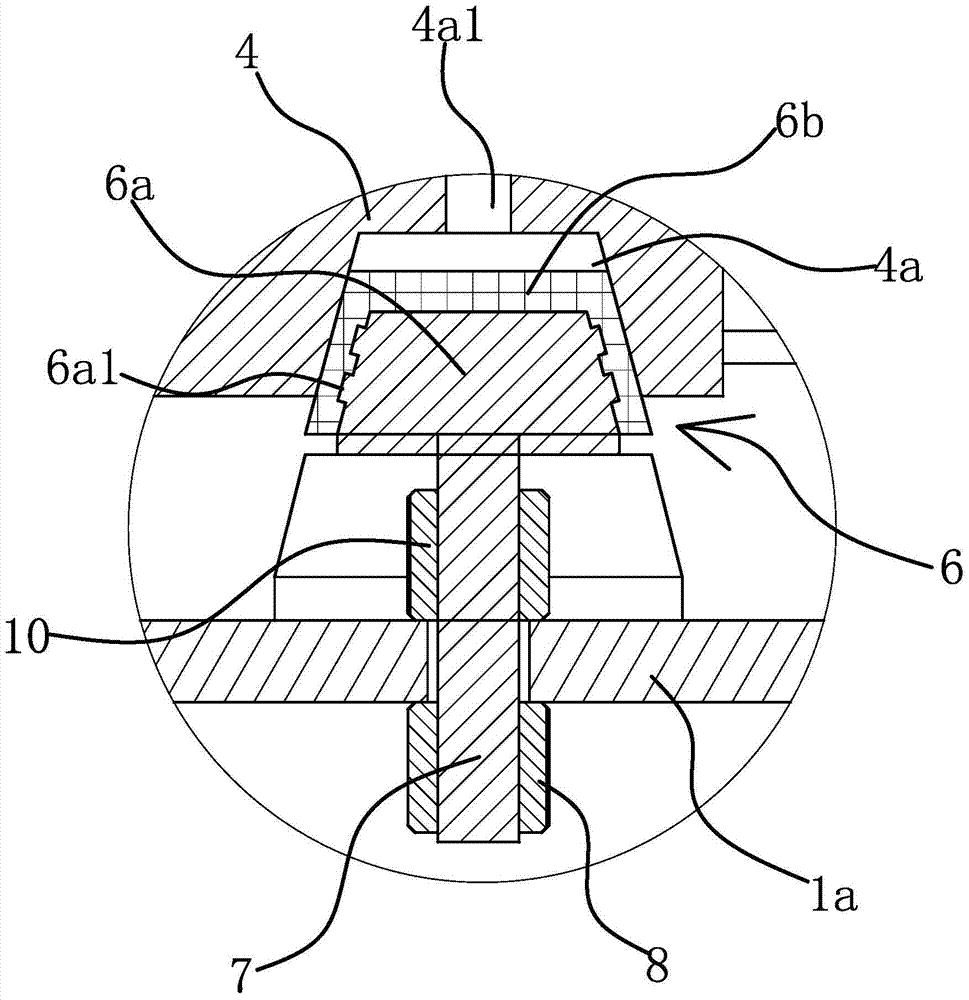

[0025] The template sewing machine includes a frame 1 , a machine head 2 and a worktable 3 , and the worktable 3 is arranged on the frame 1 . The head installation structure of the template sewing machine includes a base 4, a positioning hole 4a, a support portion 1a, a relief hole 1a1, a support pad 5, a head 6, a stud 7 and a lock nut 8.

[0026] Specifically, as figure 1 and Figure 4 As shown, there is an accommodating space inside the middle position of the frame 1 , the base 4 is located in the accommodating space, and the support portion 1 a of the frame 1 is located below the base 4 . In actual production and manufacturing, the support part 1a can also be fixed on the frame 1 by using a separate component. The machine head 2 is fixed on the base 4 , and the machine head 2 protrudes from the upper surface of the worktable 3 .

[0027] Such as figure 1 and figure 2 As shown, several supporting pads 5 are arranged between the base 4 and the supporting part 1a. In th...

Embodiment 2

[0032]The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, a positioning block 9 is arranged between each supporting pad 5 and the supporting part 1a, and the positioning The blocks 9 are in rigid contact with the supporting pads 5 , and the studs 7 of each of the supporting pads 5 respectively pass through the corresponding relief holes 1a1 and are threadedly connected with locking nuts 8 . The function of setting the positioning block 9 is to keep the base 4 level by adjusting the height of the positioning block 9 , thereby ensuring the position accuracy of the machine head 2 relative to the worktable 3 .

Embodiment 3

[0034] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that in this embodiment, the support pad 5 is made of metal material, and the positioning hole 4a is provided with a shape of the inner wall of the positioning hole 4a Matching rubber gaskets. After the rubber gasket is damaged or fails, it is more convenient to replace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com