Dual-lead-screw synchronous drive zero-latency full-automatic single-end sewing machine

A technology of synchronous transmission and double screw, which is applied in the direction of sewing machine components, floral stitch sewing machines, sewing machine control devices, etc. It can solve the problems of complex structure of the movement mechanism, inability to sew, and many transmission shafts, etc., to achieve good synchronization , no vibration, stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

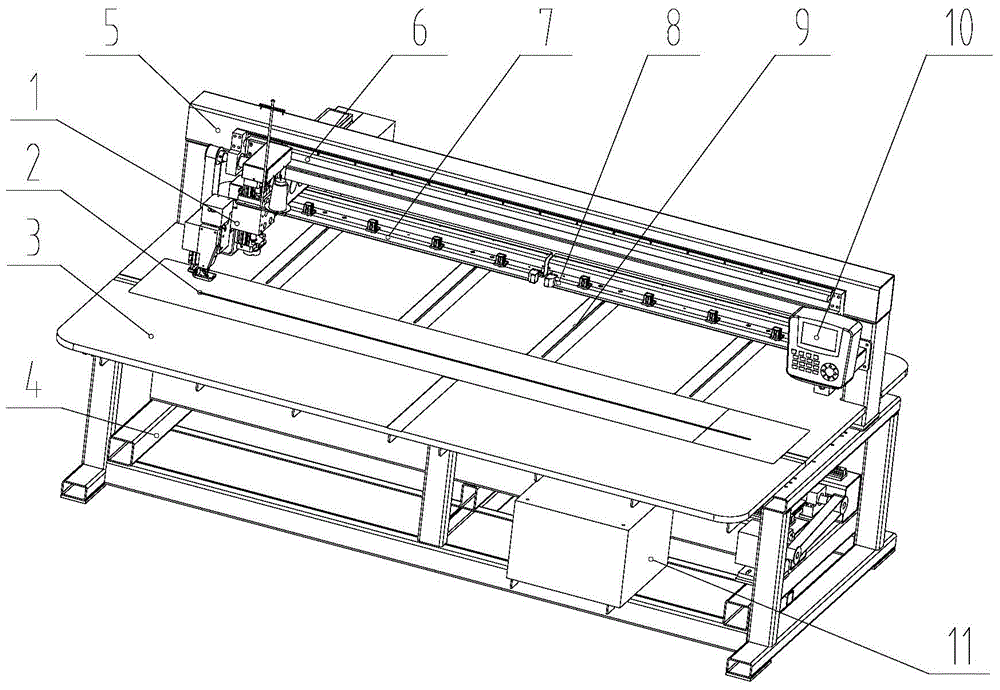

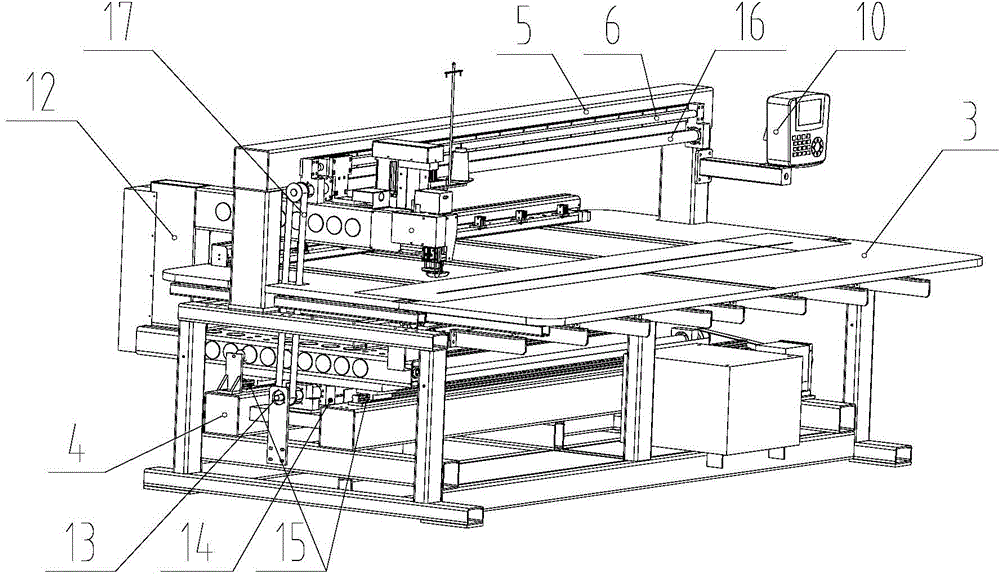

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The double-screw synchronous transmission zero-waiting full-automatic single-head sewing machine includes a frame 4 of a bridge frame, a platen 3 located under the frame girder 5 in the middle of the frame 4, and a X-direction of the frame girder. Guide rail 6, Y-direction A working group 7 located on the platen 3, Y-direction B working group 8, Y-direction driving device 9, machine head assembly 12, X-down transmission screw 13, X-direction transmission screw nut 14, X to slide guide rail 15, X upward transmission leading screw 16 and synchronous belt 17, and frame girder 5 is installed on X direction with frame girder X guide rail 6 and X upward transmission leading screw 16; Frame girder X guide rail 6 and The X upward transmission lead screw 16 is connected with the head assembly 12 to ensure the linearity and stability of the movement of the head assembly 12 in the X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com