Cylinder block with replaceable needle roller bearings

A technology of needle roller bearings and cylinders, which is applied in the field of cylinders with needle roller bearings, can solve problems such as damage to other accessories, deformation and lock damage, and small fit clearances, so as to improve service life, reduce maintenance costs, and replace easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

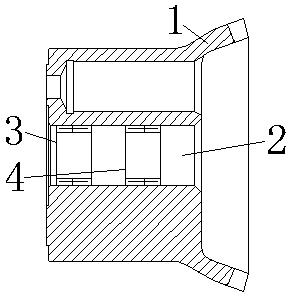

[0012] Such as figure 1 As shown, the cylinder with replaceable needle roller bearing according to the present invention includes a bevel gear cylinder 1, a bearing hole 2 is arranged in the middle of the bevel gear cylinder 1, and a bearing is arranged in the bearing hole 2 I3 and bearing II4, the distance between the outer surface of the bearing I3 and the end face of the bevel cylinder 1 on the same side of the outer surface and the length ratio of the bearing hole 2 is 1: (12-13), the bearing II4 The distance between the outer surface and the end face of the bevel gear cylinder 1 on the same side of the outer surface and the length ratio of the bearing hole 2 is 1: (16 / 25-18 / 25); the bearing I3 and bearing II4 are pressed into the bearing hole 2. Inner tight fit connection; said bearing I3 and bearing II4 are needle roller bearings. The structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com