Machine head of flat knitting machine

A technology of flat knitting knitting machine and machine head, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of unreasonable structure design, low running speed of the machine head, short life of the machine head, etc. Head running fast, running fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is further described in conjunction with the following examples.

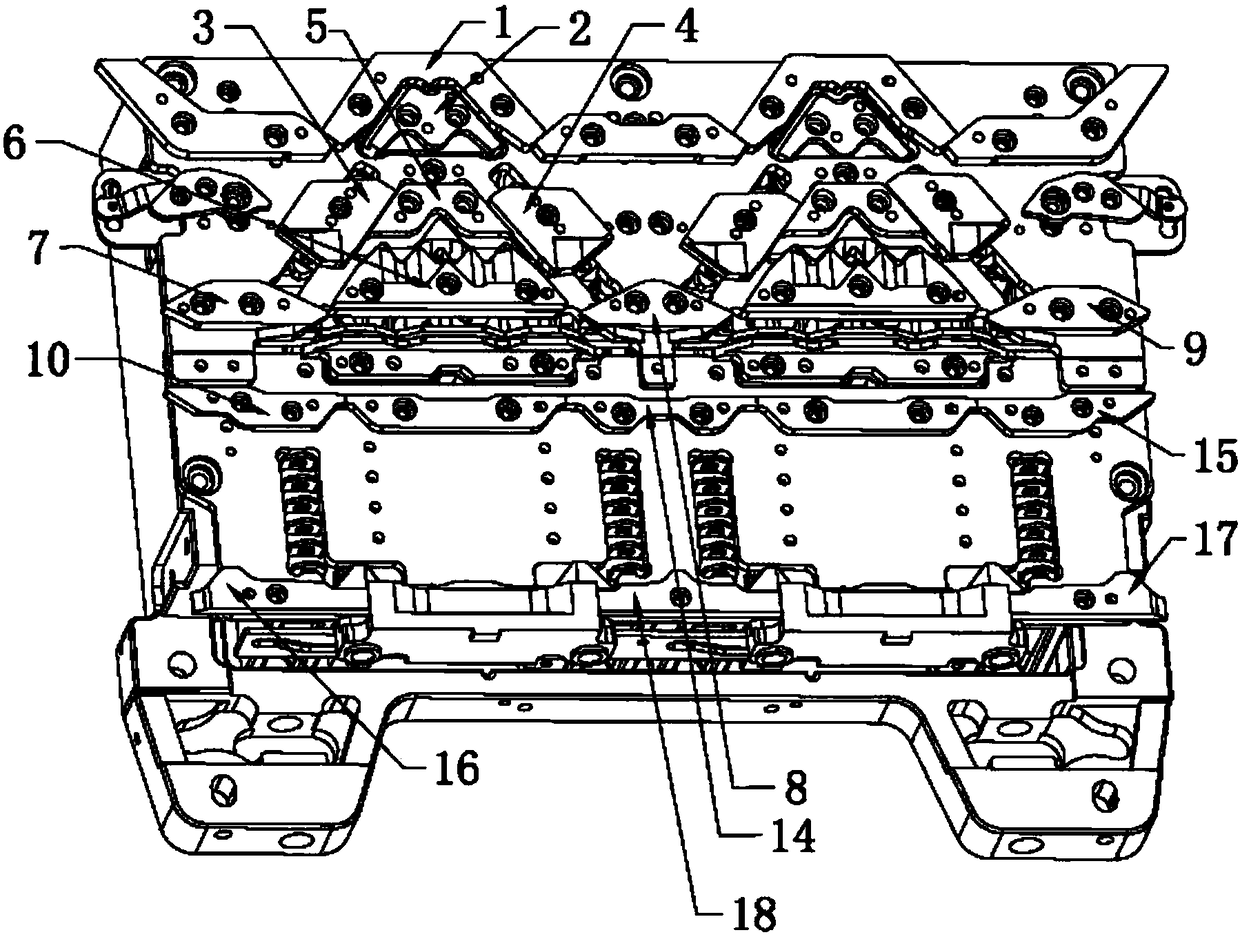

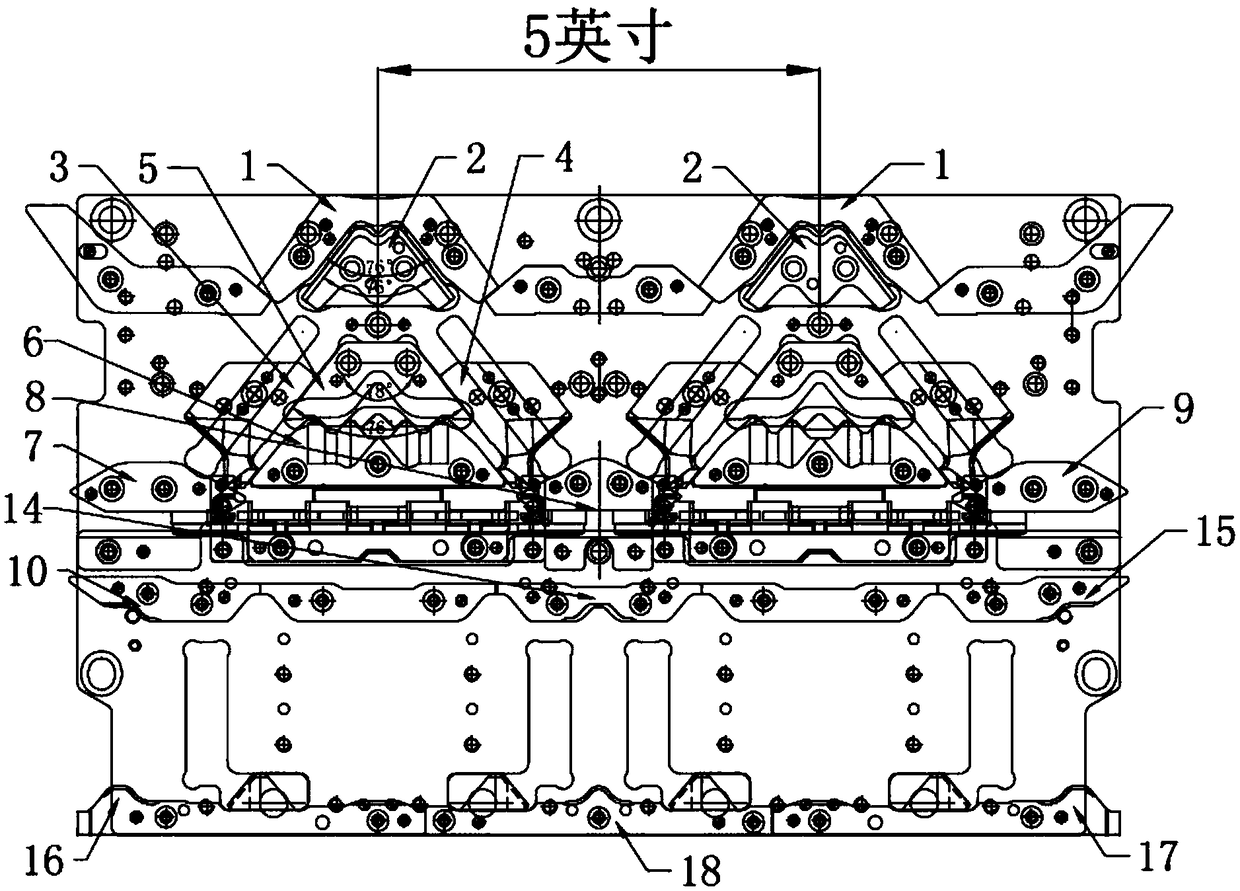

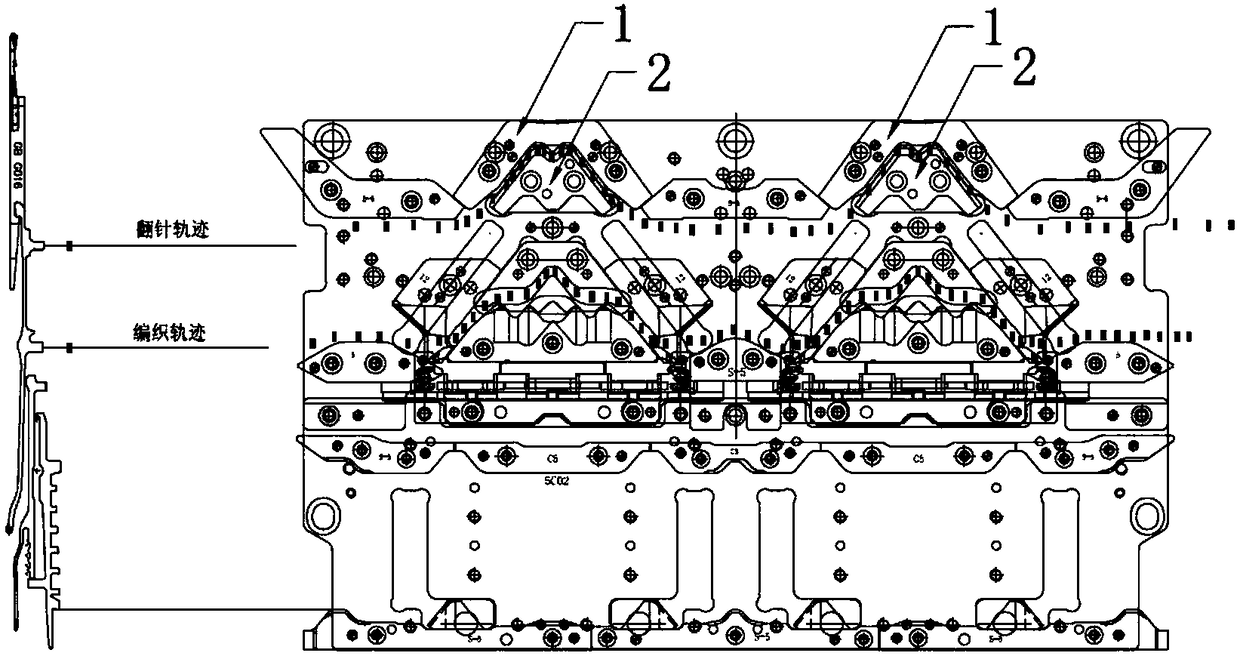

[0054] A head of a flat knitting machine in this embodiment, such as Figure 1 to Figure 9 As shown, a cam device is included, and the types of the cam device include a stitch cam 1, a transfer cam 2, a stitch cam, a knitting cam 5 and a stitch cam 6, and the stitch cams include a left stitch cam 3 and a right stitch cam.

[0055] Surrounding triangle 1 is used to limit the direction of transfer, transfer triangle 2 is used for transfer, stitch triangle is used to control fabric density, knitting triangle 5 is used for knitting fabrics, and connecting triangle 6 is used for connecting needles when transferring role.

[0056] Such as figure 2 As shown, the distance between the two transfer triangles 2 is 5 inches.

[0057] The needle-encircling triangle 1 comprises a left inclined part 11, a middle part 12 and a right inclined part 13, and the left inclined part and the right inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com