A garment template machine

A template machine and movable plate technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, etc., can solve the problems that the template shell cannot be fixed, the waste of resources is rationally used, and the tools cannot be placed on the workbench, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

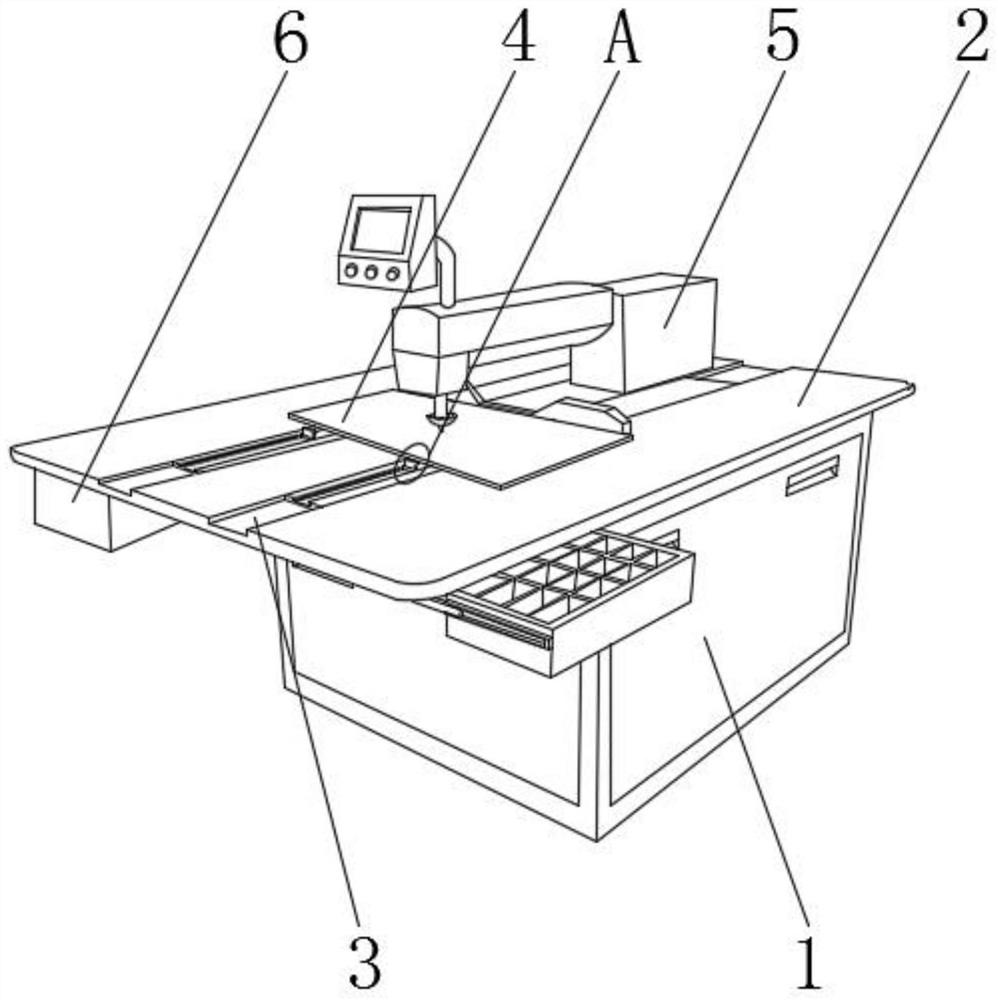

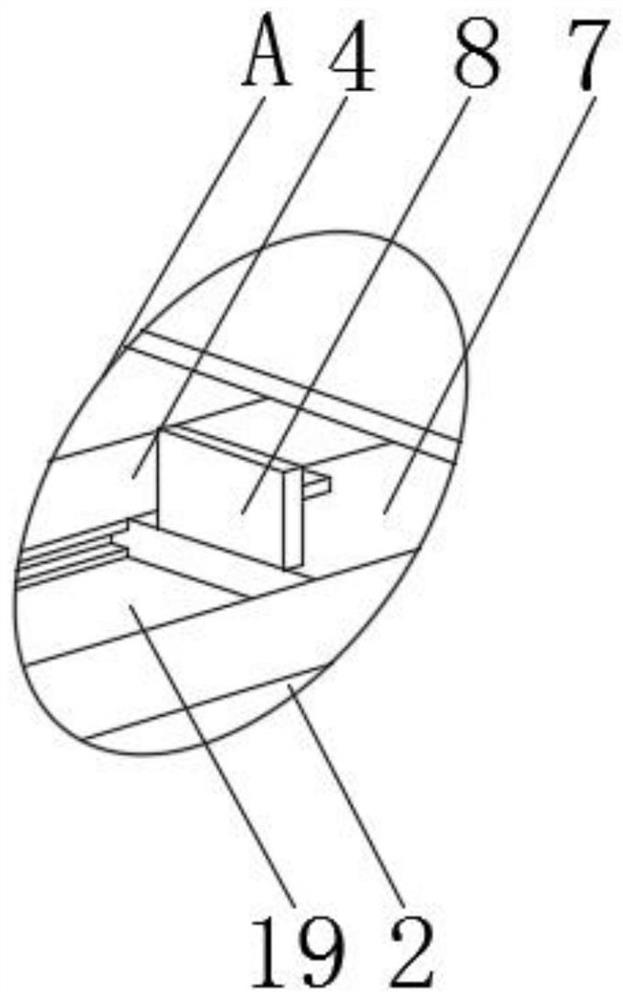

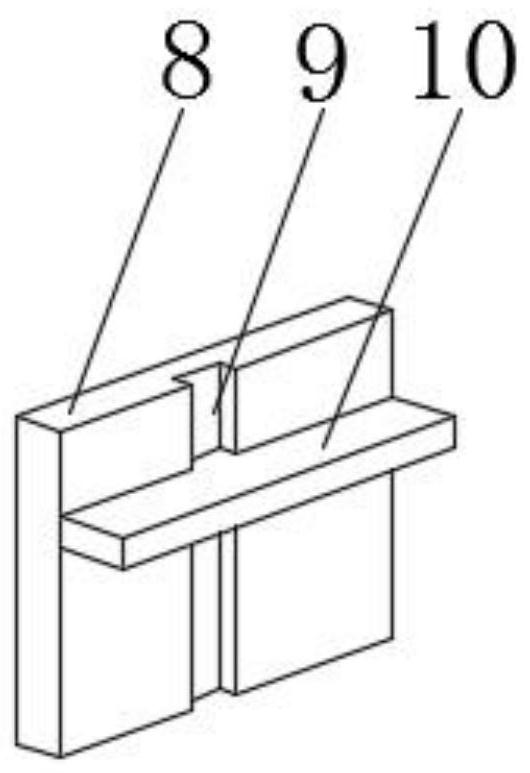

[0029] like Figure 1-3 As shown, the formwork machine base 1 is included, and the outer surface of one side of the formwork machine base 1 is fixed with a protective plate by bolts, and the front end outer surface of the protective plate is provided with a handle near the top position. The surface near the four corners is fixed with support columns by bolts, and the bottom end of the support columns is bonded with a rubber pad. The top outer surface of the template machine base 1 is fixed with a workbench 2 by bolts. The template shell is placed near the position of the sewing machine, and the top outer surface of the workbench 2 is provided with guide grooves 3 near both sides. The inner surface of the guide groove 3 is movably equipped with movable plates 4, and the two groups of movable plates 4 A connecting frame is welded near the outer surface of the top end, the outer surface of the front end of the connecting frame is fixed with a fixing clip by bolts near the bottom ...

Embodiment 2

[0032] like Figure 4 As shown, the outer surfaces on both sides of the storage box 6 are fixed with slide rails 11 near the top position by bolts, and the inner surface of the slide rails 11 is movably equipped with a slide bar 12, between the slide rail 11 and the slide bar 12 A pulley is provided, and the slide rail 11 is movably connected with the slide bar 12 by the pulley, the outer surface of the front end of the slide bar 12 is welded with a connecting rod 13, and the outer surface of the top end of the placement box 6 is provided with a placement groove 14, and the placement groove The inside of 14 is fixed with many sets of dividing plates 15 by bolts.

[0033] By installing the placement box 6, the tool can be stored more conveniently. By installing the slide bar 12 and the slide rail 11 between the two sides of the placement box 6 and the workbench 2, when it needs to be taken or retracted, manually place the When the box 6 is pushed inward or pulled outward, it c...

Embodiment 3

[0036] like Figure 5-7 As shown, the top outer surface of the connecting rod 13 is welded with a connecting shaft 16 close to both sides, and the top outer surface of the connecting shaft 16 is fixed with a rotating shaft 17 by bolts, and the bottom outer surface of the workbench 2 is provided with T-slot 18.

[0037] By installing a slidable connecting shaft 16 on both sides of the top of the connecting rod 13, and then cooperating with the T-shaped groove 18 at the bottom of the workbench 2, when it needs to be moved and used, it is only necessary to manually pull the placement box 6 to one side, and the connecting shaft The rotating shaft 17 at the top of 16 rotates inside the T-shaped slot 18 and moves to one side. When turning, because the two sets of connecting shafts 16 are two points, and the connecting rod 13 is not in the T-shaped slot 18, it will not affect the placement box The normal rotation of 6 can move the placement box 6 more freely and conveniently, improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com