Motor of stator and rotor split type for sewing machine

A sewing machine, split technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem that the stator or rotor cannot be used as a separate component, the length and size of the motor vary greatly, and the size of the motor shaft is difficult to ensure. Achieve the effect of small axial size, space saving and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

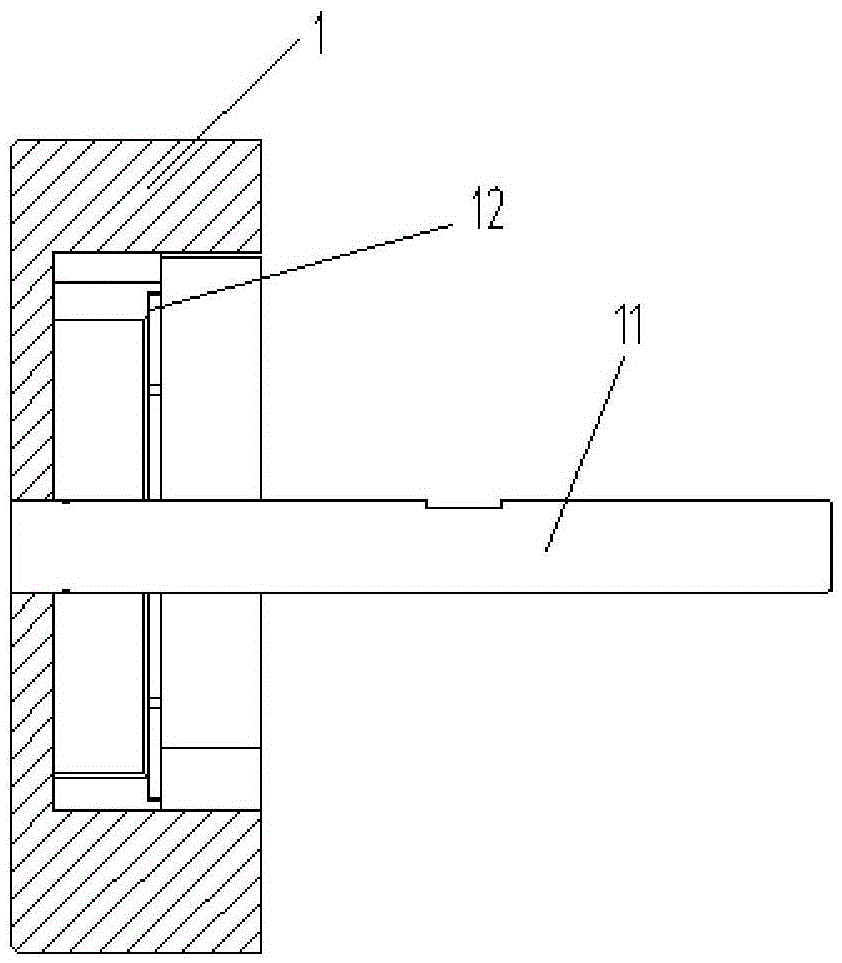

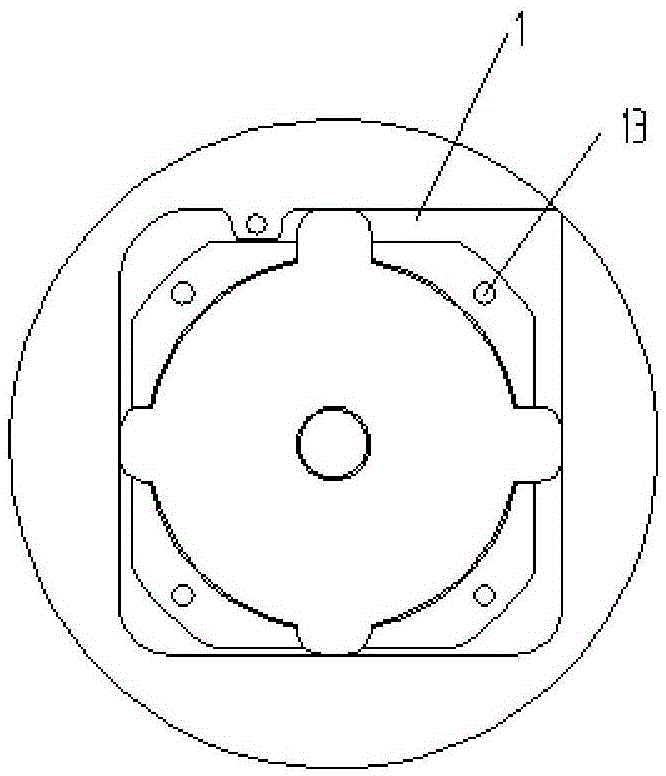

[0064] Sewing machines for household or industrial use, including sewing machine heads1, such as figure 2 and image 3 As shown, the center of the sewing machine head 1 is provided with a sewing machine main shaft 11, and the right end surface of the sewing machine head 1 is provided with a notch 12 and several stator mounting threaded holes 13.

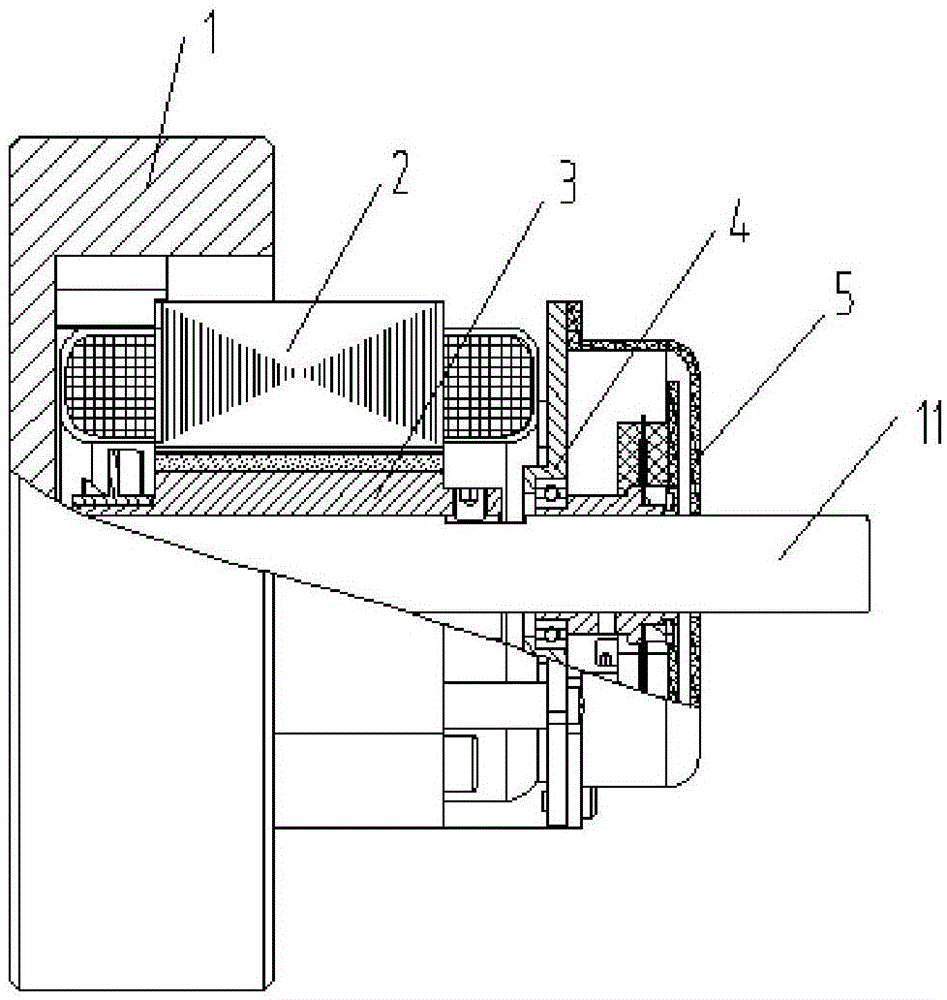

[0065] Such as figure 1 As shown, a stator and rotor split motor for a sewing machine includes a stator 2, a rotor 3, an integrated encoder 4 and a rear cover 5.

[0066] The center of above-mentioned rotor 3, integrated encoder 4 and back cover 5 is all provided with axial central hole 31, and the diameter of this axial central hole 31 is greater than the outer diameter of sewing machine main shaft 11; Rotor 3, integrated encoder 4 and rear The cover 5 is coaxially fixed and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com