Disposable internal incision and closure stapler

A one-time, stapler technology, applied in the fields of application, medical science, surgery, etc., can solve the problems of not being able to withstand the pressure of 220 mm Hg, not being able to form a wide surgical field of view, and being unable to be disassembled by the user, so as to provide accurate surgery degree, solve the bleeding problem, and increase the effect of suture density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

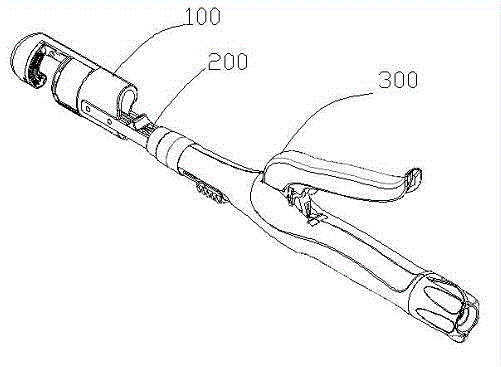

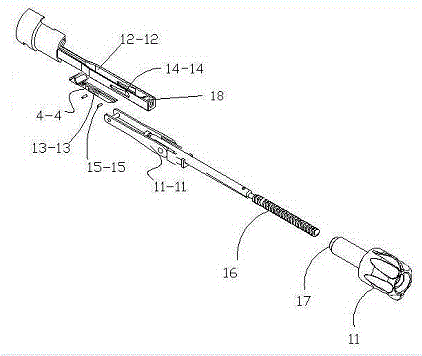

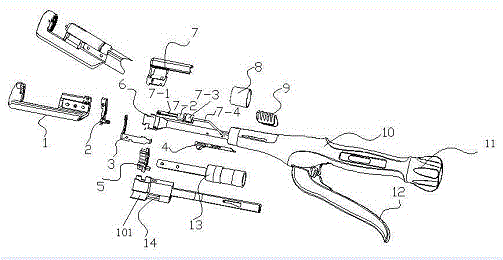

[0025] Attached below Figure 1~4 And embodiment further illustrate the present invention.

[0026] Such as figure 1 , 2 As shown in , 3, a disposable internal opening incision and closure stapler includes a cutting and forming assembly 100, a transmission assembly 200 and a gun body 300 with a firing assembly, and the cutting and forming assembly 100 includes a staple cartridge bracket 1, a backing knife ring 2, nail abutment seat 3, nail pusher 5, staple bin support 14 and staple bin 7, the end of the nail bin bracket 1 is installed with a spacer ring 2, nail abutment seat 3, nail pusher 5 in turn, and the staple bin 7 passes through The buckle 201 is stuck in the slot 101 of the magazine holder 14 , and the magazine holder 14 is directly connected to the gun body 300 through the transmission assembly 200 . In this embodiment, the transmission assembly 200 can directly push the staple cartridge 7 to move, and because of the buckle connection, the staple cartridge 7 can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com