Method for pre-judging occurrence of oriented silicon steel cold rolling brittle failures

A technology for brittle fracture of oriented silicon steel, which is applied in the field of predicting the occurrence of brittle fracture in cold rolling of oriented silicon steel, can solve the problems of lagging results and low sampling samples, and achieve the effect of improving cold rolling processing performance and reducing the risk of strip breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

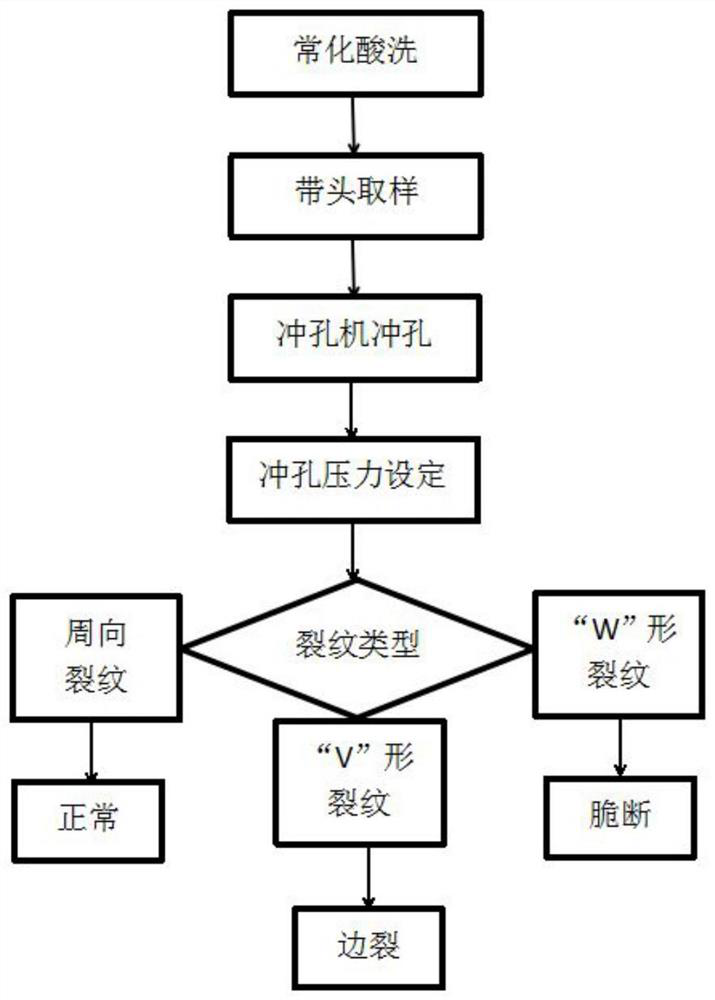

[0034] Due to the complexity of the manufacturing process of high magnetic induction grain-oriented silicon steel and the influence of actual production equipment, the generation of rolling cracks under different conditions is simulated through human intervention. The method of predicting the stamping machine by using the welding seam of the welding machine to predict the crack morphology formed after the normalized pickling plate after stamping, the steps are:

[0035] 1) On a normalized board, take a1, a2, a3, three normalized boards with a thickness of 2.3mm and a width of 20-30cm to take the leading sample, and send them to the punching machine;

[0036] 2) Punch a1 with a punching machine to punch the model, the interval between each punching point is 20cm, and the pressure is adjusted at 0-1MPa;

[0037] 3) After the stamping is completed, its appearance is the elastic deformation stage of the first stage, and a circular shallow pit is formed at the stamping place withou...

Embodiment 2

[0042] Adjust the edge cooling rate so that the edge cooling on the working side is greater than that on the drive side.

[0043] 1) On a normalized board, take b1, b2, b3, three normalized boards with a thickness of 2.3mm and a width of 20-30cm to take the lead samples and send them to the punching machine;

[0044]2) Use a punching machine to stamp b1 on the model, the interval between each stamping point is 20cm, and the pressure is adjusted at 0-1MPa;

[0045] 3) After the stamping is completed, its appearance is the elastic deformation stage of the first stage, and a circular shallow pit is formed at the stamping place, and the appearance of the sides on both sides is consistent without cracks;

[0046] 4) Increase the pressure of b2. When the pressure is 1-2 MPa, its appearance is the second stage of plastic deformation, and "V"-shaped micro-cracks are generated on the working side, and micro-cracks are generated on the transmission side along the circumferential directi...

Embodiment 3

[0050] Adjust the cooling rate of the entire board so that the cooling rate is twice the current rate;

[0051] 1) On a normalized board, take c1, c2, c3, three normalized boards with a thickness of 2.3mm and a width of 20-30cm to take the lead sample and send them to the punching machine;

[0052] 2) Use a punching machine to stamp c1 on the template, the interval between each stamping point is 20cm, and the pressure is adjusted at 0-1MPa;

[0053] 3) After the stamping is completed, its appearance is the elastic deformation stage of the first stage, and a circular shallow pit is formed at the stamping place, and the appearance of the sides on both sides is consistent without cracks;

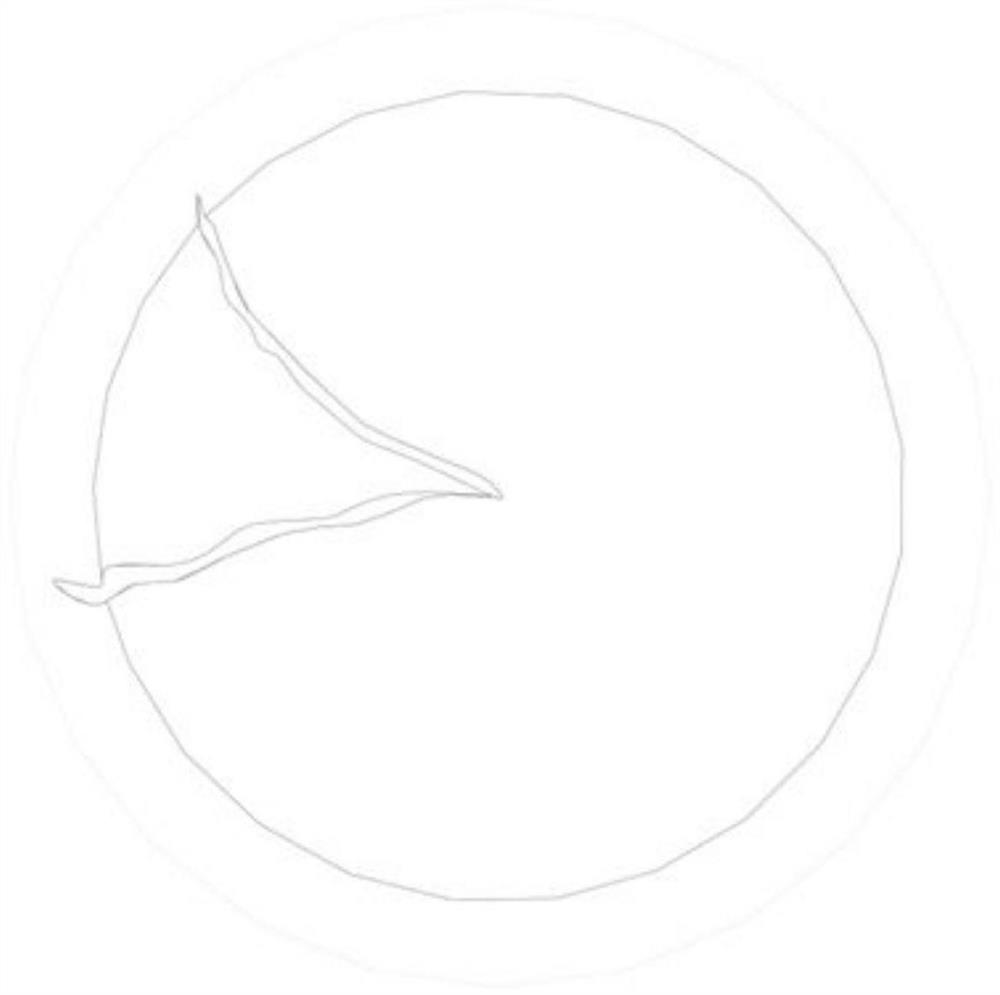

[0054] 4) Increase the pressure of c2. When the pressure is 1-2MPa, its appearance is the second stage of plastic deformation. The whole sample has the same stamping appearance, and brittle cracks obviously occur during the stamping process, resulting in a "W" shape. microcracks (see image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com