Elevator

An elevator and traction technology, applied in elevators, transportation and packaging, etc., can solve the problems of high material cost, thin belt thickness, shortening, etc., and achieve the effect of avoiding too thin thickness, avoiding excessive force, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

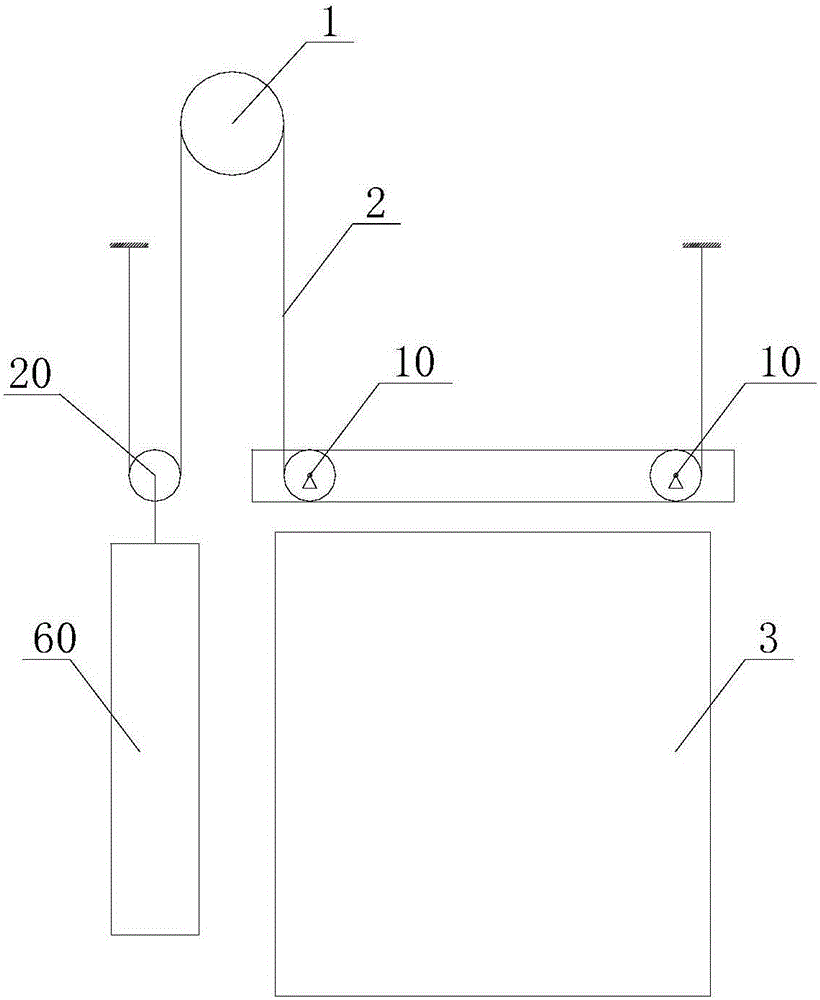

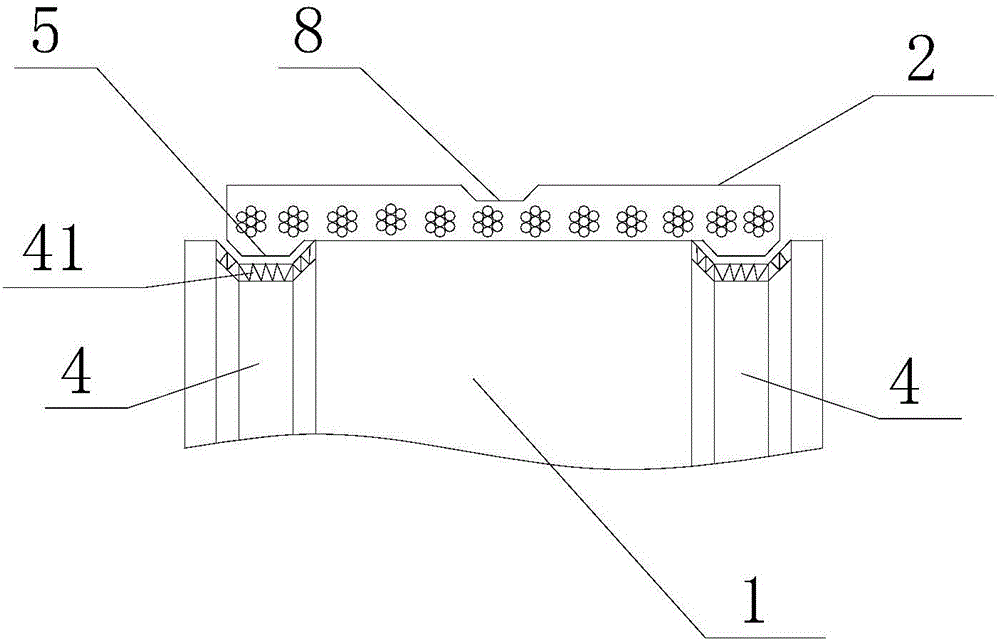

[0032] see Figures 1 to 4 , an elevator, comprising a car 3, a counterweight 60 and a traction carrying mechanism, the traction carrying mechanism comprises a traction carrying unit 2, a plurality of rotating wheels matched with the traction carrying unit 2, the traction carrying unit 2 is used It is used to carry and move the car 3, and wraps part of the circumference of the rotating wheel. Such as figure 1 As shown, in the present embodiment, the rotating sheave includes 1 traction sheave 1 , 2 car reversing sheaves 10 , and 1 counterweight reversing sheave 20 . One end of the traction bearing unit 2 is fixed above the hoistway, the other end extends downwards and bypasses the two car anti-rope pulleys 10 from below, then extends upwards, then bypasses the traction sheave 1 from above and then extends downwards, and finally Go around the counterweight anti-sheave 20 from below and extend upwards and be fixed above the hoistway.

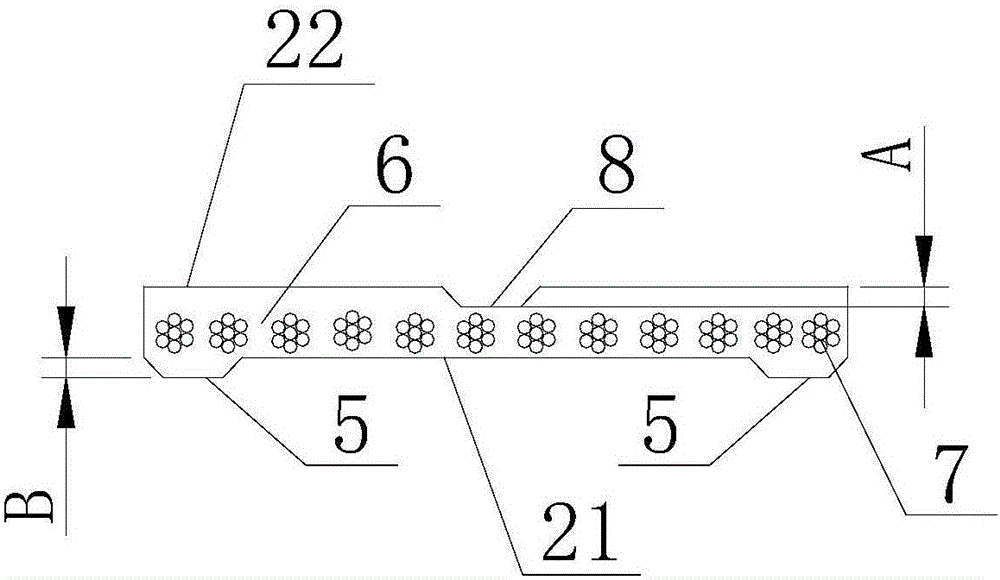

[0033] Such as figure 2 As shown, the t...

Embodiment 2

[0042] see Figure 5 The difference between this embodiment and Embodiment 1 is that a protruding guide body 5 is provided in the middle of the first working surface 21 of the traction bearing unit 2, and a guide belt groove 8 is respectively opened on both sides of the second working surface 22. . Correspondingly, the center of the traction sheave 1 has a guide wheel groove 4 matching with the protruding guide body 5, and the two sides of the car anti-sheave 10 or the counterweight anti-sheave 20 respectively have a guide belt groove 8 to cooperate with. The rotating wheel protruding body 9.

Embodiment 3

[0044] see Figure 6 , The difference between this embodiment and Embodiment 1 is that the cross-sectional shape of the protruding guide body 5 is triangular, and the cross-sectional shape of the guide belt groove 8 is triangular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com