Car-frame-free elevator driven by traction steel belt

A traction steel belt, no car frame type technology, applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of reducing the safety of elevator load-bearing devices, aggravating wire rope wear, and low space utilization, etc. Achieve the effect of improving space utilization and scope of application, avoiding space occupation, and increasing load-bearing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

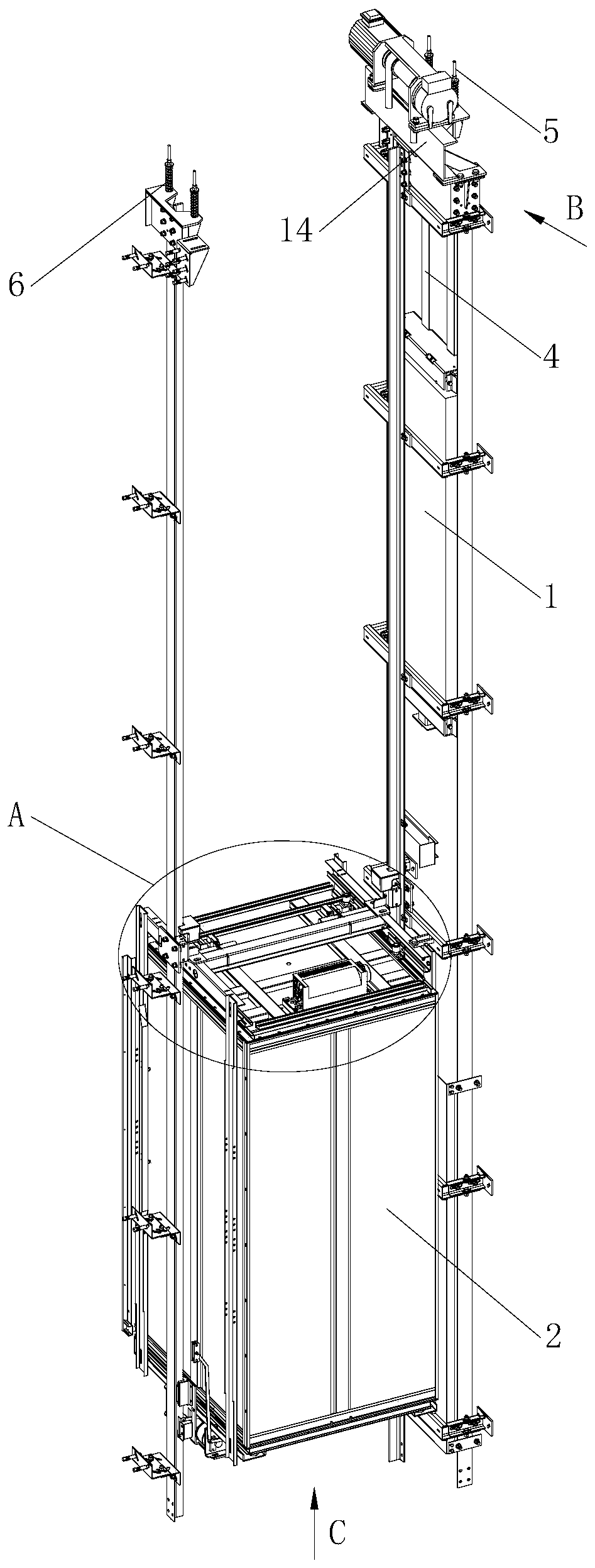

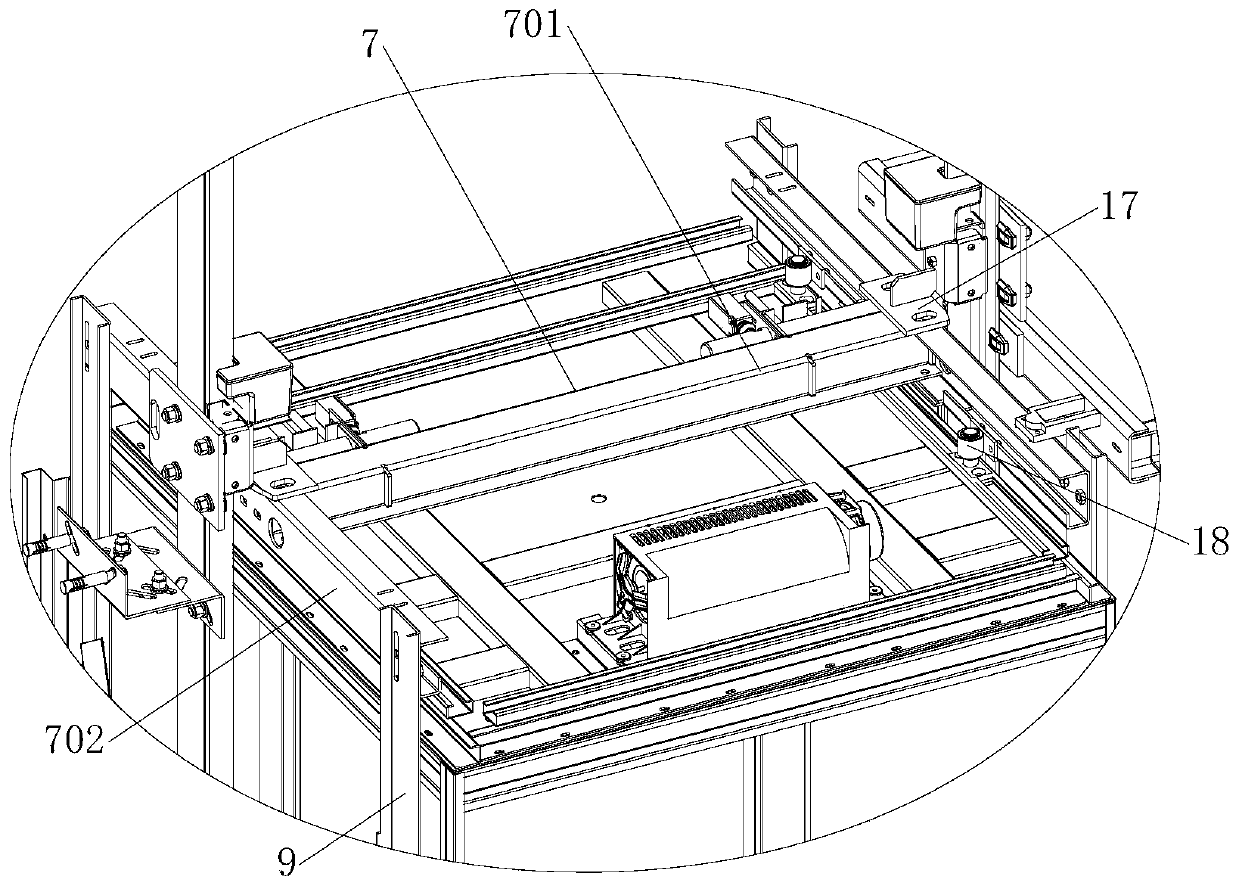

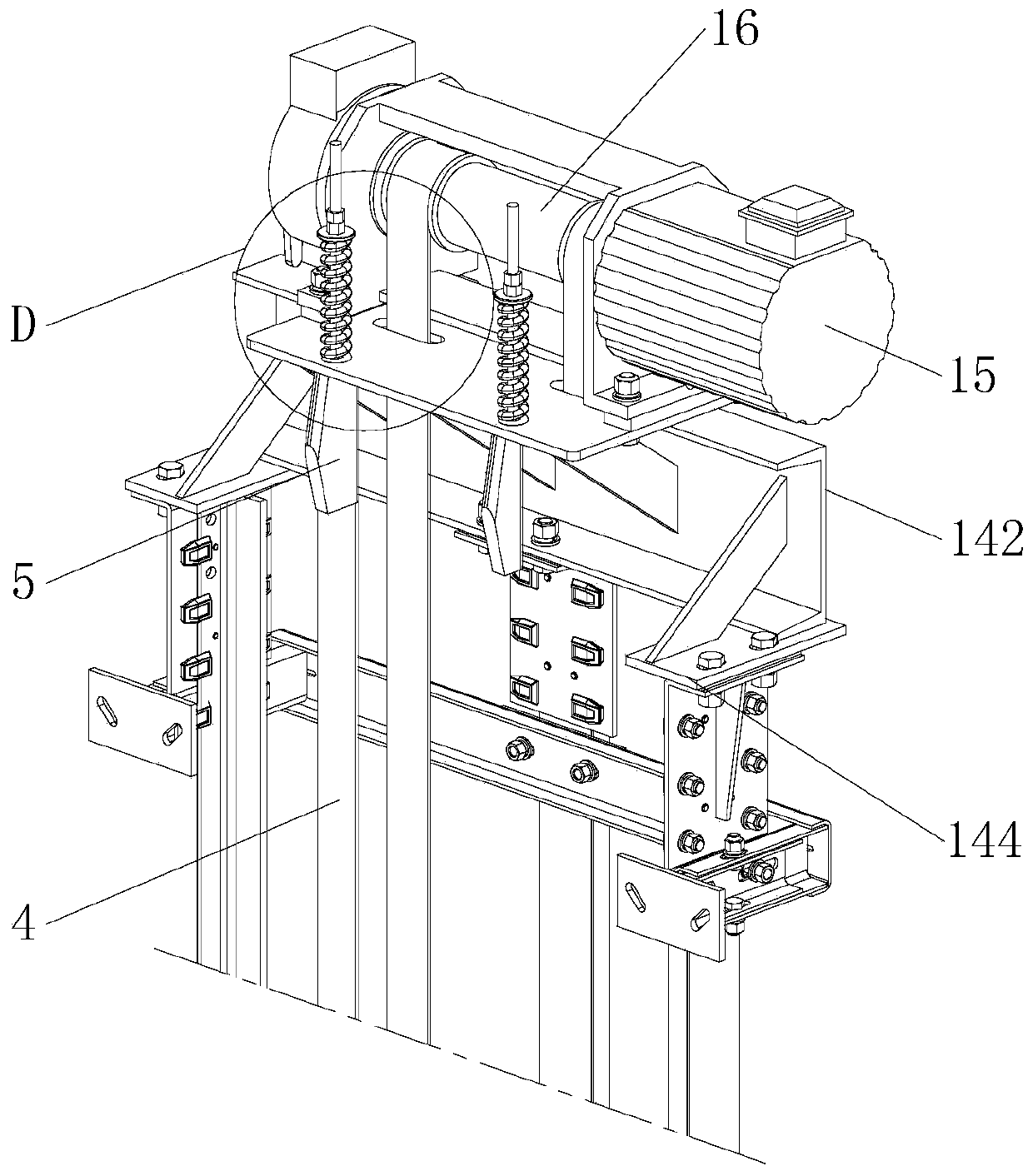

[0033] Example. A car frameless elevator driven by traction steel belts, consisting of figure 1 As shown, it includes a load-bearing device 1, a driving device and a car 2. The top of the load-bearing device 1 is provided with a load-bearing wheel 3, and the outer side of the load-bearing wheel 3 is provided with a traction steel belt 4, and one end of the traction steel belt 4 is connected to the first steel belt. Termination device 5, the other end of the traction steel belt 4 passes through the driving device and car 2 in turn and is connected with a second steel belt termination device 6; the top of the car 2 is provided with a car roof beam 7, and the bottom of the car 2 There is a base 8, and the base 8 and the car roof beam 7 are connected to each other through the vertical plate 9. The lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com