Dual-component room-temperature cured type waterproof building adhesive

A room temperature curing, two-component technology, applied in adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as poor water resistance, achieve fast curing speed, prolong service life, and avoid excessive aging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

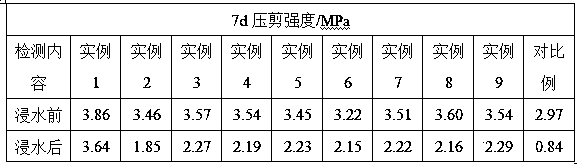

Examples

example 1

[0024]In parts by weight, successively take 40 parts of phthalic anhydride, 22 parts of diethylene glycol, 15 parts of ethylene glycol, 10 parts of propylene glycol, 15 parts of linoleic acid, 6 parts of fumaric acid, and 15 parts of maleic anhydride , 50 parts of styrene, first add phthalic anhydride, diethylene glycol, ethylene glycol, propylene glycol and linoleic acid into a three-necked flask with a reflux device, heat and reflux for 3 hours at a temperature of 195°C, and then add to the three-necked flask Add fumaric acid and maleic anhydride into the flask, continue to heat and reflux at 185°C for 5 hours, then gradually cool down to 155°C at a rate of 5°C / min, and then vacuumize the pressure in the three-necked flask to 600kPa, keep the pressure for 45 minutes, then add styrene into the three-necked flask, and stir and mix at a speed of 500r / min for 60 minutes, and then cool down to 60°C under the stirring state, and discharge the material to obtain a modified unsaturat...

example 2

[0026] In parts by weight, 40 parts of phthalic anhydride, 22 parts of diethylene glycol, 15 parts of ethylene glycol, 10 parts of propylene glycol, 6 parts of fumaric acid, 15 parts of maleic anhydride, 50 parts of styrene, First add phthalic anhydride, diethylene glycol, ethylene glycol, and propylene glycol into a three-necked flask with a reflux device, heat and reflux for 3 hours at a temperature of 195°C, and then add fumaric acid and maleic acid into the three-necked flask Alkenic anhydride, continue to heat and reflux for 5 hours at a temperature of 185°C, then gradually lower the temperature to 155°C at a rate of 5°C / min, then vacuumize the pressure in the three-necked flask to 600kPa, keep the pressure for 45min, and then add to the three-necked flask Add styrene into the flask, stir and mix at 500r / min for 60min, then cool down to 60°C naturally under stirring, and discharge to obtain modified unsaturated polyester resin; Oil and gelatin solution with a mass fractio...

example 3

[0028] According to the mass ratio of 1:30, mix linseed oil and 6% gelatin solution into a beaker, and move the beaker into an ultrasonic disperser, and ultrasonically disperse for 60 minutes at an ultrasonic frequency of 55 kHz and a temperature of 50 °C. To obtain the emulsion, add 10% of the emulsion mass to a beaker with a 20% sodium sulfate solution, then heat, stir and mix for 4 hours at a temperature of 90°C and a rotational speed of 500r / min, stop heating, and cool down to 60 ℃, then add 10% of the emulsion mass fraction in the beaker and formaldehyde solution with a mass fraction of 37%, and adjust the pH of the material in the beaker to 9.4, stir and mix with a glass rod for 15 minutes, stand and solidify for 460 minutes, and then filter with suction to obtain a filter cake , and wash the filter cake with deionized water for 5 times, then freeze-dry the washed filter cake to obtain linseed oil microcapsules; pulverize the sepiolite and pass through a 300-mesh sieve to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com