A kind of electroplating pc/abs alloy material and preparation method thereof

A technology of alloy materials and raw materials, which is applied in the field of electroplating PC/ABS composite materials and its preparation, can solve the problems of poor coating adhesion, decreased performance of plated parts, and low yield, and achieves easy adsorption, improved chemical resistance, The effect of preventing bridging flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

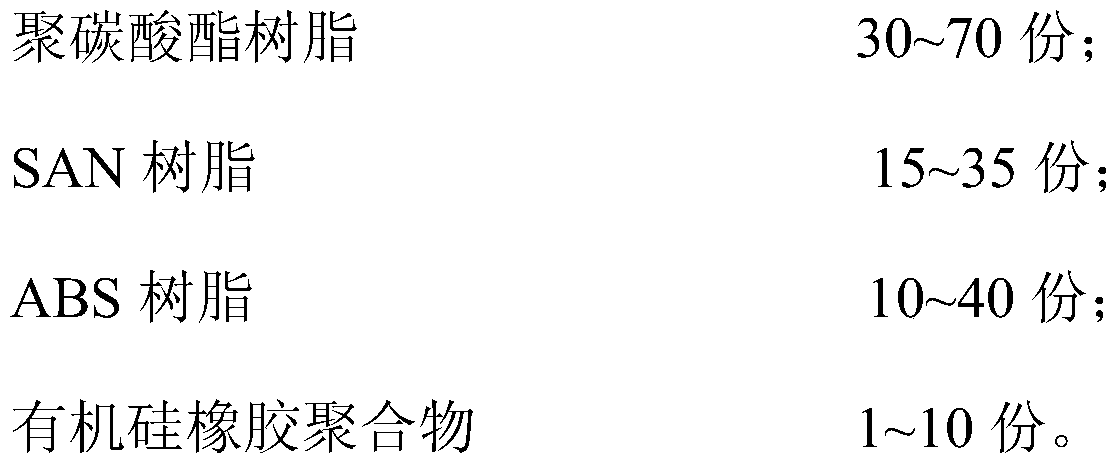

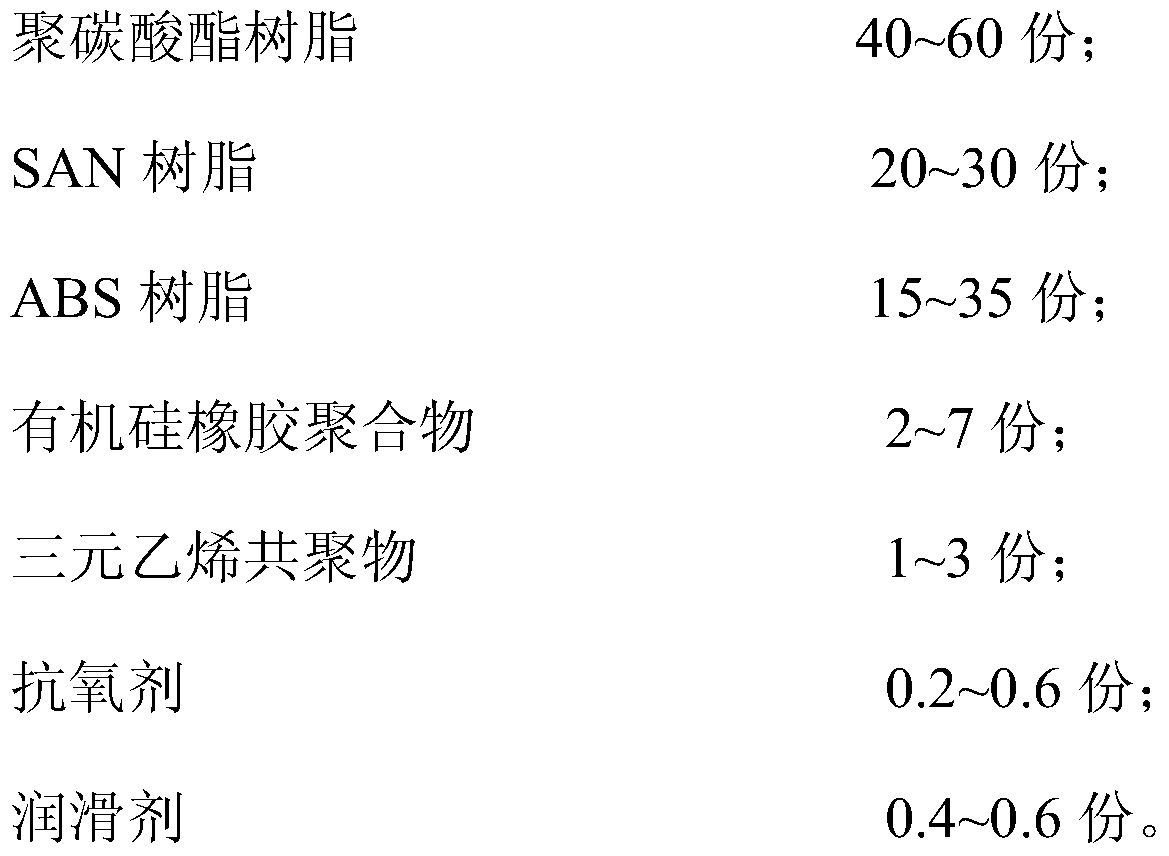

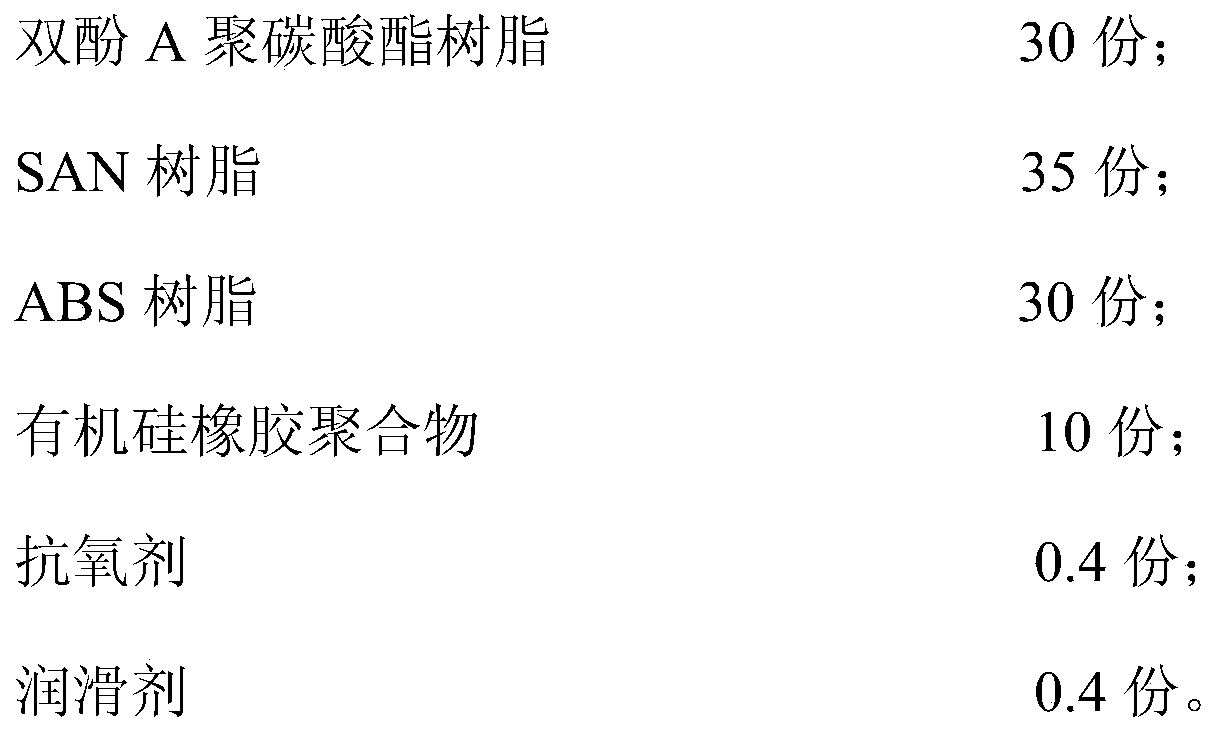

[0032] Embodiment 1: The electroplated PC / ABS alloy material of the present embodiment, by mass parts, comprises the following components:

[0033]

[0034] The method for preparing the above-mentioned electroplated PC / ABS alloy material comprises the following steps:

[0035] In the mixing and homogenizing section of the twin-screw extruder, the meshing block and the ZME toothed screw element are used to form a highly dispersed screw. 30 parts of bisphenol A polycarbonate resin, 35 parts of SAN resin, and 30 parts of ABS resin 10 parts, 10 parts of silicone rubber polymer, 0.4 part of antioxidant and 0.4 part of lubricant are stirred evenly to prepare the mixture;

[0036] The mixture was put into a twin-screw extruder, under the conditions of vacuum pressure of -0.05Mpa and rotation speed of 400r / min, heat melting, blending plasticization and shear dispersion were carried out, and extruded at 225°C for granulation , after pulling the strips, cooling in the water tank, de...

Embodiment 2

[0046] Embodiment 2: Compared with Embodiment 1, ethylene-acrylic acid-methyl glycidyl ester copolymer is added in Embodiment 2. Under the premise that the impact resistance does not change substantially and the falling ball test does not crack, the electroplating adhesion and hundred grids The yield rate is significantly improved, the electroplating adhesion is excellent, and the 100-grid yield rate reaches 97%, which shows that the ethylene-acrylic acid-methyl glycidyl ester copolymer greatly improves the electroplating adhesion and 100-gram yield rate of the alloy material.

Embodiment 3

[0047] Example 3: Compared with Example 2, Example 3 further optimizes the content of each component. Under the falling ball test without cracking and impact resistance, the elongation and 100-grid yield of the alloy material are obtained. Improve further; In comparative example 4, do not add organosilicon rubber polymer, cause falling ball test slight fracture, compare with comparative example 4, add organosilicon rubber polymer in embodiment 3, fall ball test is not fractured, and have improved coating adhesion Effort, 100-gram yield and elongation further illustrate that silicone rubber polymers improve the chemical resistance and toughness of alloy materials, prevent hardening, embrittlement and cracking after roughening electroplating, and at the same time, improve the toughness and electroplating adhesion of alloy materials. Focusing also helps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com