High-efficiency ceramic grinding roller and ceramic lining plate

A ceramic lining plate and ceramic technology, which is applied in the field of high-efficiency ceramic grinding rollers and ceramic lining plates, can solve the problems of insufficient output of coal mills, increase energy consumption, affect boiler combustion, etc., so as to reduce power consumption, increase output, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

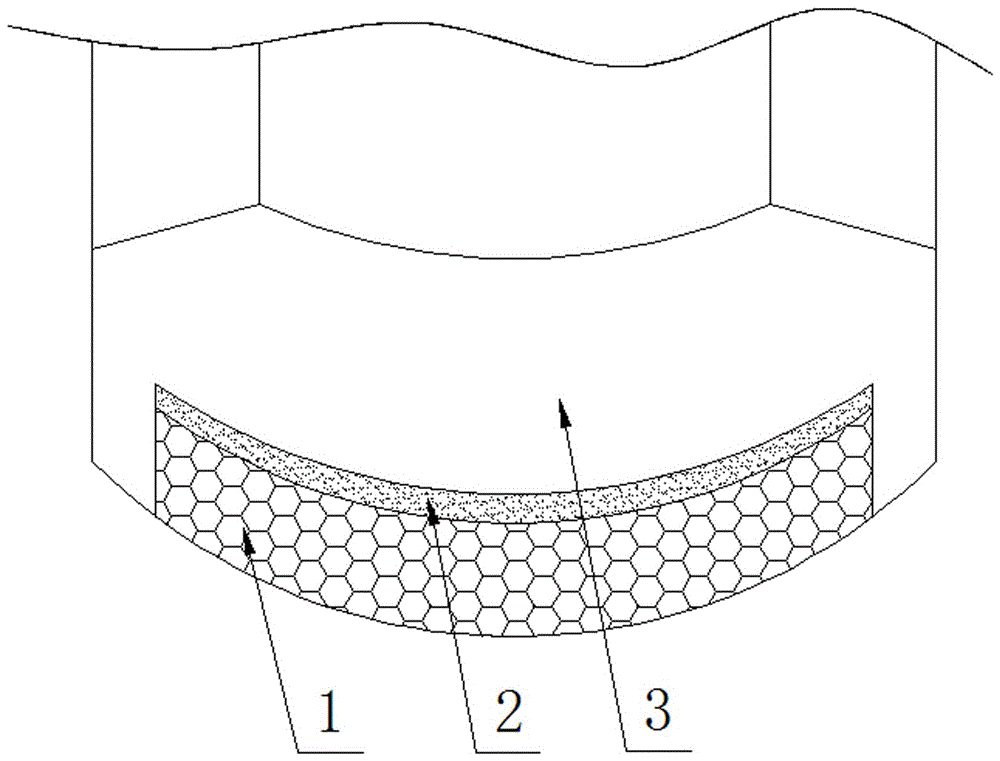

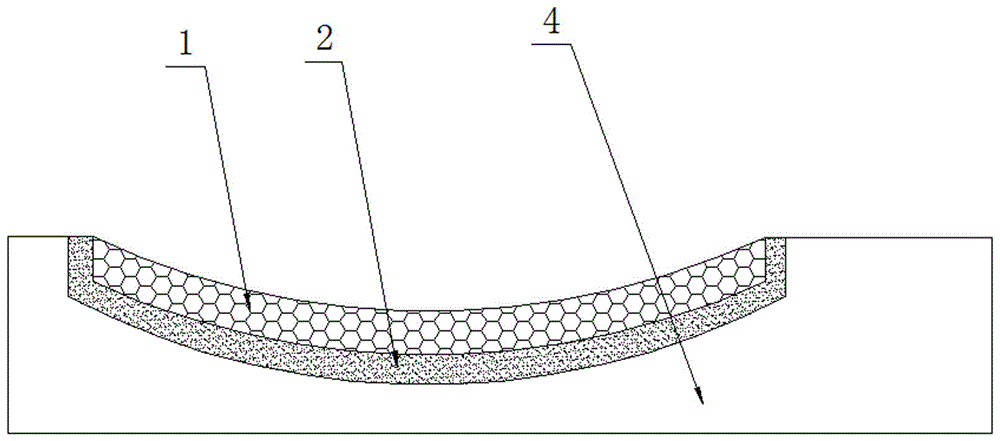

[0027] Referring to each figure, a high-efficiency ceramic grinding roller and a ceramic lining plate, the ceramic grinding roller and the ceramic lining plate form a relatively moving grinding mechanism, and the ceramic grinding roller includes a grinding roller base 3, an adhesive layer 2 and a composite ceramic layer 1. The ceramic liner includes a liner base 4, an adhesive layer 2 and a composite ceramic layer 1; the material of the composite ceramic layer 1 is one of silicon carbide, silicon nitride, tungsten carbide, alumina and zirconia The adhesive layer 2 is an adhesive with high temperature resistance and strong viscosity; the grinding roller base 3 is made of metal; the liner base 4 is made of metal The composite ceramic layer 1 of the ceramic grinding roller is assembled from ceramic modules, and gaps that can increase the friction of the ceramic surface are formed between the ceramic modules.

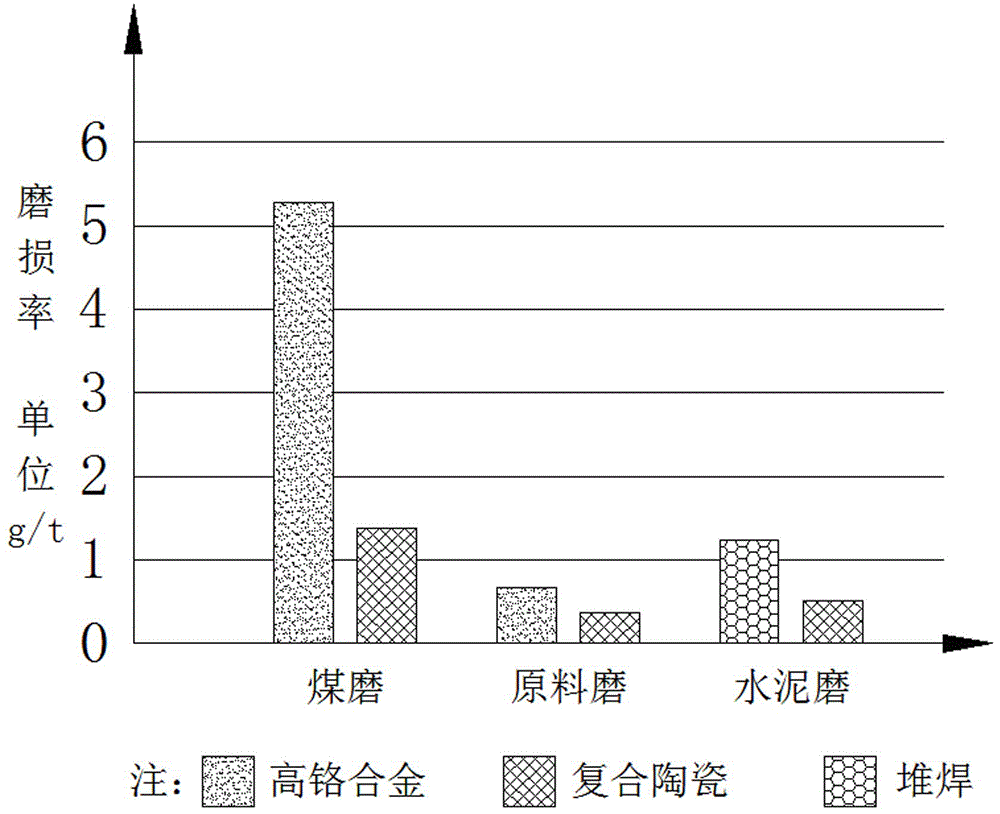

[0028] The existing grinding rollers of coal mills are mostly made of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com