Patents

Literature

103results about How to "Avoid brittle fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

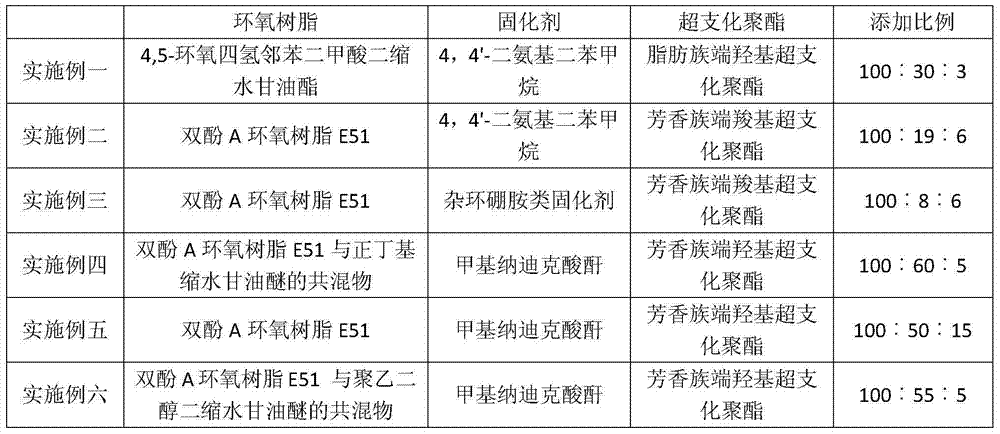

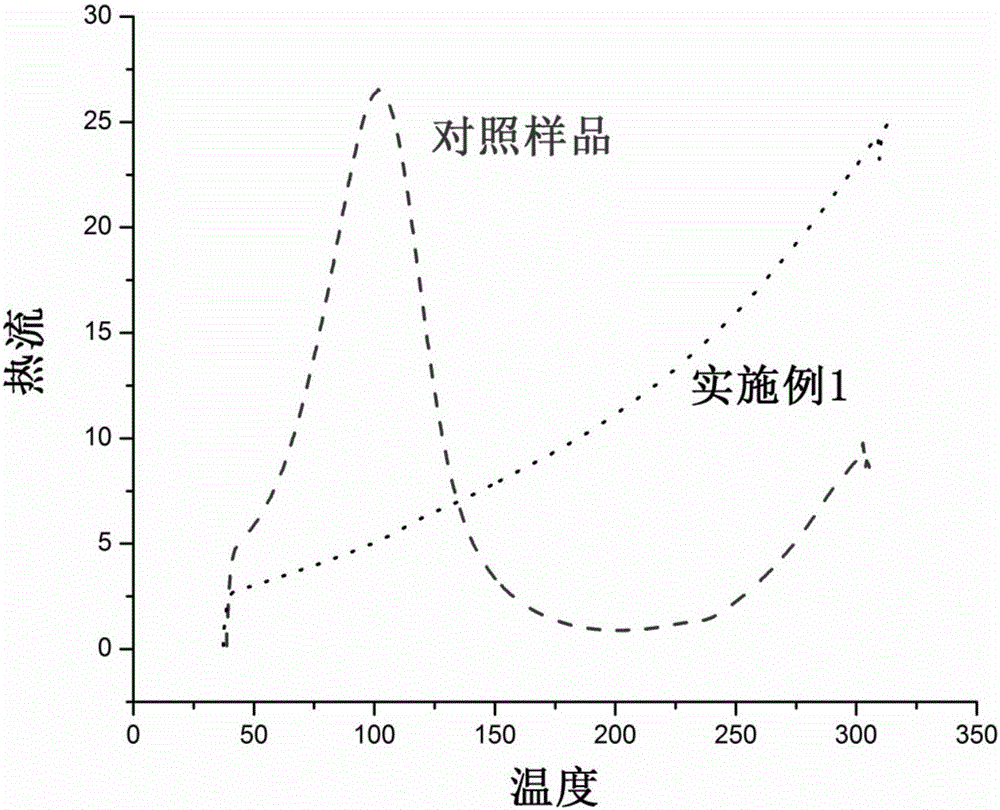

Shape memory epoxy resin and preparation method thereof

The invention relates to a shape memory epoxy resin and a preparation method thereof. The shape memory epoxy resin comprises epoxy resin, a curing agent and hyperbranched polyester at a weight part ratio of 100:(8-80):(3-20). The preparation method comprises the following steps: firstly mixing the epoxy resin and hyperbranched polyester, then adding the curing agent, evenly mixing, then injecting into a die, curing at 50 DEG C-170 DEG C for 1h-6h, then curing at 80 DEG C-200 DEG C for 0h-6h, cooling to room temperature and demoulding, so as to obtain the shape memory epoxy resin. The shape memory epoxy resin has high tenacity within the secondary shape forming temperature range, and has no difference in heat resistance property compared with the corresponding type of shape memory epoxy resin without hyperbranched polyester, is difficult to crack and damage, and has great values on the engineering application aspect of a shape memory epoxy resin-based composite material.

Owner:TONGJI UNIV +1

Ligament-bone bionic support with initial self-fixing function and forming method of support

Disclosed are a ligament-bone bionic support with an initial self-fixing function and a forming method of the support. The method includes: using a computer to design a bone support, using a fast forming technique to prepare a resin model of the bone support, and using the resin model as a core to prepare a negative silicon rubber mold of the bone support; using static spinning technology to prepare a directional ordered nano fiber film, and coiling the nano fiber film to form a nano fiber ligament support; matching and positioning the ligament support and the negative bone support, sequentially filling bone support material solution into the negative silicon rubber mold to obtain the bone support with the inherent initial self-fixing function; filing composite solution mixed with bone support materials and ligament support materials to form a transition layer; and performing post-treatment in a freeze drier to obtain the ligament-bone bionic support with the initial self-fixing function. By changing surface structures of the bone support, the bone support is allowed to be matched with autogenous bones, and initial fixing strength and stability are improved.

Owner:XI AN JIAOTONG UNIV

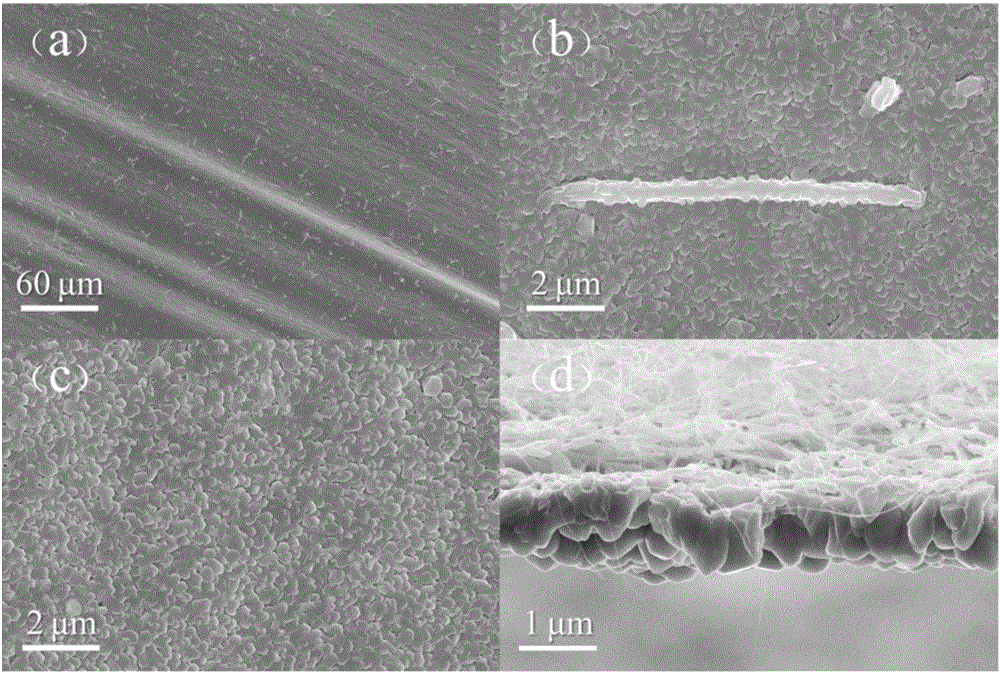

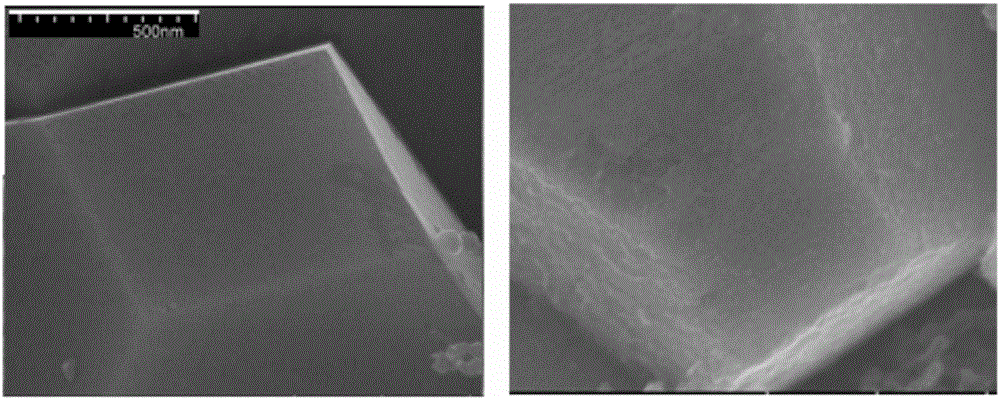

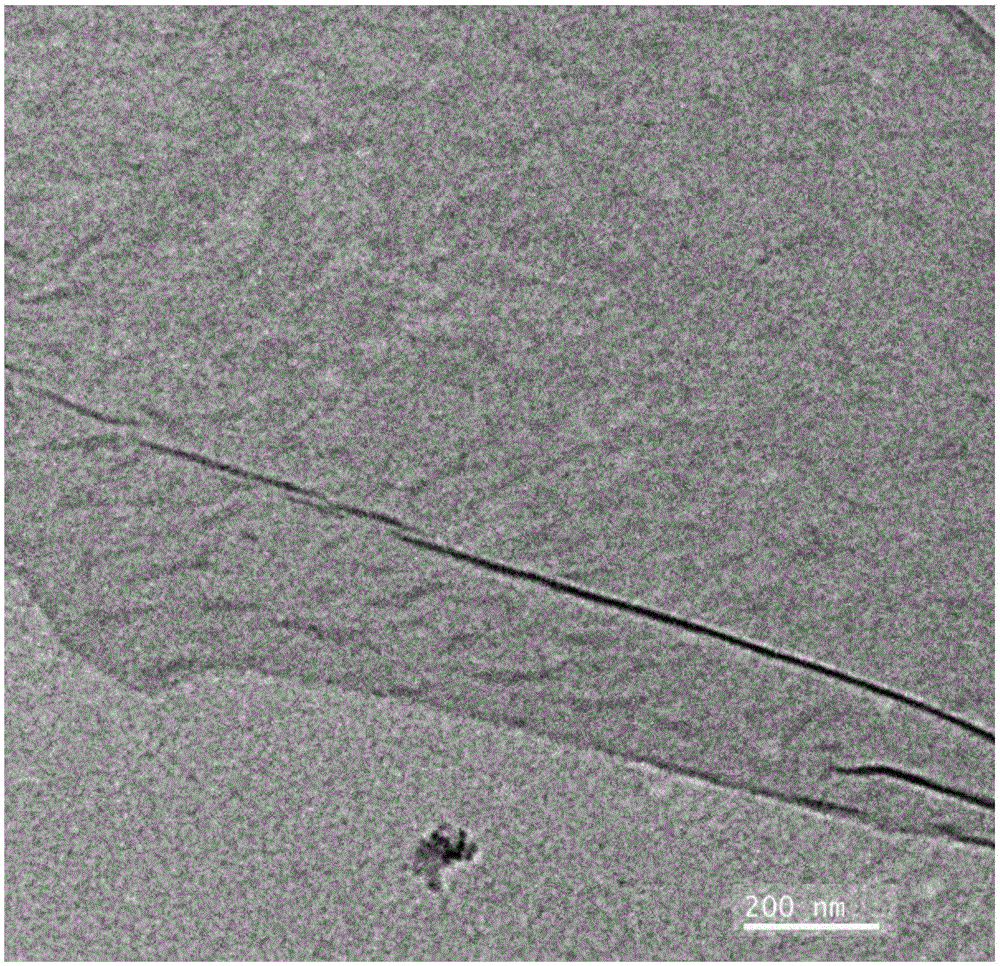

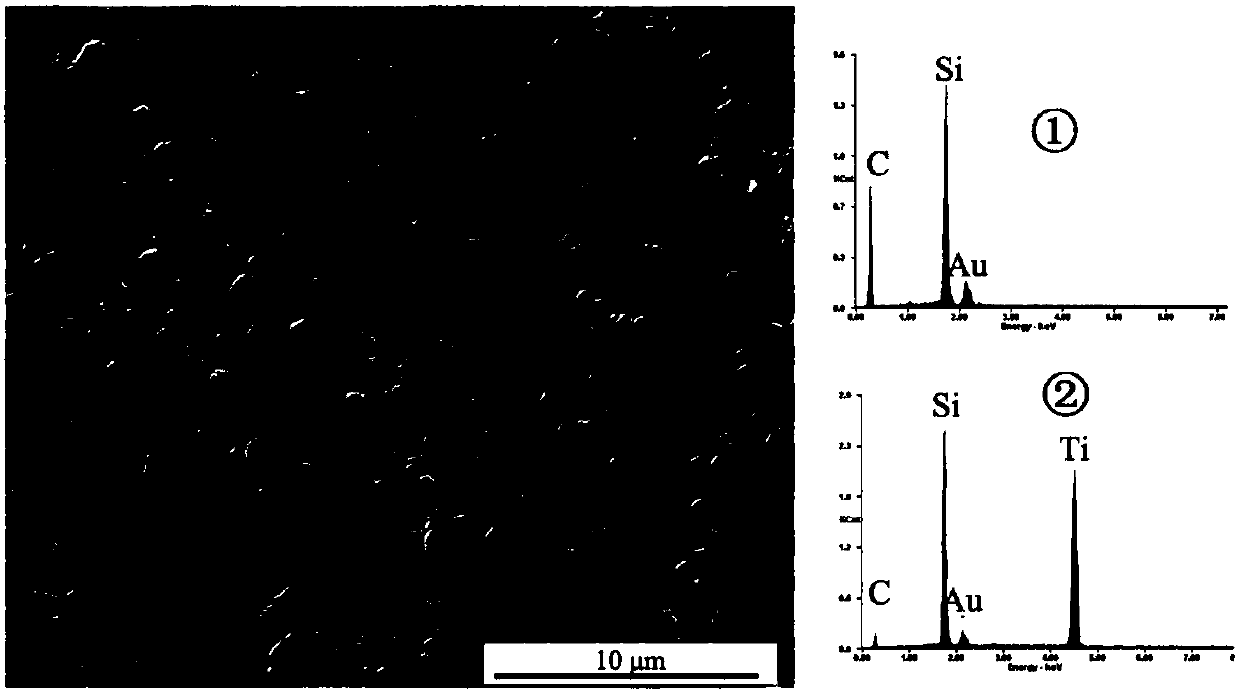

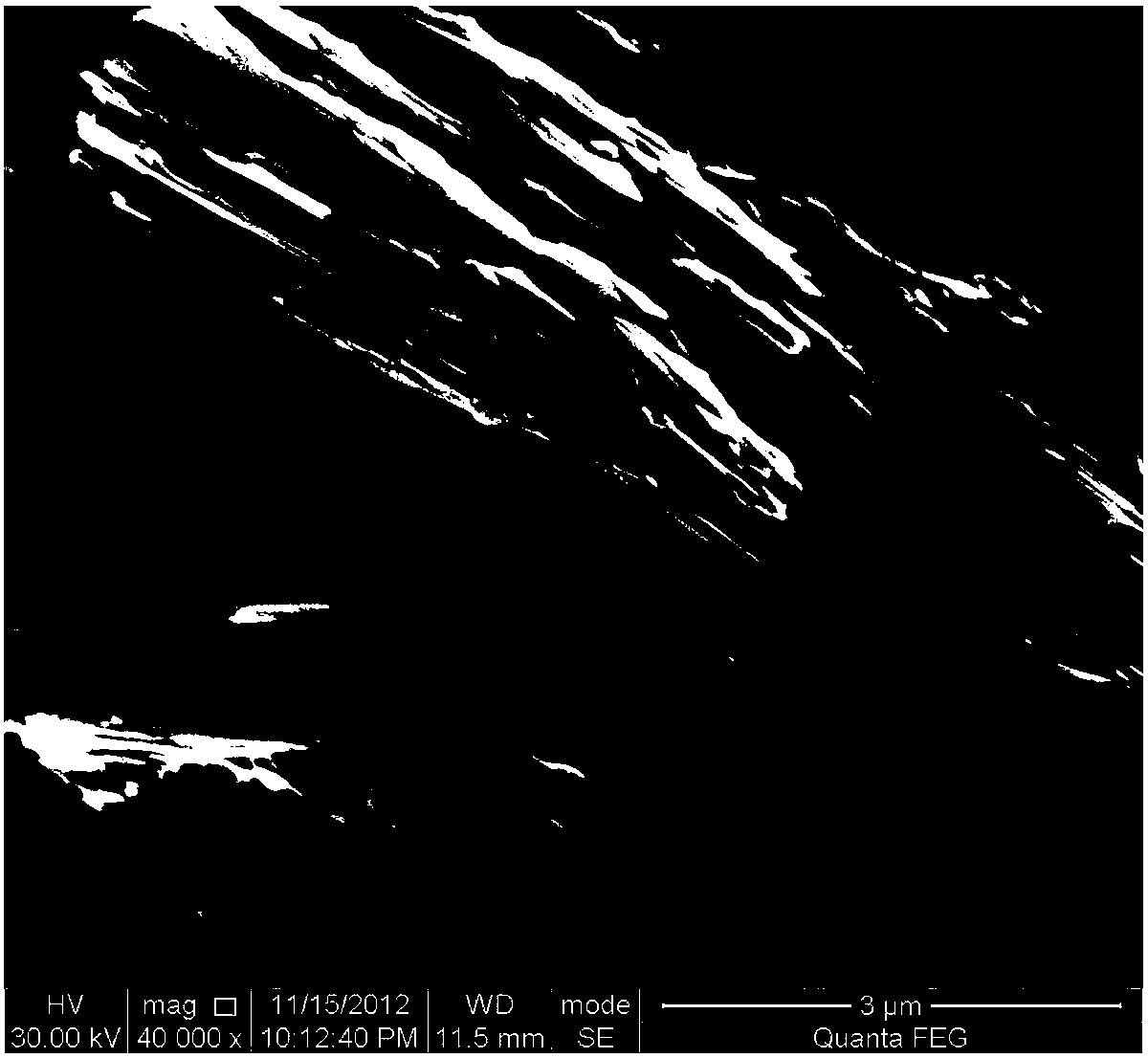

Laminated metal chalcogenide/carbon nanotube flexible compound film material of highly ordered structure and preparation

ActiveCN106744820APrecise control of ingredientsPrecise control structureCarbon compoundsVacuum evaporation coatingComposite filmCarbon nanotube

The invention belongs to the field of composite materials and in particular relates to a laminated metal chalcogenide (LMC) / carbon nanotube (CTNs) flexible compound film material of a highly ordered structure and a preparation method thereof. The composite material comprises an ultrathin self-supporting (transparent) CNTs film substrate and an LMC film which uniformly wraps the surface thereof to form the flexible composite film material which has a nanoscale porous structure and a three-dimensional network structure of a high electric channel. The preparation method comprises the following steps: providing an alloy bracket for bearing a self-supporting CNTs film and cleaning the carried CNTs film under a heating condition with plasma; and preparing the LMC / CNTs composite functional film material from the pre-treated CNTs film at an air pressure of 0.2-2Pa and at a temperature of 30-800 DEG C by virtue of a magnetron sputtered deposition technology. According to the material provided by the invention, a crispy laminated metal chalcogenide functional two-dimensional (2D) material and one-dimensional (1D) CNTs are effectively connected to form a three-dimensional (3D) network structure of structural flexibility.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

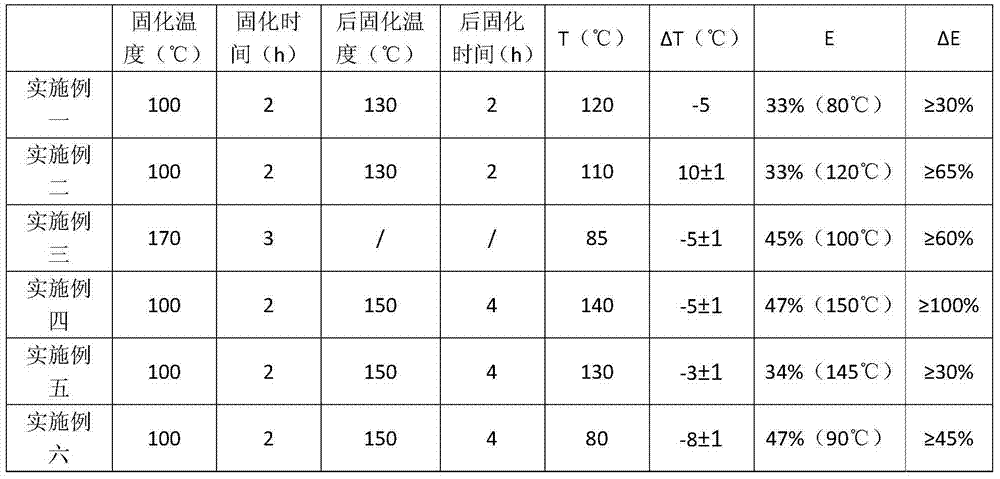

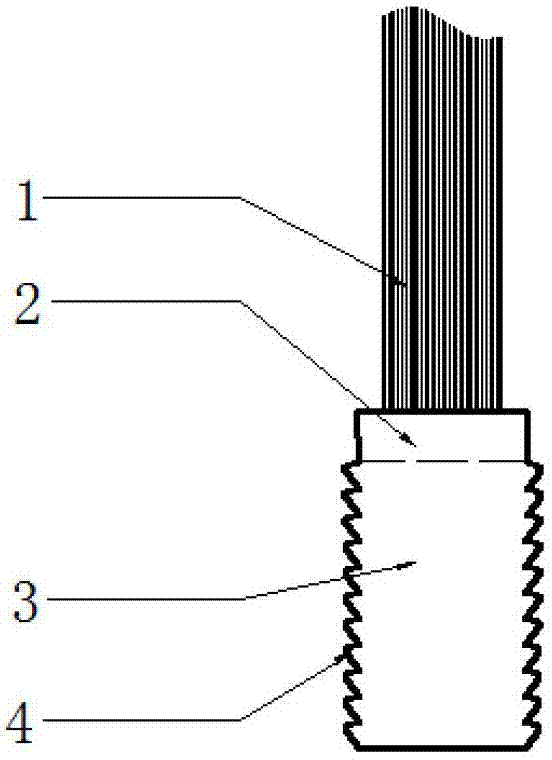

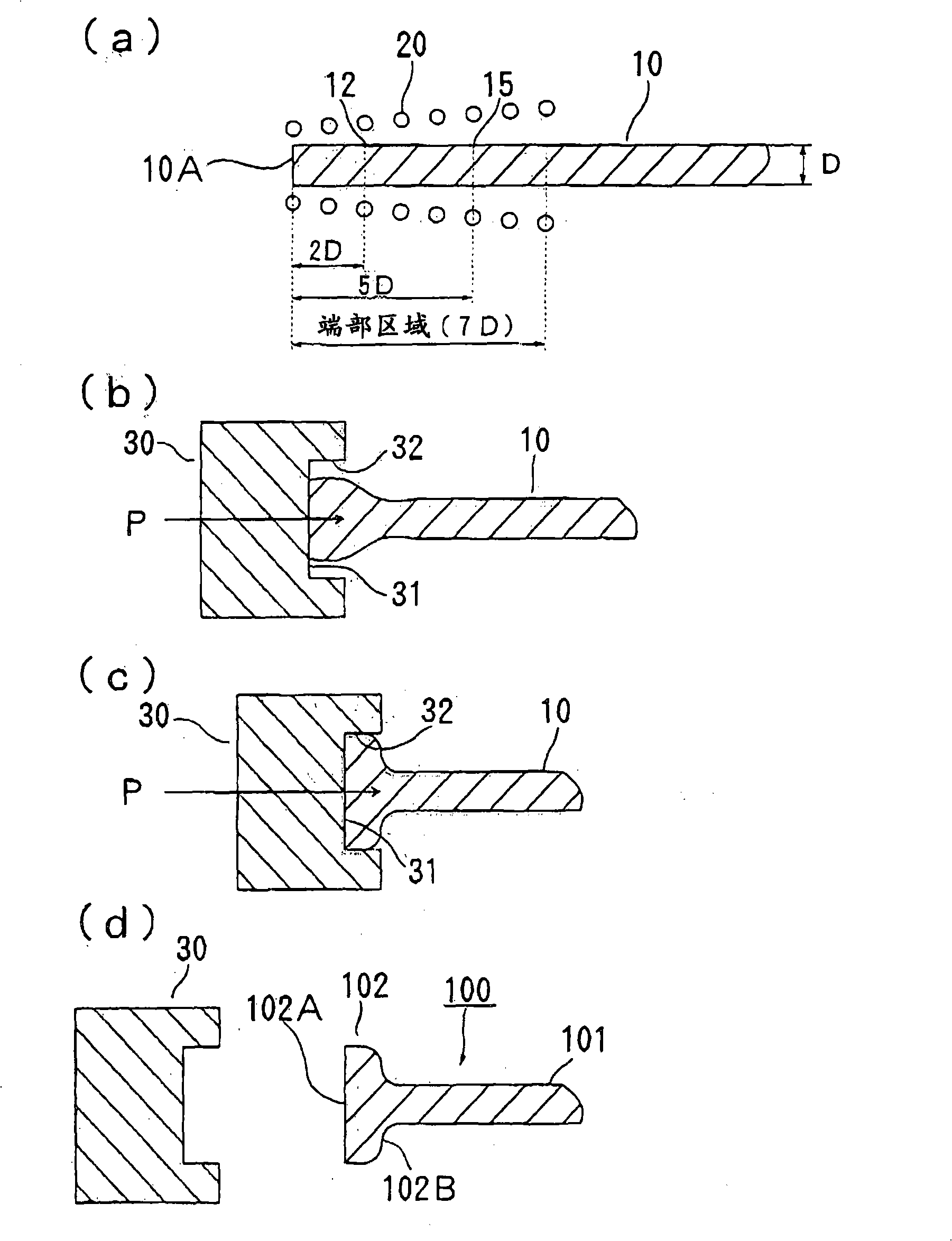

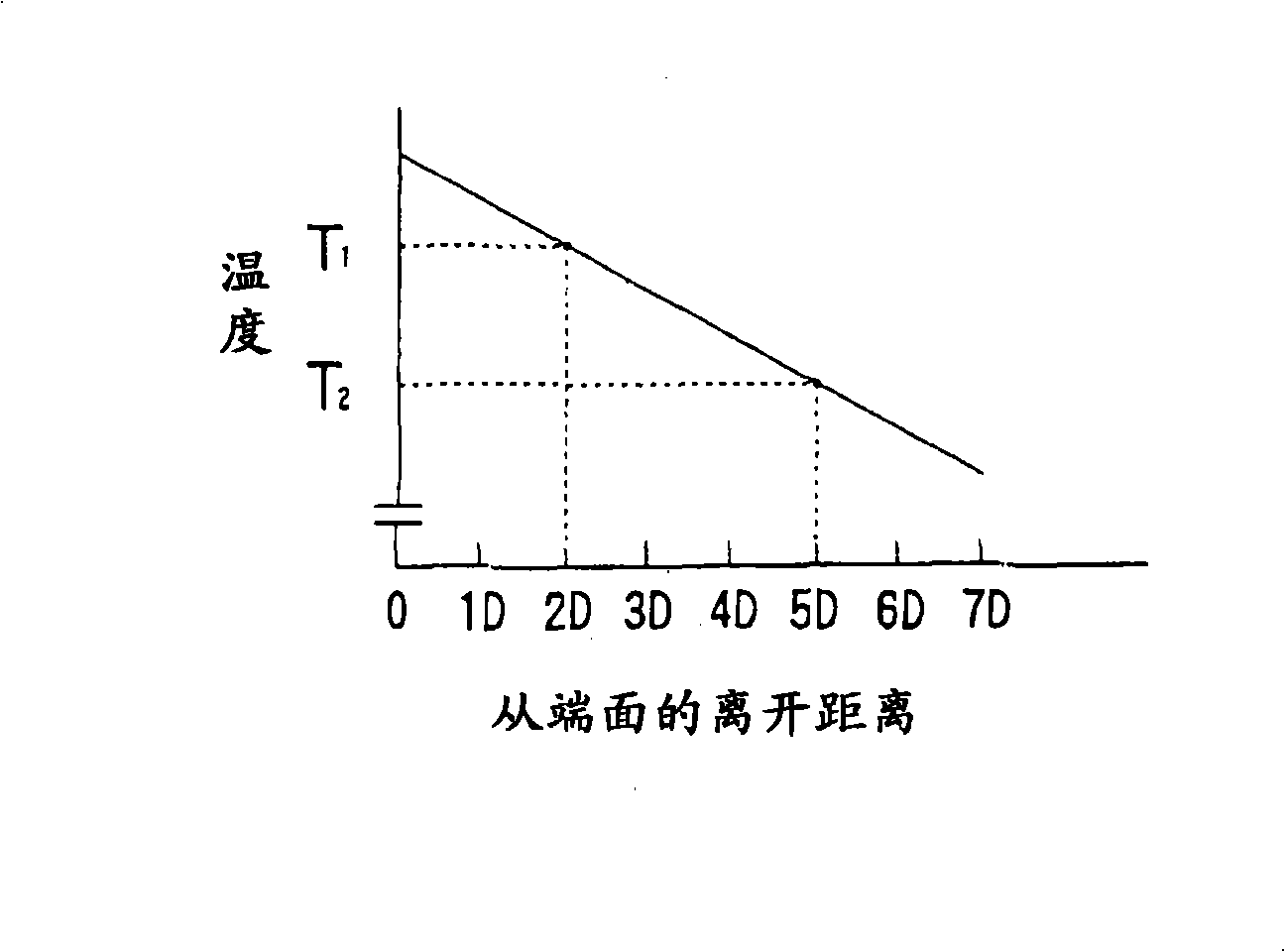

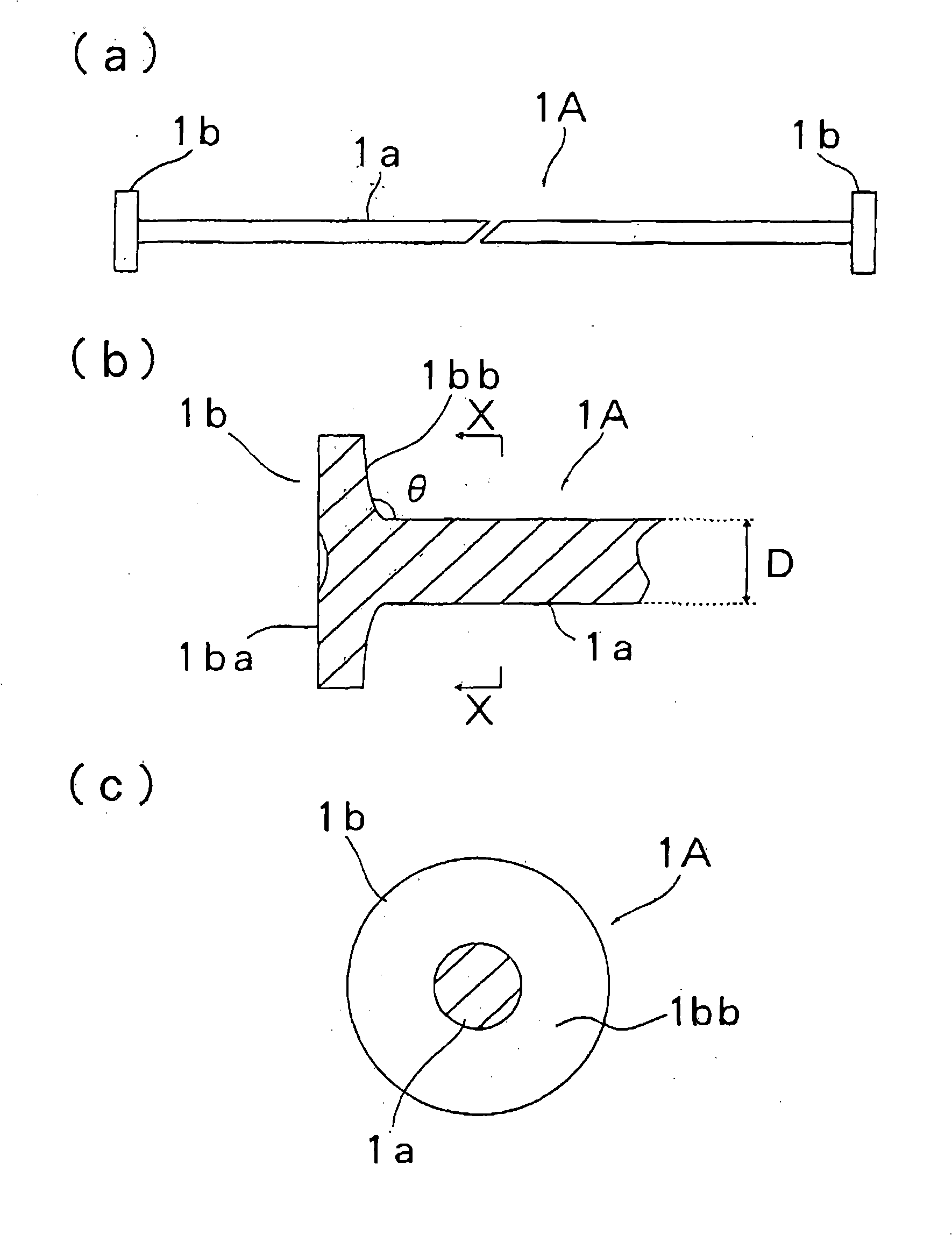

Method for producing reinforced bar with anchoring section

InactiveCN101352748AHigh strengthImprove toughnessMetal-working apparatusBuilding reinforcementsRebarHot Temperature

The invention aims at providing a manufacturing method of a steel bar with an anchoring part. By adopting the manufacturing method, a diameter expansion part with proper shape can be practicably formed to be used as the anchoring part. The manufacturing method of the steel bar comprises the following procedures: an end area of a steel bar (10) is heated, and high-temperature upsetting processing is carried out: the end area to be heated is compressed in the axial direction to be deformed by increasing the outer diameter, thus a diameter expansion part (102) of the anchoring part is formed integrally; heating is carried out to continuously or periodically raise the temperature of the end area of the steel bar (10) with the approaching of an end face (10A), the temperature (T1) of a part away from 2.0D in the axial direction from the end face (10A) of the steel bar (10) is not less than 1300 DEG C which is less than the melting point of the steel bar, and the temperature (T2) of a part away from 5.0D in the axial direction from the end face (10A) of the steel bar (10) is not less than Ac3 phase-transition temperature of the steel bar and not more than 1200 DEG C.

Owner:DAI ICHI HIGH FREQUENCY

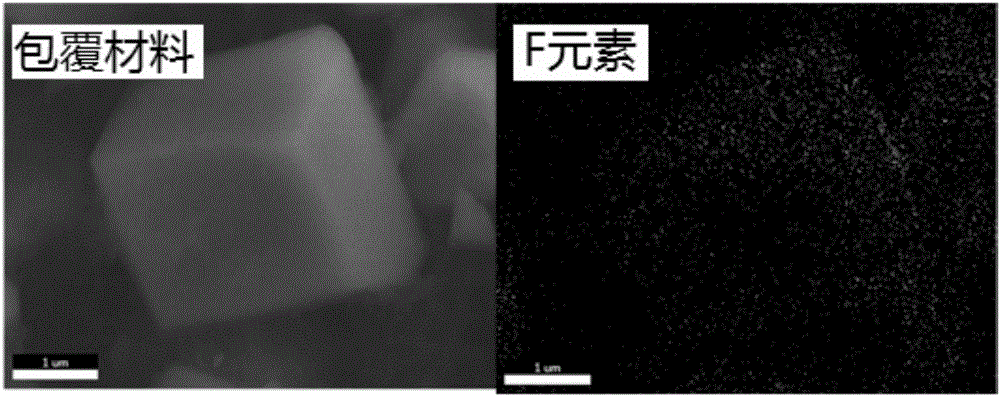

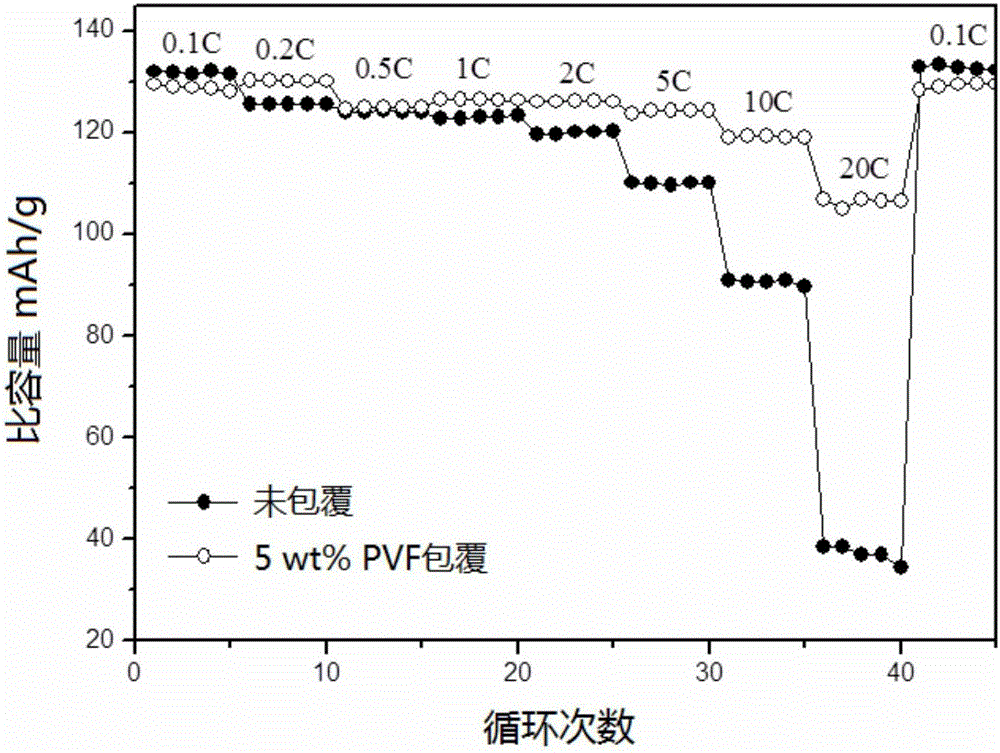

Preparation method of polymer coated lithium ion battery electrode material

InactiveCN106848241AIncrease migration rateAvoid chalkingCell electrodesSecondary cellsPolyolefinFiltration

The invention relates to a preparation method of a polymer coated lithium ion battery electrode material. The method comprises the steps as follows: (a) fluorine-containing or chlorine-containing polyolefin is dissolved in an organic solvent to form a macromolecular solution; (b) an inorganic electrode material is immersed in the macromolecular solution, and filtration and drying are performed after stirring; (c) a product in step (b) is subjected to heat treatment under the vacuum or inert gas condition at the temperature of 100-220 DEG C. The surface of the lithium ion battery electrode material is coated with polymer macromolecules with a liquid phase impregnation method, one thin and compact polymer coating layer is formed on the surface of the material, and after being subjected to heat treatment at proper temperatures, the coating layer does not dissolve in conventional slurry dispersing agents (water and N-methyl pyrrolidone) and cannot be damaged in the following slurry making process; the polymer coating layer contributes to release of internal stress produced by volume expansion and contraction of the electrode material, and the problems of electrode active substance particle powdering and active substance loss are solved.

Owner:JIANGSU DAOYING TECH CO LTD

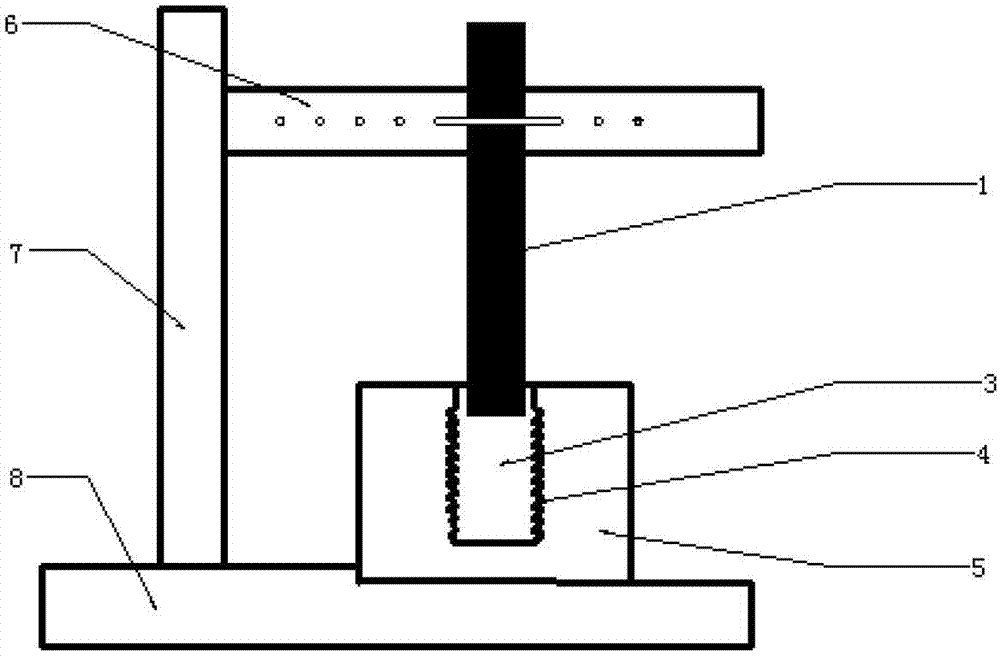

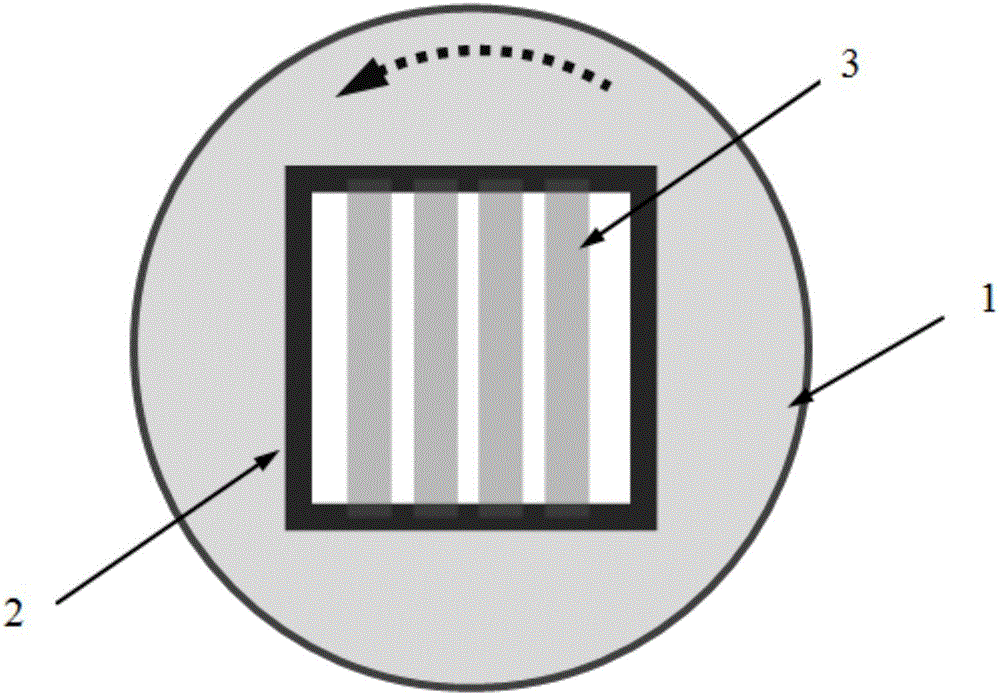

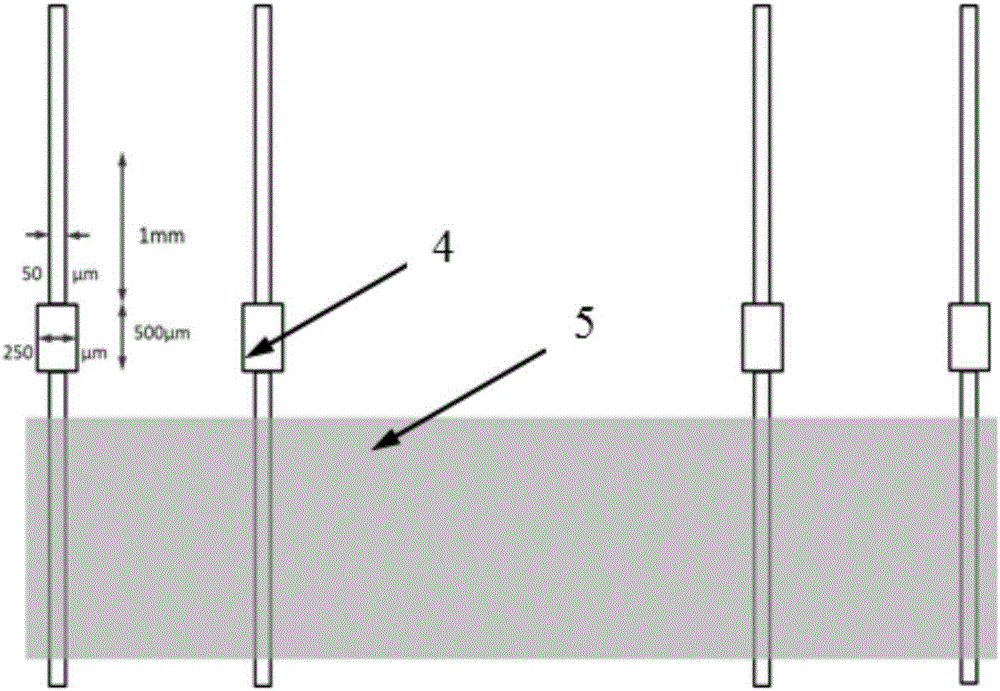

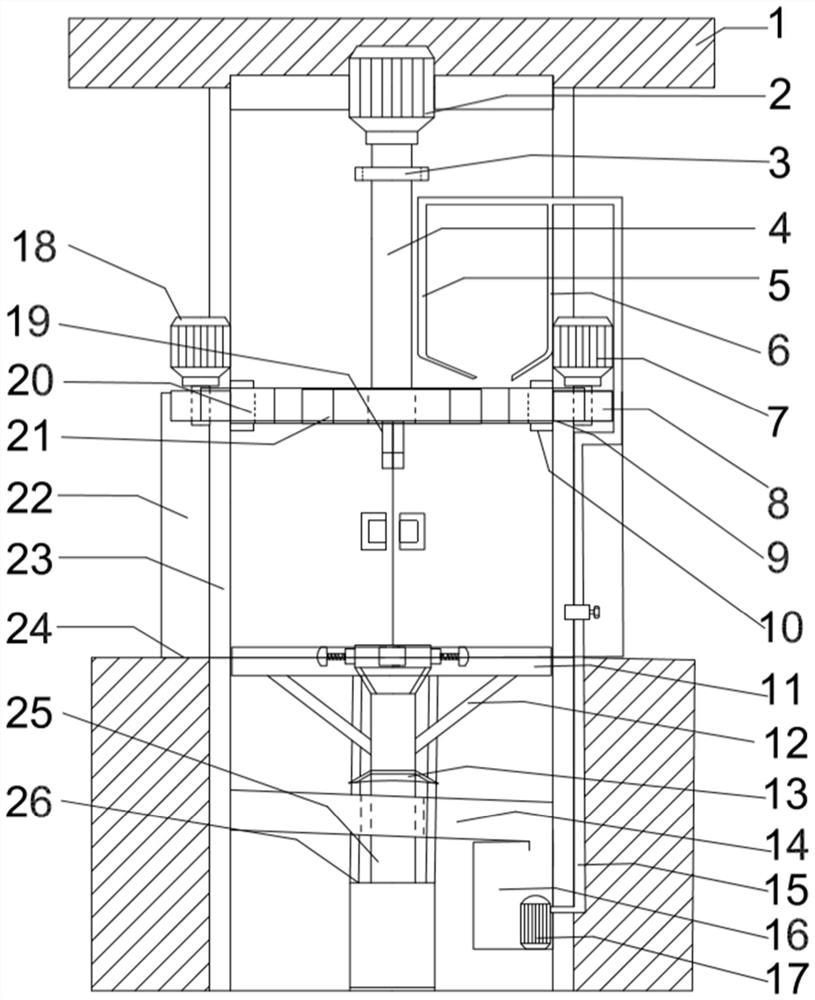

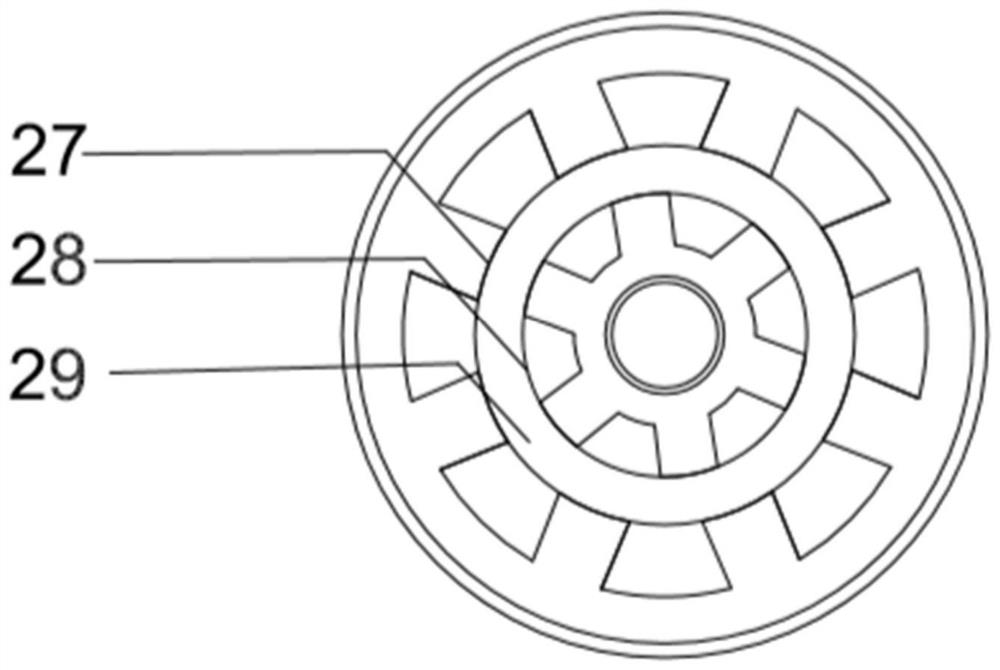

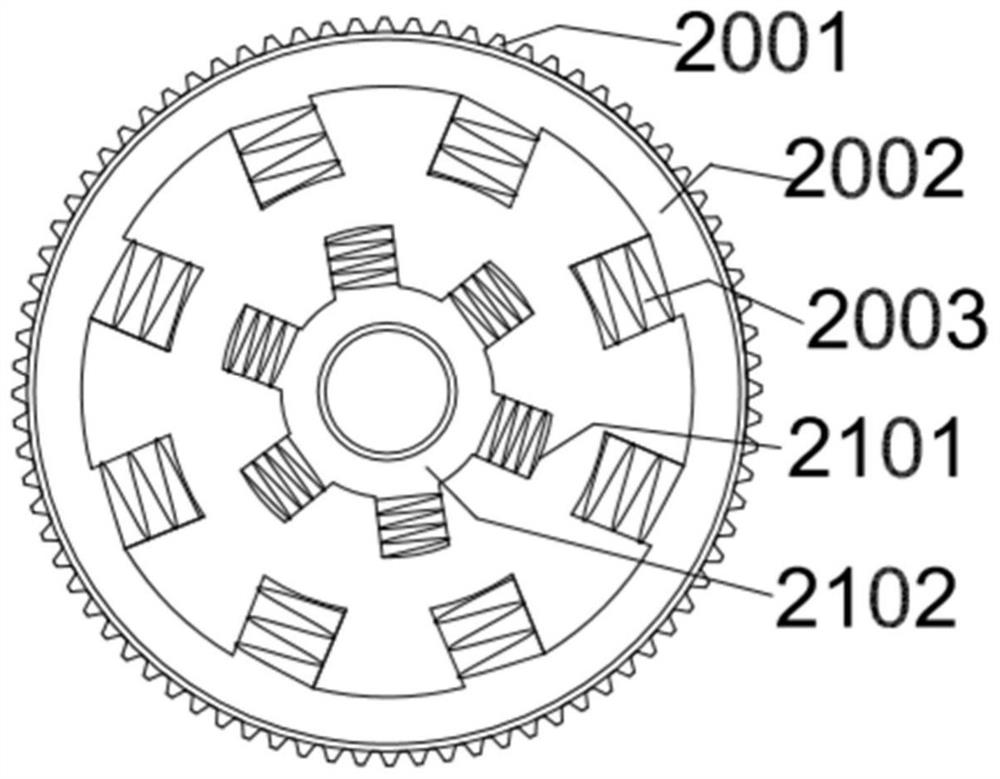

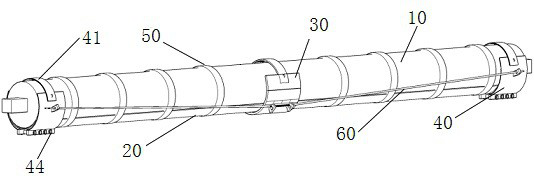

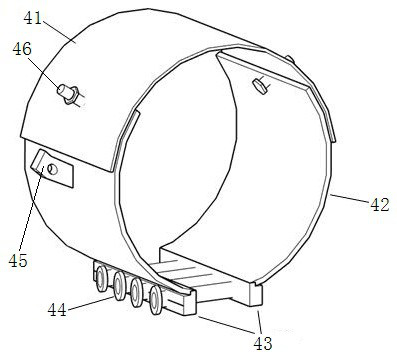

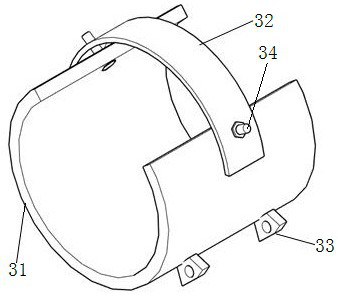

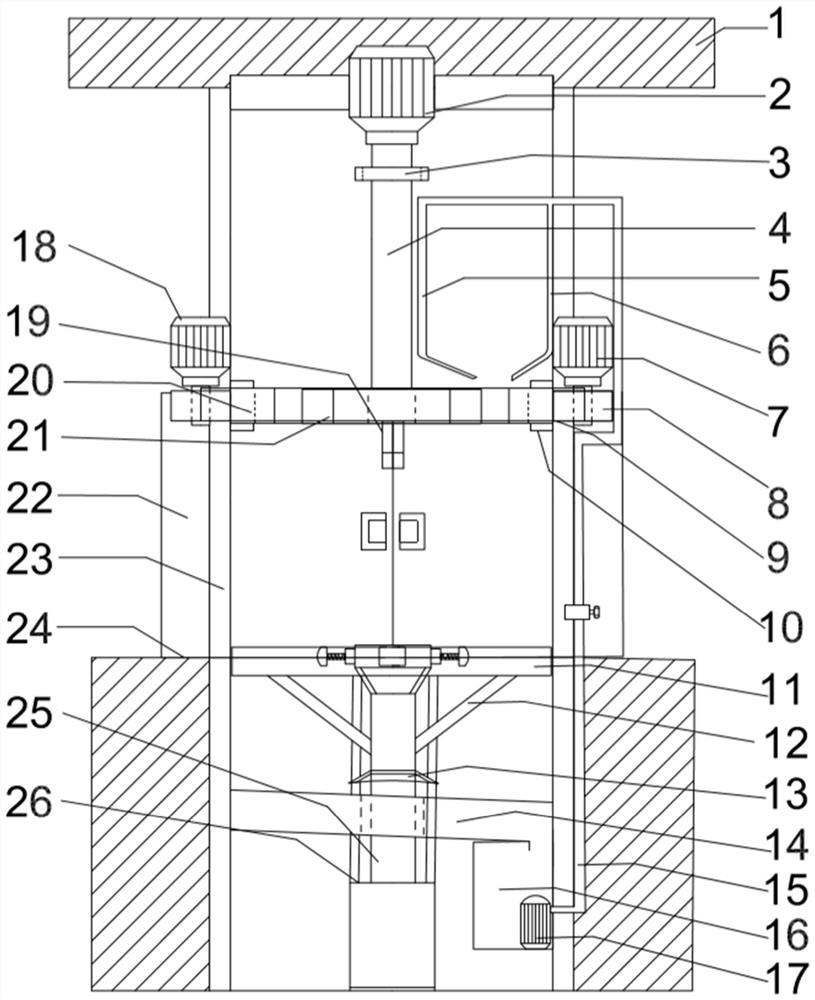

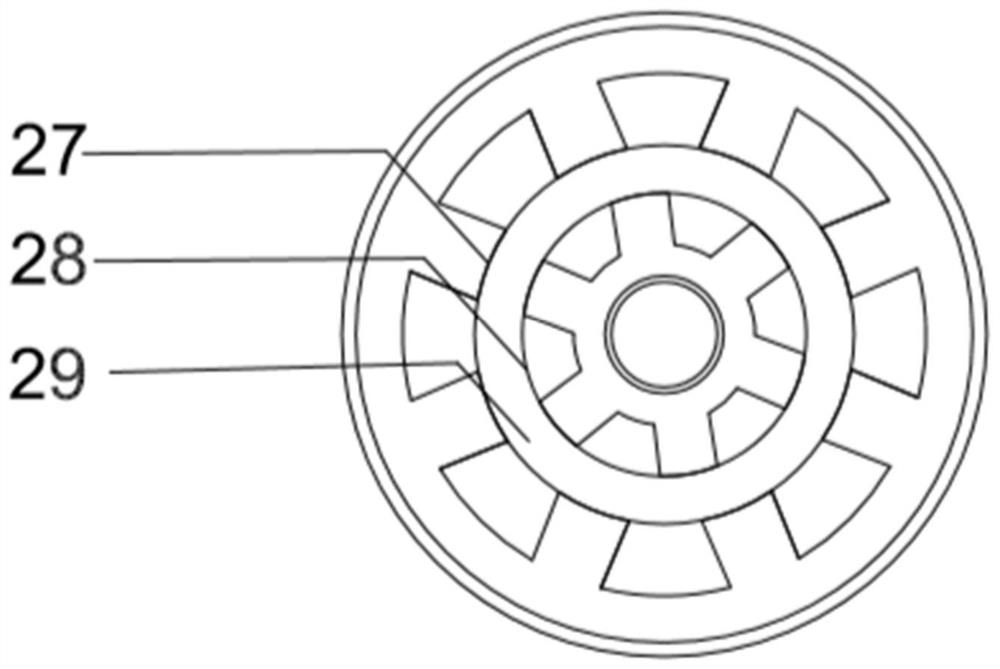

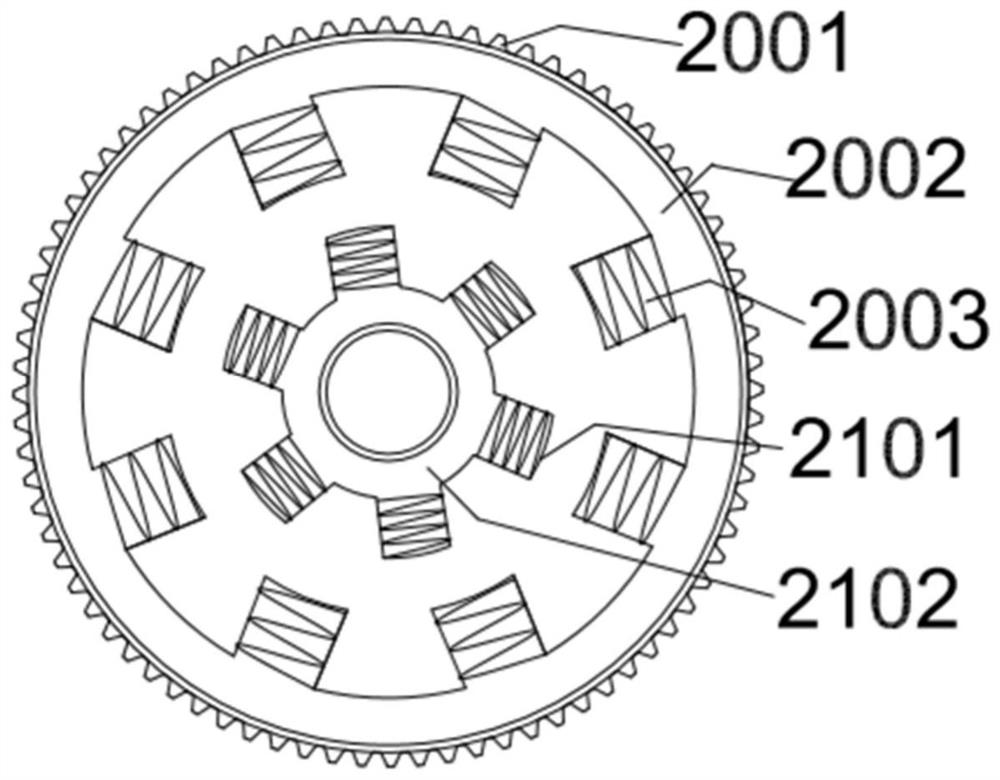

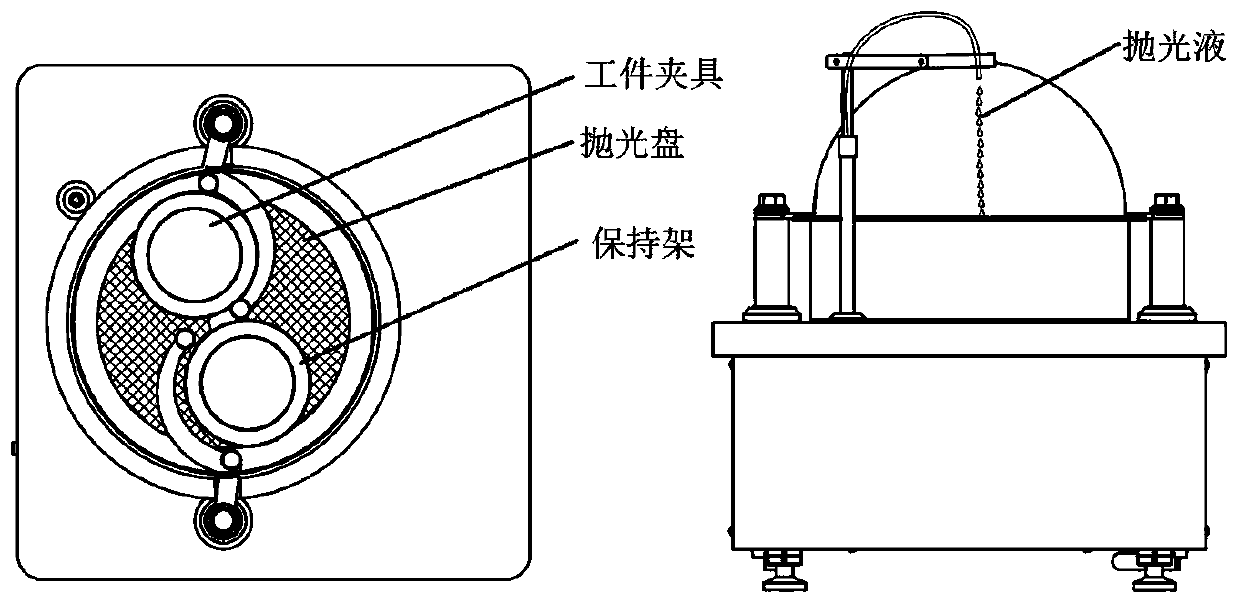

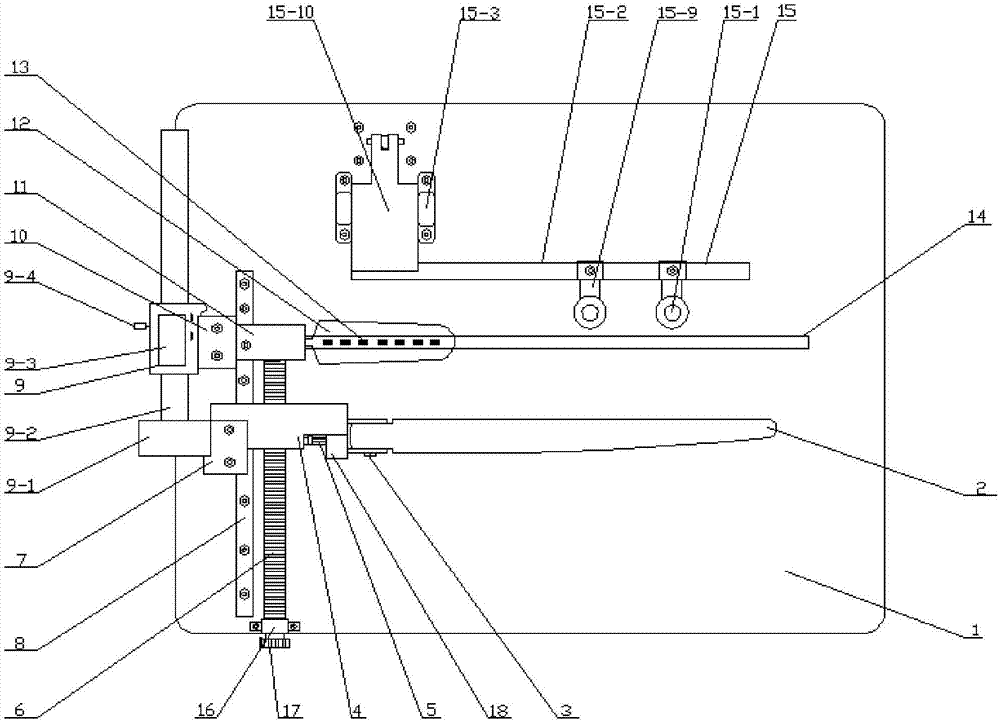

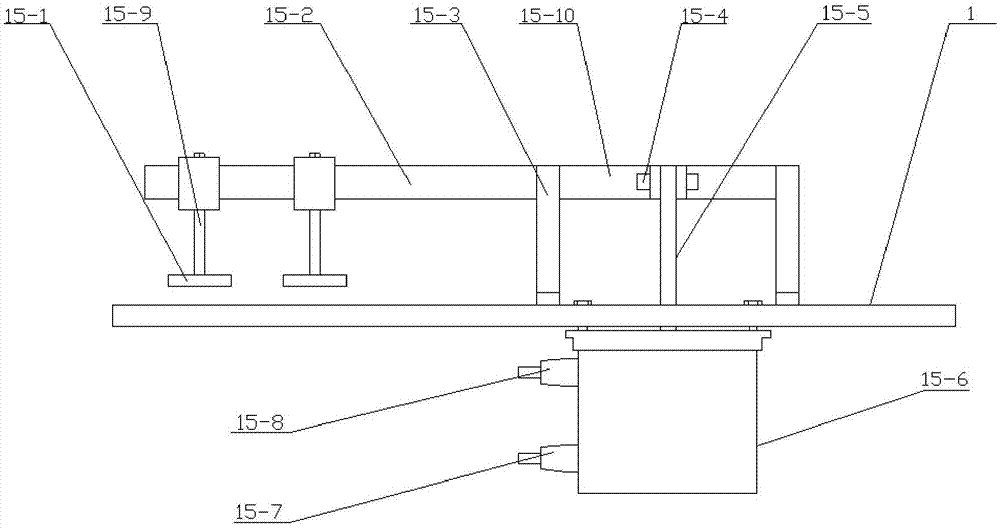

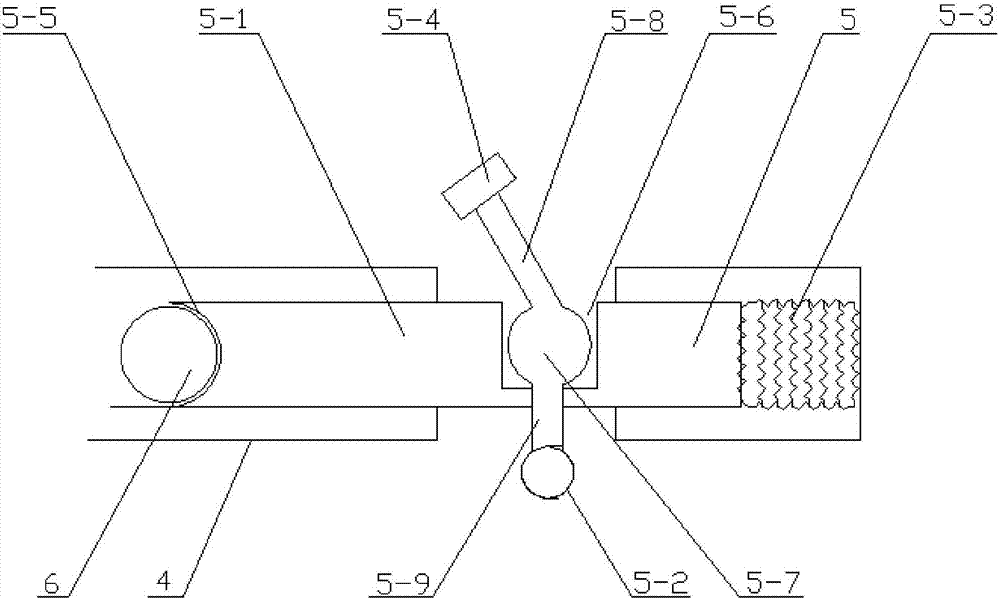

Magneto-rheological polishing machine for both inner surface and outer surface of short ceramic pipe

InactiveCN111673547AAvoid brittle fractureEliminate Polishing PrecisionEdge grinding machinesPolishing machinesPolishingMagneto

The invention discloses a magneto-rheological polishing machine for both inner surface and outer surface of a short ceramic pipe. The magneto-rheological polishing machine for both the inner surface and outer surface of the short ceramic pipe comprises a workbench as well as a polishing part, a stepper motor, a clamping rotation mechanism and a magneto-rheological fluid supply mechanism which arearranged on the workbench, wherein the polishing part comprises a first polishing part and a second polishing part which are driven through the stepper motor to mutually reversely rotate separately; and through the reverse rotation of an inner polishing head and an outer polishing head (that is, the first polishing part and the second polishing part mutually reversely rotate), the ceramic pipe isclamped on a saddle and carries out reciprocating rotation movement, and relative movement is generated between the ceramic pipe and the polishing heads (comprising the polishing head A and the polishing head B), so that simultaneous polishing for the inner surface and the outer surface of the ceramic pipe is realized, high-efficiency polishing for the ceramic pipe is realized, and high-accuracy location for the ceramic pipe is realized.

Owner:FUJIAN UNIV OF TECH

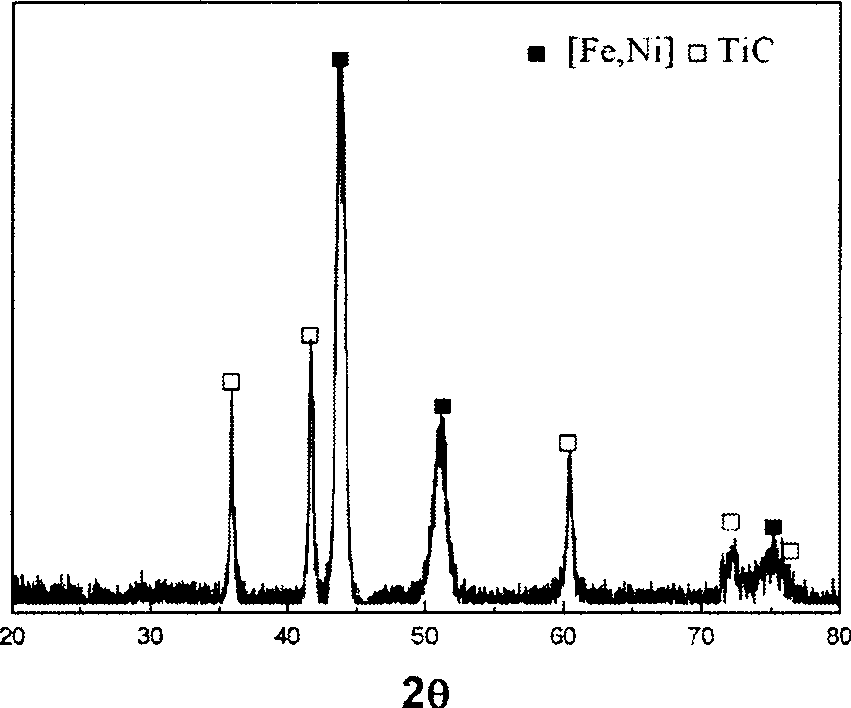

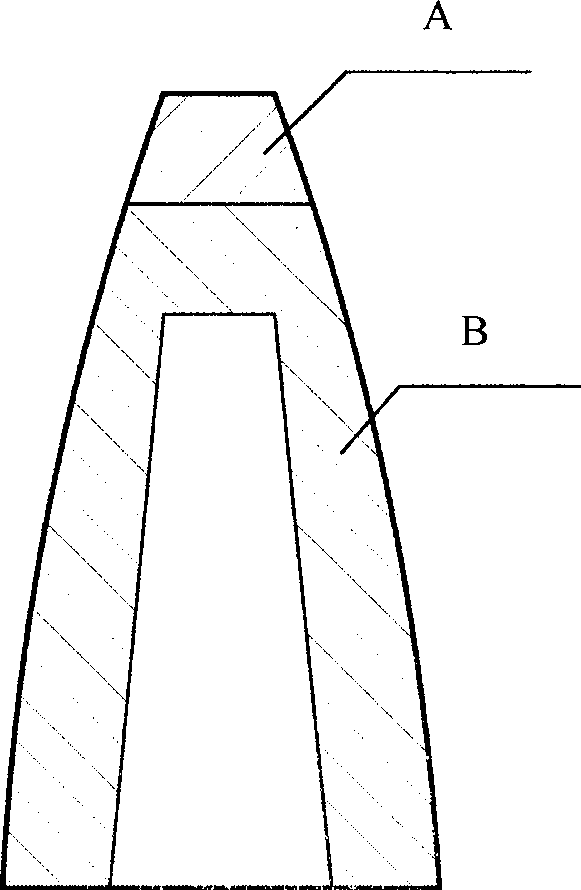

Base steel composite material for seamless steel pipe top and preparation method thereof

ActiveCN101391265AImprove antioxidant capacityImprove high temperature performanceMandrelsMetal rolling arrangementsCombustionChemical reaction

Disclosed is base steel composite material used for the top of a seamless pipe machine and the preparation method thereof, belonging to the application field of metal tube mills. Combustion synthesis chemical reaction in a negative-pressure casting type die cavity can be utilized; a TiC porcelain-metal enhancing area with the thickness of 15-20 mm is formed at the nasal part at the front edge of the top; and the combination between the porcelain-metal enhancing area and the top is metallurgy combination. The technology is as follows: firstly, Ti powder, C powder and Ni powder are used as reactants, are evenly mixed according to certain proportion and are pressed into blank material; secondly, the pressed blank material after degasification is positioned at a corresponding position of the top needing enhancement in the negative-pressure casting type die cavity, and vacuum suction of a negative-pressure sand box is kept; high-temperature and hot-made mould steel liquid is poured into casting mould to ignite the chemical reaction in the pressed blank material to form TiC porcelain granules so as to prepare roughcast of the top casting; and thirdly, the roughcast of the top casting is performed with mechanical process of turning or grinding and the like so as to achieve the designing size requirement of the top.

Owner:JILIN UNIV

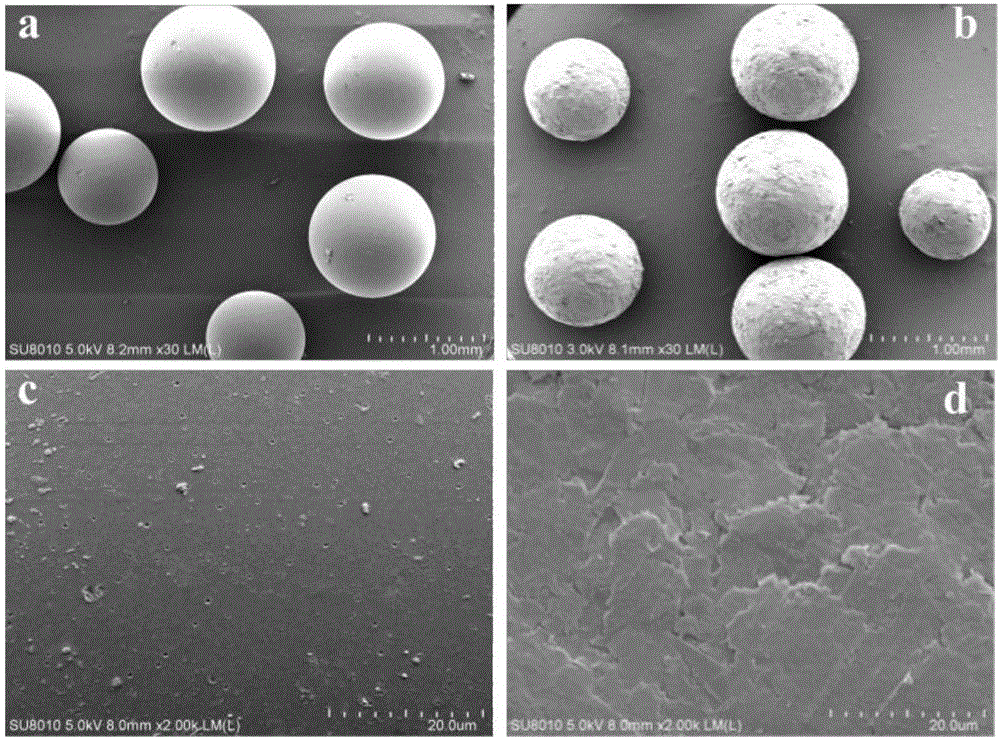

Graphene modified ultralow-density propping agent and preparation method thereof

InactiveCN106833601AHigh strengthLow thermal conductivityFluid removalDrilling compositionCross-linkMicrosphere

The invention belongs to the field of petroleum and gas fracturing extraction and in particular relates to a graphene modified ultralow-density propping agent and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing graphene, an olefin monomer, a cross-linking agent (divinyl benzene) and an initiator under ultrasonic or stirring conditions so as to obtain a monomer mixture in which a Pi-Pi assembly effect is achieved between graphene and aromatic ring components; adding the monomer mixture into an aqueous solution of dispersing agents, performing the processes of balling, cross-linking and curing under the heating condition so as to obtain a microsphere precipitate; and filtering, washing and drying, thereby obtaining the graphene modified ultralow-density propping agent. According to the method disclosed by the invention, the organic polymer microsphere has low density, while the graphene has the performances of ultrahigh strength, high thermal conductivity and high temperature resistance, and then the composite material has ultralow density as well as the characteristics of high strength and high temperature resistance, so that the deep-well hydraulic fracturing requirement is met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

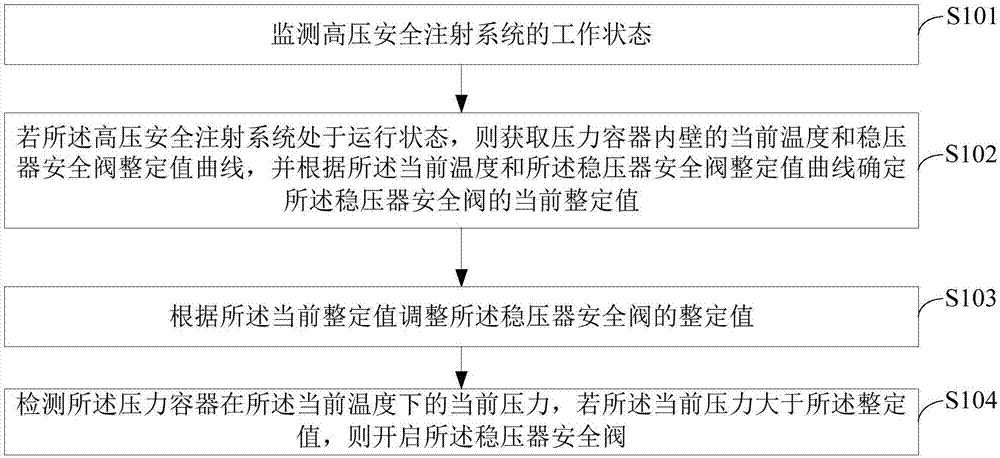

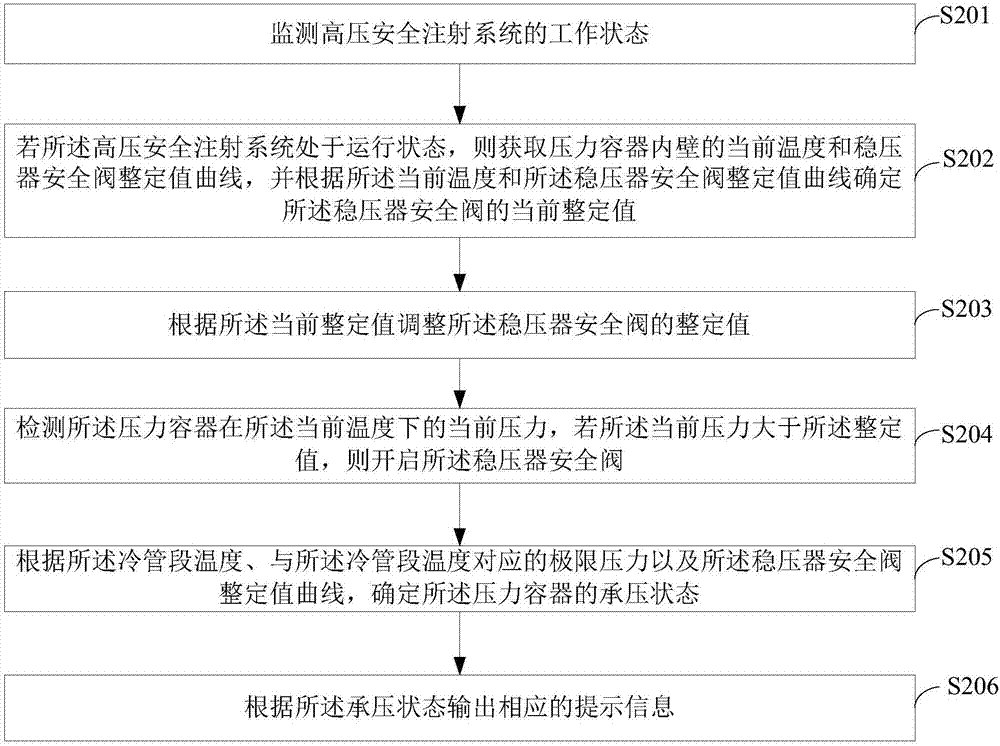

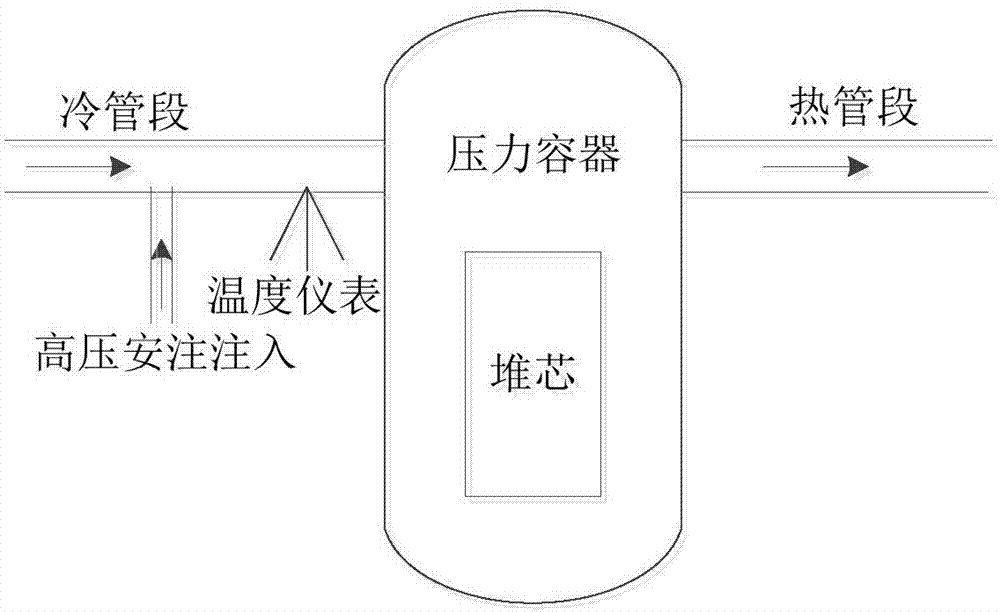

Method and device for preventing cold and excess pressure in nuclear power plant

ActiveCN107887038AAvoid brittle fractureNuclear energy generationNuclear monitoringNuclear powerHigh pressure

The invention is applicable to the technical field of nuclear power, and provides a method and device for preventing cold and excess pressure in a nuclear power plant. The method for preventing cold and excess pressure includes the steps of: monitoring the working state of a high-pressure safety injection system; if the high-pressure safety injection system is in operation, acquiring the current temperature of the inner wall of a pressure vessel and a setting value curve of a voltage regulator safety valve, and determining a current setting value of the voltage regulator safety valve accordingto the current temperature and the setting value curve of the voltage regulator safety valve; regulating the setting value of the voltage regulator safety valve according to the current setting value; detecting the current pressure of the pressure vessel under the current temperature; and if the current pressure is greater than the setting value, switching on the voltage regulator safety valve. According to the method and device for preventing cold and excess pressure in the nuclear power plant, continuous rising of the pressure of a primary circuit can be avoided, so that the pressure whichis applied to the pressure vessel is controlled within an allowable range, and the pressure vessel can be prevented from brittle fracture.

Owner:中广核工程有限公司 +1

Environmental-friendly high-temperature-resistant cable material for computer

InactiveCN105778366AIncrease the degree of cross-linkingImprove toughnessPlastic/resin/waxes insulatorsCellulose substancesBenzoyl peroxideSilanes

The invention discloses an environmental-friendly high-temperature-resistant cable material for a computer. The environmental-friendly high-temperature-resistant cable material is prepared from the following components in parts by weight: 50-80 parts of polytetrafluoroethylene, 0.4-0.9 part of polyphenylene sulfide, 0.5-1.5 parts of polybenzoate, 1-3 parts of rare earth stabilizer, 1-2 parts of coumarone resin, 10-16 parts of modified microcrystalline cellulose, 2-8 parts of nano-diamond particles, 1-2 parts of palm wax, 0.5-1.2 parts of antimonous oxide, 0.5-1.5 parts of phthalate (2-ethyl hexoate) ester, 1-3 parts of maleic anhydride, 1-2 parts of gamma-(quadrol) propyl emthyl dimethoxy silane, 0.5-1.2 parts of acrylonitrile-butadiene-styrol copolymer, 0.5-1.2 parts of benzoyl peroxide and 1-2 parts of butyl titanate. The environmental-friendly high-temperature-resistant cable material for the computer can resist high temperature and is excellent in mechanical property.

Owner:ANHUI SPECIAL CABLE GRP

Power cable sheathing compound with good thermal stability

InactiveCN106433169AImprove thermal stabilityImprove mechanical propertiesRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneChlorinated paraffins

The invention discloses a power cable sheathing compound with good thermal stability. The raw materials of the power cable sheathing compound comprises, by weight, 15-35 parts of Ethylene Propylene Diene Monomer, 5-20 parts of low density polyethylene , 20-60 parts of hydrogenated butadiene-acrylonitrie rubber, 0.2-0.8 part of 2,5-dimethyl-2,5-di(tert-butylperoxy) hexane, 1-2 parts of dicumyl peroxide, 1-2 parts of maleic anhydride, 1-2 parts of phenyl trichlorosilane, 20-30 parts of modified composite emulsion, 0.5-1.2 parts of Epoxidized linseed oil, 1-3 parts of chlorinated paraffin, 0.1-0.6 part of black factice, 0.5-1.1 part of tetramethyl orthosilicate, 15-25 parts of silk fiber, 20-40 parts of lignin, 5-15 parts of nanosilicon dioxide, 20-40 parts of white carbon black and 1-8 parts of antimonous oxide. The power cable sheathing compound has good tenacity, excellent thermal stability and good mechanical property, and can effectively avoid phenomenon of brittle failure.

Owner:ANHUI LAND GRP

Method for preparing high-toughness titanium silicon carbide-silicon carbide multiphase ceramic special-shaped components

ActiveCN107619282ASimple process routeShort production processCoatingsCeramic shaping liningsComposite ceramicSlurry

The invention relates to a method for preparing composite ceramics, particularly discloses a method for preparing high-toughness titanium silicon carbide-silicon carbide multiphase ceramic special-shaped components, and belongs to the field of technologies for preparing ceramic materials. The method includes steps of uniformly dispersing carbon black, titanium carbide powder, titanium powder, dispersing agents and plasticizers and then carrying out high-speed ball-milling to obtain ceramic slurry; degassing the ceramic slurry under the vacuum conditions, then slowly injecting the ceramic slurry into gypsum molds and drying the ceramic slurry to obtain special-shaped component biscuits; shifting the special-shaped component biscuits into a vacuum sintering furnace, uniformly flatly spreading high-purity silicon powder on the upper sides of the biscuits and carrying out infiltration-reaction sintering at the sintering temperatures of 1650-1700 DEG C for the heat preservation time of 1-2hours to obtain the high-toughness titanium silicon carbide-silicon carbide multiphase ceramic special-shaped components. The method has the advantage that the high-toughness titanium silicon carbide-silicon carbide multiphase ceramic special-shaped components prepared by the aid of the method are high in density and excellent in mechanical property and are particularly high in bending strength and fracture toughness.

Owner:SHANDONG UNIV OF TECH

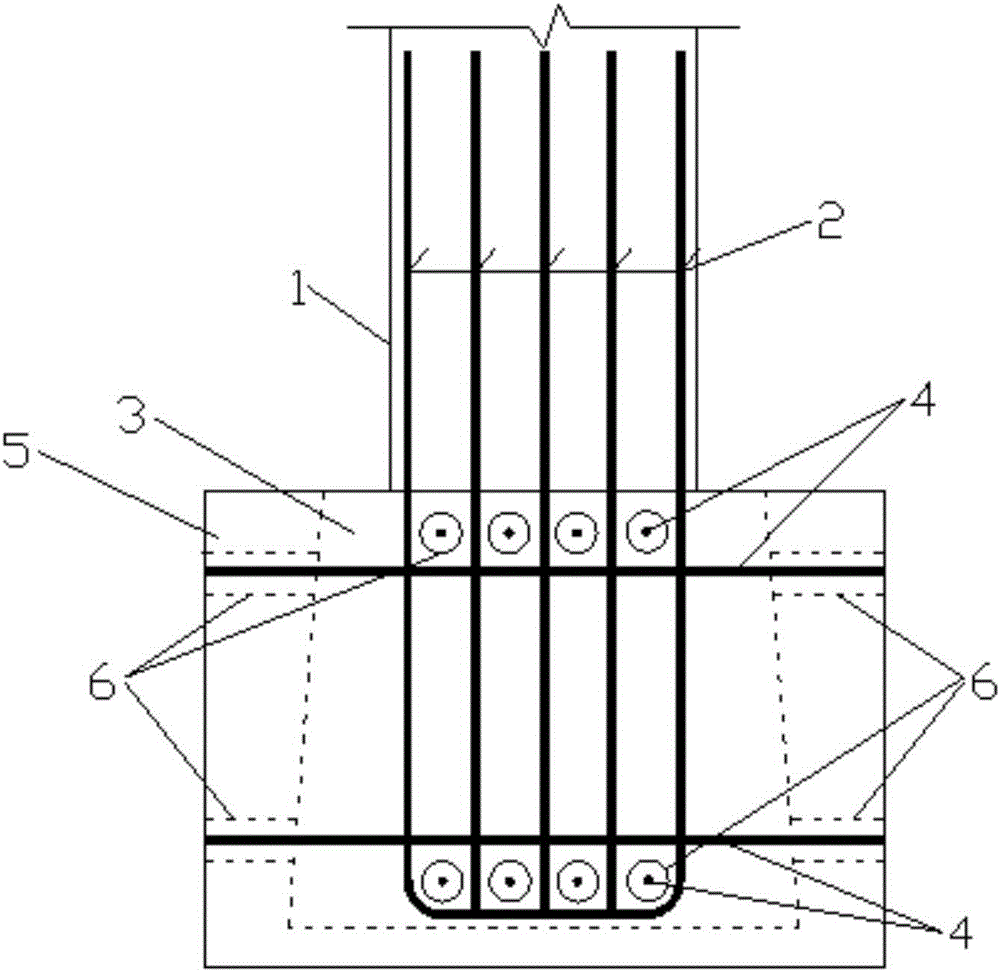

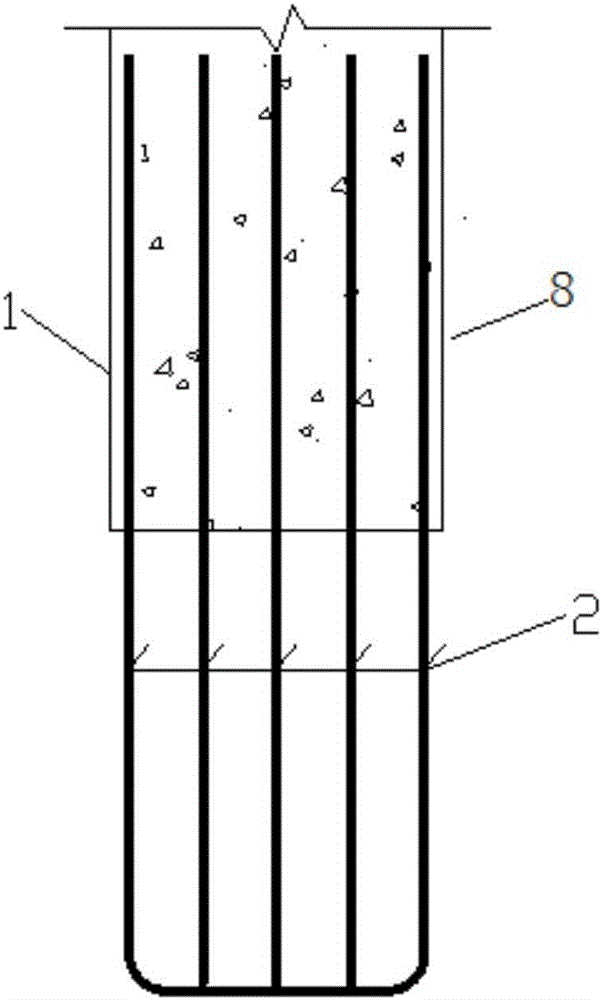

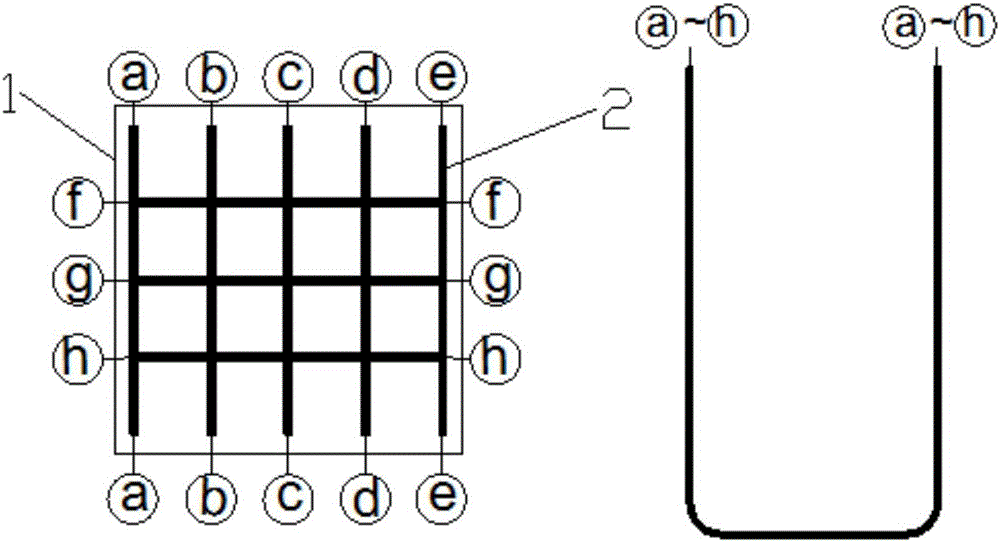

Precast assembled bridge pier manufactured from U-shaped reinforcing steel bars, and connection process of precast assembled bridge pier

InactiveCN106381804AIncrease tensile connection measuresAvoid pulling out damageBridge structural detailsBridge erection/assemblyEngineeringRebar

The invention discloses a precast assembled bridge pier manufactured from U-shaped reinforcing steel bars. The precast assembled bridge pier comprises a pier body and a bearing platform, wherein the pier body comprises a U-shaped reinforcing steel bar cage and a pier stud, a plurality of U-shaped reinforcing steel bars are mutually spaced by a certain distance and are crisscrossed to form the U-shaped reinforcing steel bar cage, and the pier stud is cast at one end of the U-shaped reinforcing steel bar cage; a groove is formed in the bearing platform, and the other end of the U-shaped reinforcing steel bar cage is arranged in the groove; a plurality of holes are formed in each of the four side surfaces of the bearing platform, and reinforcing steel bars penetrate through the holes; a reinforcing steel bar mesh is formed by the reinforcing steel bars and the U-shaped reinforcing steel bar cage, and finally concrete is cast. The invention further discloses a connection process of the precast assembled bridge pier. According to the precast assembled bridge pier and the connection process thereof disclosed by the invention, a mutual crossed and meshed manner of the U-shaped reinforcing steel bars and the reinforcing steel bars (the reinforcing steel bars penetrated subsequently) is adopted between the bearing platform and the pier body, so that the integrity between the bridge pier and the concrete, and the seismic performance of the bridge pier are greatly enhanced, and the construction speed of the bridge pier is accelerated; and the precast assembled bridge pier and the connection process thereof are suitable for the rapid construction of an urban rail transit bridge or the connection of relevant parts, and also have a certain significance on the reconstruction after disasters.

Owner:SHANGHAI INST OF TECH

Manufacturing method of injection mold

The invention discloses a manufacturing method of an injection mold. The method includes the following process steps: step 1: analyzing a plastic part production drawing, understanding the use of injection-molded parts and analyzing the manufacturing process of the plastic parts; step 2: using three-dimensional software to make a general assembly drawing of a plastic part mold and engineering drawings of components, and setting a mold tolerance standard; step 3: manufacturing the mold, and introducing a forging technology, a sawing technology, a jig boring processing technology and a milling technology into a CAM tool path program design; step 4: inspecting and assembling the mold; and step 5: testing the mold and repairing the mold. Through the method mentioned above, not only the overall design of the mold is optimized to ensure the reliable implementation of the follow-up process, but also the precision of the mold and the qualification rate of injection molding products are greatly improved.

Owner:SUZHOU ICOOLMACH EQUIP MFG

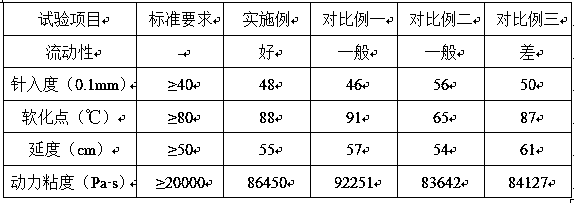

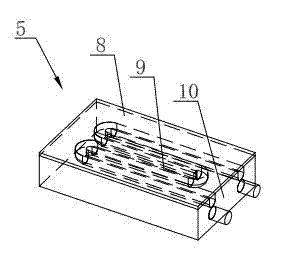

Reactive high-viscosity liquid asphalt and preparation method and application thereof

InactiveCN110643185AIncrease temperatureImprove temperature performanceBuilding insulationsOrganic solventRoad surface

The invention discloses reactive high-viscosity liquid asphalt and a preparation method and application thereof. The reactive high-viscosity liquid asphalt contains, in parts by weight, 50-60 parts ofasphalt, 25-35 parts of an organic solvent and 15-25 parts of a modifier. A reactive high-viscosity liquid asphalt mixture which is obtained through mixing of the reactive high-viscosity liquid asphalt, an inorganic active powder curing agent and graded aggregate has the advantages of low cost, high strength, rapid strength development, convenient construction and a wide application range, can beused as a super-thin abrasion layer which is laid on an original pavement, and can also be applied to newly-built drainage pavements.

Owner:湖南鑫长胜材料科技有限公司 +2

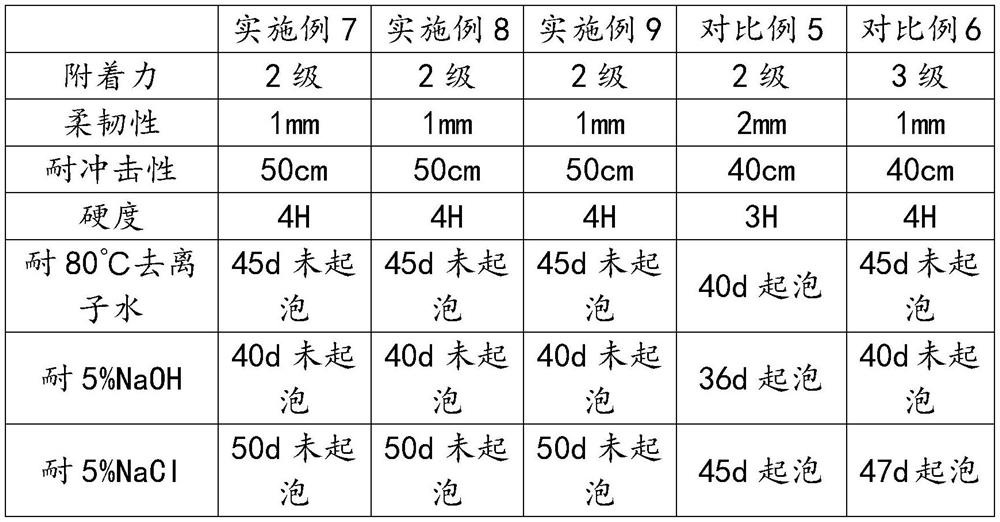

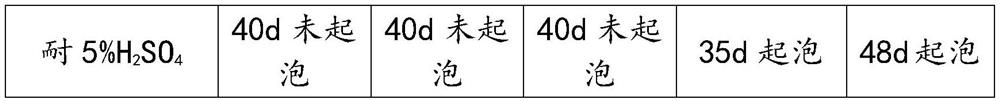

Water-resistant net-flavor waterborne ceramic simulating coating and preparation method thereof

ActiveCN105778632AAvoid water swellingAvoid crackingDextran coatingsStarch coatingsCarboxymethyl celluloseBletilla striata

The invention relates to the field of coating and discloses a water-resistant net-flavor waterborne ceramic simulating coating and a preparation method thereof. The coating comprises the following components in parts by mass: 10-20 parts of calcite powder, 10-20 parts of heavy calcium carbonate powder, 8-12 parts of calcium carbonate, 2-4 parts of bletilla striata powder, 1-3 parts of corn starch, 0.5-1.5 parts of carboxymethyl cellulose, 0.5-1.5 parts of phenoxy resin, 0.5-1.5 parts of glutaraldehyde, 1-3 parts of air purifying particles and 45-55 parts of water. The water-resistant net-flavor waterborne ceramic simulating coating provided by the invention has the advantages of relatively good water resistance, air purifying function, large adsorption capacity, long purifying time and good air purifying effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

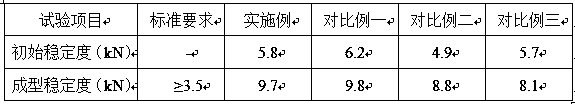

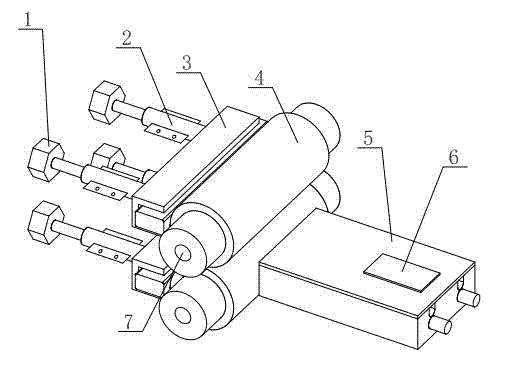

Rolling technology for pure tungsten sheet and device thereof

InactiveCN102389898AGuaranteed deformationPrevent oxidationTemperature control deviceRolling equipment maintainenceElectricityTemperature control

The invention relates to a rolling technology for a pure tungsten sheet and a device thereof. An electric heating pipe is arranged in a roller; an electric heating platform is arranged at the front part on a rolling-in side of the roller; the top surface of the electric heating platform is located at a peak on the outer periphery of a lower roller; a roller wiper is arranged on a rolling-out side of the roller; and a temperature control device is used for controlling the temperatures of the electric heating pipe and the electric heating platform. According to the rolling technology, the rolling temperature of the tungsten sheet is strictly controlled, the electric heating platform is utilized to heat the to-be-rolled tungsten sheet, and meanwhile, the roller is heated and kept warm, thereby ensuring deformation of the tungsten sheet within a suitable plastic temperature range all the time during the whole rolling process, avoiding oxidization, greatly promoting the yield and realizing batch and low-cost production of ultrathin tungsten sheets.

Owner:无锡乐普金属科技有限公司

Preparation method for high-temperature lightweight tough mullite aggregate

ActiveCN110040995AIncrease productivityReduce manufacturing costCeramicwareFoaming agentPolymer science

The invention relates to a preparation method for a high-temperature lightweight tough mullite aggregate. According to the technical scheme, the preparation method comprises the following steps: mixing 40-65 parts of mullite powder, 5-25 parts of 94.5% silica powder, 20-55 parts of soft clay and 0.3-0.5 part of water reducer in parts by weight with water while stirring at a stirring rate of 500 rad / min, thereby fully mixing main materials and forming into a uniform slurry; adding 10-40 parts of foaming agent and 0.1-0.6 part of foam stabilizer into the uniform slurry. According to the invention, a manner of one-step foaming is combined with a unique stirring process, for fully and uniformly distributing the foaming agent into the slurry and lastly forming a foam slurry; the production process is simple and practicable; volume density of aggregate body is 0.5kg / m3-0.6kg / m3; volume density of sintered aggregate is 0.3kg / m3-0.4kg / m3.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

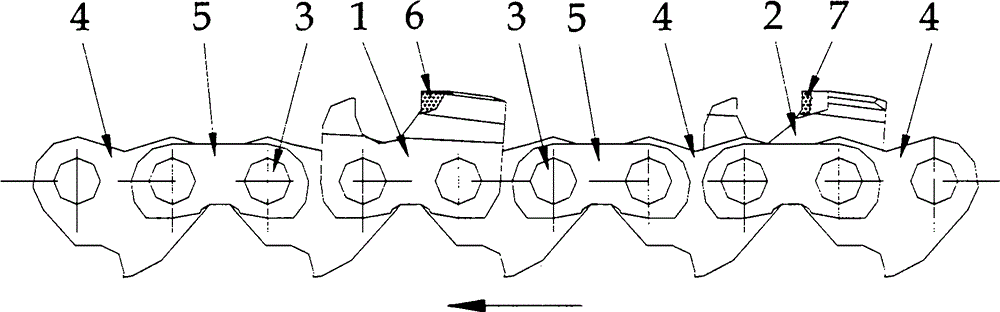

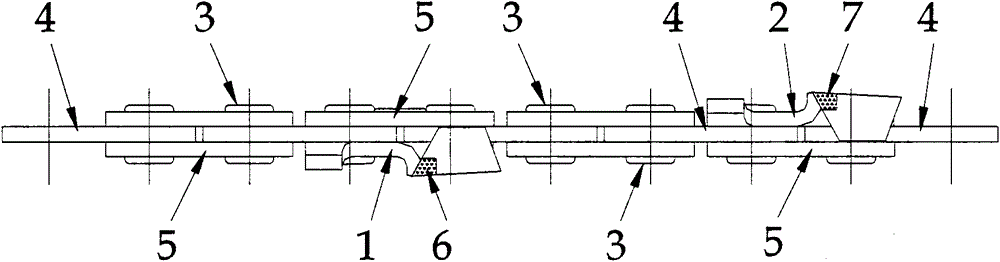

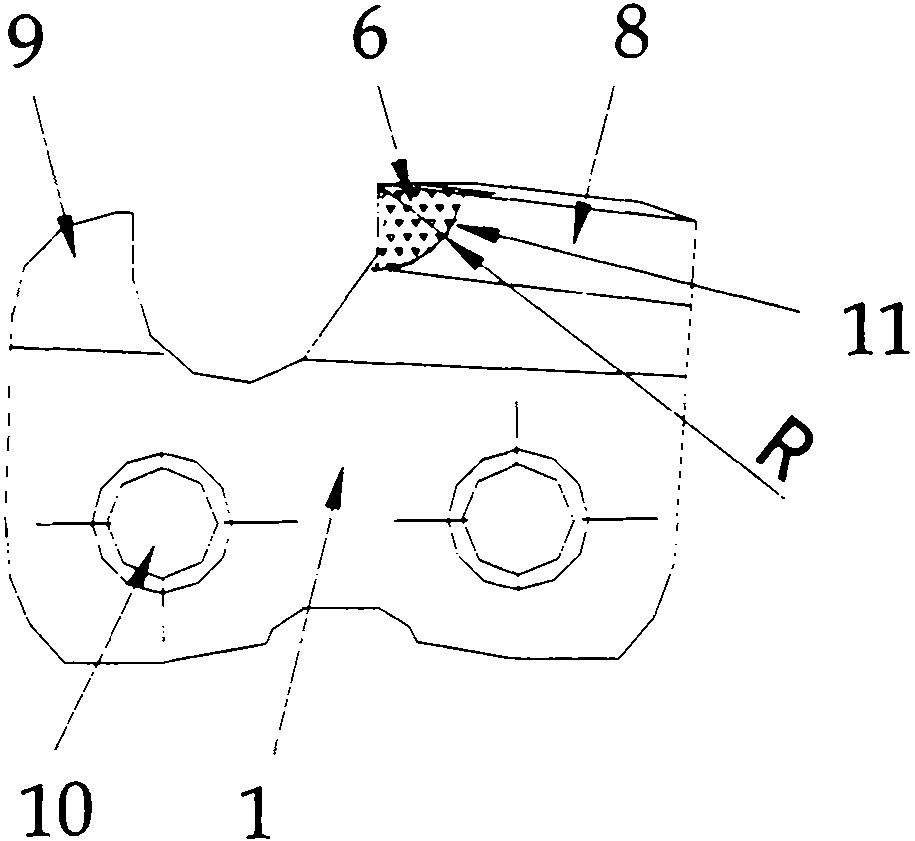

Hard alloy tooth top square tooth type saw chain

The invention relates to a hard alloy tooth top square tooth type saw chain of a chain saw. The hard alloy tooth top square tooth type saw chain is characterized in that a small hard alloy tooth block is welded on a tooth top position of the saw chain, and a hard alloy square tooth type tooth top is formed. The hard alloy tooth block is made into a fan-shaped prism, most of the welding surface is a cylindrical surface, and the circular arc radius of the cylindrical surface is 2 to 4mm, and is preferably 2.5 to 3.5mm. The hard alloy tooth top square tooth type saw chain adopts a butt welding method for welding the hard alloy tooth block with cutting teeth, the hard alloy tooth block and the cutting teeth are in directly contact and butt fusion, no middle layer is formed, the connecting intensity of welding seams is improved by 4 times through being compared with that of brazing, and the firmness is high. The heat treatment is carried out after the tooth block welding, the welding brittleness of the cutting tooth body behind the welding seams is eliminated, and the brittleness fracture of the cutting tooth body during the sawing can be prevented. Finally, the hard alloy tooth top and the cutting teeth are simultaneously subjected to tooth grinding, and the optimum consistent square tooth type corners are obtained.

Owner:缙云县鼎盛工具制造厂(普通合伙)

Prestress FRP and high-strength steel wire rope combined wood beam reinforcing device and method

PendingCN112392288AReduce disturbanceImprove reliabilityBuilding repairsBuilding material handlingIndustrial engineeringWire rope

The invention relates to a prestress FRP and high-strength steel wire rope combined wood beam reinforcing device and method. The device comprises FRP cloth pasted to the bottom face of a log beam in the length direction, a middle supporting piece is installed in the middle of the log beam, end reinforcing anchoring pieces are installed at the two ends of the log beam correspondingly, a plurality of layers of FRP hoops are pasted on the log beam and located between the middle supporting piece and the end part reinforcing anchoring pieces at intervals in the length direction, and high-strength steel wire ropes with the two ends connected to the corresponding end part reinforcing anchoring pieces are arranged on the two sides of the middle supporting piece correspondingly. The device and themethod overcome the defects of rigidity, bearing capacity and the like of flexural members such as wood beams in actual engineering, and meanwhile, through combined use of a prestress steel wire ropeand the FRP cloth, the safety reserve is improved, two defense lines are provided for the damaged wood beams, and the ductility is improved.

Owner:FUZHOU UNIV

Magneto-rheological polishing machine for inner and outer surfaces of ceramic short pipe

InactiveCN112338790AAvoid brittle fractureEliminate Polishing PrecisionEdge grinding machinesPolishing machinesPolishingElectric machinery

The invention discloses a magneto-rheological polishing machine for inner and outer surfaces of a ceramic short pipe. The machine comprises a workbench, as well as a polishing part, stepping motors, aclamping rotating mechanism and a magneto-rheological fluid supply mechanism which are arranged on the workbench, wherein the polishing part comprises a first polishing part body and a second polishing part body which are driven by the stepping motors to rotate oppositely correspondingly, inner polishing heads and outer polishing heads rotate oppositely (namely the first polishing part and the second polishing part rotate oppositely), and the ceramic pipe is clamped on a saddle to rotate in a reciprocating mode, so that the ceramic pipe and the polishing heads (including the polishing heads Aand the polishing heads B) move relatively, the inner and outer surfaces of the ceramic pipe are polished at the same time, high-efficiency polishing of the ceramic pipe is achieved, and high-precision positioning of the ceramic pipe is achieved.

Owner:FUJIAN UNIV OF TECH

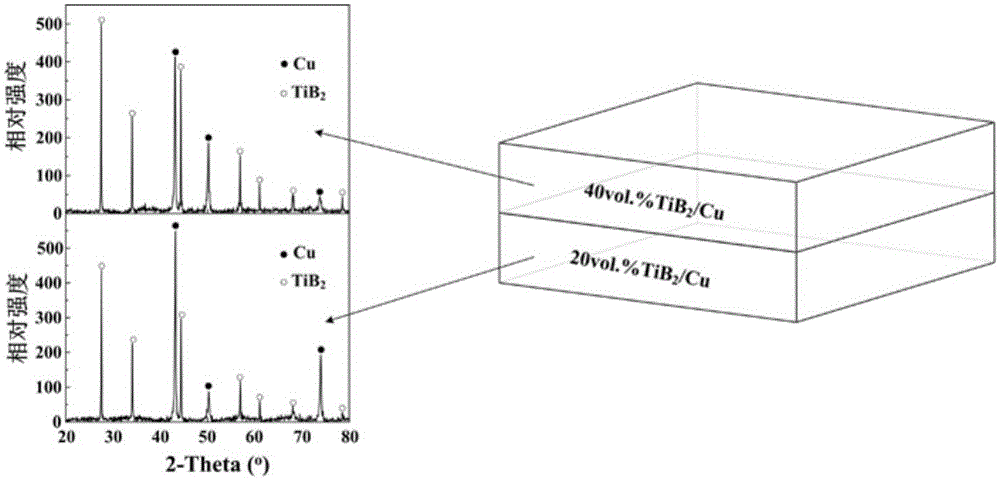

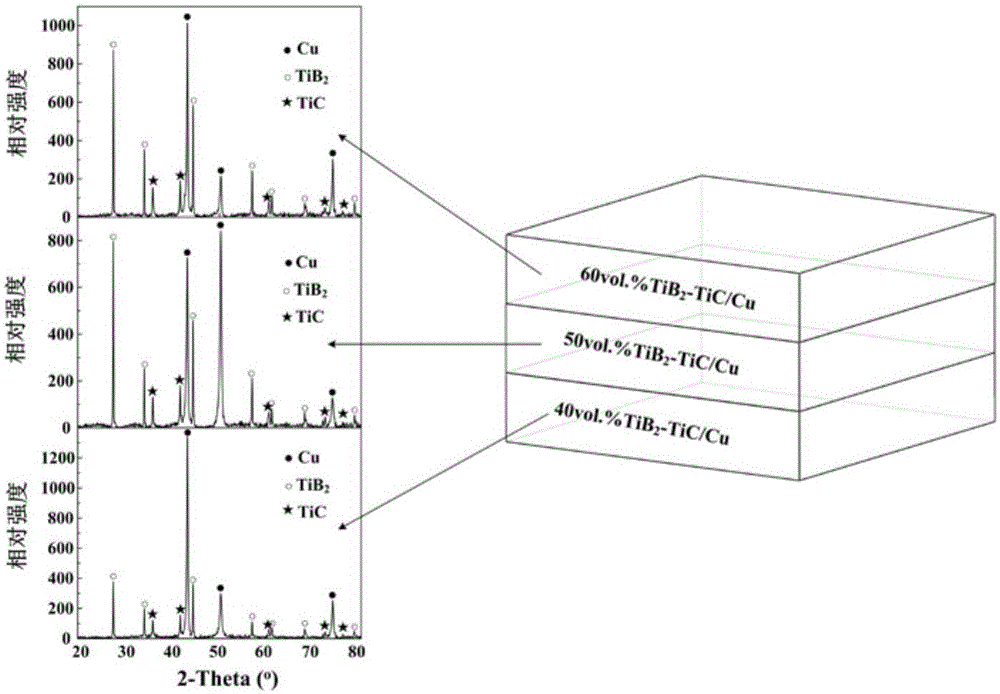

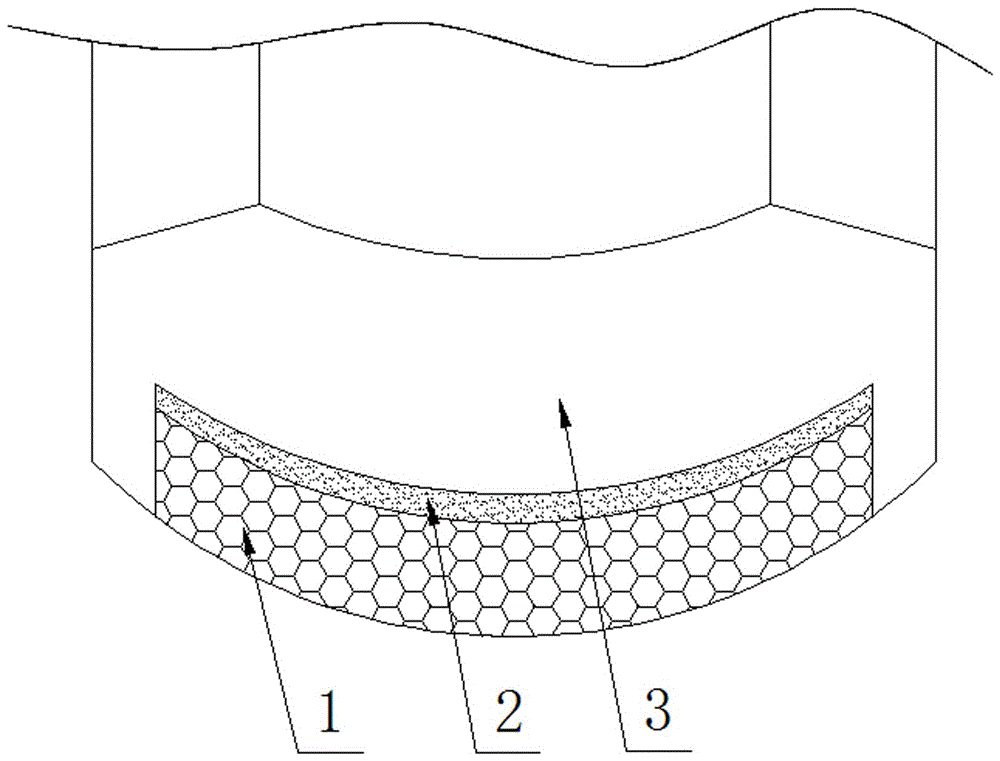

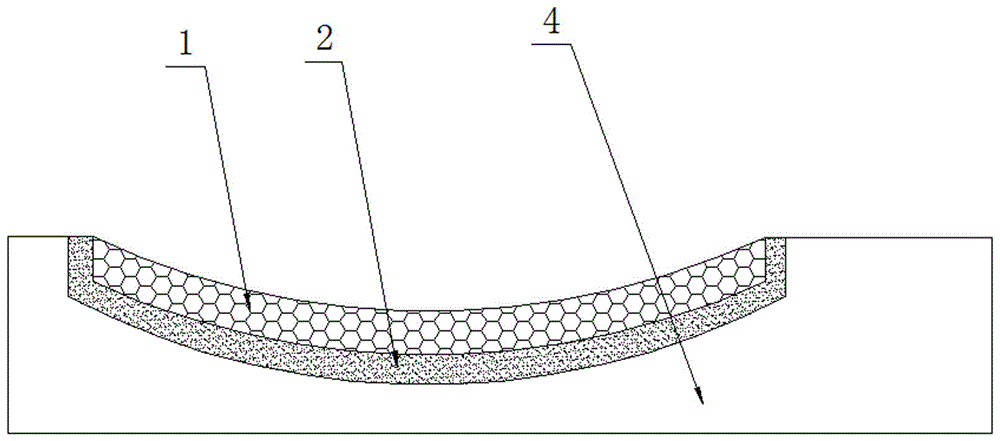

Gradient-enhanced ceramic particle Cu heat sink and preparation method thereof

The invention relates to a gradient-enhanced ceramic particle Cu heat sink and a preparation method thereof, and belongs to the technical field of chip packaging and heat radiating of semiconductor lasers. The problem that the thermal expansion coefficient of an existing heat sink cannot be matched with the thermal expansion coefficients of various chip materials at the same time is solved. The heat sink is composed of two layers of structures or three layers of structures. Each layer of structure is composed of 20-60 vol.% of ceramic particles and 40-80 vol.% of Cu. The ceramic particles are a mixture of TiB2 or TiB2-TiC. According to the heat sink, the contents of the ceramic particles in all the layers are different, and the corresponding thermal expansion coefficients are different, so that chips are welded to the functional layers with the thermal expansion coefficients matched with the thermal expansion coefficients of the chips during packaging application; the thermal expansion coefficients of the chips of a semiconductor laser are matched with the thermal expansion coefficients of the functional layers, and therefore the welding internal stress between the chips and the heat sink is lowered and the service life of the semiconductor laser is prolonged. Due to the fact that the heat sink is provided with the functional layers with different thermal expansion coefficients, the packaging use requirements of the chips with different thermal expansion coefficients can be met at the same time. The preparation technology is simple and convenient, cost is low, and application and popularization are easy.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Environmental-friendly waterproof cable material for computer

InactiveCN105778367AIncrease the degree of cross-linkingImprove toughnessPlastic/resin/waxes insulatorsEnvironmental resistanceBenzoyl peroxide

The invention discloses an environmental-friendly waterproof cable material for a computer. The environmental-friendly waterproof cable material is prepared from the following components in parts by weight: 50-80 parts of polytetrafluoroethylene, 1-2 parts of nilox resin, 0.4-0.9 part of polyphenylene sulfide, 0.5-1.5 parts of polybenzoate, 1-3 parts of magnesium stearate, 0.5-1.2 parts of antimonous oxide, 1-2 parts of C5 petroleum resin, 0.5-1.5 parts of coal tar, 2-8 parts of nanometer talcum powder, 10-16 parts of modified microcrystalline cellulose, 0.5-1.2 parts of di-tert-butyl peroxide, 0.5-1.2 parts of 2,4-dichloro benzoyl peroxide, 1-3 parts of maleic anhydride, 1-2 parts of gamma-(quadrol) propyl emthyl dimethoxy silane and 1-2 parts of butyl titanate. The environmental-friendly waterproof cable material achieves environmental friendliness, is good in water resistance and flame resistance and is excellent in mechanical property.

Owner:ANHUI SPECIAL CABLE GRP

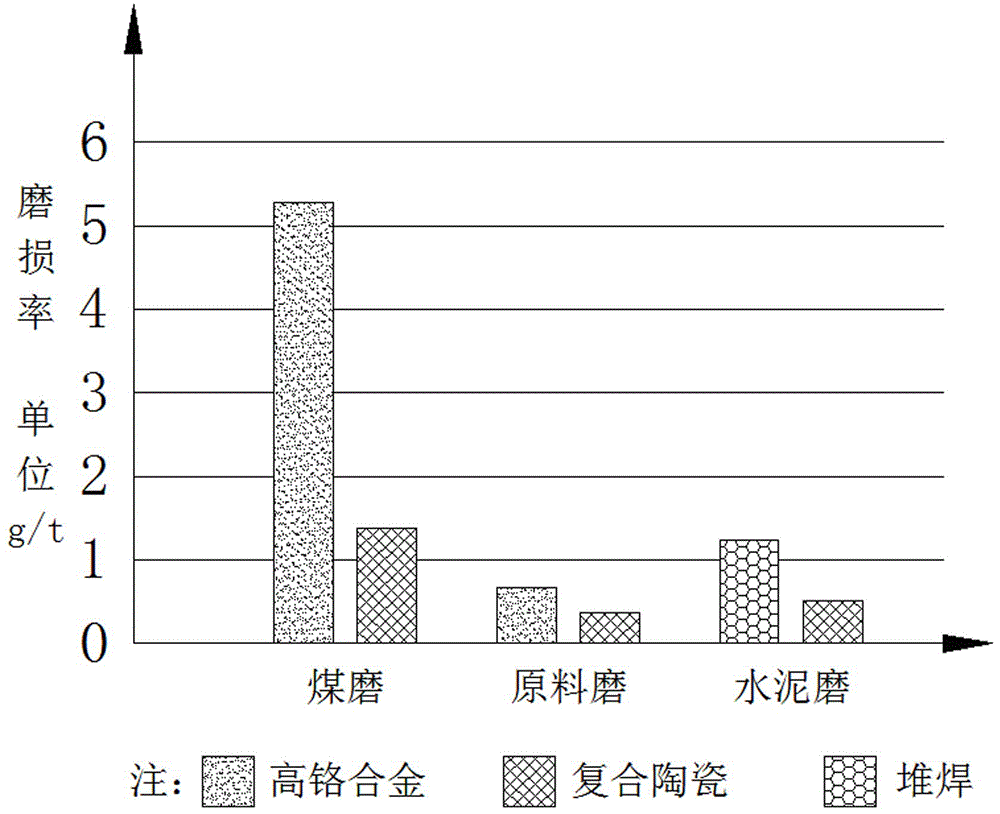

High-efficiency ceramic grinding roller and ceramic lining plate

The invention belongs to the technical field of coal mill equipment, and particularly relates to a high-efficiency ceramic grinding roller and a ceramic lining plate. A grinding mechanism with the relative movement function is formed by the ceramic grinding roller and the ceramic lining plate. The ceramic grinding roller comprises a grinding roller base body, an adhesive layer and a composite ceramic layer. The ceramic lining plate comprises a lining plate base body, an adhesive layer and a composite ceramic layer. Materials of the composite ceramic layers are formed by one or more of silicon carbide, silicon nitride, tungsten carbide, aluminum oxide and zirconium oxide in a compounded mode. The adhesive layers are adhesives resistant to high temperature and high in viscidity. The grinding roller base body and the lining plate base body are made of metal. The composite ceramic layer of the ceramic grinding roller is formed by splicing ceramic modules. Gaps capable of increasing the surface friction force of ceramic are formed between the ceramic modules. The high-efficiency ceramic grinding roller and the ceramic lining plate are simple in structure, reasonable in design, high in hardness, long in service life, economical, practicable and easy to apply and popularize on a large scale, and the cost is reduced.

Owner:张弘

Flame-retardant and waterproof coal mine cable material having excellent mechanical properties

InactiveCN105968589AAvoid brittle fractureReduce pollutionRubber insulatorsAdhesiveMagnesium stearate

The invention discloses a flame-retardant and waterproof coal mine cable material having excellent mechanical properties. The flame-retardant and waterproof coal mine cable material is prepared from, by weight, 15-35 parts of polypropylene, 30-50 parts of ethylene propylene diene monomer rubber, 20-40 parts of neoprene, 1-2 parts of maleic anhydride grafted polyethylene, 1-2 parts of maleic anhydride, 0.2-0.8 part of butyl titanate, 0.5-1 part of dicumyl peroxide, 0.2-0.8 part of triazole disulfydryl amine salt, 0.5-1.5 parts of magnesium stearate, 1-2 parts of antimonous oxide, 0.5-1.5 parts of polyethylene wax, 1-2 parts of barium stearate, 10-25 parts of a modified soybean adhesive, 20-40 parts of zinc borate, 20-40 parts of magnesium hydroxide, 5-15 parts of nano talcum powder and 10-16 parts of microcrystalline cellulose. The flame-retardant and waterproof coal mine cable material is flame-retardant and waterproof and has good mechanical properties and economic benefits.

Owner:繁昌县菲德通讯材料设计有限公司

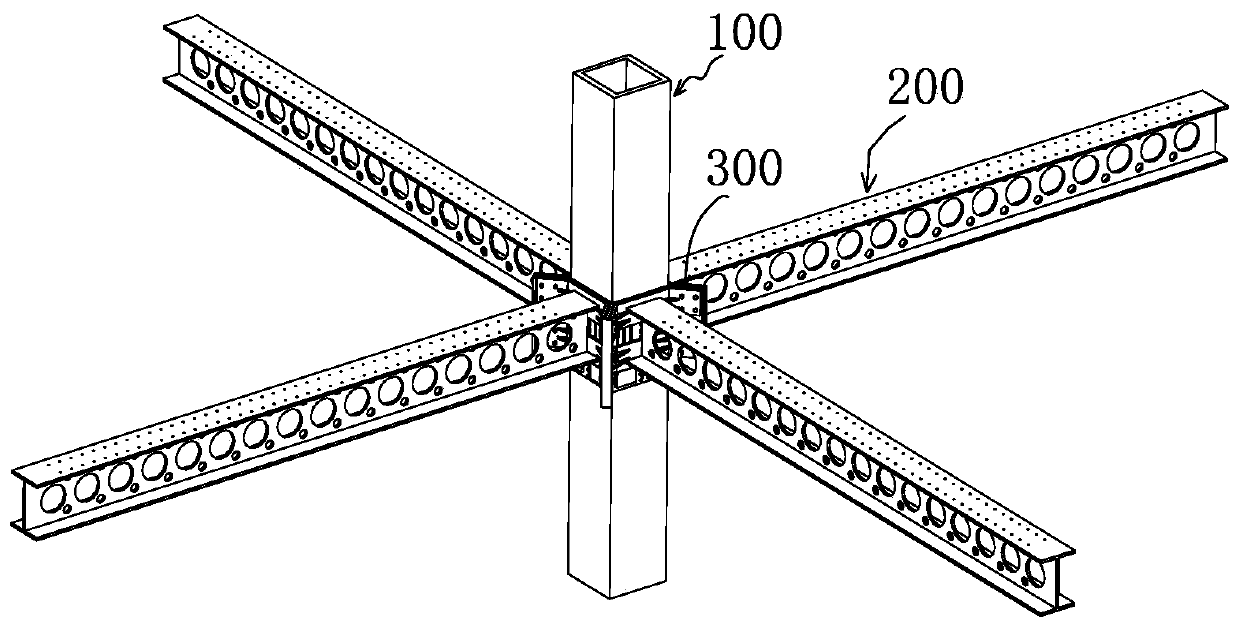

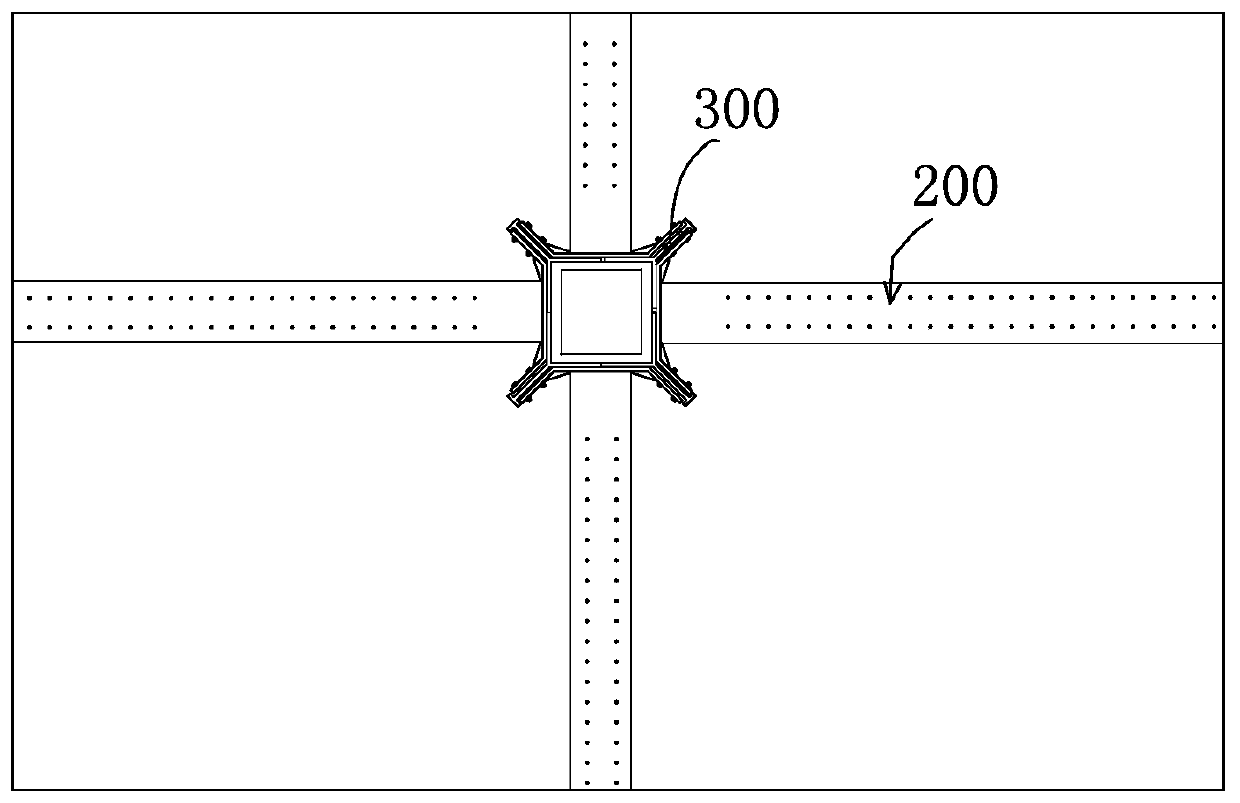

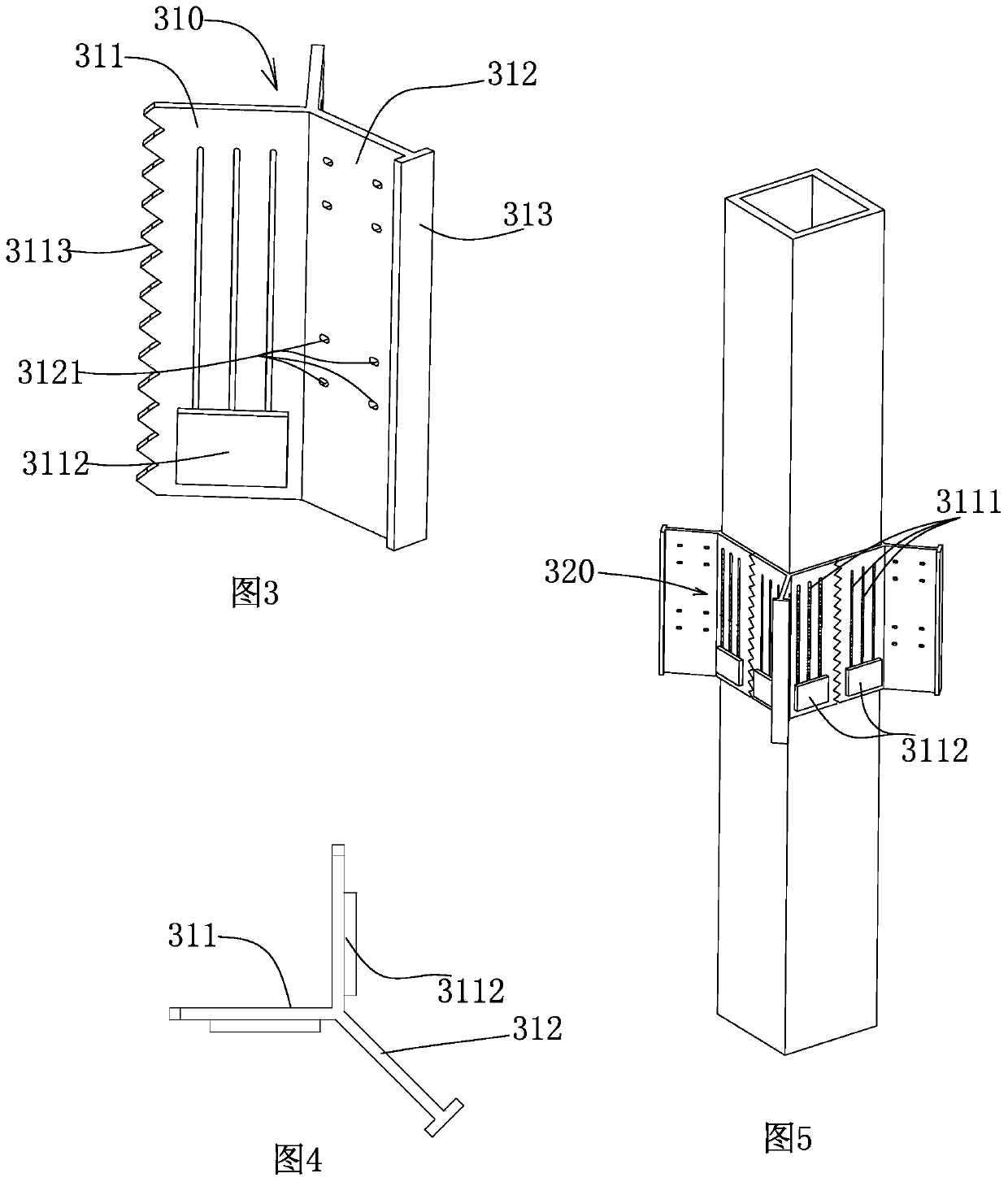

Steel structure beam column connection node and construction method thereof

InactiveCN110306659ARealize fully assembled installationEasy to assembleProtective buildings/sheltersBuilding material handlingComputer moduleEngineering

The invention discloses a steel structure beam column connection node and a connection method thereof in order to solve the problem that an existing connection node is prone to brittle fracture. The steel structure beam column connection node is used for connection between a steel column and I-shaped steel beams. The steel beams and the steel column are connected through a corbel. The corbel is anenclosing structure formed by welding a plurality of modules of the same structure to the steel column. Each module is of a Y-shaped structure composed of two fixed plates and a steel wing plate, wherein a plug space is formed between the two opposite steel wing plates. Each connecting part comprises at least one plug plate welded to the end of one steel beam. The plug plates are plugged into theplug spaces. The steel wing plates and the plug plates are connected through mounting holes and high-strength bolt assemblies. The steel beams and the corbel are preliminarily positioned in a plug-inmode and are in rigid connection or semi-rigid connection through high-strength connecting assemblies. The steel structure beam column connection node is easy to assemble and capable of realizing full-assembly installation.

Owner:孔瑞清

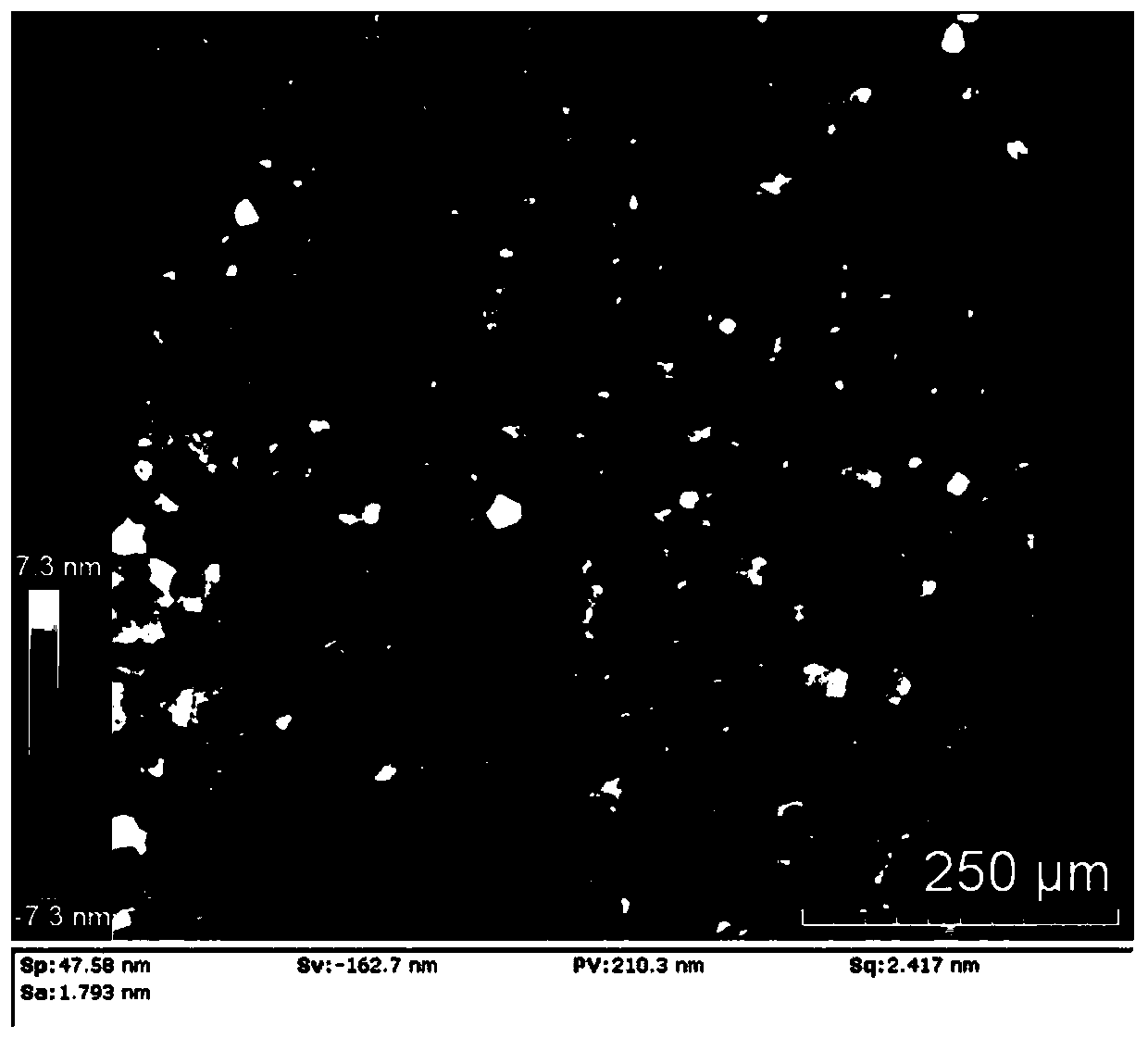

Ferrite substrate polishing method adopting acidic polishing solution and metal-based polishing disk

ActiveCN110405543AStrong chemical bondInconsistent microhardnessGrinding/polishing apparatusFerrite substratePolishing

The invention discloses a ferrite substrate polishing method adopting an acidic polishing solution and a metal-based polishing disk. The method is characterized by comprising the following steps thatan amorphous alloy substrate polishing disk is prepared by a sol-gel method; an oil-in-oil acidic silica sol polishing solution is prepared; and a ferrite substrate bonds a ceramic substrate for polishing. According to the method, an acidic polishing solution is used as a corrosive agent, so that the surface of the ferrite substrate is oxidized to form a metamorphic layer, and then the surface ofthe ferrite substrate is polished by using the silica sol and the amorphous alloy substrate polishing disk, so that the metamorphic layer on the surface is removed, and the polishing effect is achieved. An amorphous alloy matrix has the characteristics of being fine in structure, high in toughness, corrosion-resistance and strong in abrasive grain holding force. The low-surface-tension oily solvent and acidic silica sol are mixed to prepare the oil-in-oil acidic silica sol polishing solution, so that the consistency of the thickness of a polishing solution liquid film is ensured, and the tracecorrosion of a surface material is realized. The polishing method has the characteristics of good product surface type precision and no edge collapse.

Owner:东莞市创科材料科技有限公司

Manufacturing process of high-performance nano-material ceramic thin-film device

The invention relates to a manufacturing process of a high-performance nano-material ceramic thin film device, and belongs to the technical field of nano-ceramic materials. The manufacturing process comprises the following steps: step 1, treating an aluminum alloy base material; and 2, the surface of the treated aluminum alloy base material is coated with a ceramic coating, drying and curing are carried out, then sintering is carried out, and the high-performance nano-material ceramic thin film device is obtained. The ceramic coating is prepared by mixing 23-45 parts by weight of a silica sol emulsion and 85-100 parts by weight of a solution B; the solution B is prepared from the following raw materials: water, a binding agent, phenyltrimethoxysiloxane and a functional auxiliary agent; the silica sol emulsion comprises the following raw materials: water, an emulsifier, silica sol and an auxiliary material. The bonding strength of the ceramic coating and the base material is improved by introducing the binder and the auxiliary material, the brittle fracture of the ceramic coating during sintering is avoided by introducing the functional additive, and the oxidation resistance, high temperature resistance and wear resistance of the ceramic film obtained by sintering are enhanced.

Owner:湖南湘瓷科艺有限公司

Sealing part for automobile LED instrument panel

The invention discloses a sealing part for an automobile LED instrument panel. The sealing part is prepared from raw materials in parts by weight as follows: 50-60 parts of a main material, 0.5-1.2 parts of disproportionated rosin, 1-2 parts of polyphenylene sulfide, 0.4-1 part of polybenzoate, 55-65 parts of filler, 0.2-1 part of di-tert-butyl peroxide, 1-2 parts of 2,4-dichlorobenzoyl peroxide, 0.4-1 part of maleic anhydride, 0.2-0.8 parts of 3-(2-aminoethylamino)propyl-dimethoxymethylsilane, 0.4-1 part of butyl titanate, 1-3 parts of magnesium stearate, 1-2 parts of coal tar and 1-3 parts of an anti-aging agent. The sealing part for the automobile LED instrument panel has high density, good toughness, extremely high waterproof performance and excellent tearing resistance.

Owner:ANHUI LAND GRP

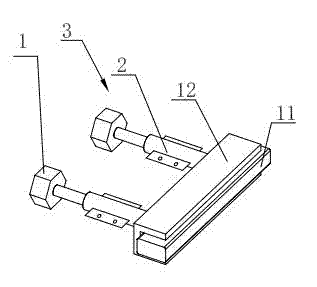

Multifunctional precision sliding table saw for laboratory and using method thereof

ActiveCN107053348AEasy to operateImprove cutting efficiencyCircular sawsBark-zones/chip/dust/waste removalSize measurementFixed frame

The invention discloses a multifunctional precision sliding table saw for a laboratory and a using method of the multifunctional precision sliding table saw. The problem that an existing sliding table saw cannot achieve rapid size measurement, precision cutting and safety is solved. The multifunctional precision sliding table saw for the laboratory is composed of a workbench, a guiding rule, a rotary nut, a first fixing frame, a buckle spanner, a guide screw rod, a first fixing block, a fixing rod, an electronic digital display caliper, a second fixing block, a second fixing frame, a knife saw shell, a pneumatic compression device, a third fixing frame, a guide nut, a third fixing frame and a sliding table saw box body. The using method comprises the steps that 1, a contour to be cut is drawn on a plate at first; 2, the contour line on one side of the plate overlaps with a circular saw web and is laid; 3, the pneumatic compression device is started, the buckle spanner is moved away, the guiding rule moves along the guide screw rod to the edge of the plate, and then the guide nut is rotated to enable the guiding rule to be tightly attached to the plate; 4, the rotating speed of the circular saw web is adjusted; and 5, the workbench is pushed to move along a sliding groove to cut the plate.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com