Magneto-rheological polishing machine for both inner surface and outer surface of short ceramic pipe

A technology of magnetorheological polishing and ceramic tubes, which is applied to surface polishing machine tools, grinding/polishing equipment, and parts of grinding machine tools, etc. problem, to achieve the effect of increasing the difficulty of positioning and fixing, high-precision positioning, and avoiding brittle fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

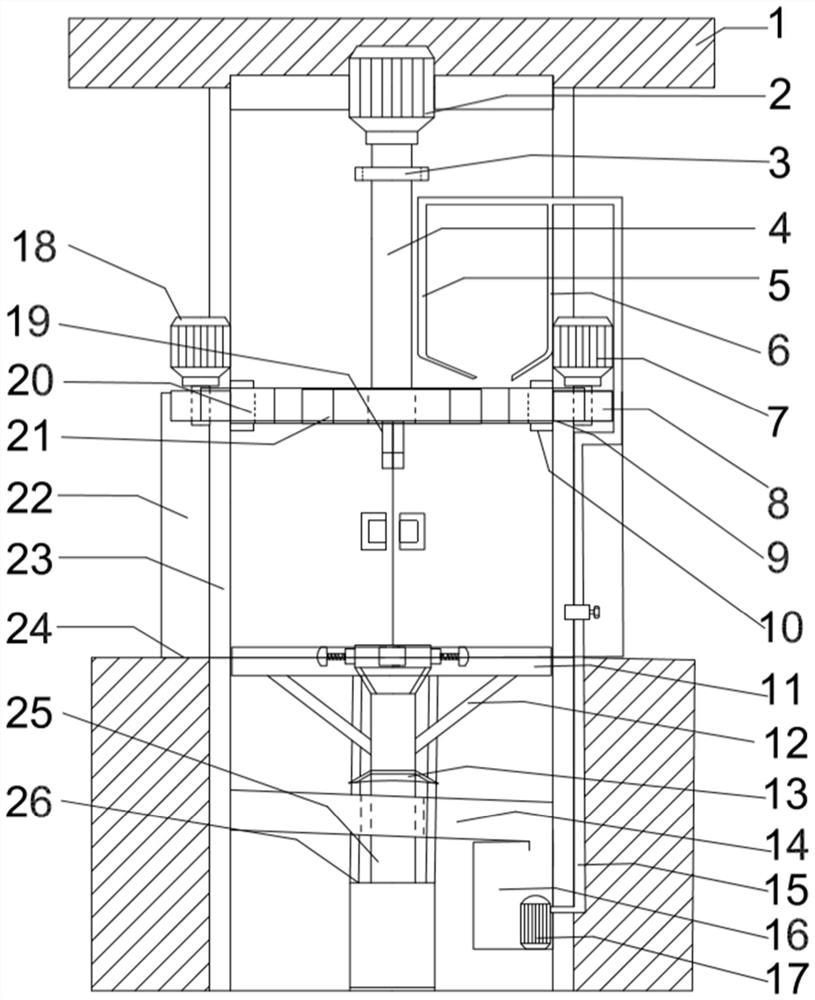

[0046] Such as Figure 1 to Figure 6 As shown in one of them, the double-sided magnetorheological polishing machine inside and outside the short ceramic tube of the present invention comprises:

[0047] Workbench 24;

[0048] The top plate 1 is fixed above the workbench 24 through the vertical beam 23, the lower end of the vertical beam 23 is fixedly connected with the workbench 24, and the upper end of the vertical beam 23 is fixedly connected with the top plate 1;

[0049] The fixing frame 9 has a ring structure and is fixedly arranged between the workbench 24 and the top plate 1;

[0050] The first driving gear 8 is four and is connected to the upper end surface of the fixed frame 9 in a circular array;

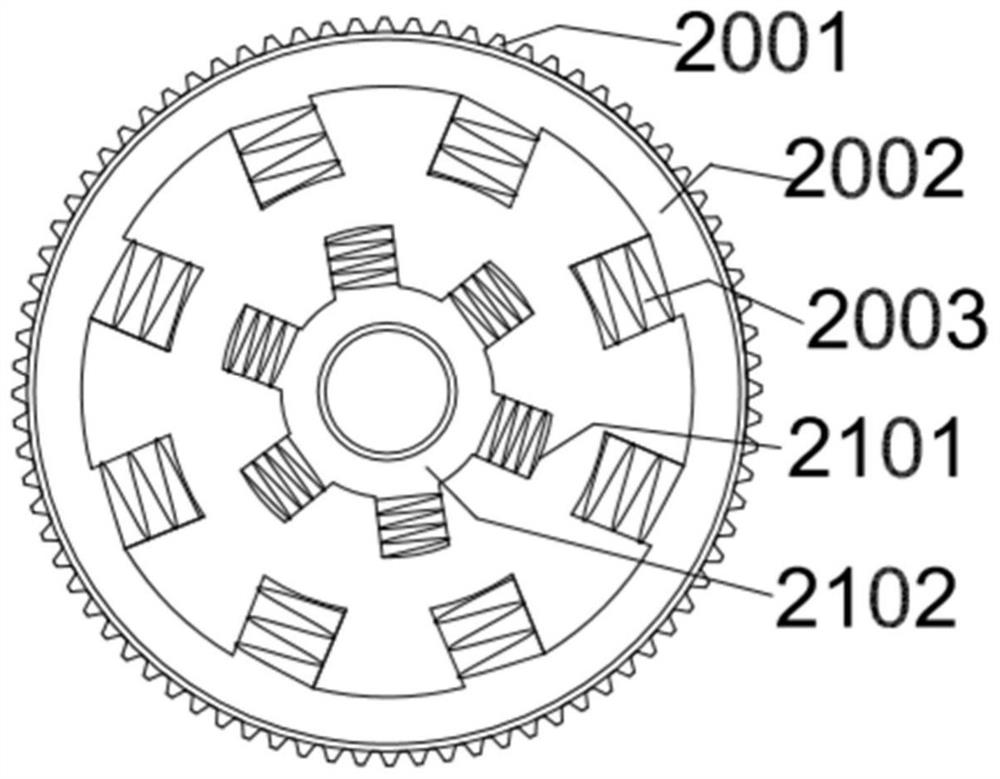

[0051] The first polishing part 2002 is an annular structure and its outer peripheral side is provided with a gear structure 2001 and meshed with four first driving gears 8. The inner peripheral side of the first polishing part 2002 is formed with a number of polishing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com