Multifunctional precision sliding table saw for laboratory and using method thereof

A multi-functional, push table saw technology, used in circular saws, sawing equipment, metal processing and other directions, can solve the problem that push table saws cannot meet the requirements of rapid size measurement and accurate cutting safety, etc., to improve operational safety and simplify Operation steps, the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

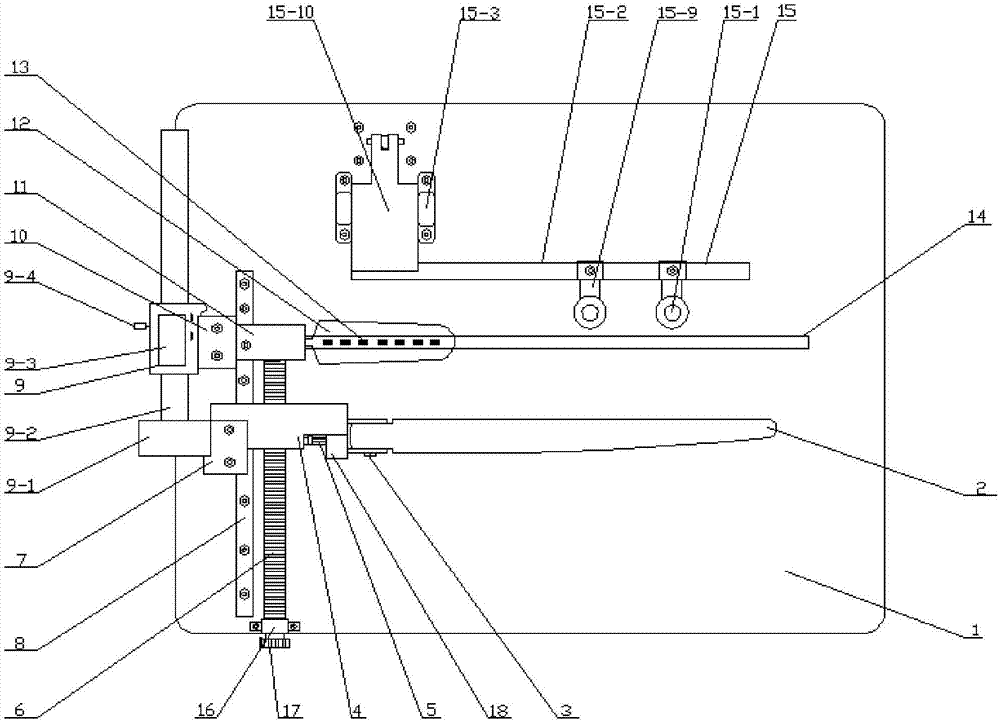

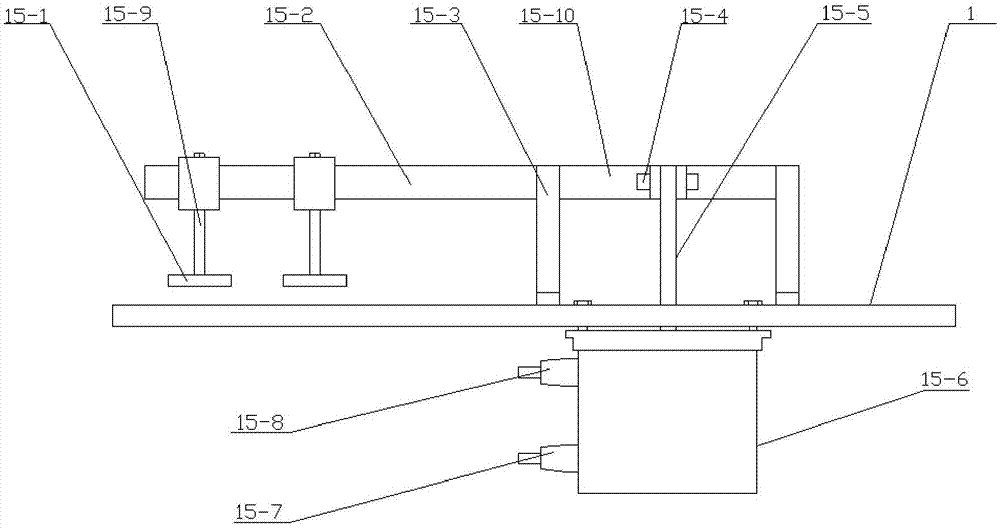

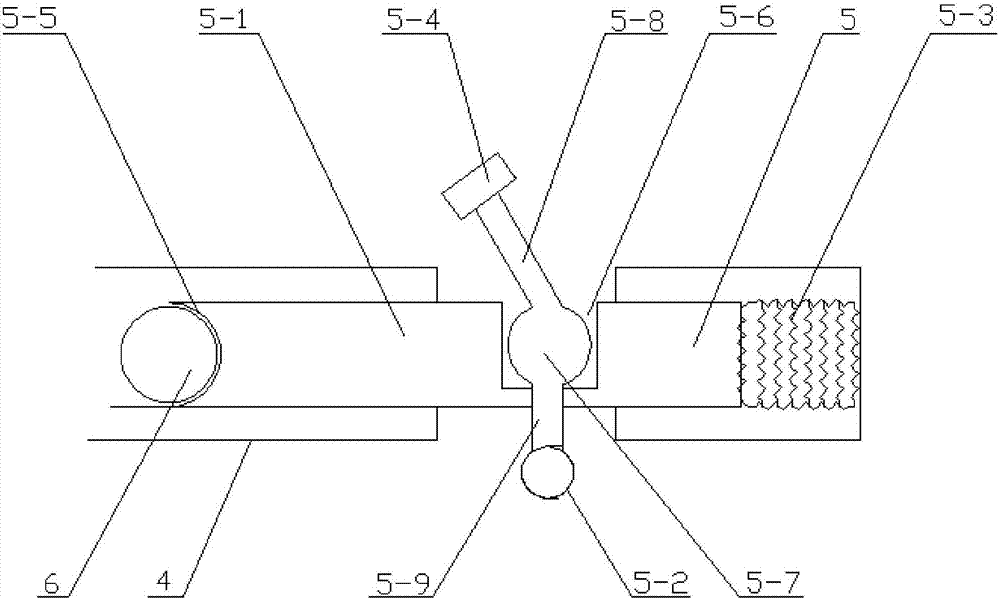

[0045] Specific implementation mode one: combine Figures 1 to 3 , this embodiment is a laboratory multifunctional precision sliding table saw consisting of a workbench 1, a ruler 2, a rotating nut 3, a first fixing frame 4, a buckle wrench 5, a guide screw 6, a first fixing block 7, and a fixing rod 8 , electronic display caliper 9, second fixing block 10, second fixing frame 11, knife saw casing 12, pneumatic pressing device 15, third fixing frame 16, guide nut 17, third fixing frame 18 and table saw box ;

[0046] The workbench 1 upper surface is provided with fixed rod 8, is fixedly provided with the second fixed mount 11 on the fixed rod 8, is provided with the first fixed mount 4 slidingly on the fixed rod 8, the left side of the second fixed mount 11 and the first fixed mount 4 There is an electronic display caliper 9 on the side;

[0047] And electronic display caliper 9 is positioned at workbench 1 side edge, and described electronic display caliper 9 is made up of ...

specific Embodiment approach 2

[0062] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the electronic display caliper 9 is an electronic vernier caliper. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0063] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that a counterweight is provided inside the workbench 1 . Others are the same as in the first or second embodiment.

[0064] The advantage of this specific embodiment: there is a counterweight inside the workbench 1 , and the workbench 1 can be automatically restored after being pushed away from the workbench 1 each time. This automatic design further reflects the rationality of the design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com