Rolling technology for pure tungsten sheet and device thereof

A rolling equipment and tungsten sheet technology, applied in the field of pure tungsten sheet rolling process and equipment, can solve the problems of difficulty in preparing extremely thin pure tungsten sheets, and achieve the effects of improving work efficiency, improving yield, and optimizing working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

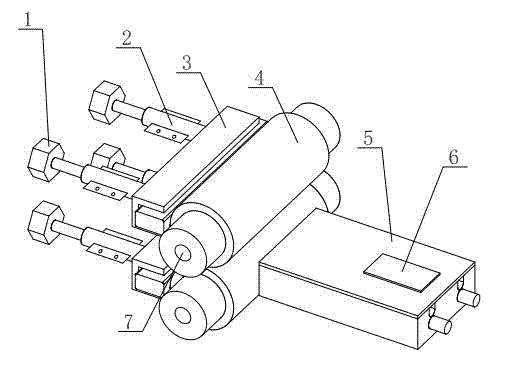

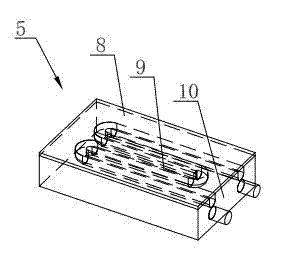

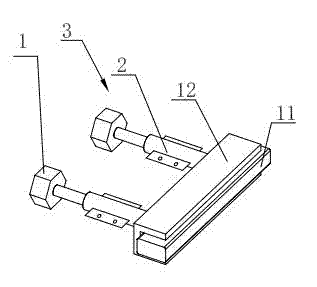

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0022] The pure tungsten sheet rolling process of the present invention comprises the following steps:

[0023] Step 1: Heat and keep the pure tungsten sheet to be rolled to ensure its temperature is 150-250°C;

[0024] Step 2: Feed the heated pure tungsten sheet into the roll, at this time ensure that the surface temperature of the roll is 150-250°C, and the rolling speed is 4-7 m / min;

[0025] The third step: use the roller wiper to clean the surface of the roller in time;

[0026] Step 4: Reduce the gap value between the rolls, and repeat the above three steps until the tungsten sheet with the required thickness is obtained.

[0027] like figure 1 As shown, the present invention is provided with an electric heating tube 7 inside the roll 4, and an electric heating platform 5 is provided at the front part of the roll-in side of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com