Reactive high-viscosity liquid asphalt and preparation method and application thereof

A liquid asphalt, reactive technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of no asphalt liquefaction at room temperature and high viscosity, complex preparation process, affecting road performance, etc., to improve storage stability. , stable chemical properties, solve the effect of heterogeneous separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

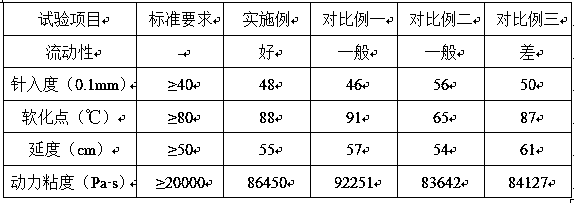

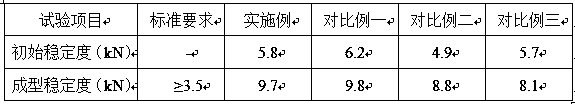

Examples

Embodiment 1

[0026] 1. Preparation of reactive high-viscosity liquid asphalt

[0027] Weigh 55 parts of base asphalt, 30 parts of organic solvent and 20 parts of modifier in parts by weight. The organic solvent is prepared from linoleic acid, linolenic acid and sodium methyl silicate in a weight ratio of 10:10:2; the modifier is composed of GT012 type SBS latex, RWE10 type epoxy resin and liquid carbon system C9 type petroleum resin is formulated according to the weight ratio of 3:21:11. and prepared as follows:

[0028] (1) Heat the base asphalt weighed in parts by weight to 140°C and keep it warm for later use;

[0029] (2) Add the organic solvent to the base asphalt treated in step 1, stir at a speed of 100r / min for 10 minutes, and stir at a speed of 30r / min for later use;

[0030] (3) Add the modifier weighed by weight, and stir for 8 minutes at a speed of 120r / min to prepare a reactive high-viscosity liquid asphalt;

[0031] (4) Put the prepared asphalt into a container, keep it s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com