Method for producing reinforced bar with anchoring section

A manufacturing method and technology of anchoring parts, applied in the direction of building structure, structural elements, building components, etc., can solve the problems of appearance and commodity value reduction, and achieve the effect of excellent high-temperature processability and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

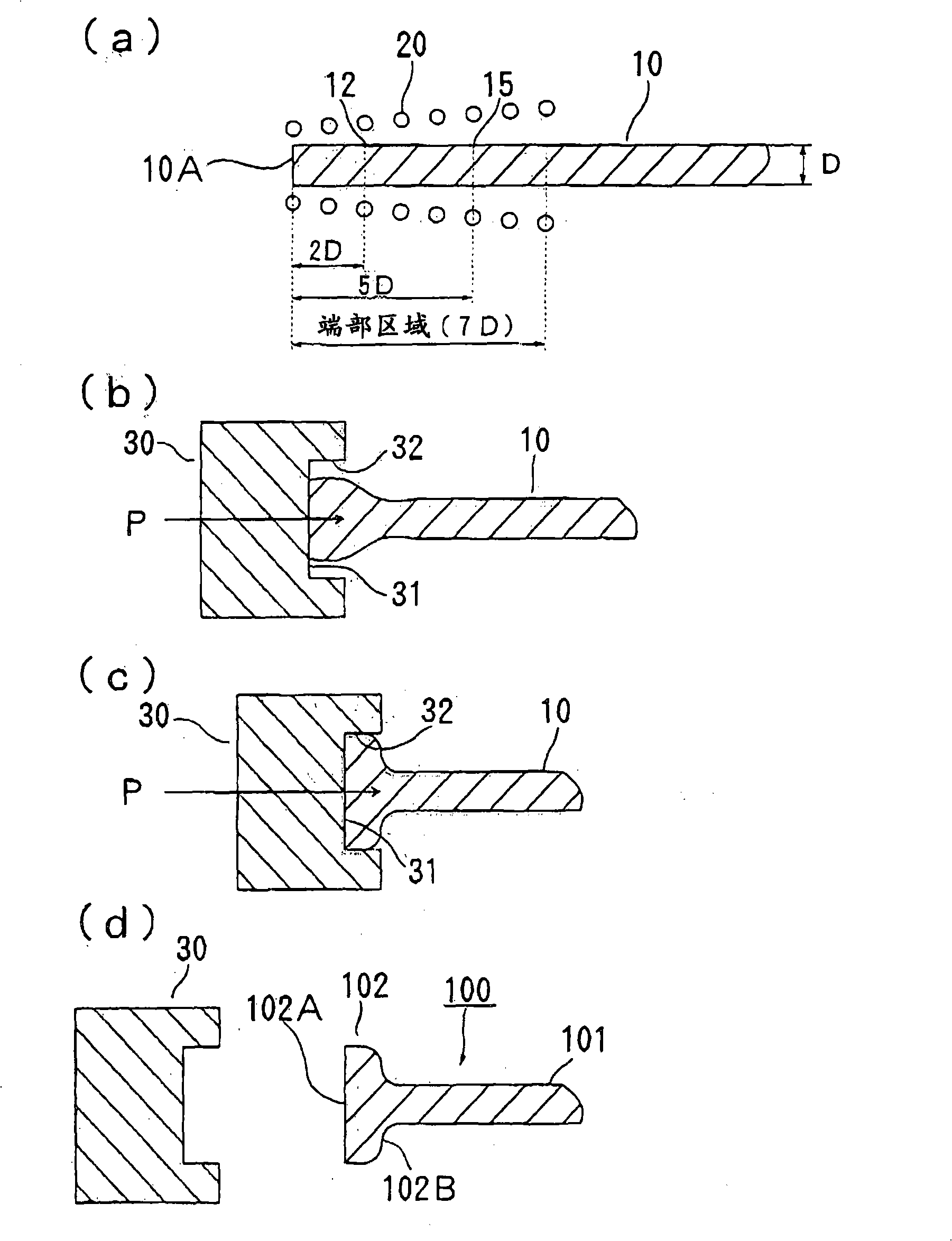

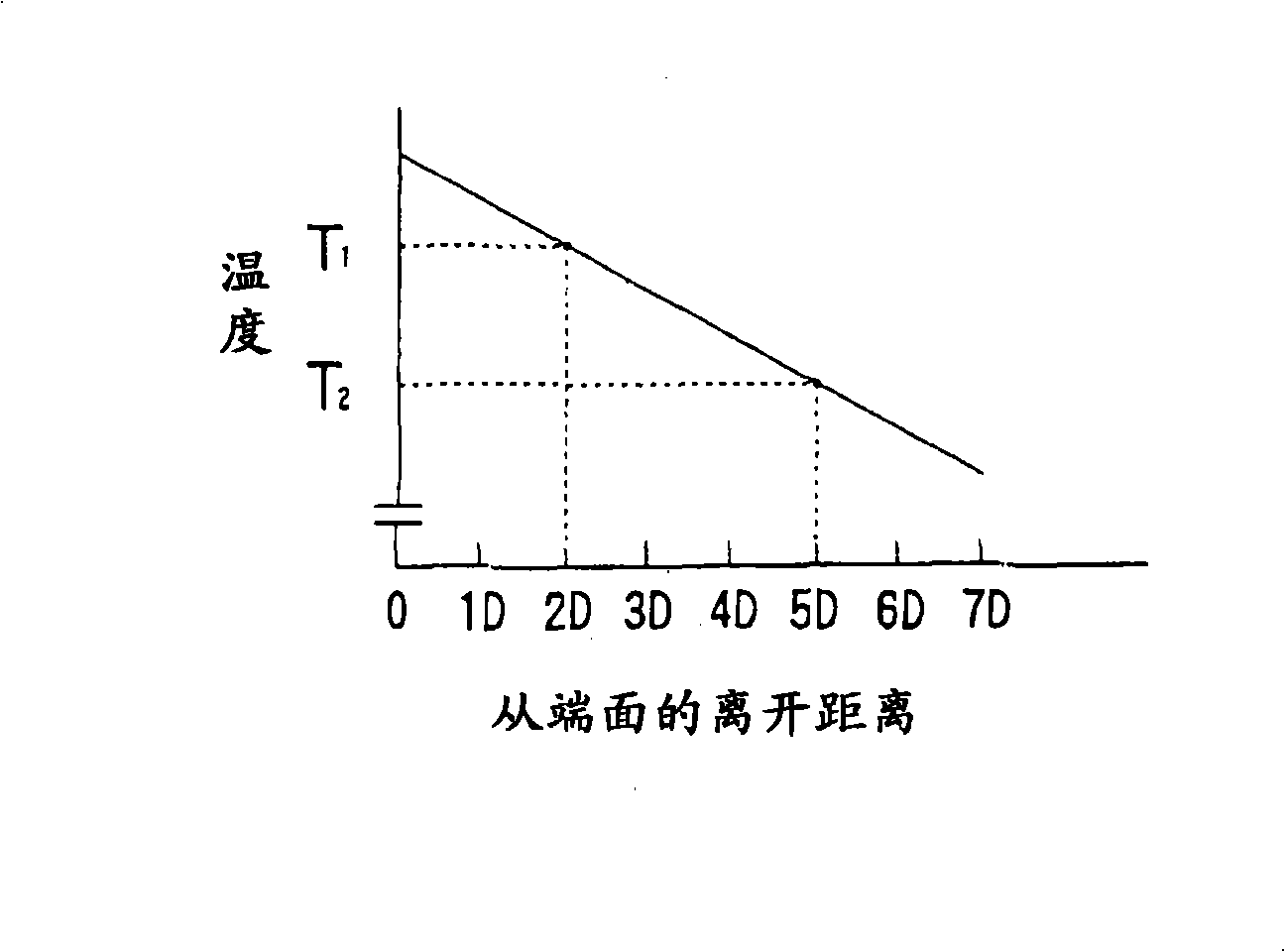

[0095] has the composition shown in Table 1 below, by using figure 1 (a) The heating device for the induction coil (20) of the shape shown, the heating is formed by a special-shaped bar steel (specific bar steel) with an Ac3 phase transition temperature (calculated value) of 809°C and an outer diameter D (nominal diameter) = 25mm The end region (length = 7D) on one end of the bar such that it has a temperature distribution in such a way that the temperature of the end region increases continuously as it approaches the end face of the bar.

[0096] Measure the temperature (T 1 ), and the temperature (T 2 ), temperature (T 1 ) is 1350℃, temperature (T 2 ) is 1000°C.

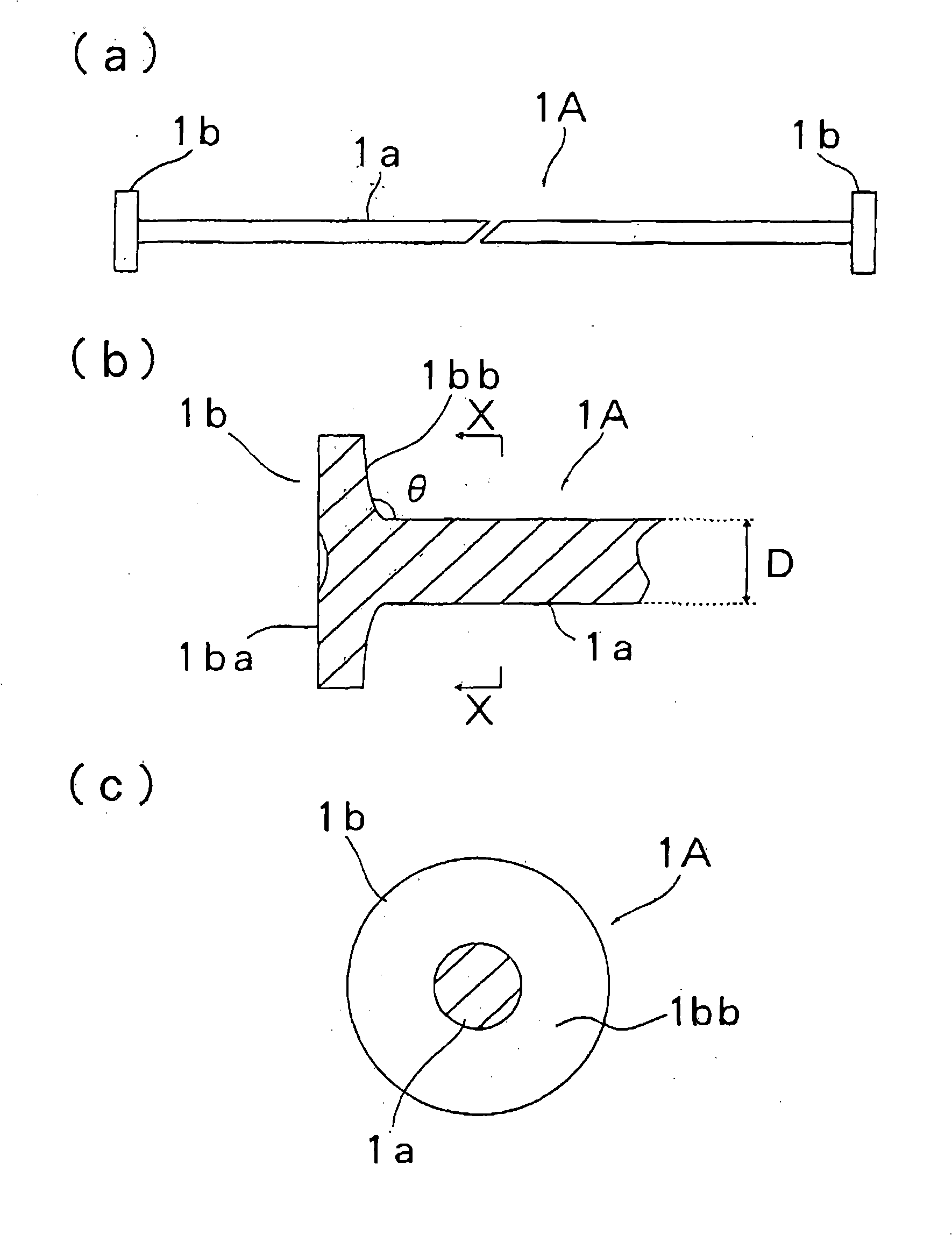

[0097] Immediately thereafter, the induction coil 20 is retreated from the end region, and the figure 1 The molding surface (31) of the mold (30) shown in (b) to (d) presses the end surface of the steel bar, and applies an axial compressive force to the steel bar to compress the end region. Here, the compre...

Embodiment 2~4

[0099] In addition to making the temperature (T 1 ) and temperature (T 2 ) was changed to the numerical values shown in Table 1 below, except that the heating conditions were changed in the same manner as in Example 1, and a steel bar with an anchorage portion was produced.

Embodiment 5~10

[0101] Except for changing the composition of the reinforcing bar (special-shaped steel bar) according to Table 1 below, the reinforcing bar with the anchorage part was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com