Ligament-bone bionic support with initial self-fixing function and forming method of support

A bone support and self-fixation technology, applied in ligaments, bone implants, medical science, etc., can solve the problems of neglect of ligament connection and fixation, fusion of autologous bone and ligament tissue, and poor clinical efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with examples and accompanying drawings.

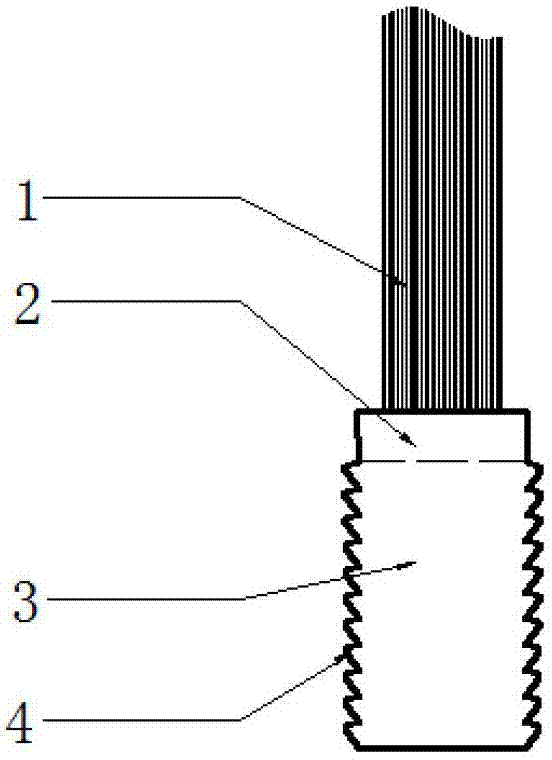

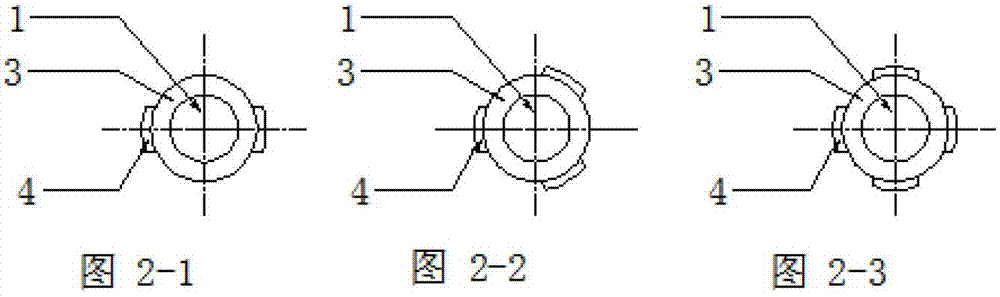

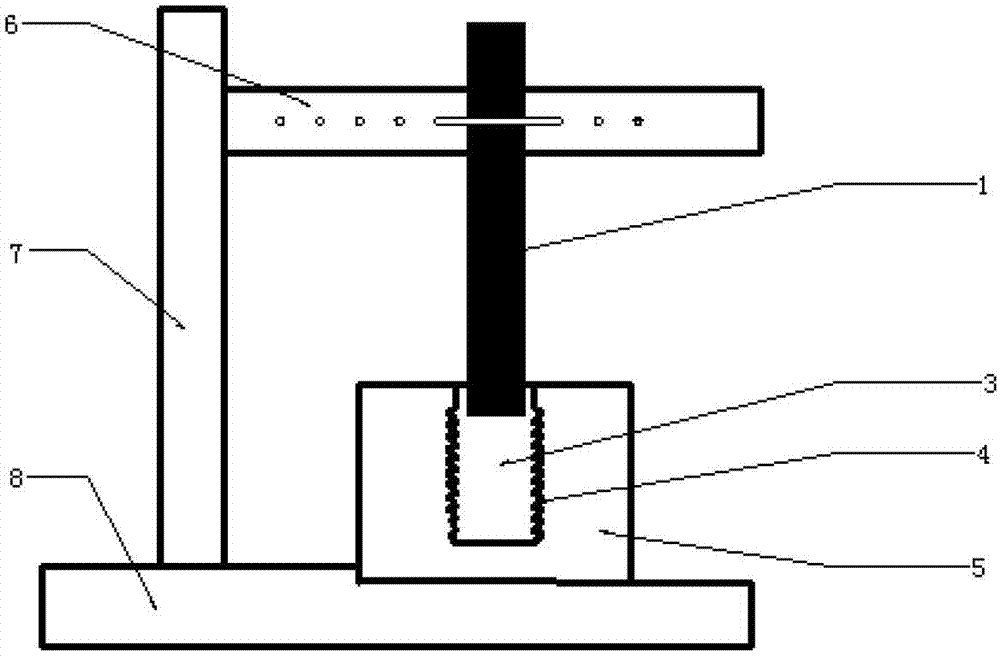

[0019] refer to figure 1 , a ligament-bone biomimetic scaffold with initial self-fixation function, including ligament support 1, transition layer 2 and bone support 3 with inherent initial self-fixation function, the connection interface between ligament support 1 and bone support 3 is perfused by three different The transition layer 2 structure of the composite solution mixed with β-TCP and silk fibroin in proportion to simulate the natural ligament-bone interface, the ligament scaffold 1 is composed of silk fibroin oriented fibers spun by electrospinning technology, and the bone scaffold 3 is bone-oriented scaffold Porous ceramics formed by solidification of the β-TCP solution perfused in the negative mold. There are more than two evenly distributed inverted triangular structures 4 on the surface of the bone support 3. The inverted triangular structures 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com