Shape memory epoxy resin and preparation method thereof

An epoxy resin and aliphatic epoxy resin technology, applied in the field of shape memory epoxy resin and its preparation, can solve the problems of insufficient toughness of the resin matrix, damage of the resin material, etc., so as to improve the exercise ability, consume energy, and avoid brittle fracture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

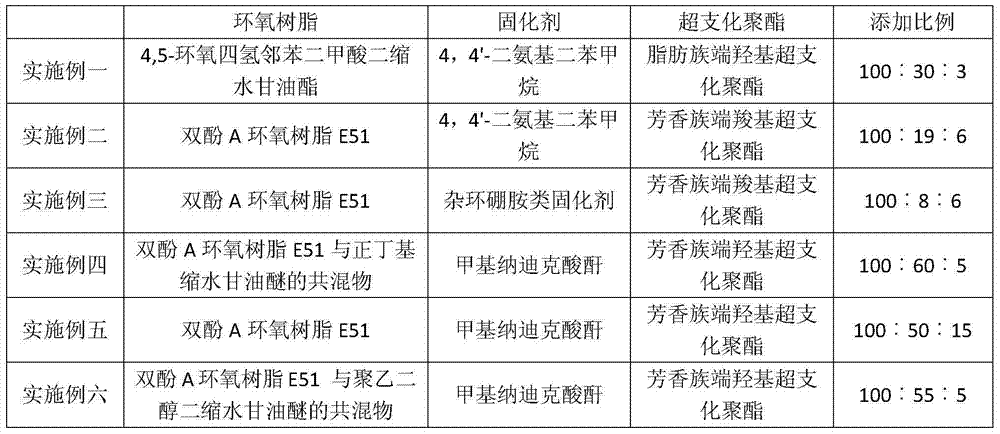

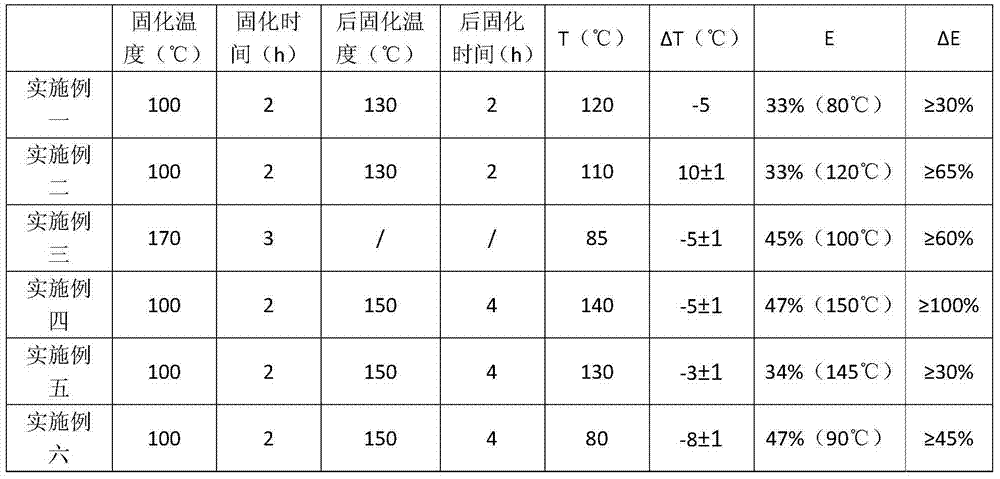

[0048]

[0049] The preparation method of shape memory epoxy resin of the present invention comprises the steps:

[0050] (1). Epoxy resin and hyperbranched polyester are mixed in proportion and constantly stirred until hyperbranched polyester is completely dissolved in epoxy resin;

[0051] (2). Add curing agent in proportion and continue to stir until the mixture is evenly mixed to obtain a mixture;

[0052] (3). Inject the mixture obtained in step (2) into the mold, cure at 50°C-170°C for 1h-6h, and then continue to post-cure at 80°C-200°C for 0h-6h;

[0053] (4). Cool to room temperature and demold to obtain the shape memory epoxy resin of the present invention.

[0054] Wherein, the ratio by weight of epoxy resin, curing agent and hyperbranched polyester is 100: (8-80): (3-20), most preferably 100: 50: 5.

[0055] In step (3), the post-curing time can also preferably be 1h-5h, and the post-curing temperature is preferably 30°C-50°C higher than the curing temperature. ...

Embodiment 1

[0059] This embodiment provides a shape memory epoxy resin, which includes 100 parts by weight of epoxy resin, 30 parts by weight of curing agent and 3 parts by weight of hyperbranched polyester.

[0060] Among them, the epoxy resin is 4,5-epoxy tetrahydrophthalate diglycidyl ester TDE-85.

[0061] The curing agent is 4,4'‐diaminodiphenylmethane.

[0062] The hyperbranched polyester is an aliphatic hydroxyl-terminated hyperbranched polyester. Each hyperbranched polyester molecule contains 48 hydroxyl-terminated functional groups. The molecular weight of the hyperbranched polyester is 5450, and the softening point is 100°C ± 5°C.

[0063] The preparation method of the shape memory epoxy resin of the present embodiment comprises the following steps:

[0064] (1). Epoxy resin and hyperbranched polyester are mixed in proportion and constantly stirred until hyperbranched polyester is completely dissolved in epoxy resin;

[0065] (2). Add curing agent in proportion and continue to...

Embodiment 2

[0070] This embodiment provides a shape memory epoxy resin, which includes 100 parts by weight of epoxy resin, 19 parts by weight of curing agent and 6 parts by weight of hyperbranched polyester.

[0071] Wherein, the epoxy resin is bisphenol A epoxy resin E51.

[0072] The curing agent is 4,4'‐diaminodiphenylmethane.

[0073] The hyperbranched polyester is an aromatic carboxyl-terminated hyperbranched polyester, and each hyperbranched polyester molecule contains 12 carboxyl-terminated functional groups. The molecular weight of the hyperbranched polyester is 2680, and the softening point is 100°C±5°C.

[0074] The preparation method of the shape memory epoxy resin of the present embodiment comprises the following steps:

[0075] (1). Epoxy resin and hyperbranched polyester are mixed in proportion and constantly stirred until hyperbranched polyester is completely dissolved in epoxy resin;

[0076] (2). Add curing agent in proportion and continue to stir until the mixture is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com