High-performance fiber and preparation method thereof

A technology of fiber modification, applied in the field of high-performance fiber and its preparation, can solve the problems of reducing the thermal performance and deficiency of fiber, and achieve the effect of enhancing the compression resistance and the force between fiber molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) In a three-necked flask equipped with a condensation and stirring device, add 0.5mol of dimethyl 2-hydroxyterephthalate and 1.1mol of paraformaldehyde, then add 80ml of solvent dimethylformamide, and heat to 70 ℃, after the reagents are fully mixed and dissolved, add 0.5 mol of aniline, raise the temperature to 100 ℃, and react for 10 hours. The system is precipitated, washed and dried to obtain dimethyl terephthalate containing oxazine side groups. Under stirring, add 100 ml of methanol solution containing 1 mol of potassium hydroxide, heat to reflux for 7 hours, add dilute hydrochloric acid to acidify, and dry to obtain terephthalic acid containing oxazine side groups.

[0049] (2) In the reaction kettle equipped with nitrogen protection and stirring device, add 0.2mol of 4,6-diaminoresorcinol hydrochloride, 0.16mol of terephthalic acid, 0.04mol of p- Phthalic acid, 100g polyphosphoric acid (P 2 o 5 Concentration is 83wt%), 80g P 2 o 5 . Wherein, the molar r...

Embodiment 2

[0057] The molar ratio of terephthalic acid to terephthalic acid containing oxazine side groups in Example 1 was changed to n:m=95:5. That is, 31.54g (0.18mol) of terephthalic acid and 2.99g (0.02mol) of terephthalic acid containing oxazine side groups. Other steps are the same as in Example 1.

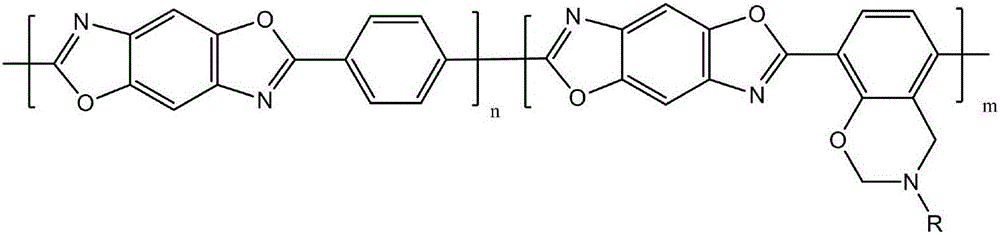

[0058] The molecular structure of modified PBO in the present embodiment is:

[0059]

[0060] The tensile strength of the modified PBO fiber obtained in this example is 5.2 GPa, the thermal decomposition temperature in air is 575° C., and the compressive strength is 0.9 GPa.

Embodiment 3

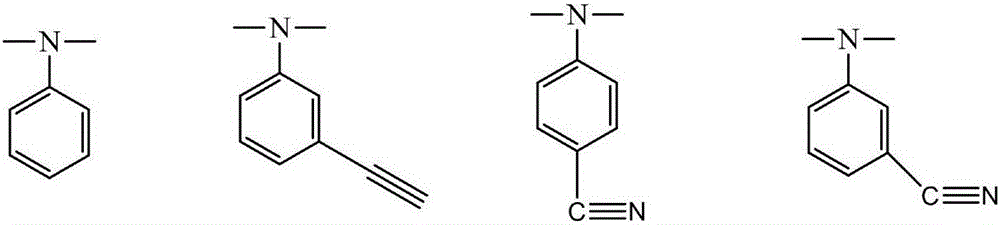

[0062] The aniline in Example 2 is changed to p-cyanoaniline, and the feeding amount is changed accordingly. Other operating steps are the same as those in Example 1.

[0063] The molecular structure of modified PBO in the present embodiment is:

[0064]

[0065] The tensile strength of the modified PBO fiber obtained in this example is 5.1 GPa, the thermal decomposition temperature in air is 571° C., and the compressive strength is 1.3 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com