Patents

Literature

37results about "Cellulose substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for preparing porous dielectric thin film containing saccharides porogen

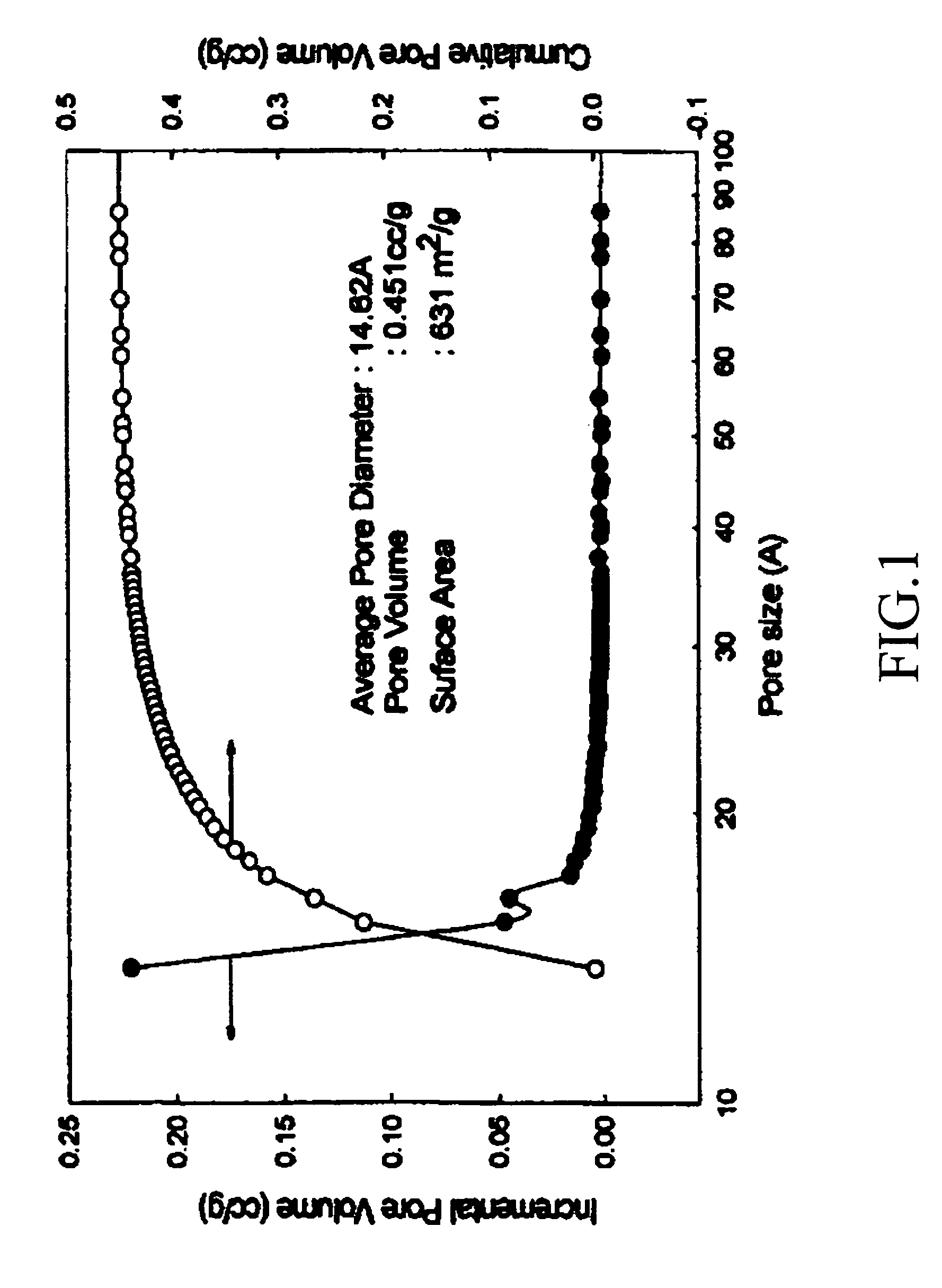

A composition for preparing a porous interlayer dielectric thin film which includes a saccharide or saccharide derivative, a thermo-stable organic or inorganic matrix precursor, and a solvent for dissolving the two solid components. Also provided is a dielectric thin film having evenly distributed nano-pores with a diameter of less than 50 Å, which is required for semiconductor devices.

Owner:SAMSUNG ELECTRONICS CO LTD

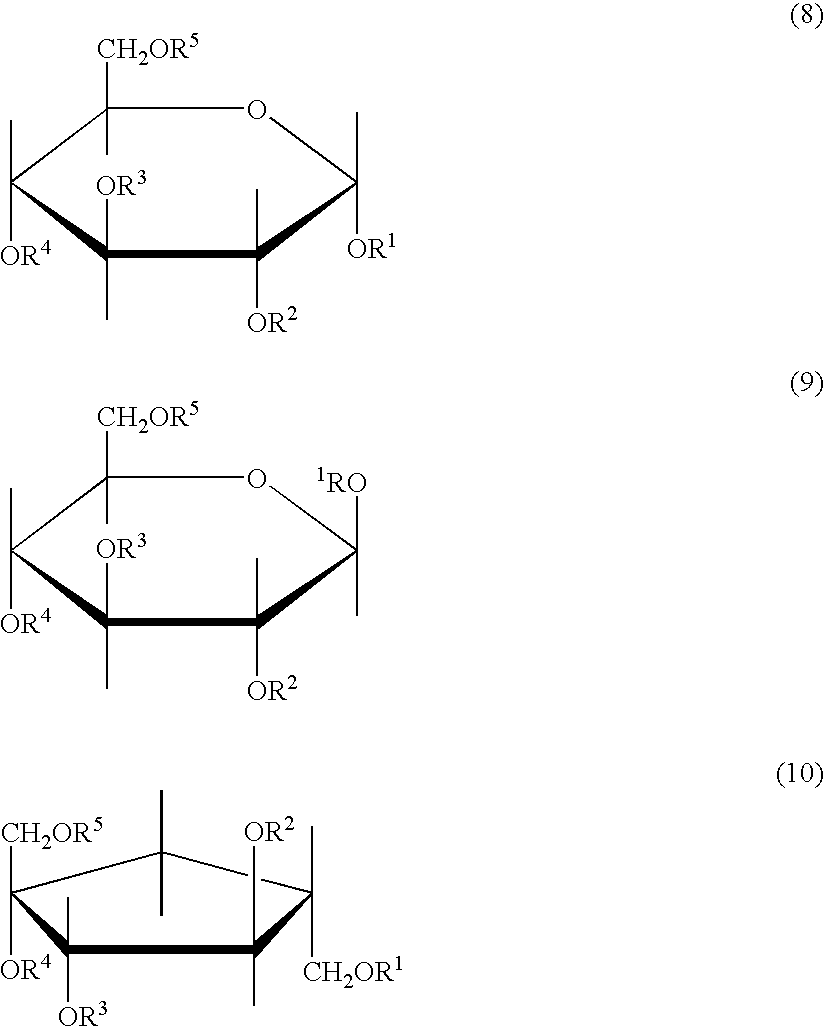

Low ionization potential additive to dielectric compositions

InactiveUS20110232940A1Increase voltage of dielectricReduce formationMaterial nanotechnologyLiquid organic insulatorsNanoparticleIonization

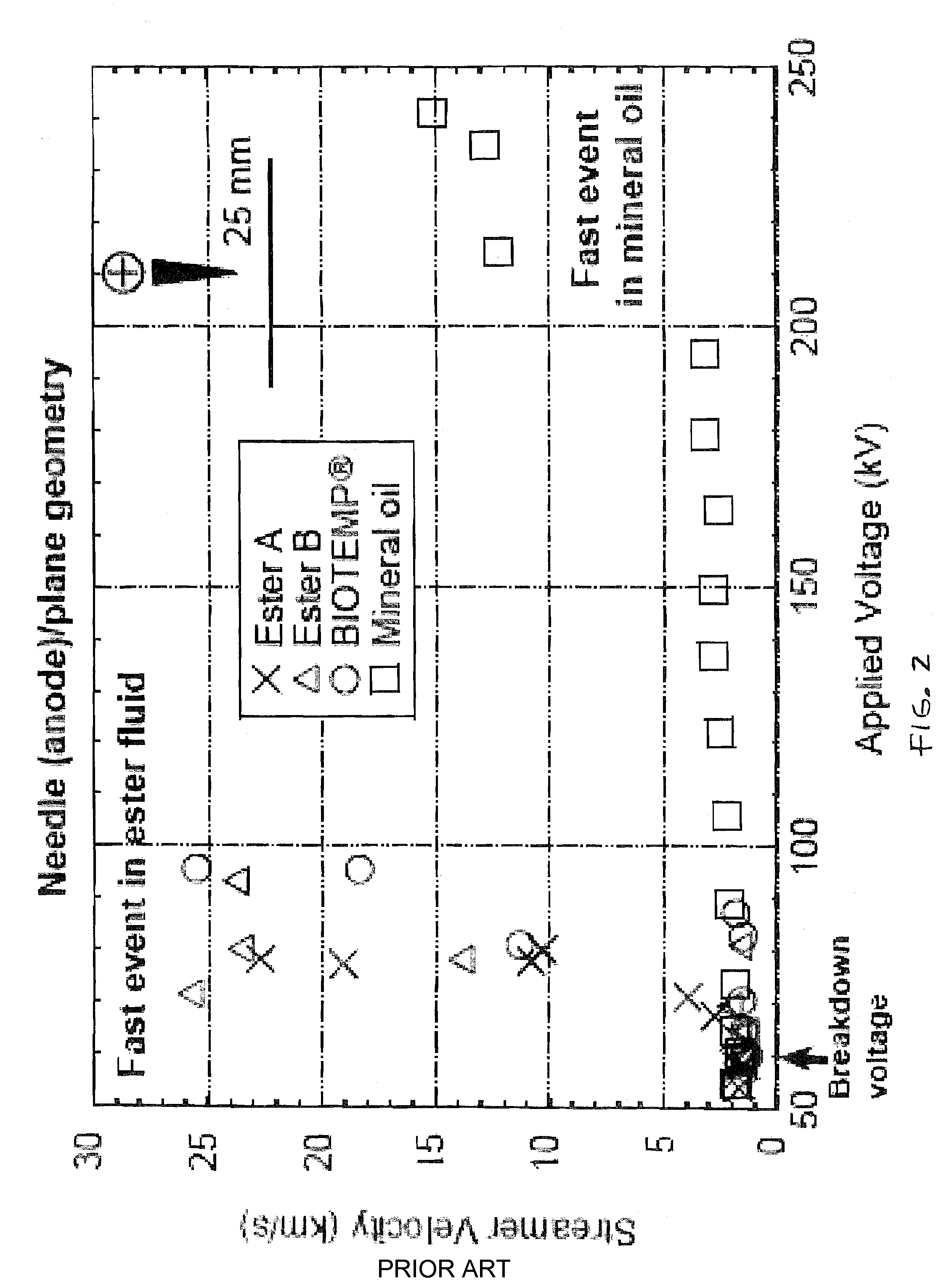

Insulating liquid. The liquid includes an ester liquid and an additive to the ester liquid having a lower ionization potential than the ionization potential of the ester liquid. In one aspect, conductive nanoparticles are also added.

Owner:MASSACHUSETTS INST OF TECH

Composition for preparing porous dielectric thin film containing saccharides porogen

Owner:SAMSUNG ELECTRONICS CO LTD

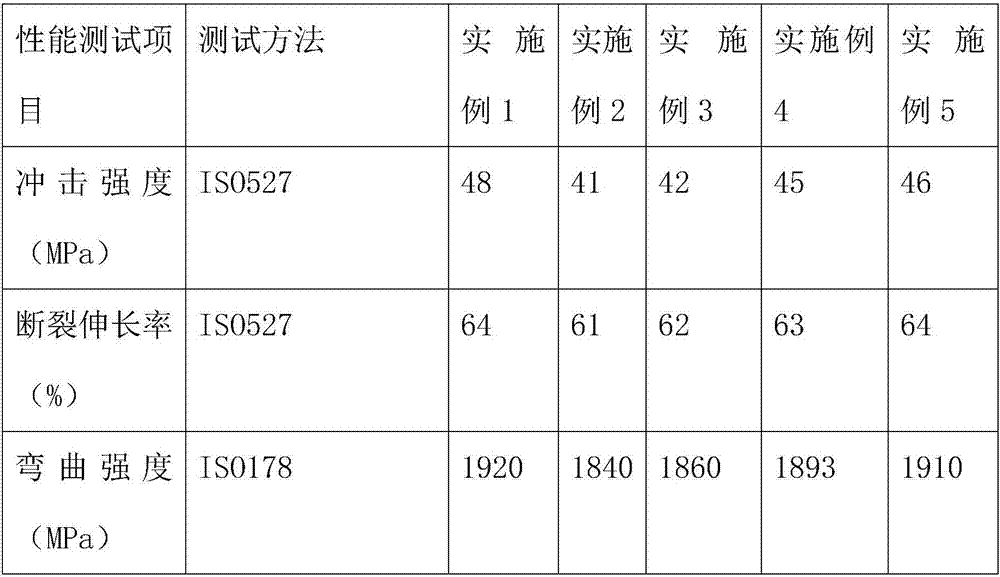

High-acid-resistance dielectric paste

ActiveCN113555146AImprove acid resistanceExtended service lifeQuartz/glass/vitreous enamelsCellulose substancesCelluloseDielectric

The invention discloses dielectric paste with high acid resistance. Glass powder used by the dielectric paste is obtained by tempering Bi-Si-B series glass powder for 20-24 hours at the temperature of 500-600 DEG C; preparing an organic carrier by using lecithin, butyraldoxime, beta-cellulose and the like; and adding chromium sesquioxide, cadmium sesquioxide, titanium dioxide and the like as oxide additives to further enhance the stability of the slurry. High-temperature tempering is added to the binding phase glass powder used by the dielectric paste on the basis of a traditional water quenching process, internal stress generated in the smelting and ball milling processes can be eliminated, and the compactness is further improved; meanwhile, terpilenol is replaced by butyraldoxime in the preparation process of the organic carrier, so the prepared slurry has extremely high acid resistance, can ensure stable breakdown voltage and lower encapsulation change rate, can adapt to a more severe use environment, prolongs the service life, and has obvious economic benefits.

Owner:西安宏星电子浆料科技股份有限公司

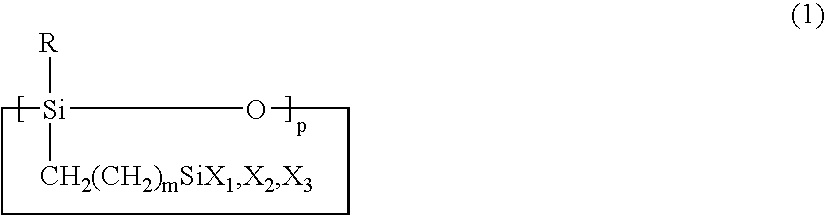

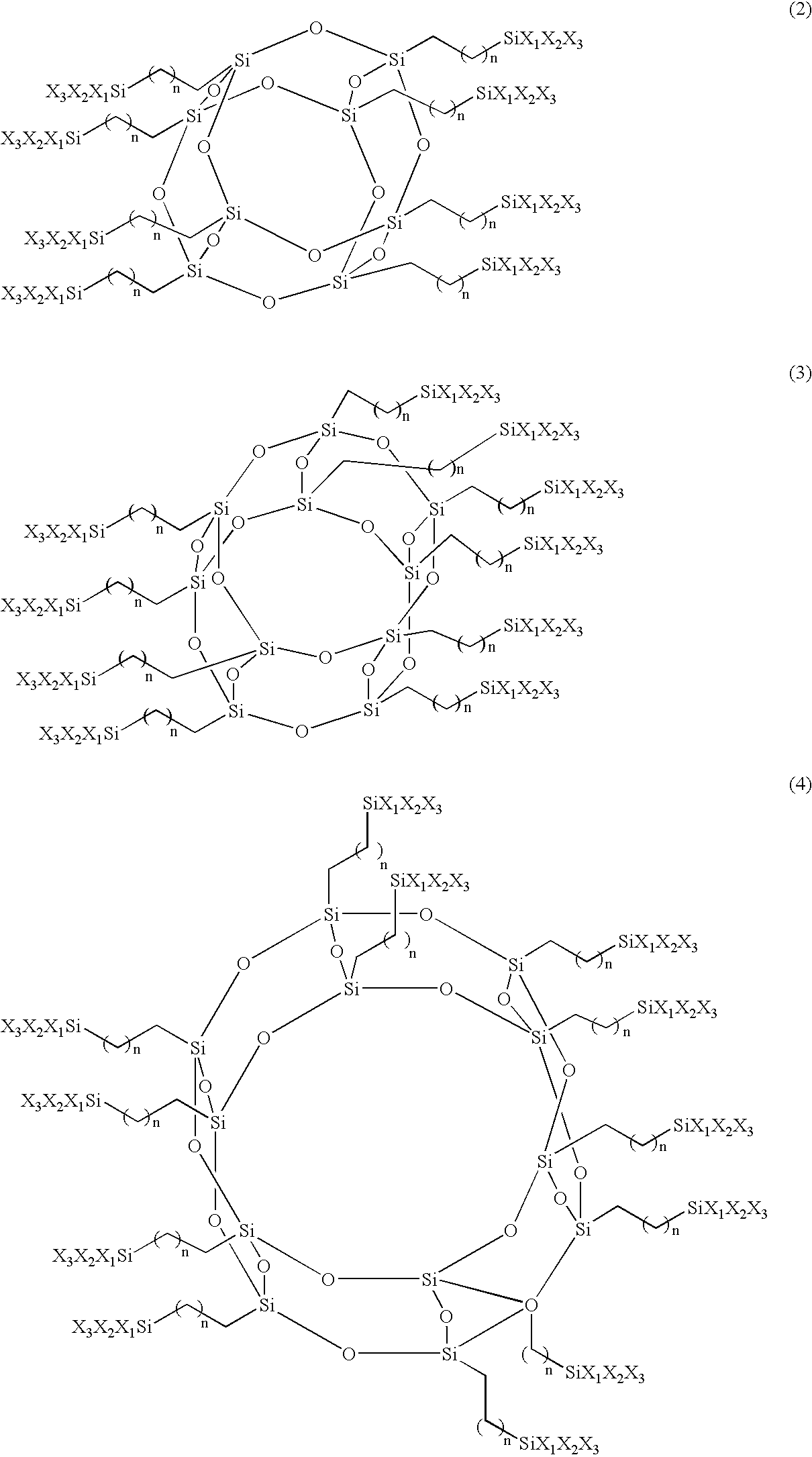

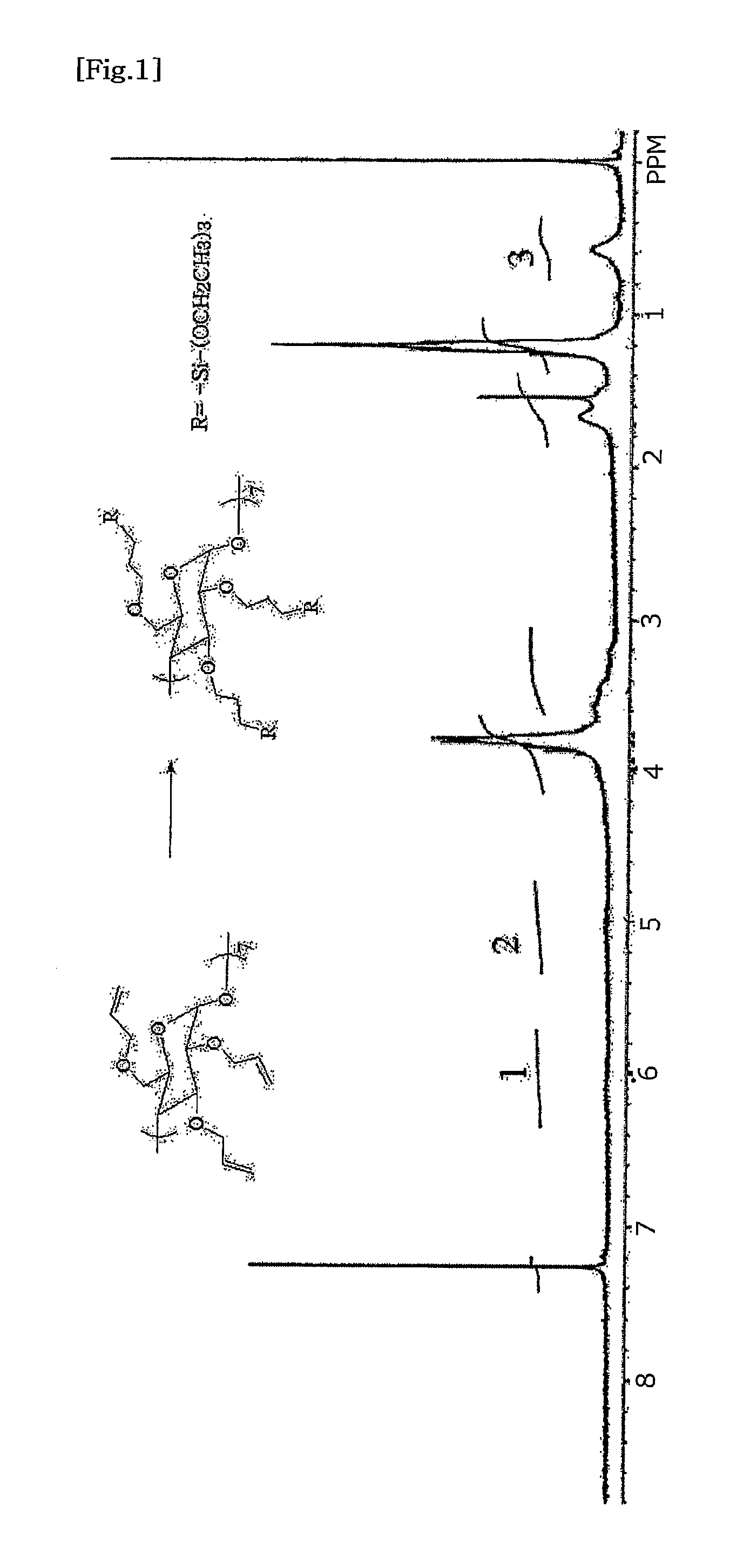

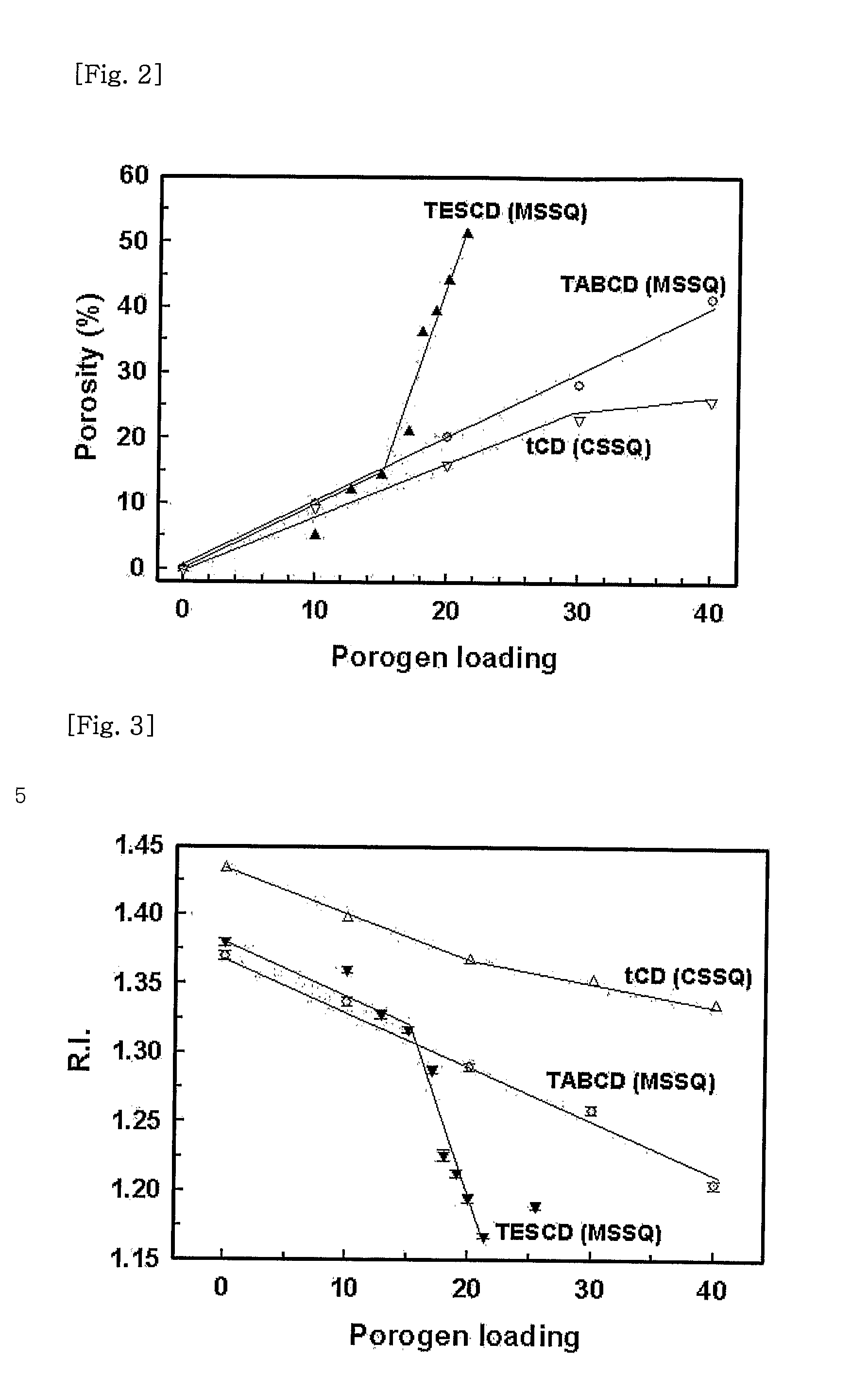

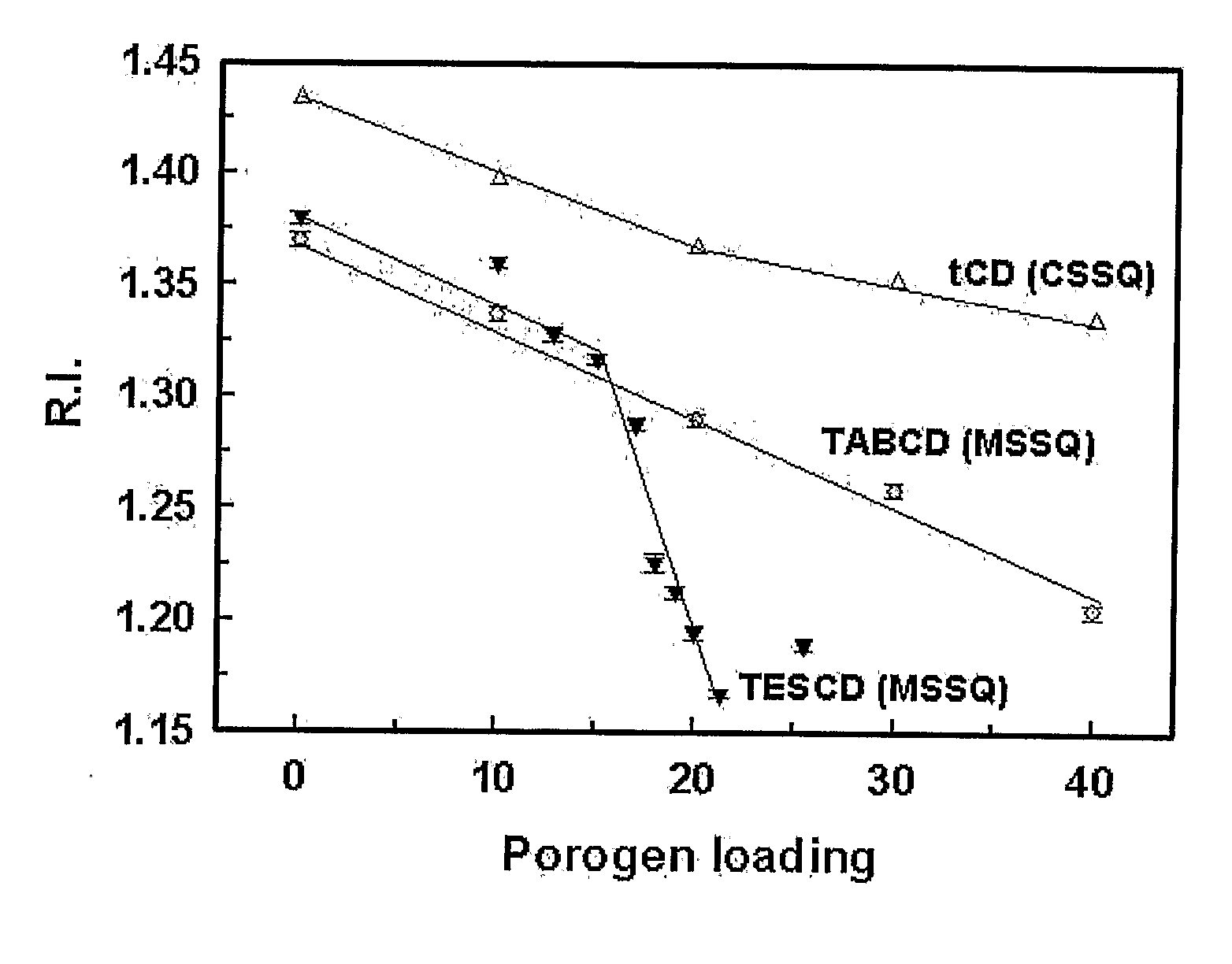

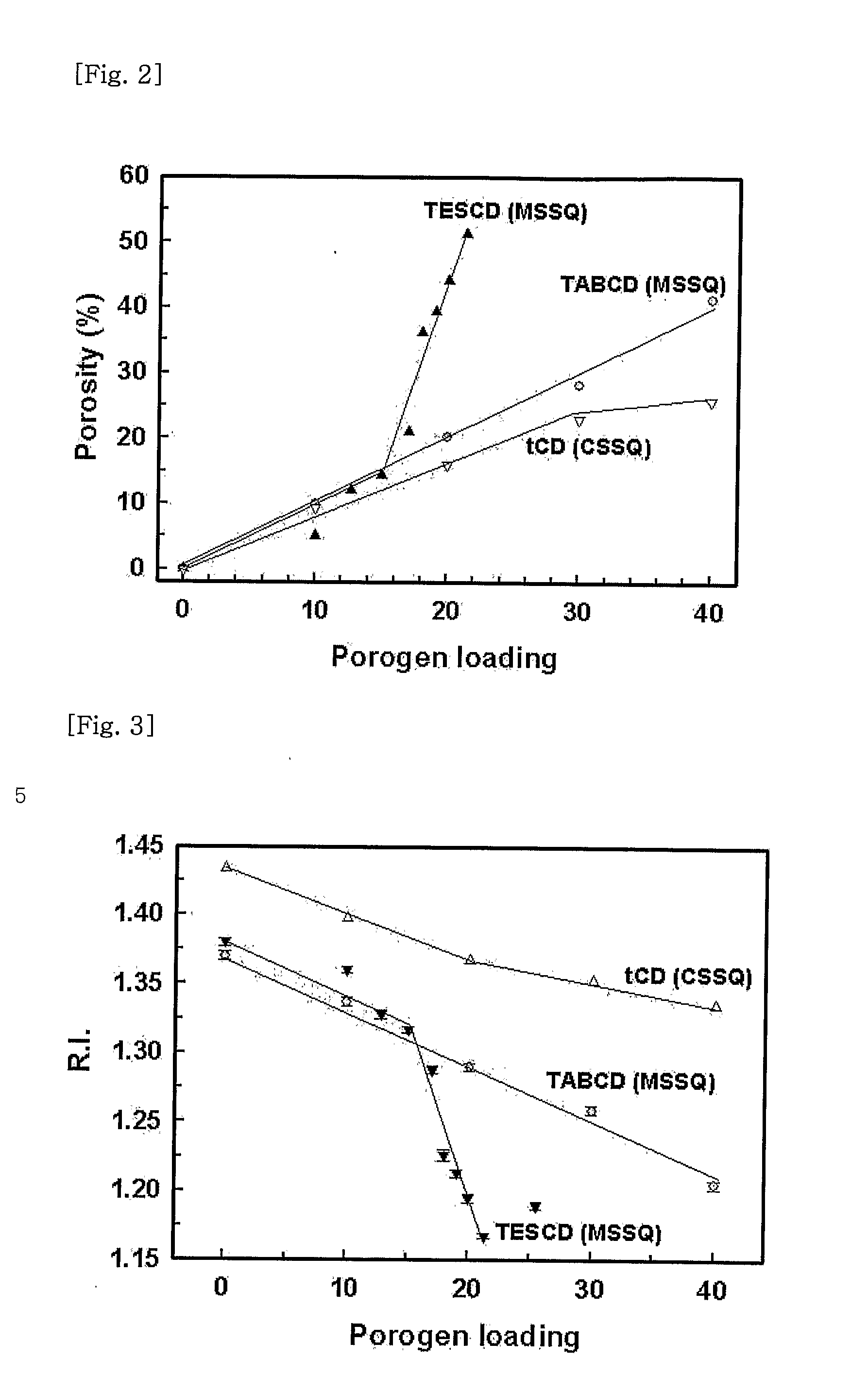

Reactive cyclodextrin derivatives as pore-forming templates, and low dielectric materials prepared by using the same

ActiveUS7462659B2Improve compatibilityExcellent dielectric propertiesPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsDielectric matrixPorosity

Owner:IND UNIV COOPPERATION FOUND SOGANG UNIV

Coating composition for forming highly dielectric film and highly dielectric film

ActiveUS20110013343A1High dielectric constantImprove propertiesFixed capacitor dielectricStacked capacitorsCelluloseDielectric loss

The present invention provides a nonporous highly dielectric film which can improve withstanding voltage, insulating property and dielectric constant, especially can decrease a dielectric loss at high temperatures and can be made thin, and a coating composition for forming the highly dielectric film comprising (A) a vinylidene fluoride resin, (B) a cellulose resin and (C) a solvent.

Owner:DAIKIN IND LTD

Reactive cyclodextrin derivatives as pore-forming templates, and low dielectric materials prepared by using the same

ActiveUS20070128879A1Improve compatibilityExcellent dielectric propertiesPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsDielectric matrixPorosity

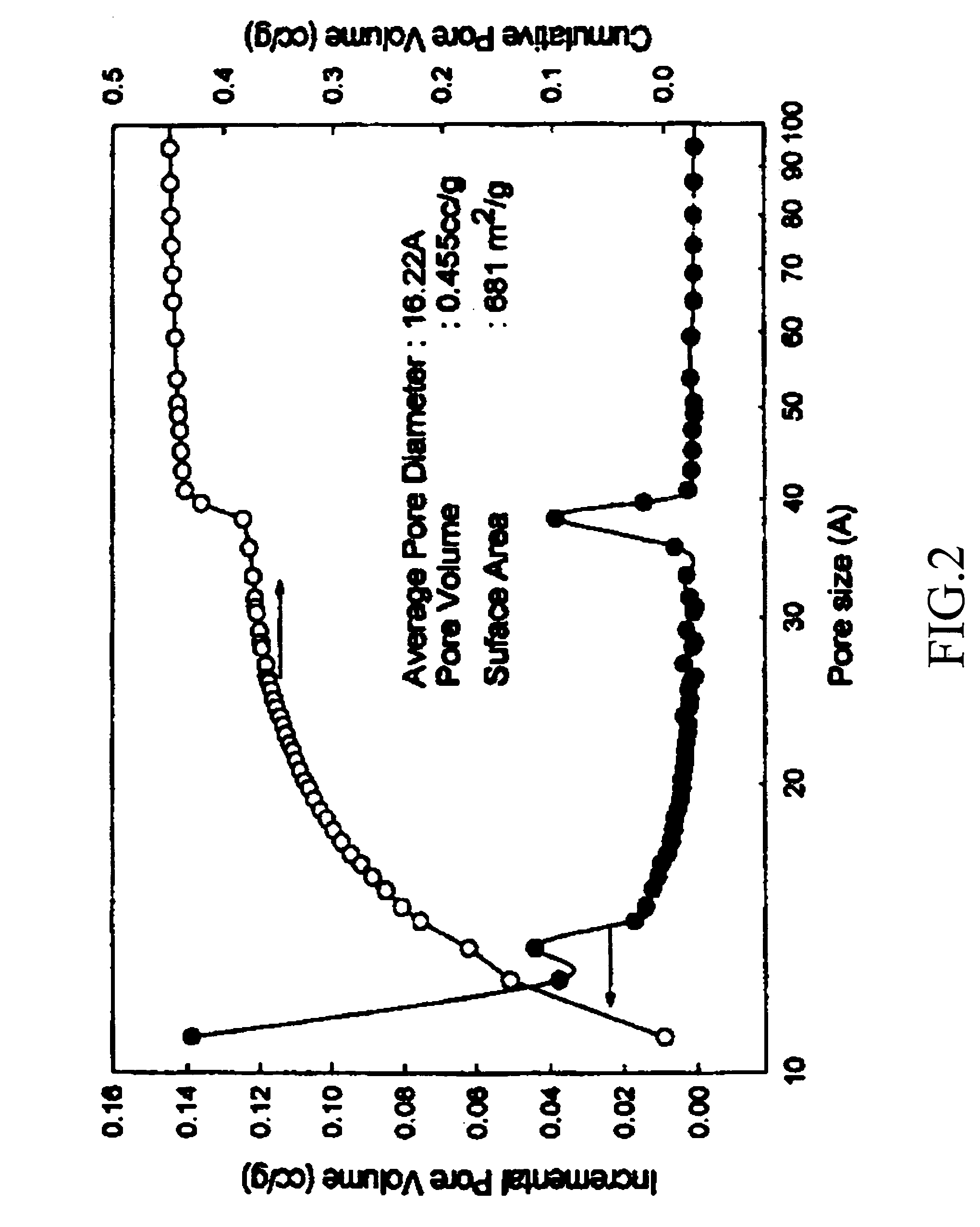

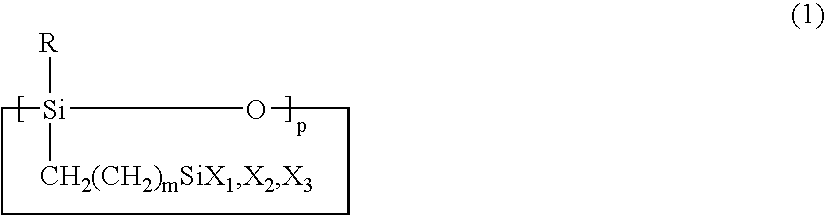

This invention is related to a reactive nanoparticular cyclodextrin derivative useful as a porogen and a low dielectric matrix, with excellent mechanical properties and uniformly distributed nanopores, manufactured by sol-gel reaction of the above reactive cyclodextrin. Furthemore, this invention also is related to an ultralow dielectric film, with uniformly distributed nanopores, a relatively high porosity of 51%, and a relatively low dielectric constant of 1.6, manufactured by thin-filming of the conventional organic or inorganic silicate precursor by using the above reactive cyclodextrin as a porogen.

Owner:IND UNIV COOPPERATION FOUND SOGANG UNIV

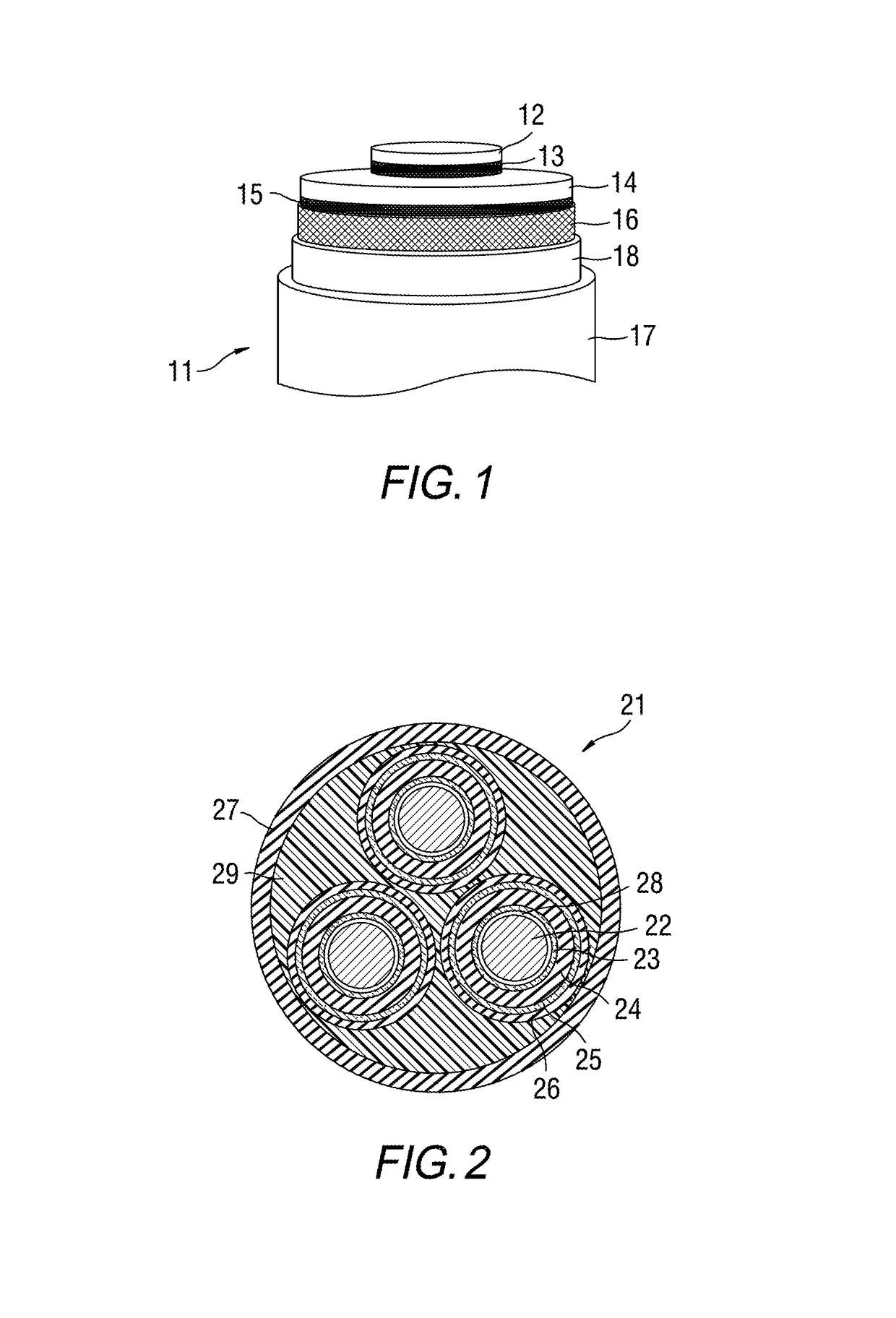

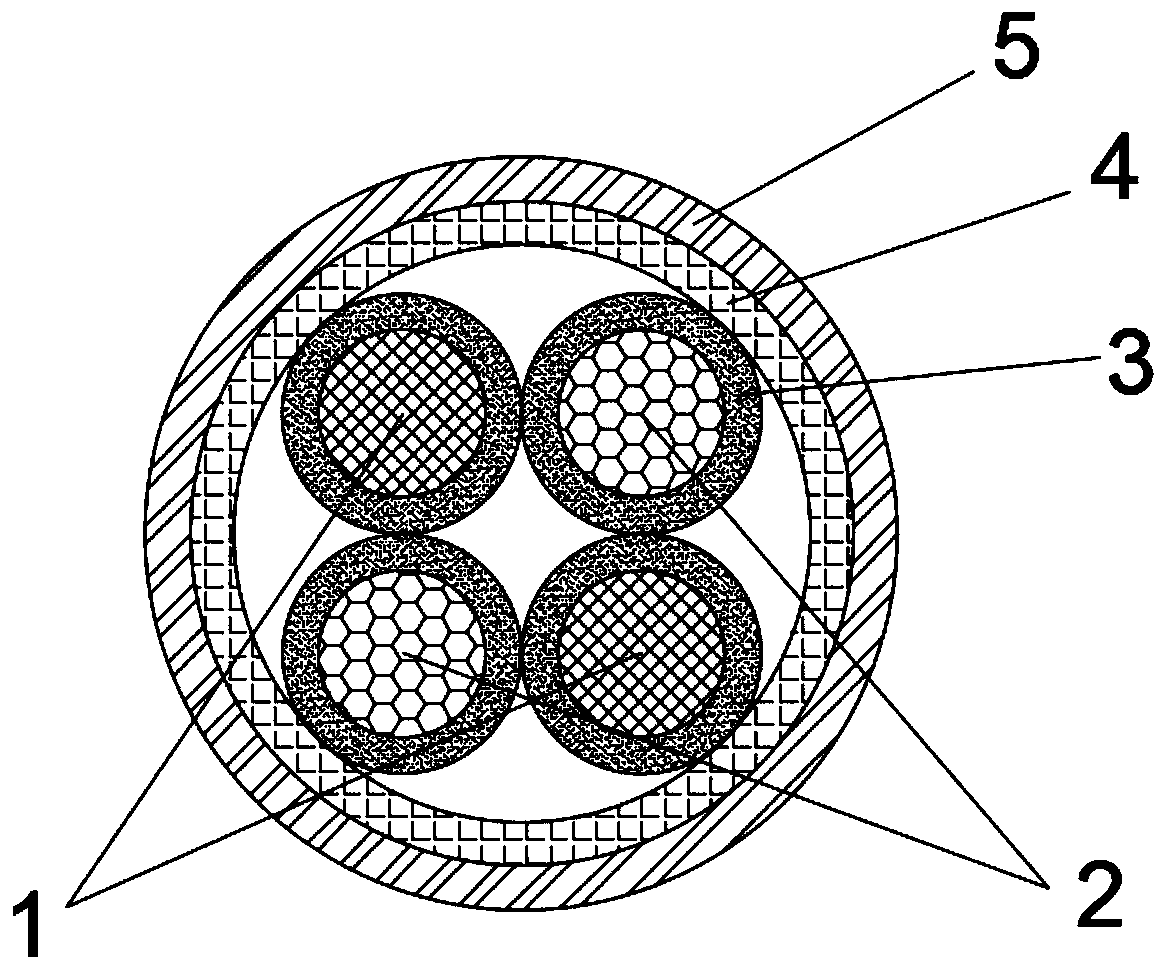

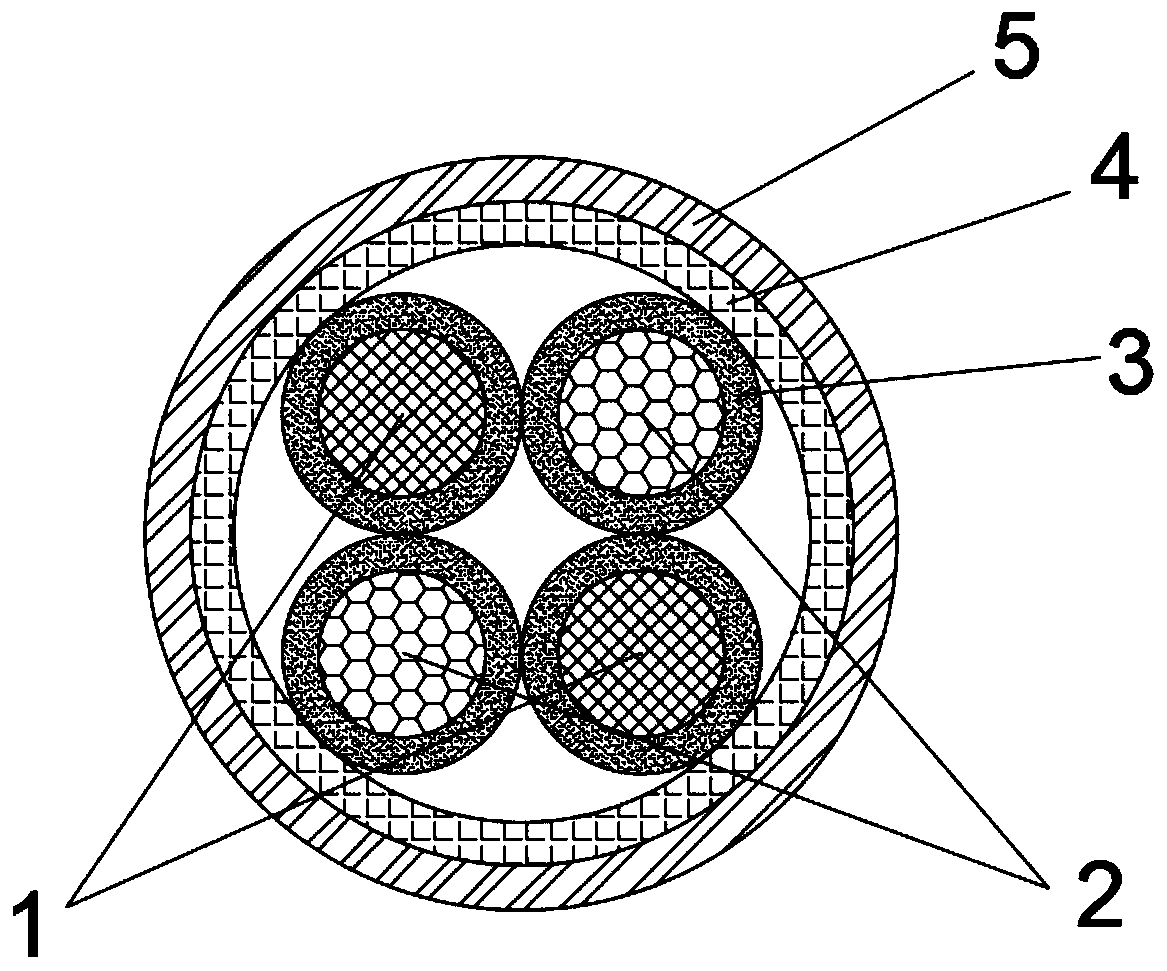

Fire-resistant fireproof cable formula

The invention discloses a fire-resistant fireproof cable formula. A formula of cable fireproof paint comprises the following ingredients in parts by weight: 15 to 16 parts of titanium dioxide, 12 to 18.2 parts of chlorcosane, 13 to 28 parts of alkyd resin, 12.6 to 13.8 parts of urethane resin, 20 to 28.6 parts of cellulose base fiber, 3 to 9 parts of methyltrimethoxysilane, 30 to 50 parts of antioxidizers, 2 to 5 parts of zinc oxide, 12 to 16 parts of compatilizers, 0.9 to 1.8 parts of nanometer aluminum nitride, 11 to 12 parts of polyvinyl alcohol, 20 to 32 parts of modified filling materials, 22 to 30 parts of polyvinyl chloride, 8 to 10 parts of chlorinated polyethylene, 30 to 55 parts of environment-friendly complex plasticizers, 28 to 32 parts of filling strengthening agents, 10 to 15 parts of low-density polyethylene and 30 to 40 parts of lubricating agents. A cable material provided by the invention has the advantage that through the effects of the coupling agents, the compatilizers, flame retardant synergists and the modified filling materials in the formula, the low-smoke halogen-free flame-retardant cable material has good processing performance and low-smoke halogen-free flame-retardant performance.

Owner:ANHUI YUANZHENG CABLE TECH

Environmental-friendly high-temperature-resistant cable material for computer

InactiveCN105778366AIncrease the degree of cross-linkingImprove toughnessPlastic/resin/waxes insulatorsCellulose substancesBenzoyl peroxideSilanes

The invention discloses an environmental-friendly high-temperature-resistant cable material for a computer. The environmental-friendly high-temperature-resistant cable material is prepared from the following components in parts by weight: 50-80 parts of polytetrafluoroethylene, 0.4-0.9 part of polyphenylene sulfide, 0.5-1.5 parts of polybenzoate, 1-3 parts of rare earth stabilizer, 1-2 parts of coumarone resin, 10-16 parts of modified microcrystalline cellulose, 2-8 parts of nano-diamond particles, 1-2 parts of palm wax, 0.5-1.2 parts of antimonous oxide, 0.5-1.5 parts of phthalate (2-ethyl hexoate) ester, 1-3 parts of maleic anhydride, 1-2 parts of gamma-(quadrol) propyl emthyl dimethoxy silane, 0.5-1.2 parts of acrylonitrile-butadiene-styrol copolymer, 0.5-1.2 parts of benzoyl peroxide and 1-2 parts of butyl titanate. The environmental-friendly high-temperature-resistant cable material for the computer can resist high temperature and is excellent in mechanical property.

Owner:ANHUI SPECIAL CABLE GRP

Aluminum-based dielectric paste containing flaky silicon dioxide and preparation method thereof

InactiveCN106847375AImprove corrosion resistanceImprove insulation performancePlastic/resin/waxes insulatorsLiquid organic insulatorsThermal expansionSilicon dioxide

The present invention discloses an aluminum-based dielectric paste containing flaky silicon dioxide and a preparation method thereof. The aluminum-based dielectric paste comprises, by mass, 40-70% of low melting-point glass powder, 0-20% (not including 0) of flaky silicon dioxide powder, 20-40% of organic carrier, and 0-3% of colorant. The aluminum-based dielectric paste has the following advantages: (1) the thermal expansion coefficient of low melting-point glass is greater than 16*10 <-6> m / K, so that the low melting-point glass can well match with an aluminum-based plate; the melting point of the low melting-point glass powder is less than 600 DEG C, so that the low melting-point glass powder can be sintered under the melting point of aluminum; (2) according to the addition of flaky silicon dioxide (quartz) powder, the corrosion resistance, oxidation resistance, heat resistance and electrical insulation performance of a dielectric layer are effectively improved; (3) an insulating dielectric layer made of the insulating dielectric paste has good binding force with the aluminum-based plate, high breakdown voltage and good insulation performance. The preparation method comprises the preparation of the low melting-point glass powder, the preparation of the organic carrier and the preparation of the dielectric paste.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Cable insulating material and preparation method thereof

InactiveCN108410021AImprove mechanical propertiesImprove insulation performanceBulk chemical productionCellulose substancesEpoxyCellulose

The invention provides a cable insulating material and a preparation method thereof. The cable insulating material is prepared from the following components: ethylene-vinyl acetate copolymer, epoxy resin, chloroprene rubber, hydrogenated nitrile rubber, high density polyethylene, modified bentonite, modified nano-crystalline cellulose, modified quick lime, titanium dioxide, zinc oxide, magnesium stearate, dibutyl phthalate, fusing agent, flame retardant, lubricant and antioxidant. The cable material prepared by the invention has excellent mechanical property and insulating property, good tensile resistance and impact resistance, has low water absorption rate and is less likely to be affected with damp, thereby having a good application prospect.

Owner:合肥羿振电力设备有限公司

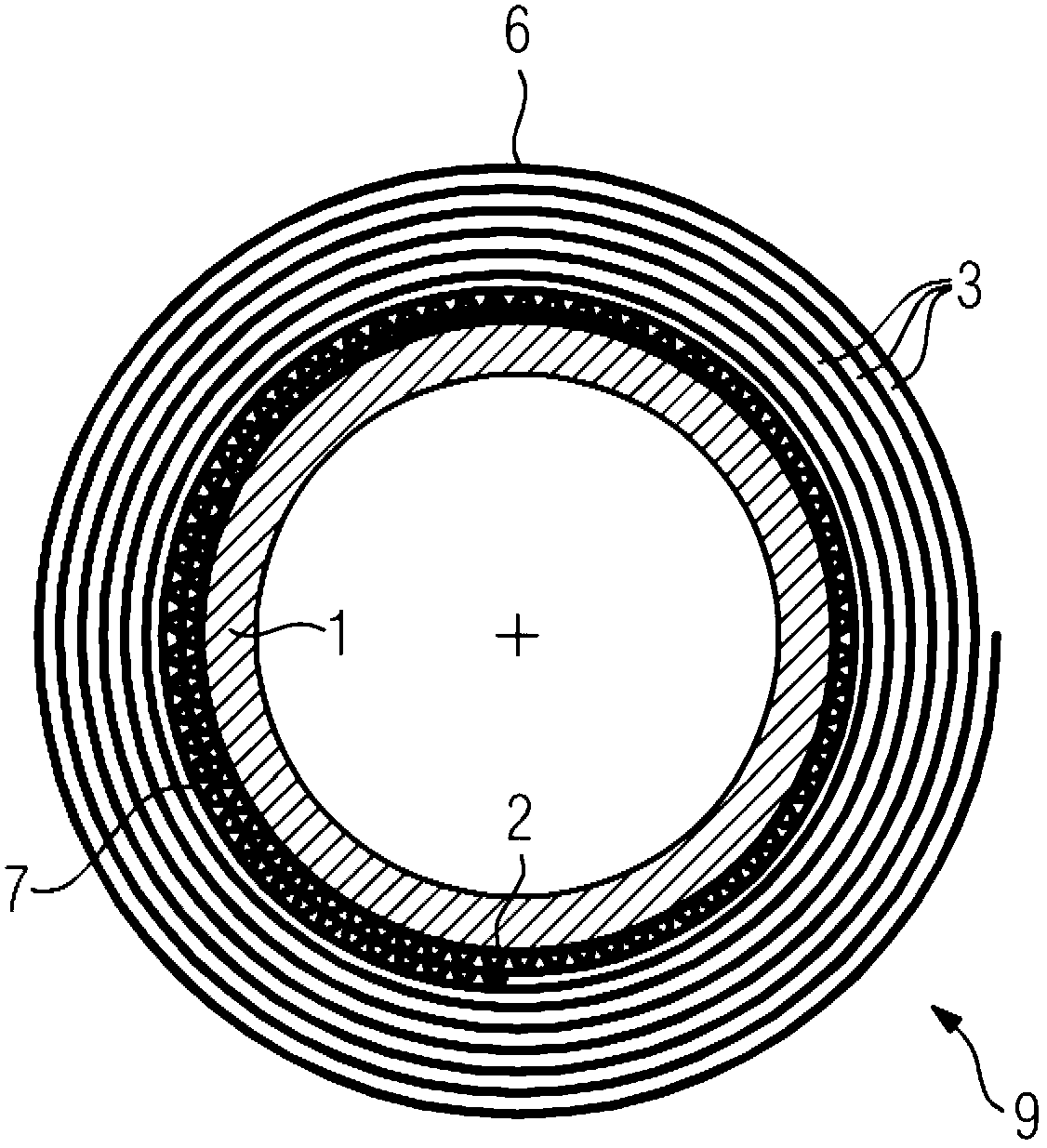

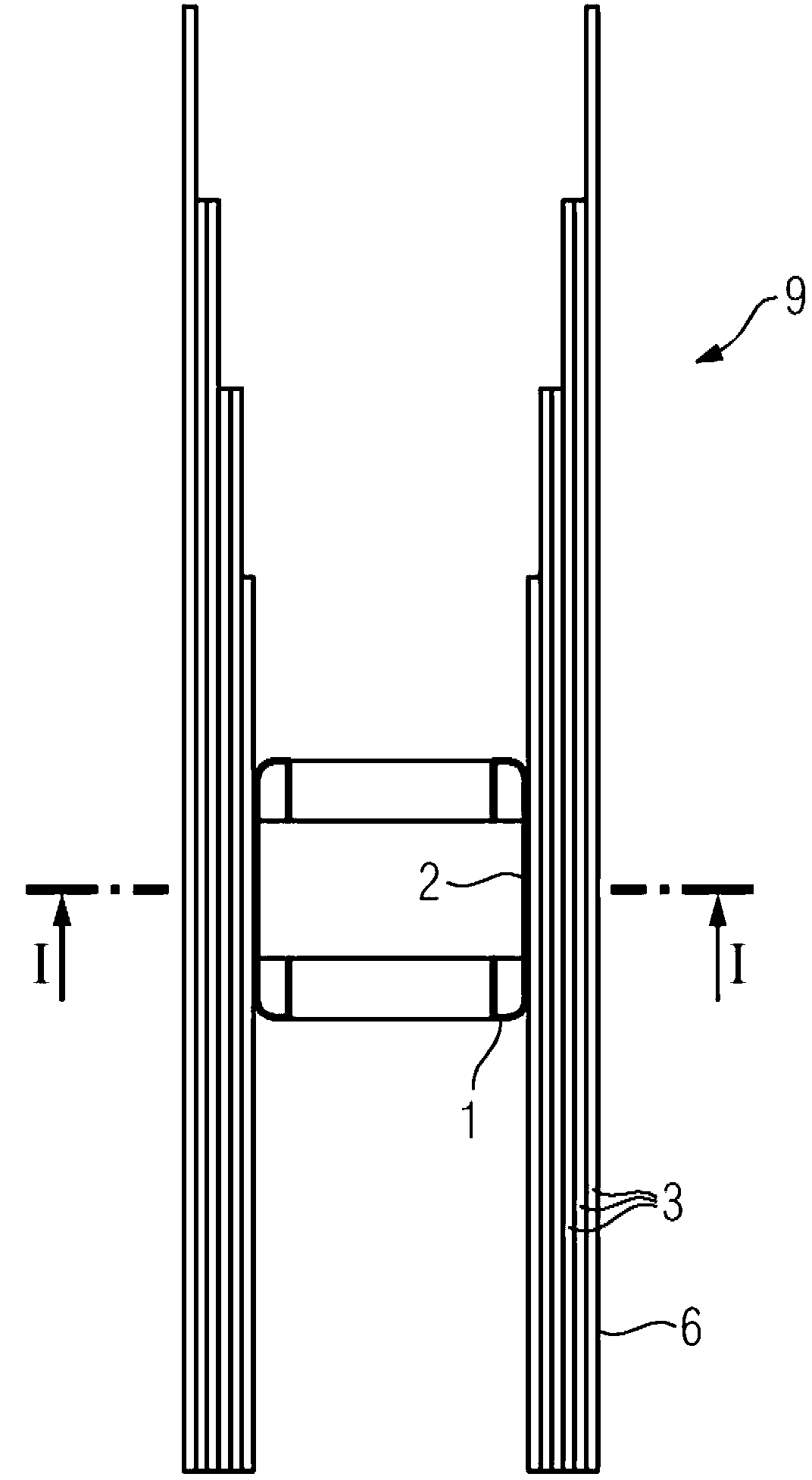

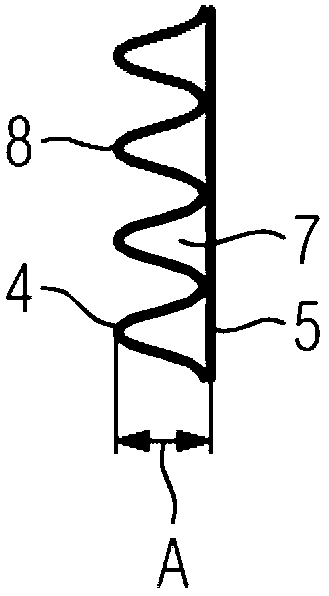

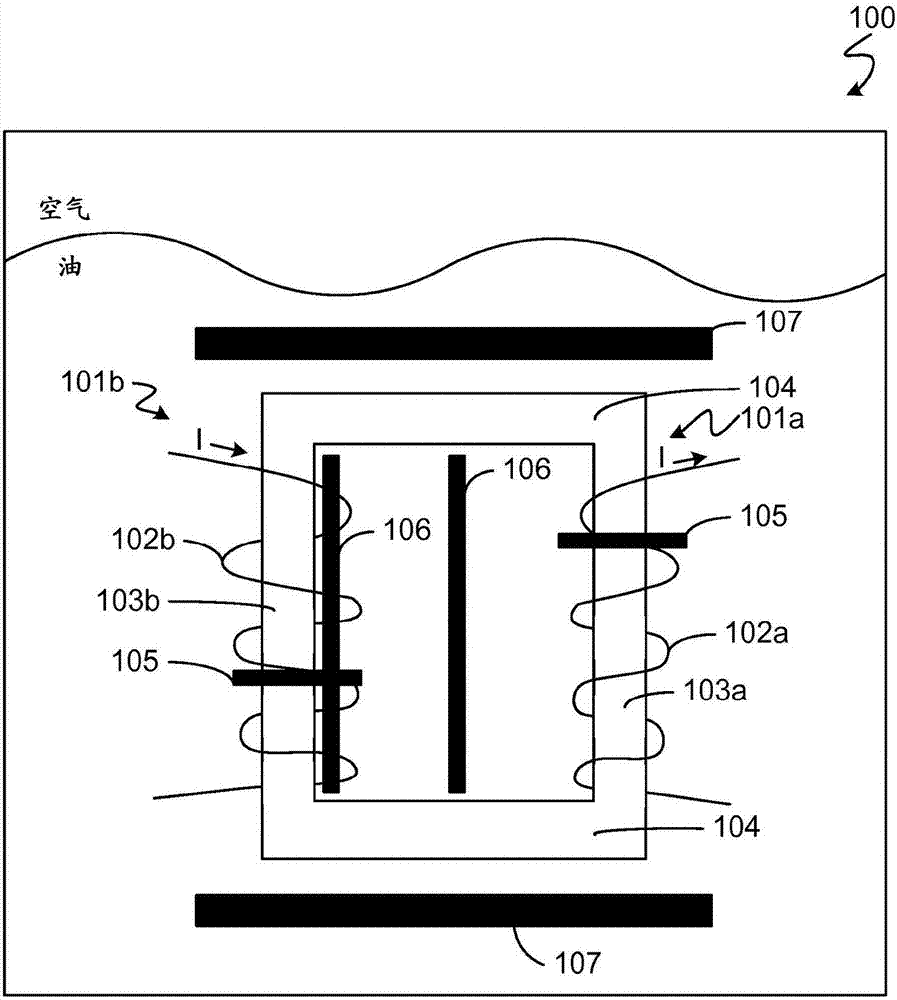

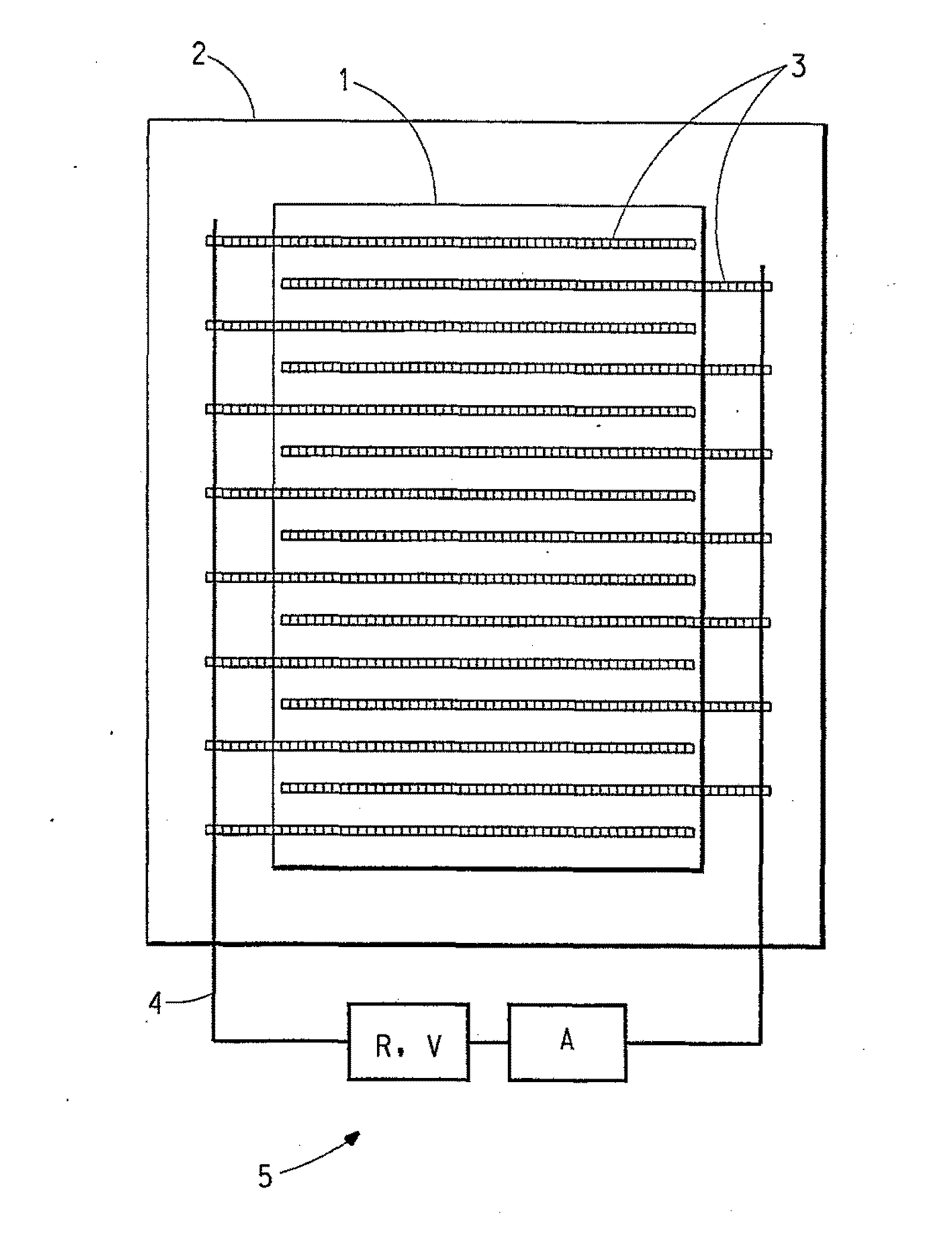

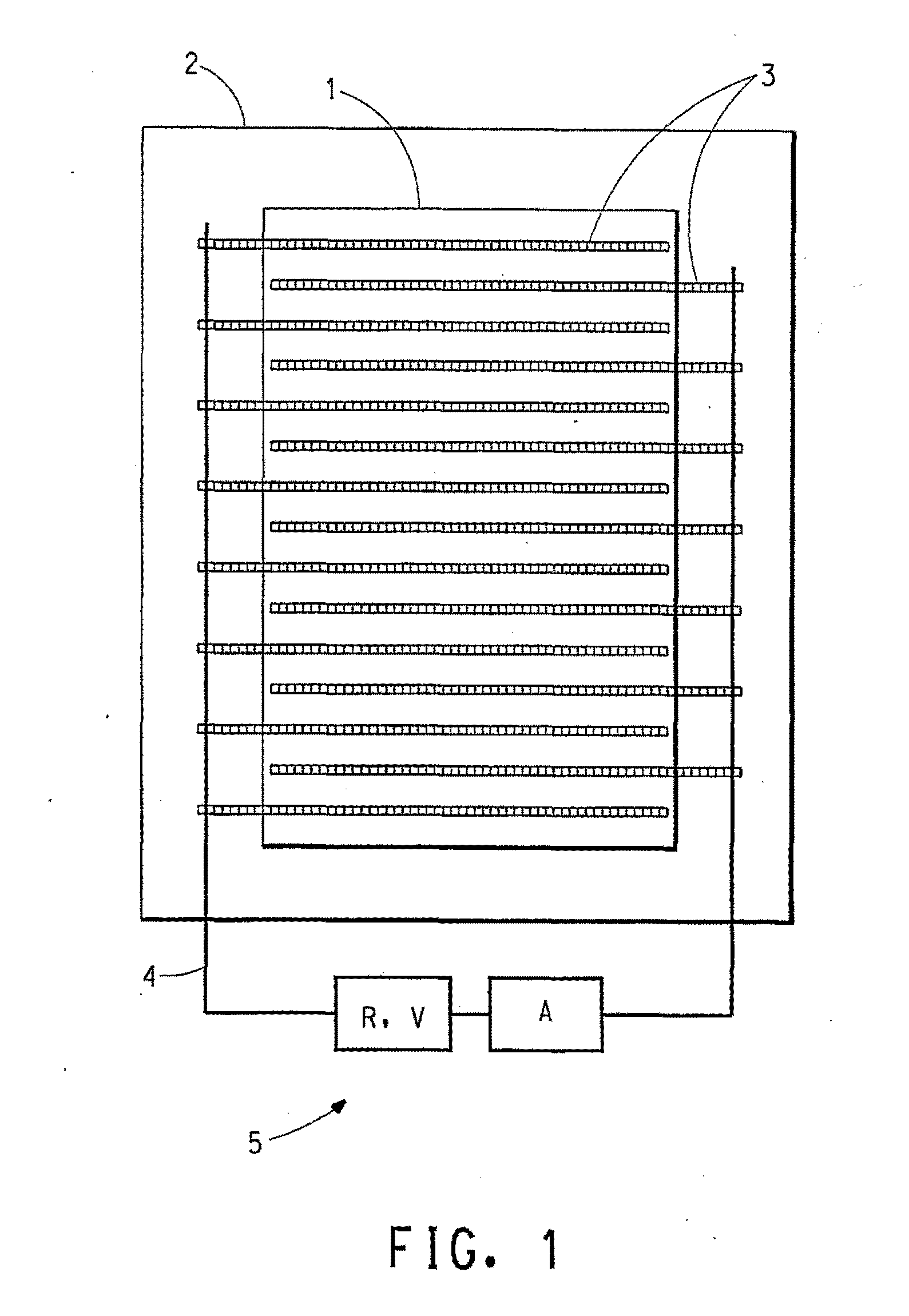

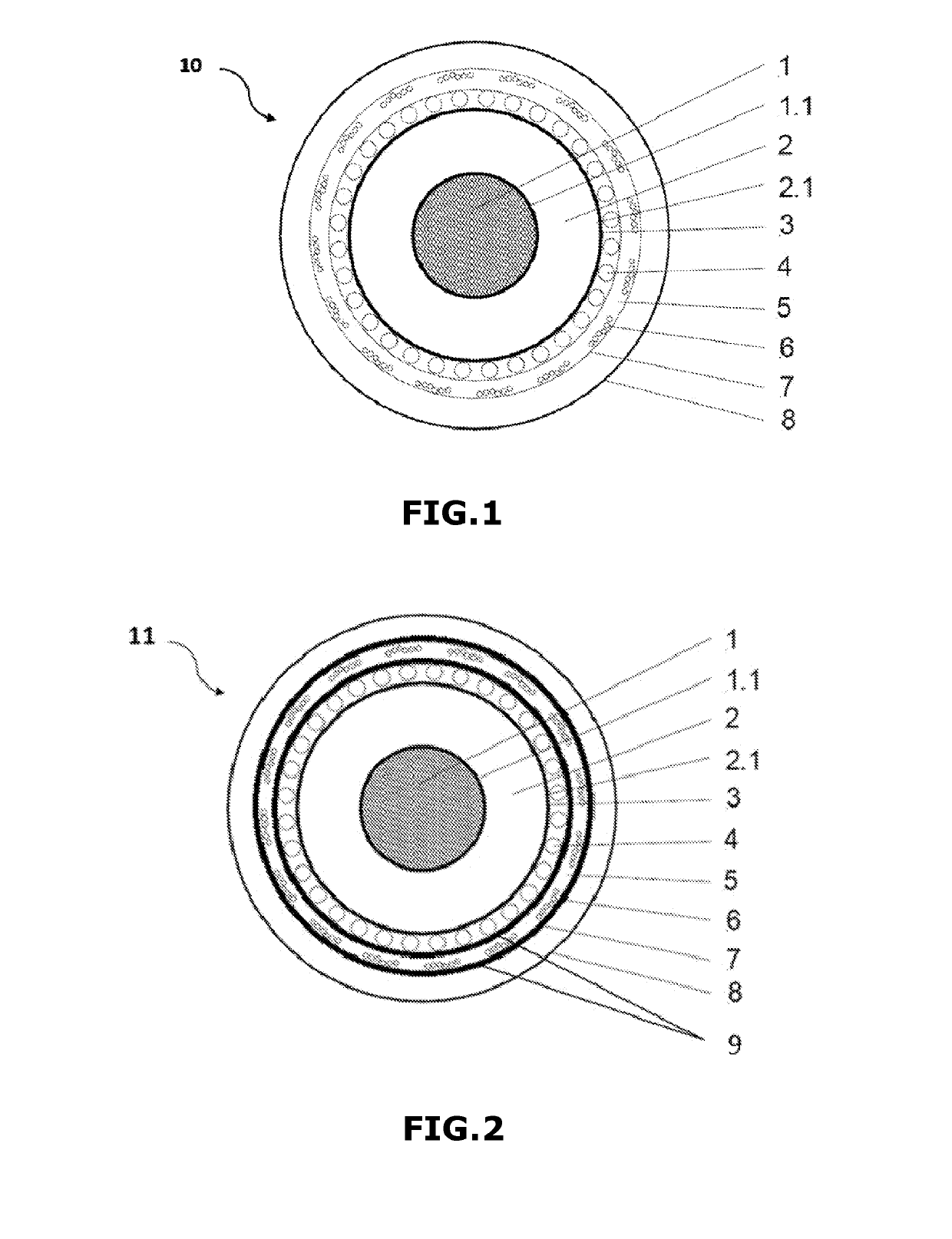

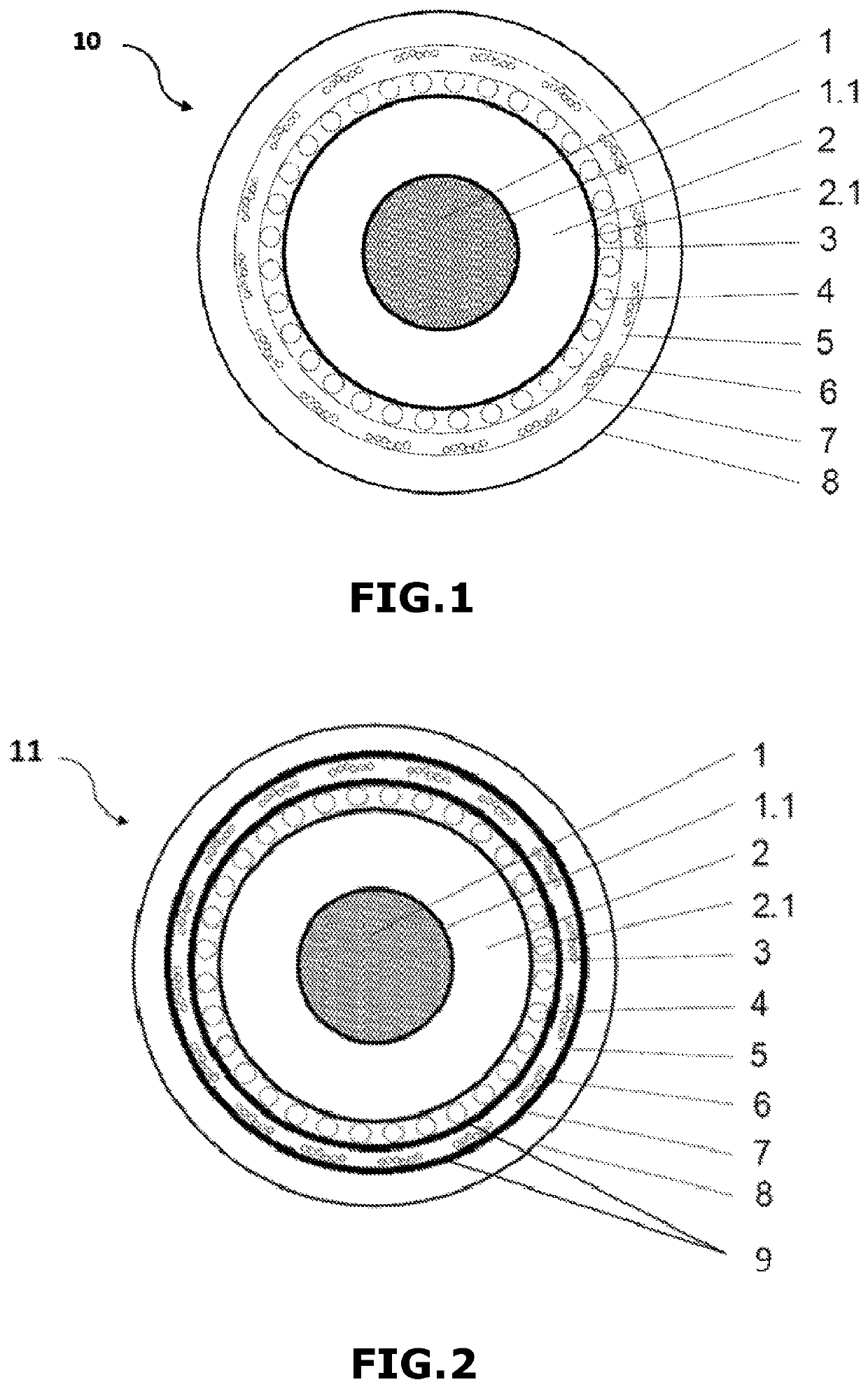

Barrier system for a high voltage device and high voltage device with a barrier system

InactiveCN103310948APrevent mutual sliding fitSubstation/switching arrangement detailsPlastic/resin/waxes insulatorsHigh pressureEmbedded system

The invention telates to a barrier system for a high voltage device and high voltage device with a barrier system. The barrier system (9) comprises a corrugated board that includes several windings (6). The invention also relates to a high voltage system having the barrier system.

Owner:SIEMENS AG

Power cable having an aluminum corrosion inhibitor

ActiveUS10217546B2Plastic/resin/waxes insulatorsClimate change adaptationElectrical conductorPower cable

A power cable having a metallic electrical conductor surrounded by one or more semiconductive layer and more or more insulating layer, wherein the cable has at least one metallic element made of aluminum, having a corrosion inhibitor provided in direct contact with the at least one metallic element made of aluminum.

Owner:PRYSMIAN SPA +1

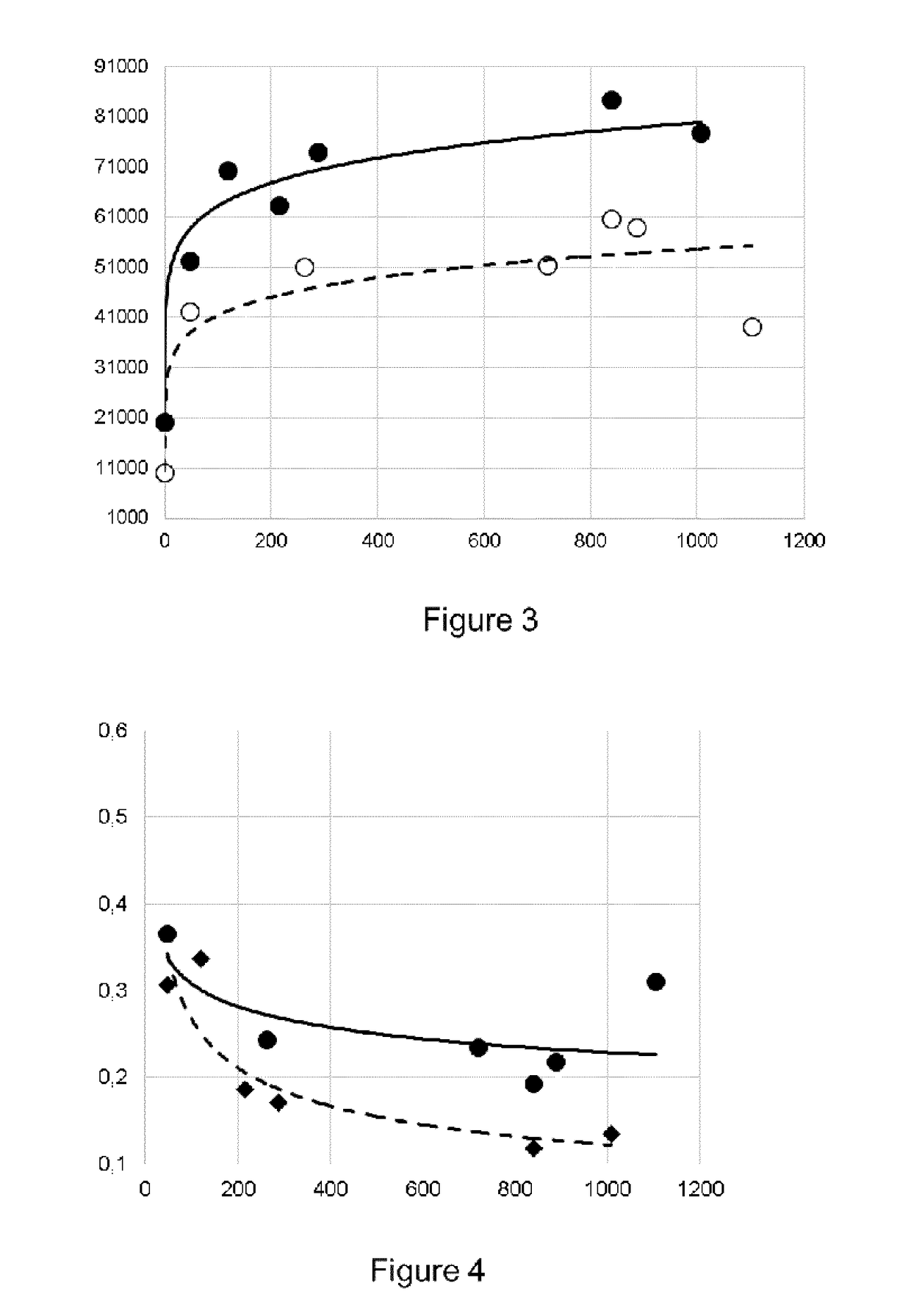

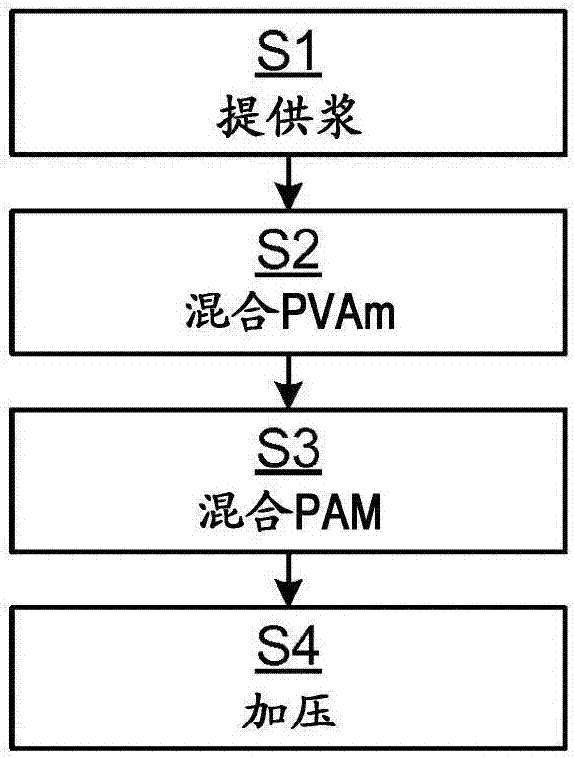

Pressboard

The invention discloses a pressboard. The present invention relates to a cellulose based pressboard for insulation in an electrical power transformer. The pressboard comprises polyvinylamine (PVAm), and polyacrylamide (PAM), in a combined amount of between 0.01% and 20% by weight of the pressboard. The invention also relates to the use of such a pressboard as insulation in a power transformer, to a power transformer comprising such pressboard, as well as to a method of producing the pressboard.

Owner:ABB POWER GRIDS SWITZERLAND AG

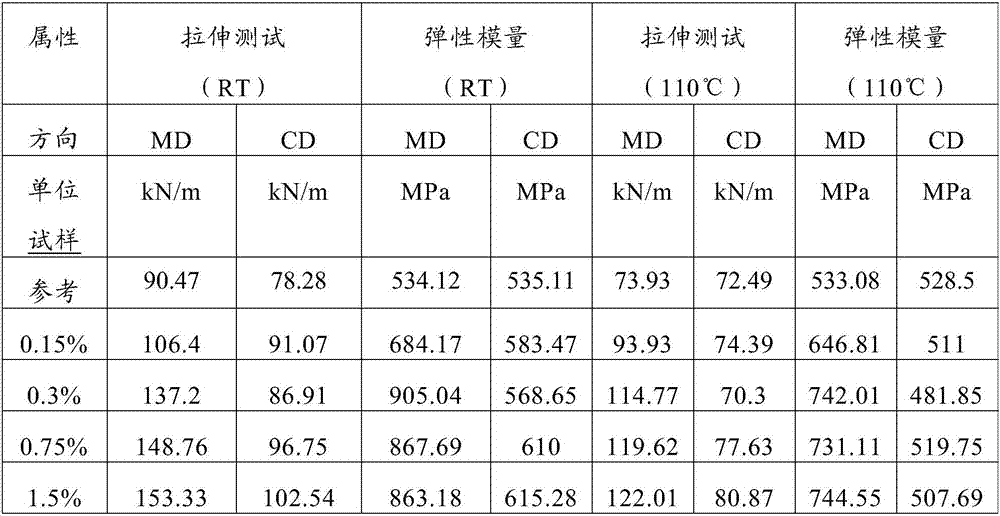

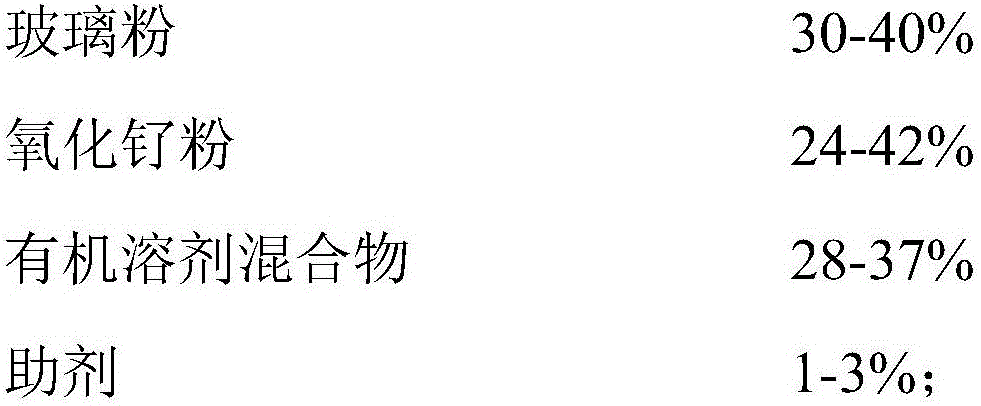

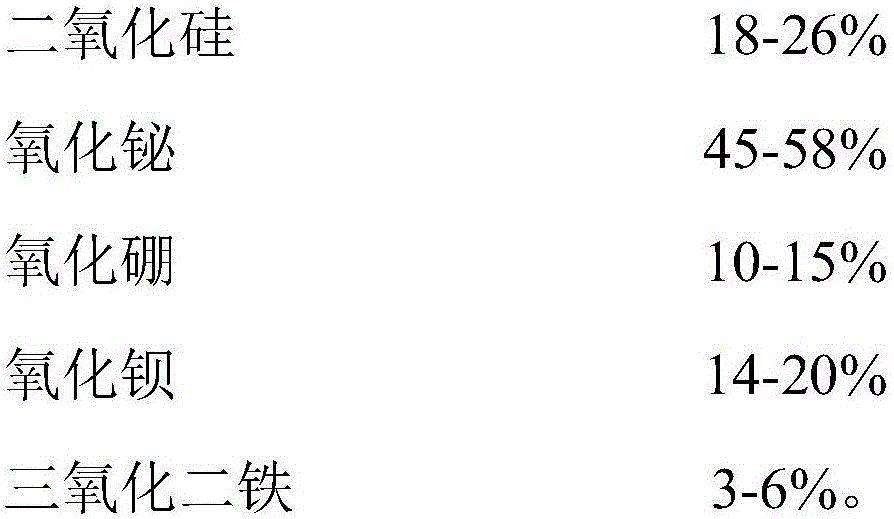

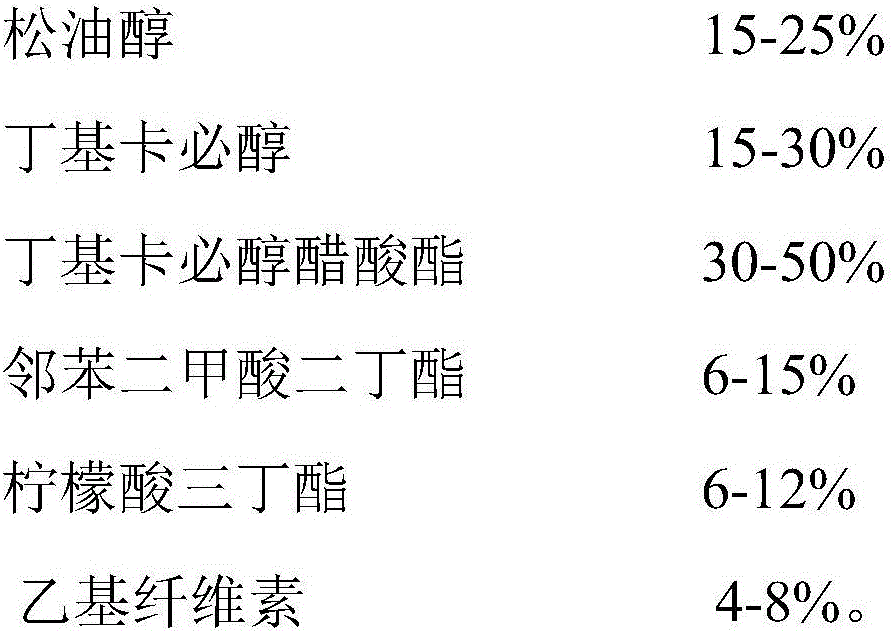

Slurry adaptive to aluminum nitride base material and preparation method thereof

InactiveCN106816204ALower sintering temperatureExcellent screen printing performancePlastic/resin/waxes insulatorsLiquid organic insulatorsCITRATE ESTEROrganic solvent

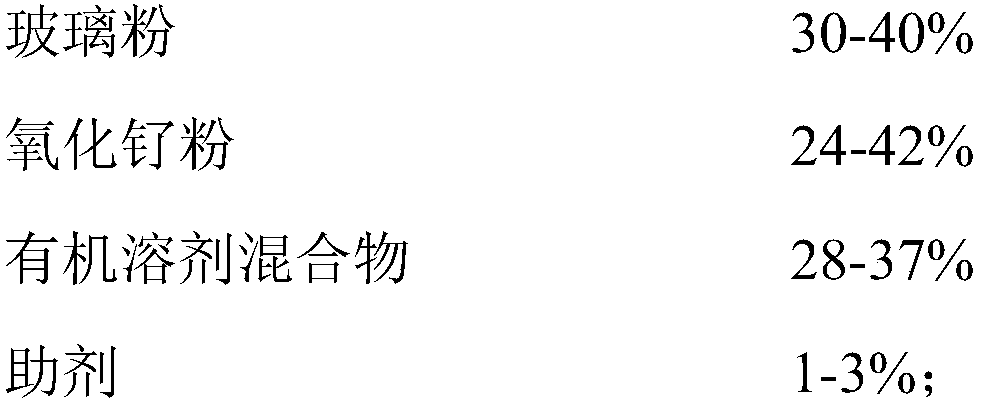

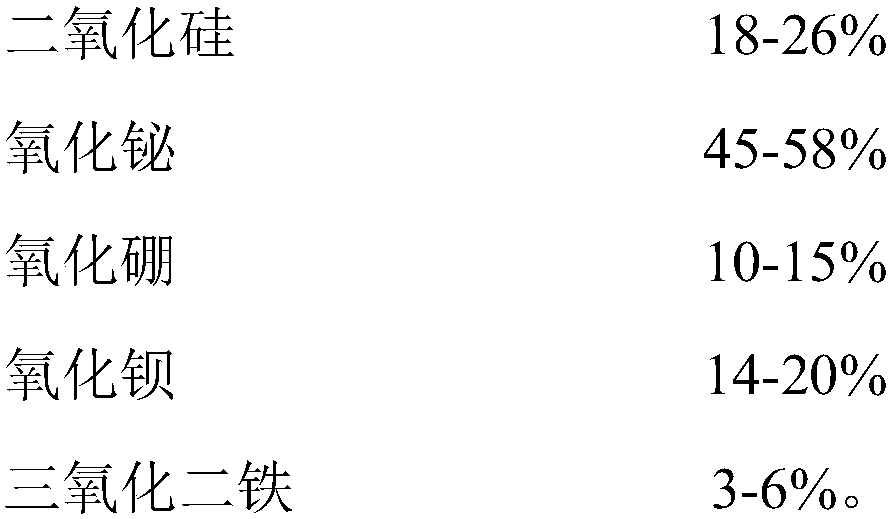

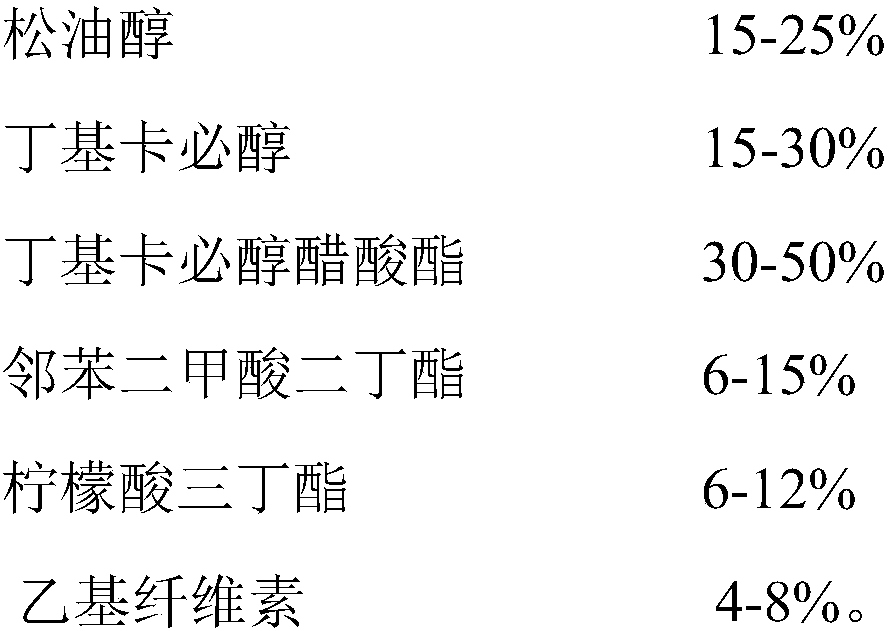

The present invention discloses a slurry adaptive to an aluminum nitride base material and a preparation method thereof. The slurry comprises the following components of mass percents of 30-40% of glass powder, 24-42% of ruthenium oxide powder, 28-37% of organic solvent mixture and 1-3% of auxiliary, and the organic solvent mixture comprises terpilenol, butyl carbitol, butyl carbitol acetat, dibutyl phthalate, tri-n-butyl citrate and ethyl cellulose. The preparation method of the slurry is characterized by, according to the mass percents, obtaining the glass powder, the organic solvent mixture and the ruthenium oxide powder, and carrying out the stirring, three-roller grinding, filtering and deaeration processes to obtain the needed slurry. The slurry adaptive to the aluminum nitride base material of the present invention adopts the glass powder of a low softening point to support the selected organic solvent mixture, thereby being able to reduce the sintering temperature of the slurry. A sintered slurry layer has the excellent performances that the resistance is low, and the refiring resistance change rate is less than 3%. Meanwhile, the slurry does not contain the lead, has an excellent silkscreen performance, and is totally suitable for being used as a large-power density (greater than 80W / cm<2>) heating device.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Coating composition for forming highly dielectric film and highly dielectric film

ActiveUS8576540B2Improve pressure resistanceDecrease a dielectric lossFixed capacitor dielectricStacked capacitorsCelluloseDielectric loss

The present invention provides a nonporous highly dielectric film which can improve withstanding voltage, insulating property and dielectric constant, especially can decrease a dielectric loss at high temperatures and can be made thin, and a coating composition for forming the highly dielectric film comprising (A) a vinylidene fluoride resin, (B) a cellulose resin and (C) a solvent.

Owner:DAIKIN IND LTD

Dielectric composition with reduced resistance

InactiveUS20110006271A1Reduce resistanceUseful in field emissionConductive materialOxide conductorsDielectricField emission device

This invention provides a dielectric composition comprising a dielectric which is fireable in air at a temperature in the range of about 450° C. to about 550° C. and a conductive oxide selected from the group consisting of antimony-doped tin oxide, tin-doped indium oxide, a transition metal oxide which has mixed valence states or will form mixed valence states after firing in a nitrogen atmosphere at a temperature in the range of about 450° C. to about 550° C. and normally conducting precious metal oxides such as ruthenium dioxide, wherein the amount of conductive oxide present is from about 0.25 wt % to about 25 wt % of the total weight of dielectric and conductive oxide. This dielectric composition has reduced electrical resistance and is useful in electron field emission devices to eliminate charging of the dielectric in the vicinity of the electron emitter and the effect of static charge induced field emission.

Owner:EI DU PONT DE NEMOURS & CO

Formula of environmental protection material for cable sheath

InactiveCN105860564AProtect against corrosionExtended service lifeCellulose substancesCross-linked polyethyleneEnvironmental resistance

The invention discloses a formula of an environmental protection material for a cable sheath. A cable comprises the following raw materials in parts by mass: 30-40 parts of ramie fiber,10-20 parts of a stabilizer, 10-20 parts of barium srearate, 10-15 parts of crosslinked polyethylene resin, 10-20 parts of chlorinated paraffin, 20-30 parts of a lubricant, 10-20 parts of calcium carbonate and 10-15 parts of pottery clay. The environmental protection material for the cable sheath has the advantages of good insulating effect, good wear resistance, strong anti-interference performance and the like.

Owner:ANHUI XINKE CABLE GROUP

High-toughness heat-resistant cable sheathing compound

The invention discloses a high-toughness heat-resistant cable sheathing compound, which is prepared from the raw materials including modified polylactic acid, ethylene-butyl acrylate copolymer, maleic anhydride grafted ethylene-octene copolymer, polyphenylene sulfide, aluminum diethylphosphinate, polyamide, ammonium polyphosphate, aluminum hypophosphite, melamine sodium polyphosphate, zinc borate, modified Lyocell fibers, glass fibers, modified silica, nano zinc oxide, nano titanium dioxide and aluminate ester. The cable sheathing compound of the invention has good toughness and excellent heat resistance.

Owner:ANHUI LIETA CABLE GROUP

Preparation method of novel flame-retardant cable material

InactiveCN108456414AFulfil requirementsEasy to preparePlastic/resin/waxes insulatorsCellulose substancesCelluloseAntioxidant

The invention provides a preparation method of a novel flame-retardant cable material. The preparation method comprises the following steps: a, mixing and smelting a thermoplastic polyurethane elastomer, a styrene elastomer, modified nanocrystal cellulose and modified magnesium hydroxide to obtain a material I; b, mixing the material I with an antioxidant, a lubricating agent, a halogen-free intumescent flame retardant, a plasticizer and deionized water, carrying out dispersion treatment, and then heating and stirring to obtain a material II; c, adding and mixing expanded graphite, magnesium stearate, a defoaming agent and a maleic anhydride stem grafting compatilizer into the material II, guiding the mixture into a double screw extrusion machine, and carrying out extrusion pelletization to obtain a material III; and d, drying the material III, and processing and forming the novel flame-retardant cable material. The preparation method provided by the invention is simple, low in cost and excellent in material flame retardant property, and has the advantages of excellent performance such as radiation resistance and insulation performance and excellent mechanical property and machining property.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

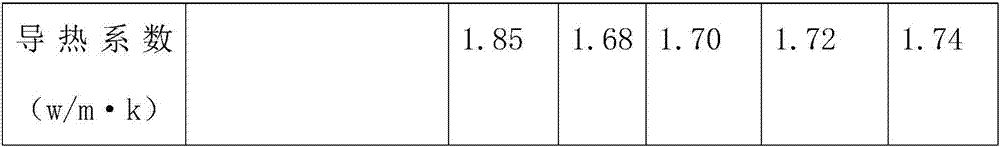

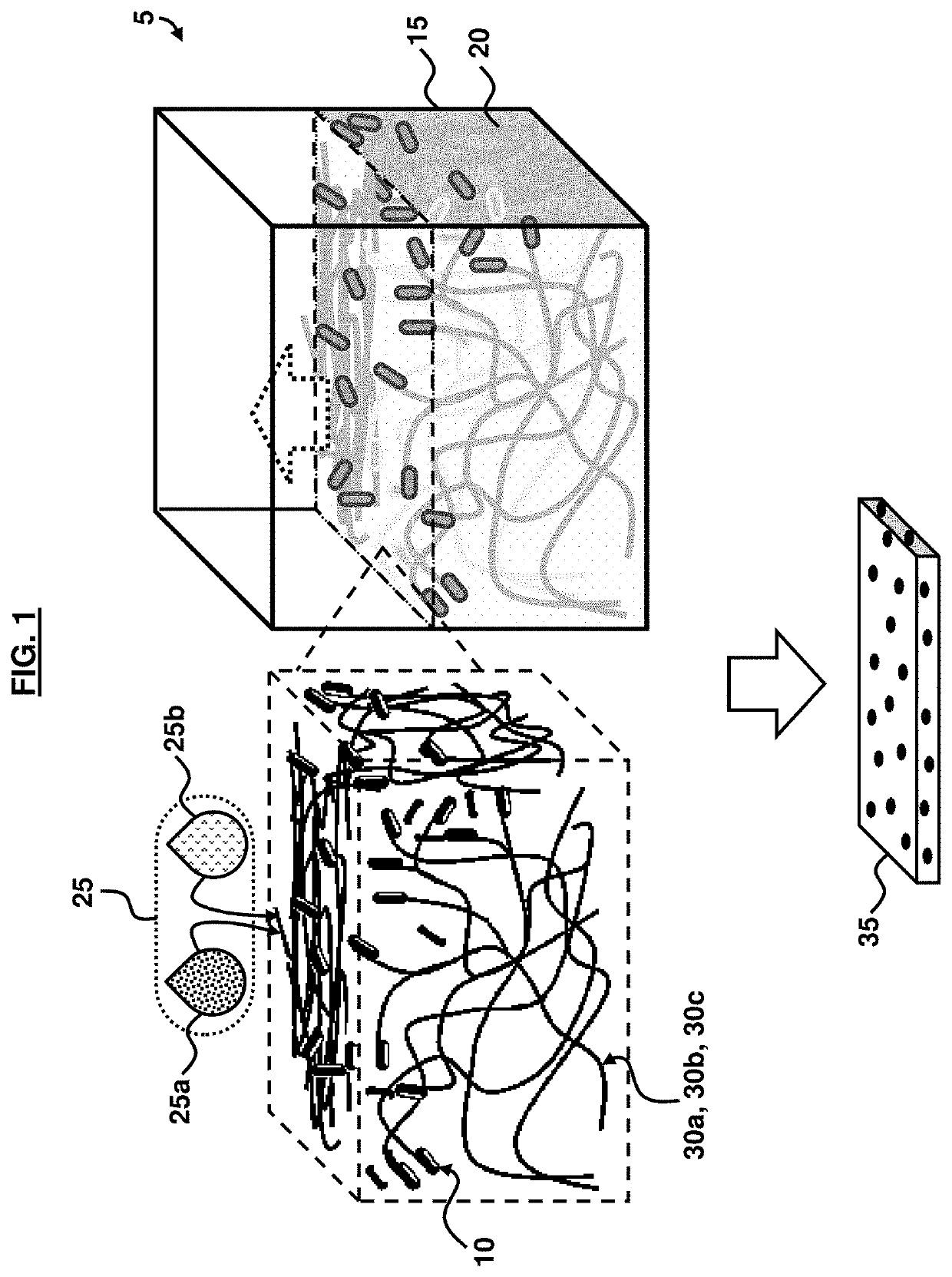

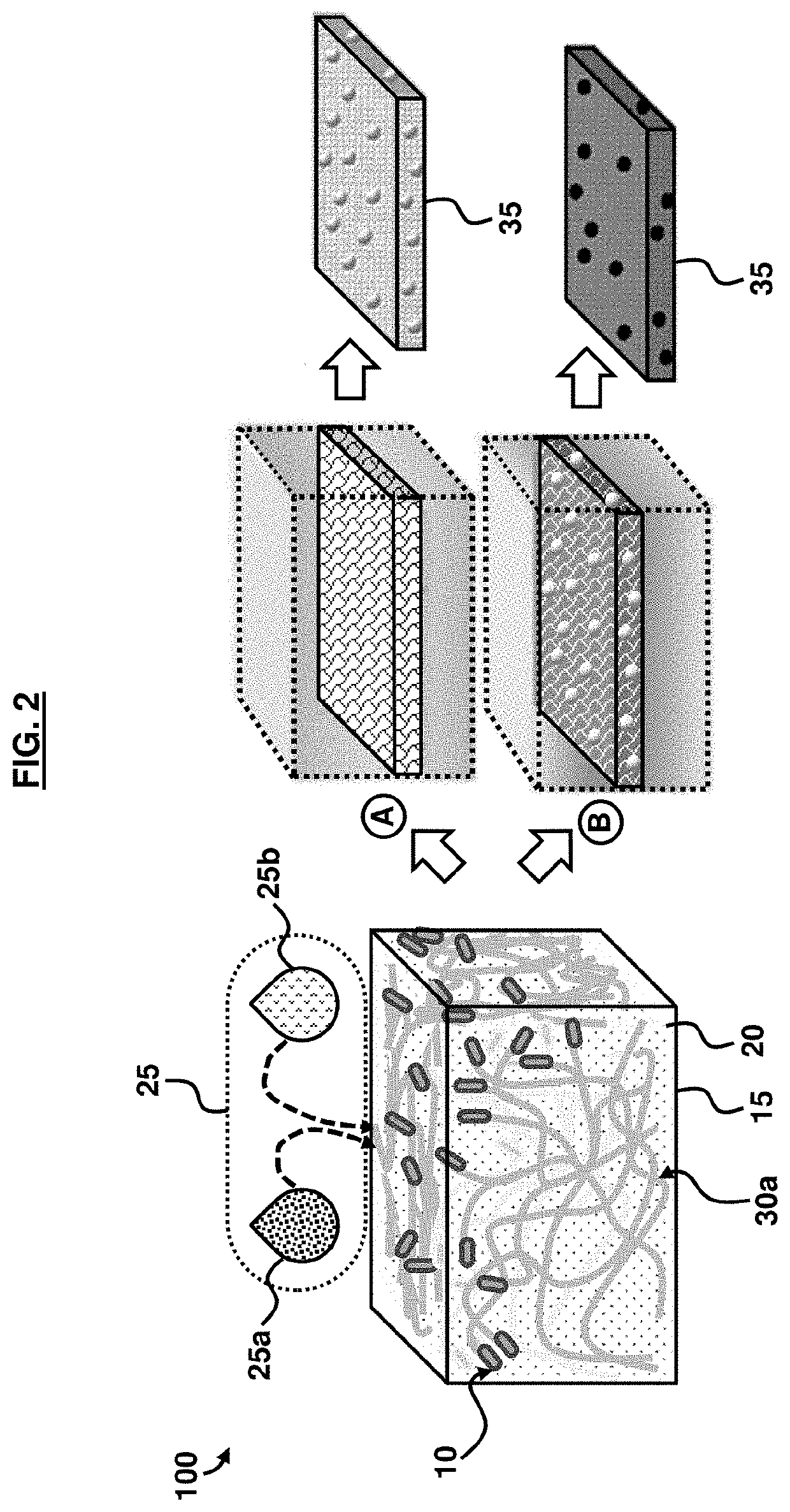

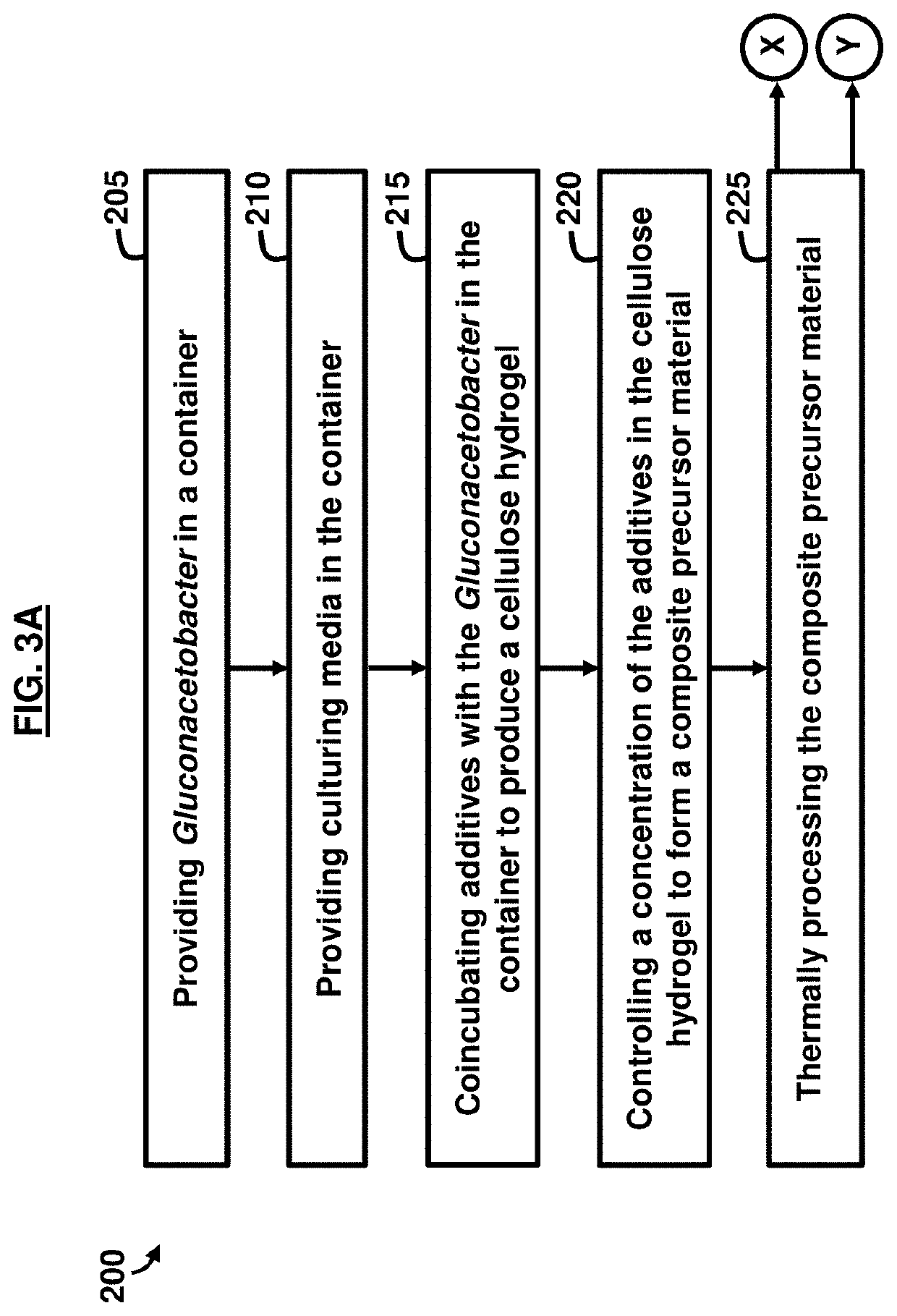

Biofabrication of advanced functional materials using bacterial cellulose scaffolds

PendingUS20220220521A1Improve concentrationPhysical/chemical process catalystsCarbon preparation/purificationBiomanufacturingGluconacetobacter

A biofabrication method for producing cellulose-based materials. The method includes providing active cellulose-producing bacteria such as Gluconacetobacter and culturing media in a container; combining organic additives or inorganic additives with the active cellulose-producing bacteria in the container to produce a cellulose hydrogel matrix composed of entangled bacteria-produced cellulose nanofibers; controlling a concentration of the additives in the cellulose hydrogel matrix; and exposing the cellulose hydrogel matrix in selected thermal environment to create a biofabricated functional material.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Dielectric Coatings and Articles

InactiveCN103229249BEasy to set upWindings insulation shape/form/constructionThin material handlingSurface resistivityCoating

The present invention relates to dielectric coatings and articles having a high but precisely defined surface resistivity.

Owner:MERCK PATENT GMBH

High-performance cable insulating material formula

InactiveCN105542232AFlame-retardant and water-resistantExcellent and stable thermal and mechanical propertiesCellulose substancesCross-linkAntioxidant

The invention discloses a high-performance cable insulating material formula. A high-performance cable insulating material is prepared from, by weight, 30-36 parts of inorganic filler, 18.3-22.6 parts of carbon black, 39-46 parts of a silane coupling agent, 16-20 parts of antioxidant, 10-30 parts of a cross-linking agent, 2.5-3.5 parts of a vulcanizing agent, 20-22 parts of flame retardant, 12-20 parts of oxide, 6-21 parts of an anti-aging agent, 28-39 parts of oxygen indexes, 6-20 parts of borax, 23-30 parts of boric acid, 18-26 parts of cellulose fibers, 9-30 parts of titanium dioxide, 13-26 parts of chlorinated paraffin, 25-32 parts of a lubricating agent and 33-36 parts of compatilizer. The material is reasonable and scientific in formula, good in irradiation resistance and waterproof performance and excellent in mechanical performance, mechanical performance and physical performance of a produced finished cable are higher than those of common rubber, and flame retardance, abrasion resistance, high using safety and long service life are achieved.

Owner:ANHUI ZHUOYUE CABLE

Device Comprising a Cable or a Cable Accessory Containing a Fire-Resistant Composite Layer

ActiveUS20190202739A1Improve fire resistanceAdvantageous cost priceCementsInsulated cablesSimple Organic CompoundsBoiling point

The present invention relates to a device comprising a cable and / or a cable accessory, said cable and / or said cable accessory comprising at least one composite layer obtained from a composite composition based on at least one cellulose derivative, at least one organic compound having a boiling point or a decomposition temperature above about 100° C. and at least one cement composition selected from an aluminosilicate geopolymer composition and a magnesium-based composition, as well as to a method of manufacturing such a device.

Owner:NEXANS

Access data cable

InactiveCN111613380AImprove wear resistanceImprove insulation performanceRubber insulatorsPlastic/resin/waxes insulatorsCelluloseCross linker

The invention provides an access data cable. The data cable comprises a data wire and an insulating layer coating the data wire, and the insulating layer comprises the following components: 4-8 partsof methyl cellulose, 8-12 parts of polytetrafluoroethylene, 6-10 parts of a cross-linking agent, 10-25 parts of 1, 3-butadiene, 15-20 parts of styrene, 15-20 parts of an ethylene-vinyl acetate copolymer and 40-65 parts of chlorinated polyethylene. The wear resistance and the insulating property of the network cable by using the insulating layer with the components are remarkably improved, and thebending resistance is improved by 60%.

Owner:江苏捷信智能设备工程有限公司

A high acid-resistant medium slurry

ActiveCN113555146BImprove acid resistanceExtended service lifeQuartz/glass/vitreous enamelsCellulose substancesCelluloseDielectric

The invention discloses a medium slurry with high acid resistance. The glass powder used in the medium slurry is obtained by tempering Bi-Si-B series glass powder at 500-600 DEG C for 20-24 hours; , β-cellulose, etc. to prepare organic carriers; chromium trioxide, cadmium trioxide, titanium dioxide, etc. are added as oxide additives to further enhance the stability of the slurry. The binder phase glass powder used in the medium slurry of the invention adds high temperature tempering on the basis of the traditional water quenching process, which can eliminate the internal stress generated in the process of smelting and ball milling, and further improve the compactness; at the same time, it is used in the preparation process of the organic carrier. Butyraldehyde oxime replaces terpineol, the prepared slurry not only has extremely high acid resistance, but also can ensure stable breakdown voltage and low encapsulation change rate, which can adapt to harsher use environments and prolong its use. It has obvious economic benefits at the same time of life.

Owner:西安宏星电子浆料科技股份有限公司

A slurry suitable for aluminum nitride substrate and preparation method thereof

InactiveCN106816204BLower sintering temperatureExcellent screen printing performancePlastic/resin/waxes insulatorsLiquid organic insulatorsOrganic solventCITRATE ESTER

The present invention discloses a slurry adaptive to an aluminum nitride base material and a preparation method thereof. The slurry comprises the following components of mass percents of 30-40% of glass powder, 24-42% of ruthenium oxide powder, 28-37% of organic solvent mixture and 1-3% of auxiliary, and the organic solvent mixture comprises terpilenol, butyl carbitol, butyl carbitol acetat, dibutyl phthalate, tri-n-butyl citrate and ethyl cellulose. The preparation method of the slurry is characterized by, according to the mass percents, obtaining the glass powder, the organic solvent mixture and the ruthenium oxide powder, and carrying out the stirring, three-roller grinding, filtering and deaeration processes to obtain the needed slurry. The slurry adaptive to the aluminum nitride base material of the present invention adopts the glass powder of a low softening point to support the selected organic solvent mixture, thereby being able to reduce the sintering temperature of the slurry. A sintered slurry layer has the excellent performances that the resistance is low, and the refiring resistance change rate is less than 3%. Meanwhile, the slurry does not contain the lead, has an excellent silkscreen performance, and is totally suitable for being used as a large-power density (greater than 80W / cm<2>) heating device.

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Device comprising a cable or a cable accessory containing a fire-resistant composite layer

ActiveUS10961156B2Improve mechanical propertiesImprove fire resistanceCementsInsulated cablesSimple Organic CompoundsGeopolymer

The present invention relates to a device comprising a cable and / or a cable accessory, said cable and / or said cable accessory comprising at least one composite layer obtained from a composite composition based on at least one cellulose derivative, at least one organic compound having a boiling point or a decomposition temperature above about 100° C. and at least one cement composition selected from an aluminosilicate geopolymer composition and a magnesium-based composition, as well as to a method of manufacturing such a device.

Owner:NEXANS

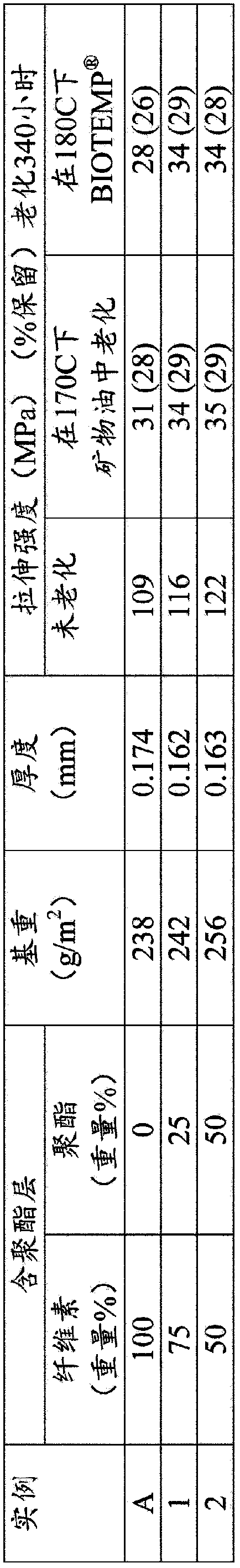

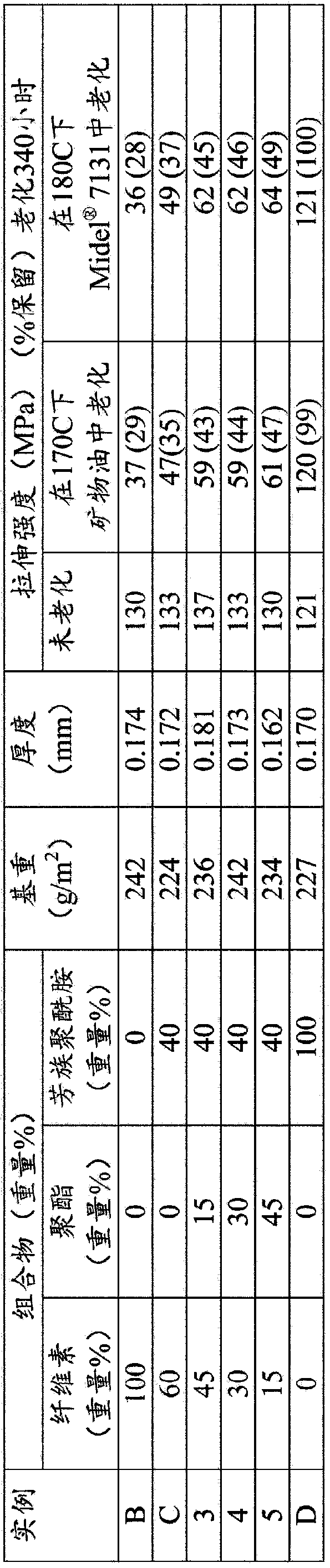

Multilayer structure useful for electrical insulation

The present invention is directed to a multilayer structure comprising: (a) a first layer containing polyester and cellulose wherein (i) the polyester is present in an amount of 0 to 50 weight percent floc and 50 to 100 weight percent fibrid, (ii) the cellulose is present in the form of cellulosic pulp fiber and; (iii) the polyester is present in an amount of 0.5 to 75 weight percent and the cellulose is present in an amount of 25 to 99 weight percent, said percentages on the basis of the polyester and cellulose and; (b) a second layer containing cellulosic pulp fiber with the proviso that the second layer does not contain polyester. The first layer may further comprise an aramid. The multilayer structure is particularly useful in a transformer.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com