High-toughness heat-resistant cable sheathing compound

A cable sheathing material, high toughness technology, applied in the direction of organic insulators, cellulose materials, etc., can solve the problem that the toughness and heat resistance of cable sheathing materials cannot meet the needs of actual use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

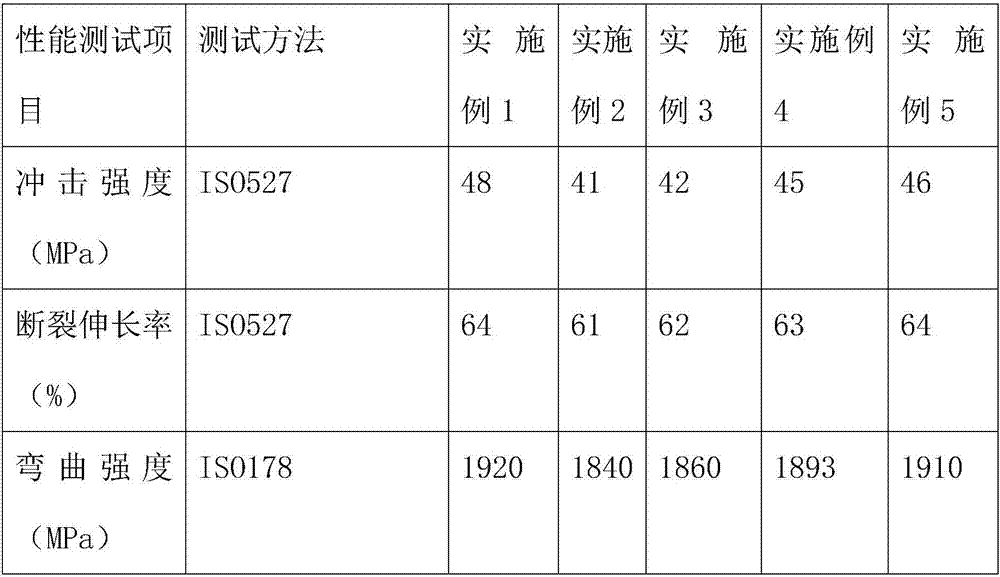

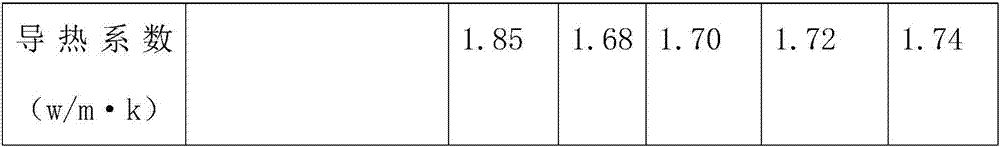

Examples

Embodiment 1

[0015] A high-toughness heat-resistant cable sheath material proposed by the present invention, its raw materials include by weight: 100 parts of modified polylactic acid, 2.5 parts of ethylene-butyl acrylate copolymer, maleic anhydride grafted ethylene-octene copolymer 6 parts, 6 parts of polyphenylene sulfide, 4 parts of aluminum diethylphosphinate, 2.5 parts of polyamide, 4.5 parts of amine polyphosphate, 3 parts of aluminum hypophosphite, 3.5 parts of melamine sodium polyphosphate, 4.5 parts of zinc borate, modified 5 parts of permanent Lyocell fiber, 3.5 parts of glass fiber, 4 parts of modified silicon dioxide, 2.5 parts of nano-zinc oxide, 4 parts of nano-titanium dioxide, and 6 parts of aluminate.

[0016] The modified polylactic acid is prepared according to the following process: 10 parts by weight of lignocellulose are soaked in 5 parts by weight of 5% sodium hydroxide solution at room temperature for 4 hours, then washed with deionized water until neutral, and Air-...

Embodiment 2

[0020] A high-toughness heat-resistant cable sheath material proposed by the present invention, its raw materials include by weight: 80 parts of modified polylactic acid, 1 part of ethylene-butyl acrylate copolymer, maleic anhydride grafted ethylene-octene copolymer 9 parts, 4 parts of polyphenylene sulfide, 6 parts of aluminum diethylphosphinate, 1 part of polyamide, 6 parts of amine polyphosphate, 1 part of aluminum hypophosphite, 5 parts of melamine sodium polyphosphate, 3 parts of zinc borate, modified 6 parts of permanent Lyocell fiber, 2 parts of glass fiber, 5 parts of modified silica, 1 part of nano-zinc oxide, 6 parts of nano-titanium dioxide, and 4 parts of aluminate.

[0021] The modified polylactic acid is prepared according to the following process: 5 parts by weight of lignocellulose are soaked in 8 parts by weight of 4% sodium hydroxide solution at room temperature for 5 hours, then washed with deionized water until neutral, and Air-dry, then dry at 70°C for 14h...

Embodiment 3

[0025] A high-toughness heat-resistant cable sheath material proposed by the present invention, its raw materials include by weight: 120 parts of modified polylactic acid, 4 parts of ethylene-butyl acrylate copolymer, maleic anhydride grafted ethylene-octene copolymer 3 parts, 8 parts of polyphenylene sulfide, 2 parts of aluminum diethylphosphinate, 4 parts of polyamide, 3 parts of polyphosphate amine, 5 parts of aluminum hypophosphite, 2 parts of melamine sodium polyphosphate, 6 parts of zinc borate, modified 4 parts of permanent Lyocell fiber, 5 parts of glass fiber, 3 parts of modified silica, 4 parts of nano-zinc oxide, 2 parts of nano-titanium dioxide, and 8 parts of aluminate.

[0026] The modified polylactic acid is prepared according to the following process: 15 parts by weight of lignocellulose are soaked in 2 parts by weight of 6% sodium hydroxide solution at room temperature for 3 hours, then washed with deionized water until neutral, and Air-dried, then dried at 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com