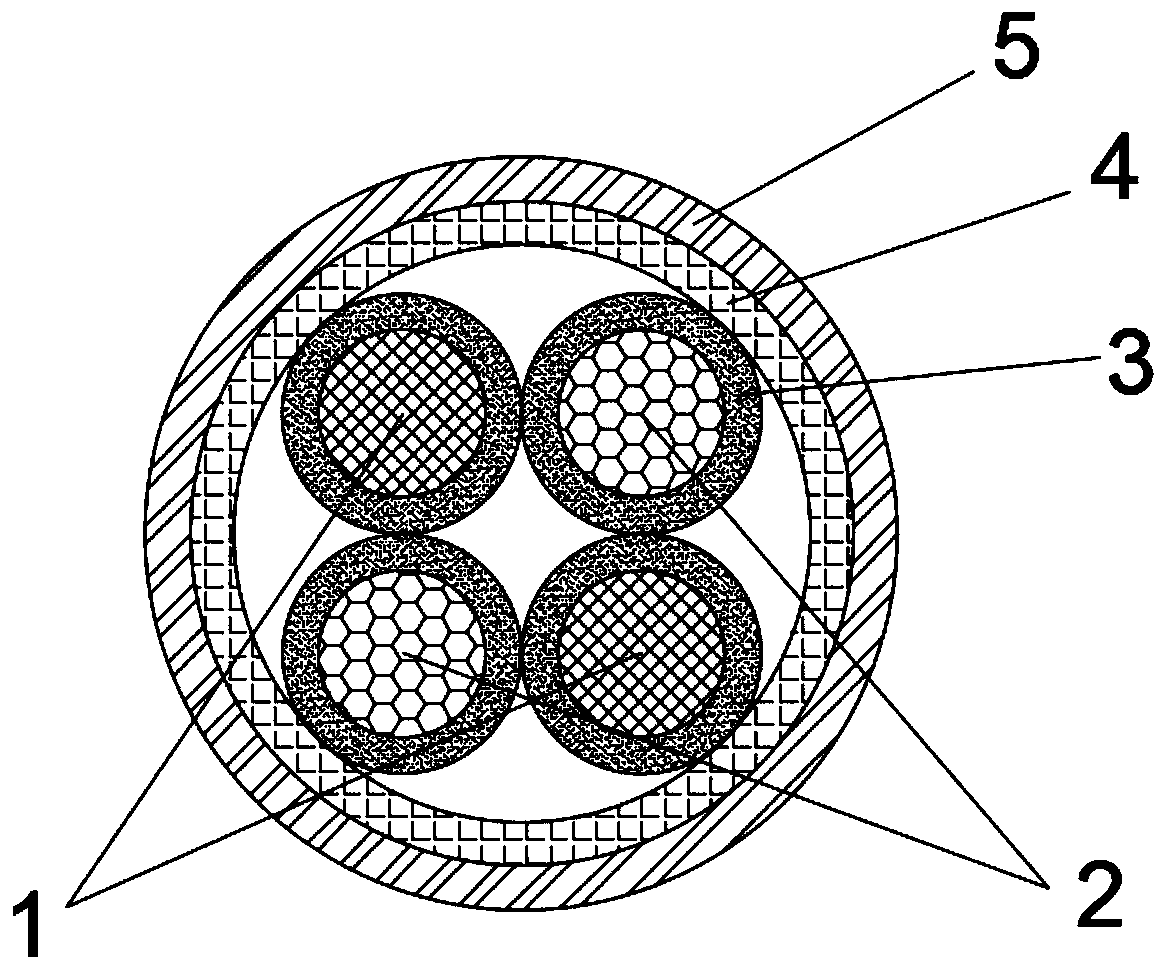

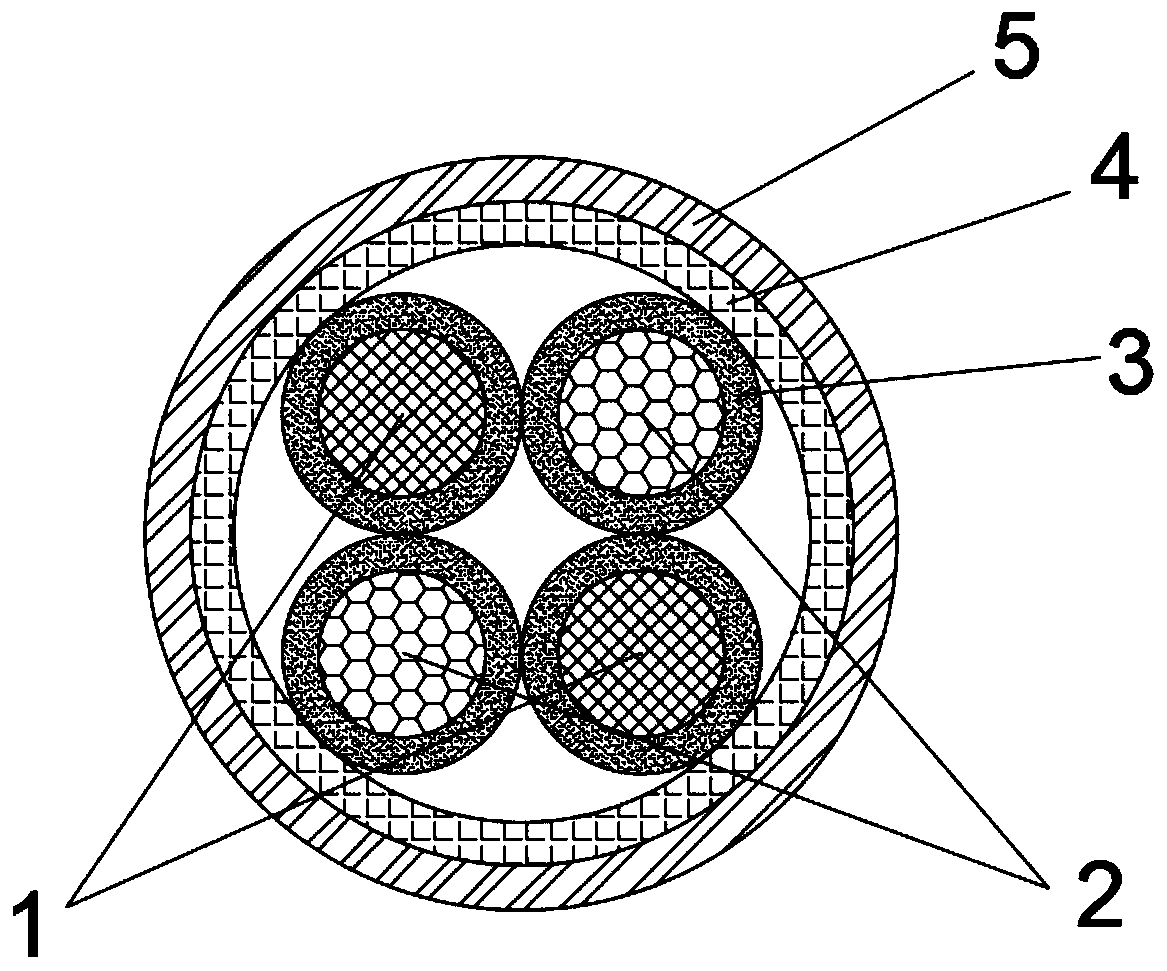

An anti-electromagnetic interference anti-break data cable

An anti-electromagnetic interference and data line technology, applied in the field of data lines, can solve problems such as poor shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the present invention, there is no special limitation on the source of the polyimide fiber paper, and any preparation method known to those skilled in the art or commercially available products can be used. In the present invention, the polyimide fiber paper is preferably prepared by a method comprising the following steps:

[0032] The polyimide fibers are sheared and dispersed in an aqueous solution of sodium dodecylbenzene sulfonate, cleaned with deionized water; then put into a tank beater for beating, and fully decomposed and dispersed to obtain polyimide fibers. The amine fiber slurry uses a cellulose film as a substrate, sprays the polyimide fiber slurry on the substrate by high-pressure airless spraying, and peels off the substrate to obtain a polyimide fiber paper. In the present invention, there is no special limitation on the dosage and concentration of the polyimide fiber and sodium dodecylbenzenesulfonate aqueous solution, and the dosage well known to th...

Embodiment 1

[0053] The polyimide fibers are sheared and dispersed in an aqueous solution of sodium dodecylbenzene sulfonate, cleaned with deionized water; then put into a tank beater for beating, and fully decomposed and dispersed to obtain polyimide fibers. For the amine fiber slurry, the cellulose film is used as the substrate, and the polyimide fiber slurry is sprayed onto the substrate by high-pressure airless spraying, and the substrate is peeled off to obtain polyimide fiber paper (thickness is 1mm).

[0054] Using sodium dodecylsulfonate (SDBS) as a debonding agent, the para-aramid chopped fibers were dissolved in warm water at 30°C, stirred for 3 minutes to fully decompose, and then washed several times with deionized water before use. Among them, the mass ratio of sodium dodecyl sulfonate, para-aramid chopped fibers and warm water is 0.05:1:200.

[0055] Using polyethylene oxide (PEO) as a dispersant, the para-aramid pulp fiber was dissolved in deionized water, and stirred for 3 ...

Embodiment 2

[0063] The polyimide fibers are sheared and dispersed in an aqueous solution of sodium dodecylbenzene sulfonate, cleaned with deionized water; then put into a tank beater for beating, and fully decomposed and dispersed to obtain polyimide fibers. For the amine fiber slurry, the cellulose film is used as the substrate, and the polyimide fiber slurry is sprayed onto the substrate by high-pressure airless spraying, and the substrate is peeled off to obtain polyimide fiber paper (thickness is 0.05 mm).

[0064] Using sodium dodecylsulfonate (SDBS) as a debonding agent, the para-aramid chopped fibers were dissolved in warm water at 50°C, stirred for 5 minutes to fully decompose, and then washed several times with deionized water before use. Among them, the mass ratio of sodium dodecyl sulfonate, para-aramid chopped fibers and warm water is 0.1:1:300.

[0065] Using polyethylene oxide (PEO) as a dispersant, the para-aramid pulp fiber was dissolved in deionized water, and stirred for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com