A slurry suitable for aluminum nitride substrate and preparation method thereof

An aluminum nitride and paste technology, which is applied in the direction of heterogeneous insulating materials, metal oxides, plastic/resin/wax insulators, etc., can solve the problem of difficult to apply the use process of aluminum nitride substrates, and achieve excellent screen printing performance , the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare the slurry suitable for aluminum nitride substrates according to the following steps.

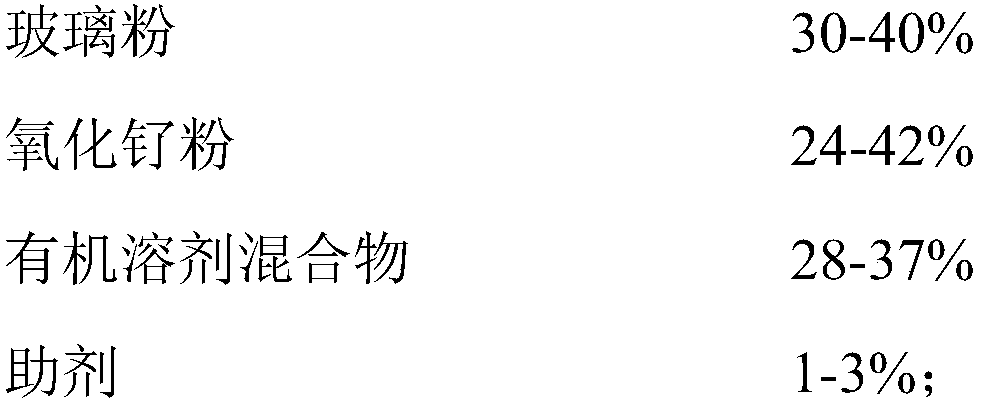

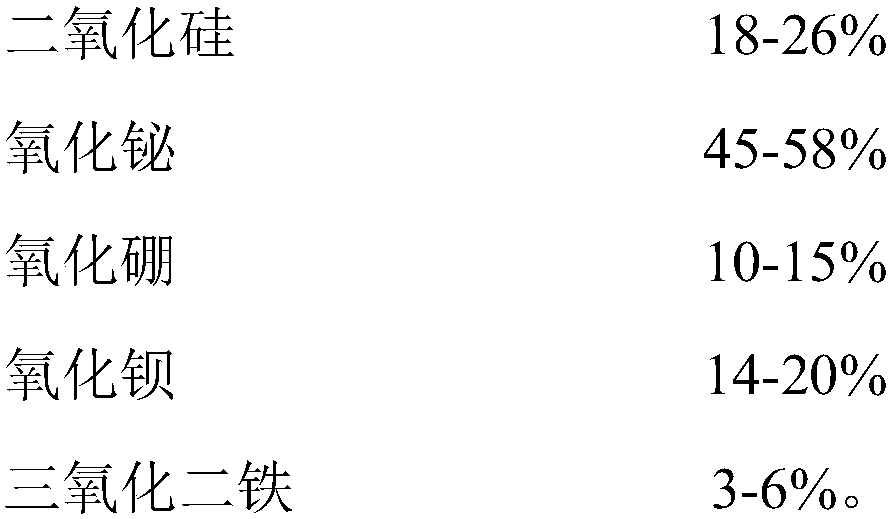

[0026] Preparation of glass powder: by mass percentage, weigh 18-26% of analytically pure grade silicon dioxide, 45-58% of bismuth oxide, 10-15% of boron oxide, 14-20% of barium oxide, 3-6% After mixing the ferric oxide, transfer it to a corundum crucible or a platinum crucible, place it in a box-type resistance furnace and heat it up to 1100-1500°C to melt and keep it for 15-30 minutes, then quench the molten liquid with water to obtain glass frit, and then crush the glass frit And ball milled into glass powder with particle size within 10μm.

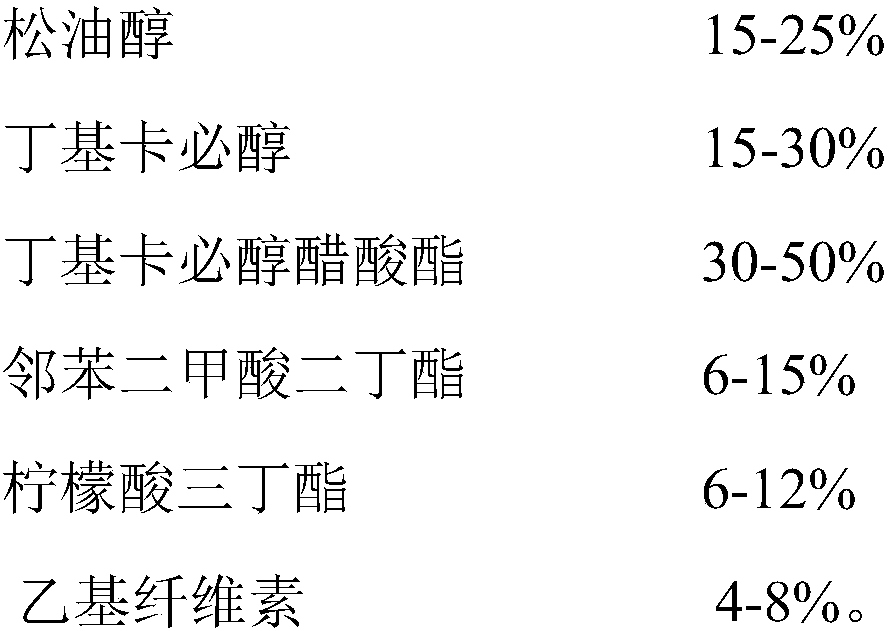

[0027] Prepare the organic phase: weigh 15-25% of terpineol, 20-30% of butyl carbitol, 30-50% of butyl carbitol acetate, 8-15% of phthalate Dibutyl diformate, 8-12% tributyl citrate and 4-8% ethyl cellulose are placed in a dispersion tank and stirred and dispersed for more than 4 hours to obtain a transparent organic solvent mixture....

Embodiment 2

[0034] According to mass percentage, weigh 40% of the glass powder prepared above, 33% of the above-mentioned organic solvent mixture, 3% of additives and 24% of ruthenium oxide powder with a purity greater than 99.9% and a particle size of less than 8 μm, and stir and three-roll grinding , Filtration and defoaming processes to obtain the required slurry.

Embodiment 3

[0036] According to mass percentage, weigh 38% of the above-mentioned prepared glass powder, 33% of the above-mentioned organic solvent mixture, 2% of additives and 27% of ruthenium oxide powder with a purity greater than 99.9% and a particle size of less than 8 μm, after stirring and three-roll grinding , Filtration and defoaming processes to obtain the required slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com