Electroplatable polycarbonate composition and preparation method thereof

A polycarbonate and polycarbonate resin technology, applied in the field of engineering plastics, can solve the problems of poor solvent resistance of MBS, easy foaming on the surface of the coating, and low strength of the substrate, so as to enhance cold resistance, enhance low temperature resistance, and prevent The hardening and brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

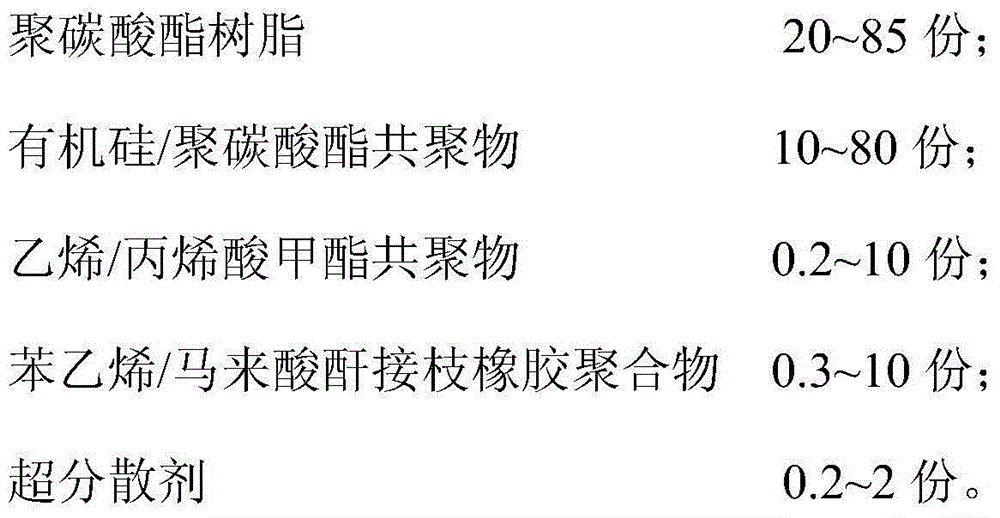

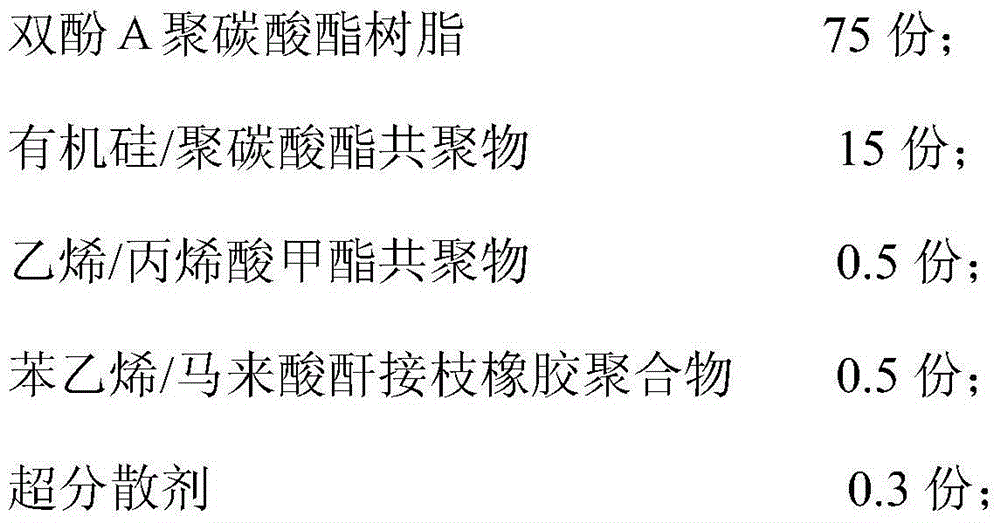

[0039] Embodiment 1: The electroplatable polycarbonate composition of this embodiment includes the following components in parts by mass:

[0040]

[0041]

[0042] The method for preparing the above-mentioned polycarbonate composition comprises the following steps:

[0043] Reduce meshing blocks in the screw combined melting section of the twin-screw extruder, add ZME toothed screw elements in the mixing and homogenizing section, and combine the twin-screw extruder into a low-shear high-dispersion screw;

[0044] Stir the above components evenly to prepare a mixture, put the mixture into the above-mentioned adjusted twin-screw extruder, heat and melt it at 290°C and a rotation speed of 400r / min, and make the mixture blend and mold Chemicalization, shearing dispersion, extruding and granulating under vacuum pressure of -0.04Mpa, drawing a strip, cooling in a water tank, dehydrating, and granulating to obtain a polycarbonate composition that can be electroplated.

Embodiment 2

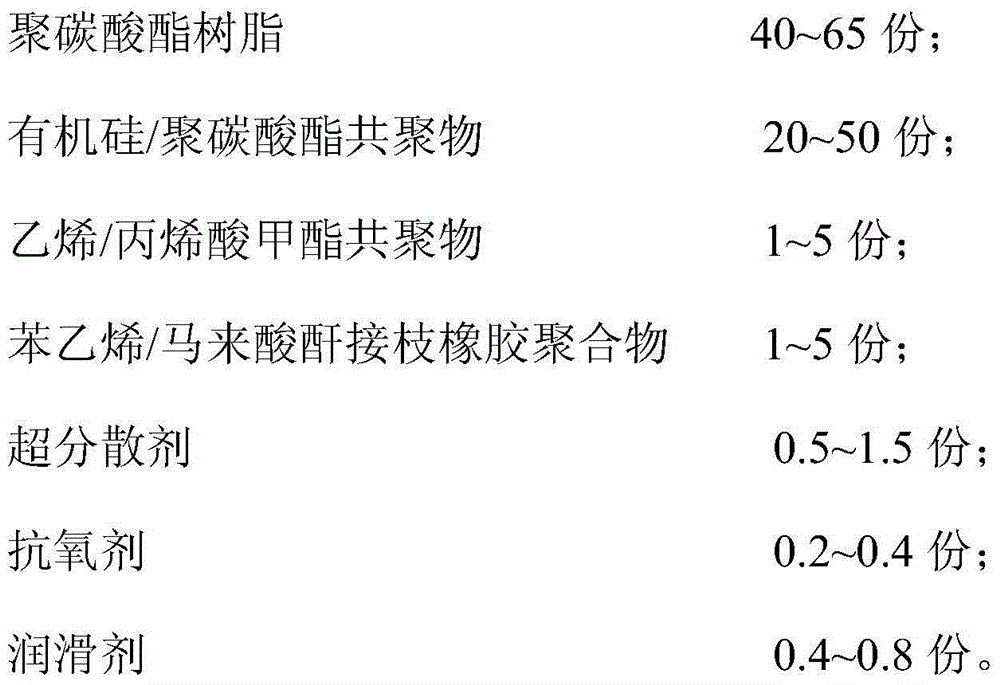

[0045] Embodiment 2: The polycarbonate composition that can be electroplated in this embodiment includes the following components in parts by mass: .

[0046]

[0047] The method for preparing the above-mentioned flame-retardant polycarbonate composition is as follows:

[0048] Reduce meshing blocks in the screw combined melting section of the twin-screw extruder, do not use reverse thread elements in the mixing and homogenizing section, and combine the twin-screw extruder into a low-shear high-dispersion screw;

[0049] Stir the above components evenly to prepare a mixture, put the mixture into the above-mentioned adjusted twin-screw extruder, heat and melt at 220°C and a rotation speed of 800r / min, and blend the mixture Plasticizing, shearing and dispersing, extruding and granulating at a vacuum pressure of -0.04Mpa, drawing a strip, cooling in a water tank, dehydrating, and dicing to obtain a polycarbonate composition that can be electroplated.

[0050] The polycarbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com