A high-pressure resistant steam turbine blade and its production process

A technology for steam turbine blades and production processes, which is applied in manufacturing tools, heat treatment equipment, furnaces, etc., to achieve the effect of ensuring corrosion resistance, uniform and stable structure, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

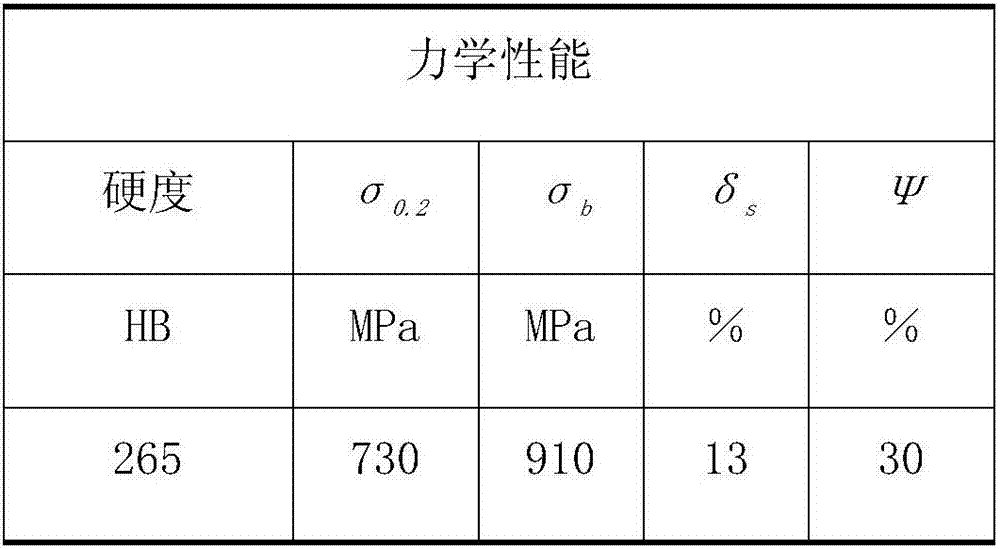

Embodiment 1

[0048] This embodiment provides a high-pressure steam turbine blade, the mass percent of its chemical composition is: C: 0.019%, Si: 0.09%, Mn: 0.83%, Ni: 0.55%, Cr: 1.7%, Mo: 0.11%, Co : 3.9%, V: 4.26%, Nb: 0.01%, Cu: 0.03%, Al: 6.21%, N: 0.007%, Ti: 0.23%, rare earth metal: 0.08%, the balance is Fe; chemical composition of rare earth metal The mass percentages are: cerium: 1%, neodymium: 11%, promethium: 4%, gadolinium: 7%, lutetium: 2%, dysprosium: 8%, lanthanum: 9%, and the balance is erbium.

[0049] The production process of the high-pressure steam turbine blade of the present embodiment, wherein:

[0050] The annealing process: after hot forging, heat preservation at 765°C for 16 minutes, then furnace cool to 258°C, heat preservation for 10 minutes, and finally cool to room temperature;

[0051] The tempering process: the tempering temperature is 703°C, and the temperature is kept for 15 minutes after reaching the temperature, and then air-cooled to room temperature; ...

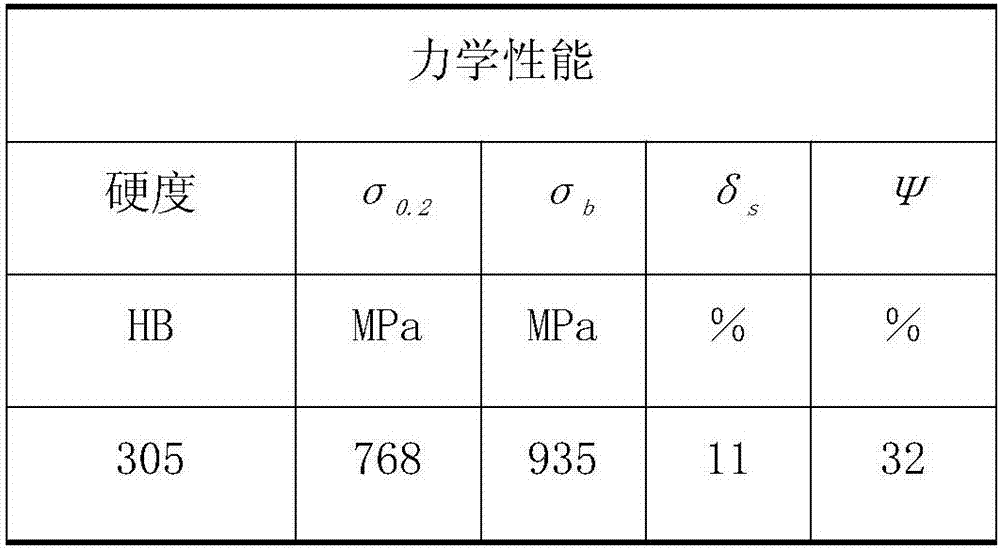

Embodiment 2

[0061] This embodiment provides a high-pressure steam turbine blade, the mass percent of its chemical composition is: C: 0.021%, Si: 0.11%, Mn: 0.85%, Ni: 0.57%, Cr: 1.9%, Mo: 0.13%, Co : 4.1%, V: 4.28%, Nb: 0.03%, Cu: 0.05%, Al: 6.23%, N: 0.009%, Ti: 0.25%, rare earth metal: 0.10%, the balance is Fe; chemical composition of rare earth metal The mass percentages are: cerium: 3%, neodymium: 9%, promethium: 6%, gadolinium: 5%, lutetium: 4%, dysprosium: 6%, lanthanum: 11%, and the balance is erbium.

[0062] The production process of the high-pressure steam turbine blade of the present embodiment, wherein:

[0063] The annealing process: after hot forging, heat preservation at 767°C for 14 minutes, then furnace cool to 260°C, heat preservation for 8 minutes, and finally cool to room temperature;

[0064] The tempering process: the tempering temperature is 705°C, and the temperature is kept for 13 minutes after reaching the temperature, and then air-cooled to room temperature;

...

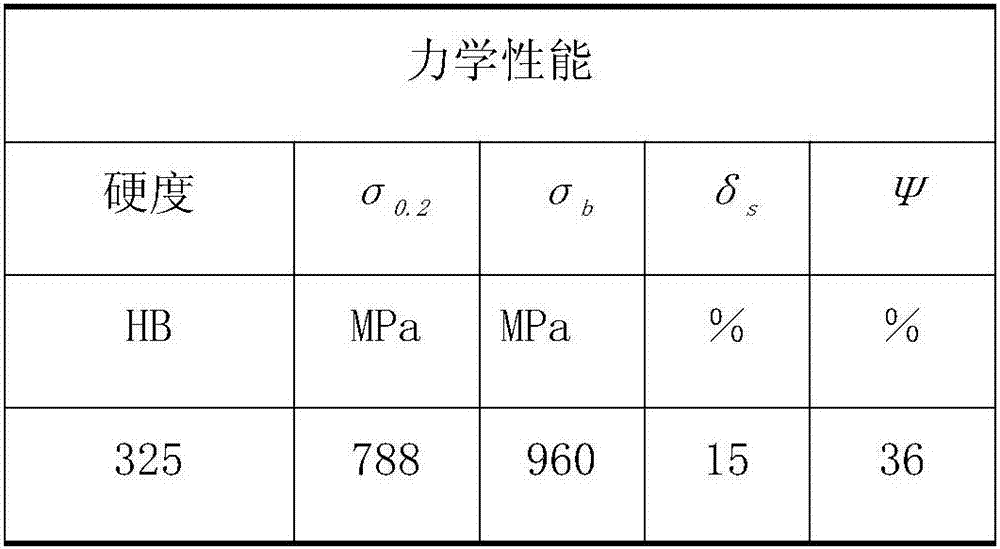

Embodiment 3

[0074] This embodiment provides a high-pressure steam turbine blade, the mass percent of its chemical composition is: C: 0.020%, Si: 0.10%, Mn: 0.84%, Ni: 0.56%, Cr: 1.8%, Mo: 0.12%, Co : 4.0%, V: 4.27%, Nb: 0.02%, Cu: 0.04%, Al: 6.22%, N: 0.008%, Ti: 0.24%, rare earth metal: 0.09%, the balance is Fe; chemical composition of rare earth metal The mass percentages are: cerium: 2%, neodymium: 10%, promethium: 5%, gadolinium: 6%, lutetium: 3%, dysprosium: 7%, lanthanum: 10%, and the balance is erbium.

[0075] The production process of the high-pressure steam turbine blade of the present embodiment, wherein:

[0076] The annealing process: after hot forging, keep warm at 766°C for 15 minutes, then furnace cool to 259°C, keep warm for 9 minutes, and finally cool to room temperature;

[0077] The tempering process: the tempering temperature is 704 ° C, and after reaching the temperature, it is kept for 14 minutes, and then air-cooled to room temperature;

[0078] The stress-relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com