Water-erosion-preventing turbine blade

A steam turbine blade and blade technology, applied in the directions of blade support elements, mechanical equipment, engine elements, etc., can solve problems such as affecting the service life of the blades, and the blades are easily eroded by water droplets, so as to increase the utilization rate, improve the dehumidification performance, and avoid the The effect of water drop erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

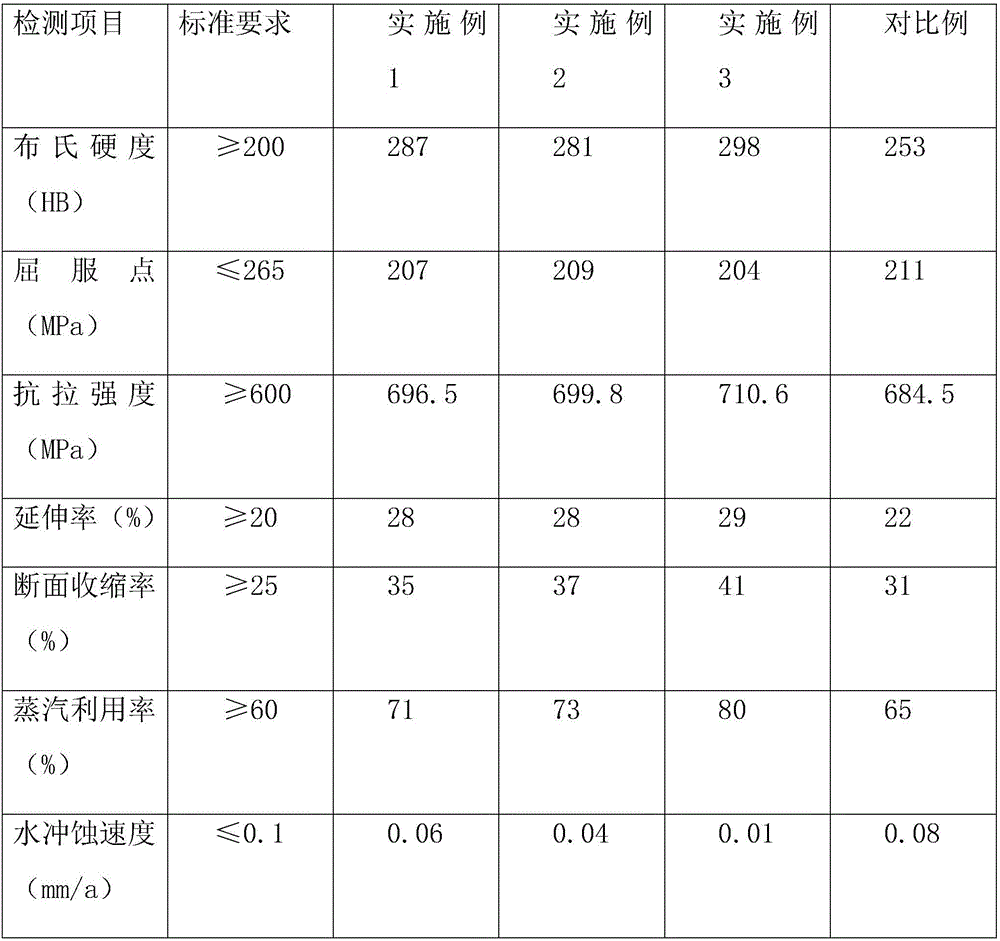

Embodiment 1

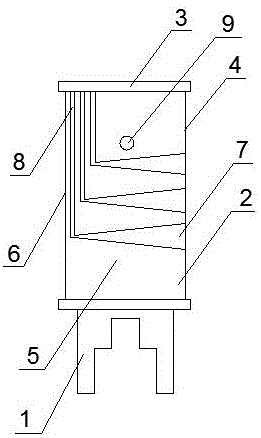

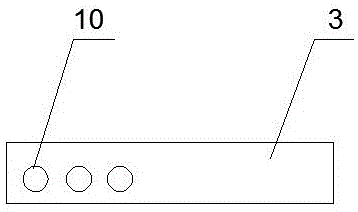

[0033] An anti-corrosion steam turbine blade provided in this embodiment has a structure such as figure 1 As shown, it includes the blade root 1, the blade shape 2 and the blade crown 3, the blade root 1, the blade shape 2, and the blade crown 3 are connected in sequence, the blade root 1 is a fork-shaped blade root 1, and the blade shape 2 includes the intake edge 4, the inner The arc 5, the air outlet edge 6 and the outer arc, the middle and upper part of the airfoil 2 are provided with tension holes 9, and the airfoil 2 is provided with an air guide groove 7 and a dehumidification groove 8,

[0034] There are at least two air guide grooves 7, and the air guide grooves 7 are all parallel to the air outlet edge 6, and the width of the air guide groove 7 gradually narrows from the air inlet edge 4 to the air outlet edge 6. One end of the air guide groove 7 is located at the inlet side 4, the air guide groove 7 is from the air inlet side 4 to the air outlet side 6,

[0035] On...

Embodiment 2

[0047] An anti-corrosion steam turbine blade provided in this embodiment has a structure such as figure 1 As shown, it includes the blade root 1, the blade shape 2 and the blade crown 3, the blade root 1, the blade shape 2, and the blade crown 3 are connected in sequence, the blade root 1 is a fork-shaped blade root 1, and the blade shape 2 includes the intake edge 4, the inner The arc 5, the air outlet edge 6 and the outer arc, the middle and upper part of the airfoil 2 are provided with tension holes 9, and the airfoil 2 is provided with an air guide groove 7 and a dehumidification groove 8,

[0048] There are at least two air guide grooves 7, and the air guide grooves 7 are all parallel to the air outlet edge 6, and the width of the air guide groove 7 gradually narrows from the air inlet edge 4 to the air outlet edge 6. One end of the air guide groove 7 is located at the inlet side 4, the air guide groove 7 is from the air inlet side 4 to the air outlet side 6,

[0049] On...

Embodiment 3

[0061] An anti-corrosion steam turbine blade provided in this embodiment has a structure such as figure 1 As shown, it includes the blade root 1, the blade shape 2 and the blade crown 3, the blade root 1, the blade shape 2, and the blade crown 3 are connected in sequence, the blade root 1 is a fork-shaped blade root 1, and the blade shape 2 includes the intake edge 4, the inner The arc 5, the air outlet edge 6 and the outer arc, the middle and upper part of the airfoil 2 are provided with tension holes 9, and the airfoil 2 is provided with an air guide groove 7 and a dehumidification groove 8,

[0062] There are at least two air guide grooves 7, and the air guide grooves 7 are all parallel to the air outlet edge 6, and the width of the air guide groove 7 gradually narrows from the air inlet edge 4 to the air outlet edge 6. One end of the air guide groove 7 is located at the inlet side 4, the air guide groove 7 is from the air inlet side 4 to the air outlet side 6,

[0063] On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com