Granite decorative panels

A technology of decorative panels and granite, applied in building components, covering/lining, fire protection, etc., can solve the problems of poor moisture resistance and moisture resistance of the surface coating layer, separation and peeling off of the substrate surface, and unevenness, etc., to achieve obvious decorative effects and overall Reasonable and small shrinkage gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

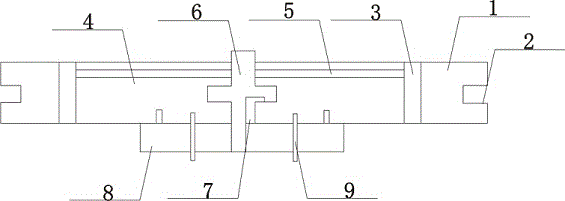

[0013] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0014] Such as figure 1 The shown preferred embodiment of the granite decorative board of the present invention includes a decorative board body 1, which is provided with connecting grooves 2 on both sides of the decorative board body 1, and a vermiculite board 3 is provided near the connecting groove 2 of the decorative board body 1, and the vermiculite board 3 is vertical. The two vermiculite boards 3 are installed on the decorative board body 1, and the two vermiculite boards 3 are connected with a paint layer 5, and the lower surface of the paint layer 5 is installed with an insulation board 4, and the thickness of the insulation board 4 is greater than the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com