Patents

Literature

40results about How to "Prevent arching deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

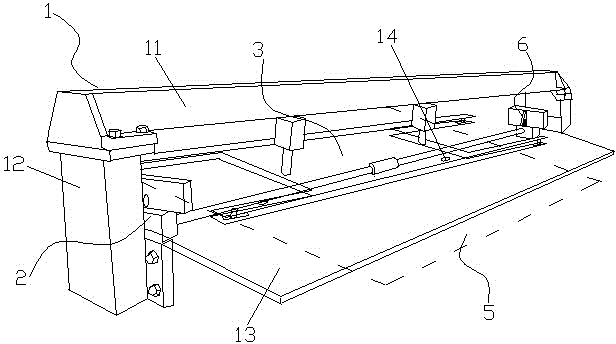

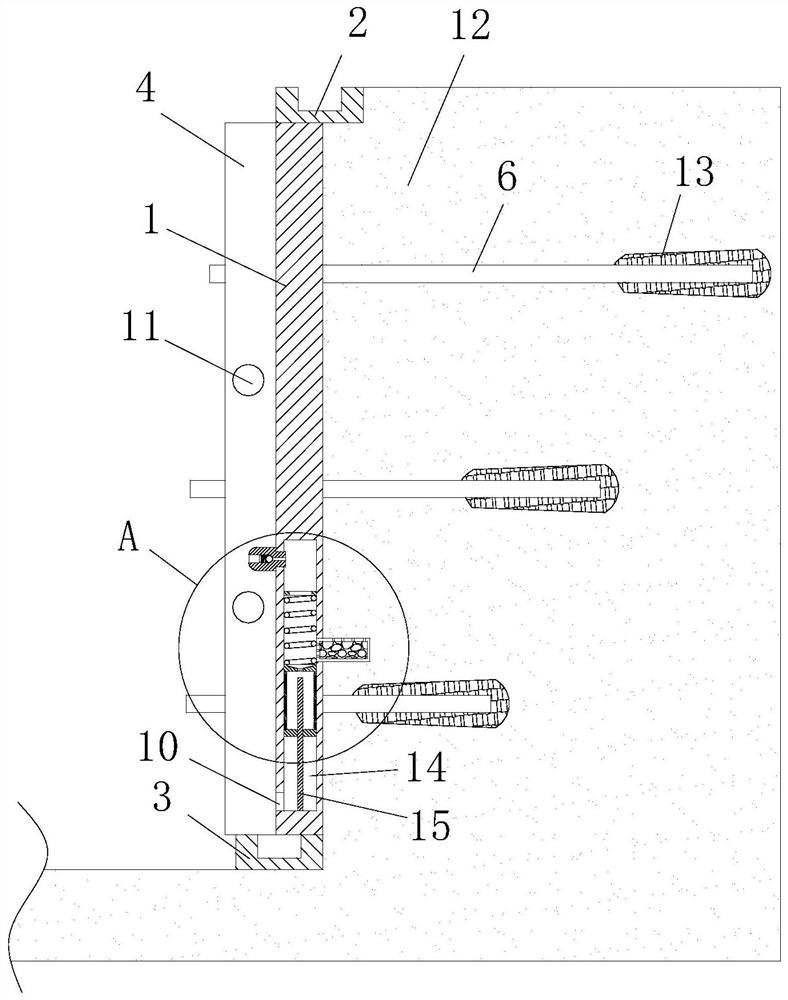

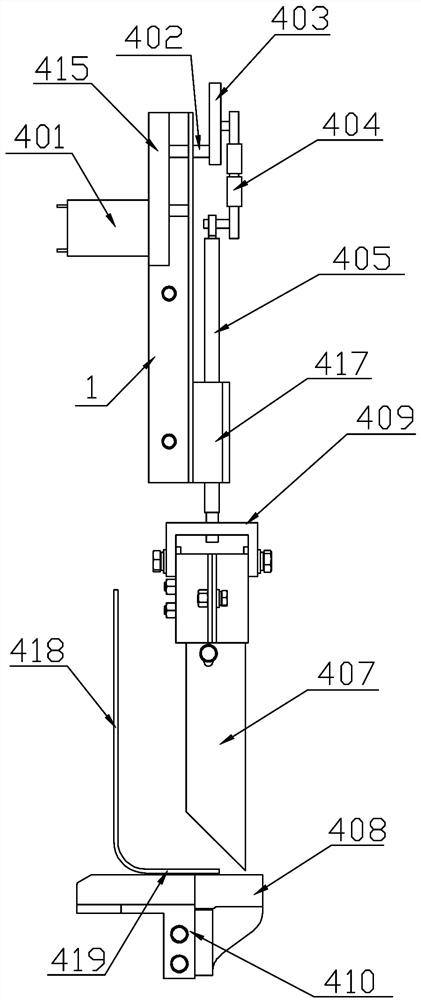

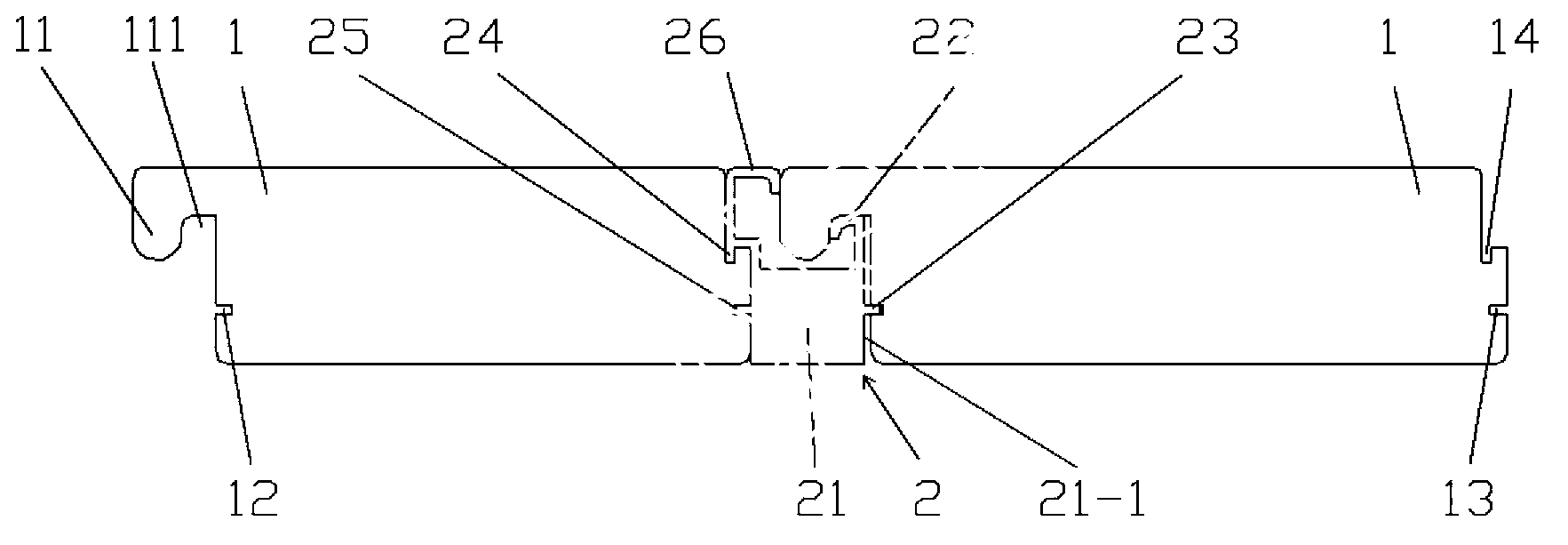

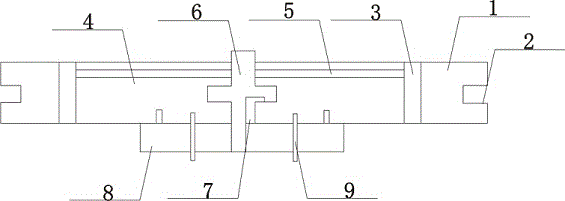

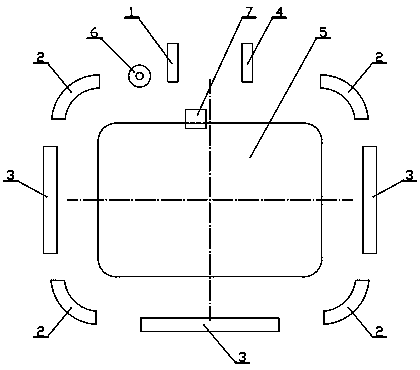

Pressing plate type side guide centering device

ActiveCN105290654APrevent arching deformationOvercome vulnerabilityWelding/cutting auxillary devicesAuxillary welding devicesStrip steelGuiding center

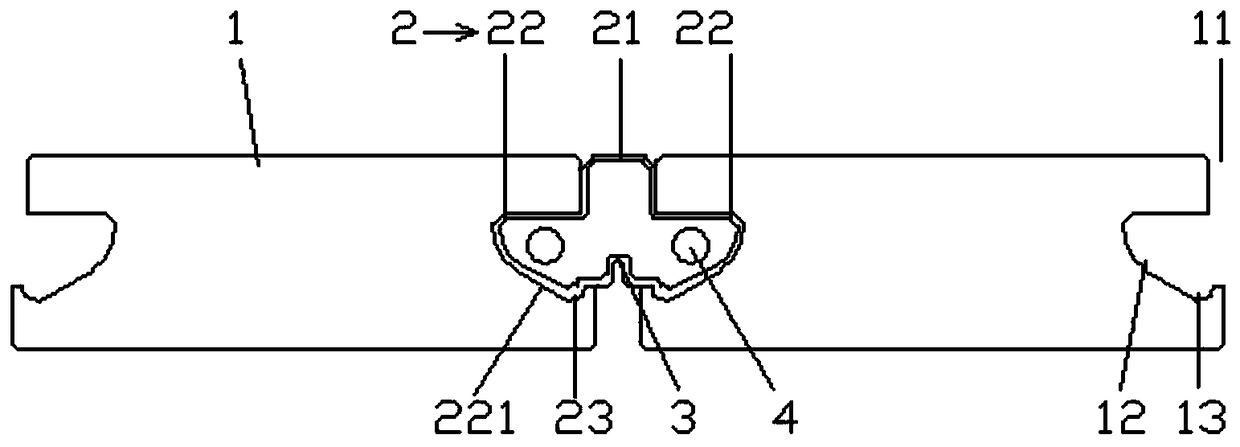

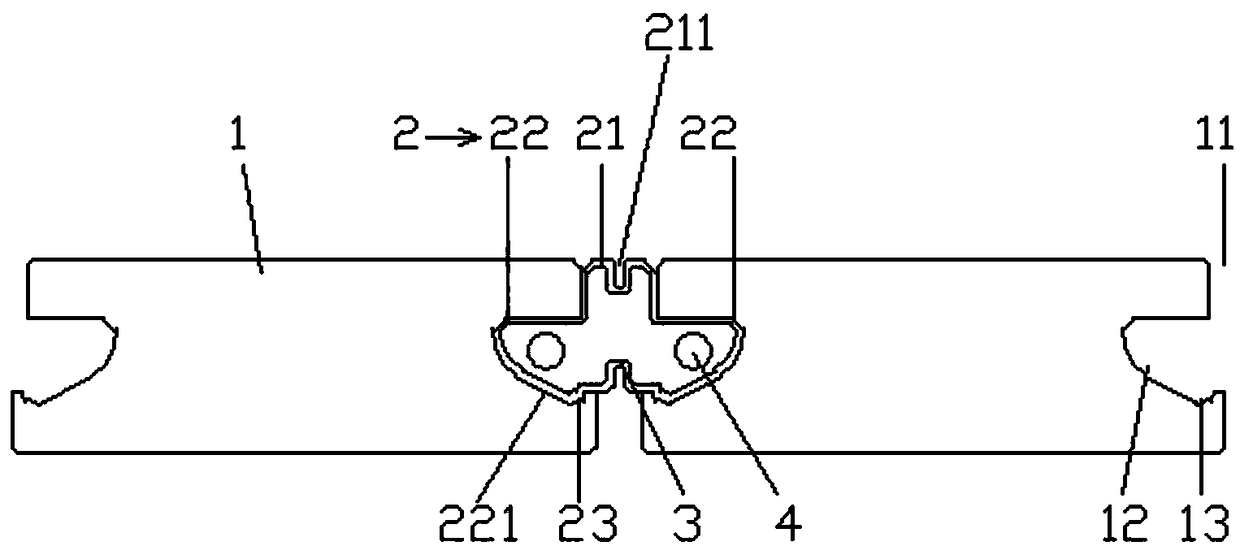

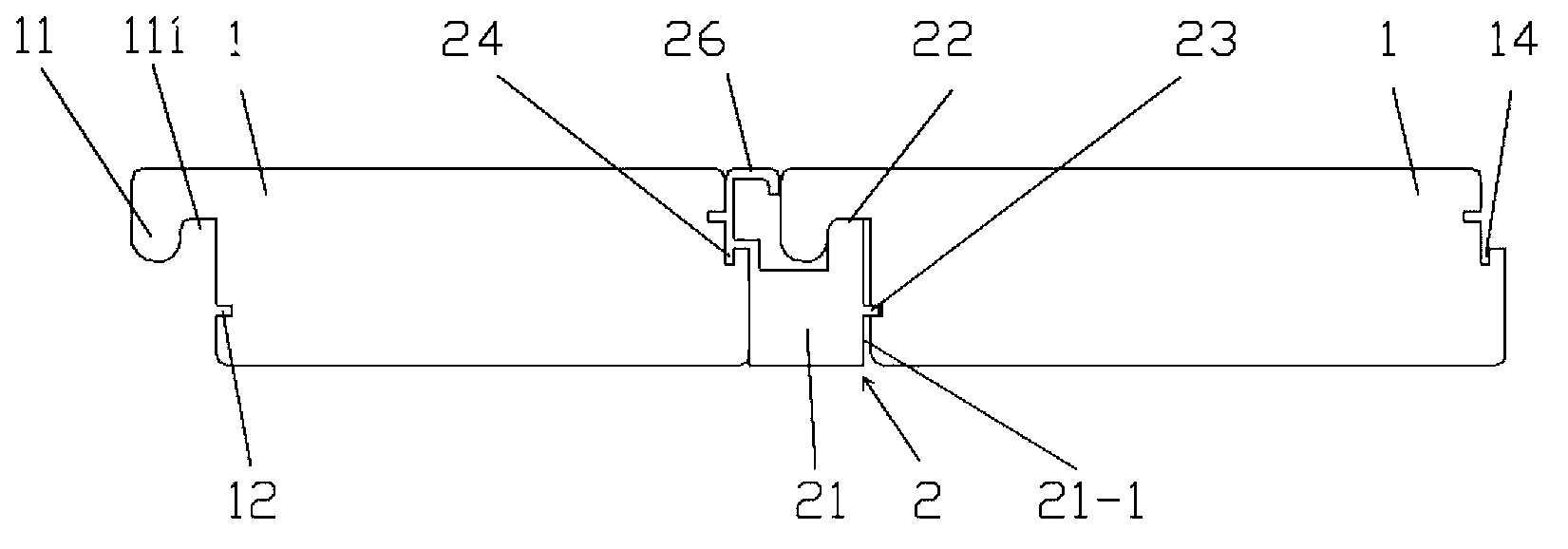

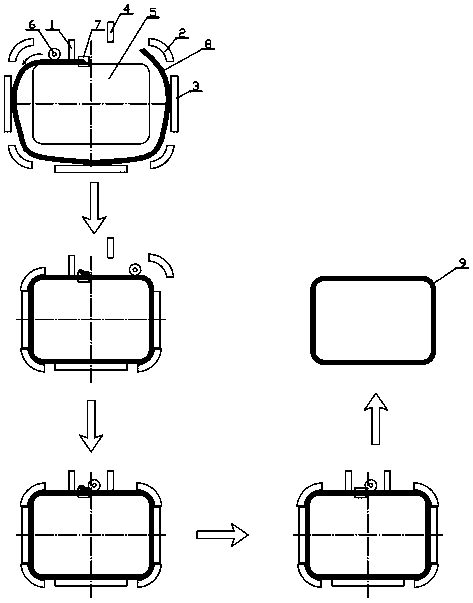

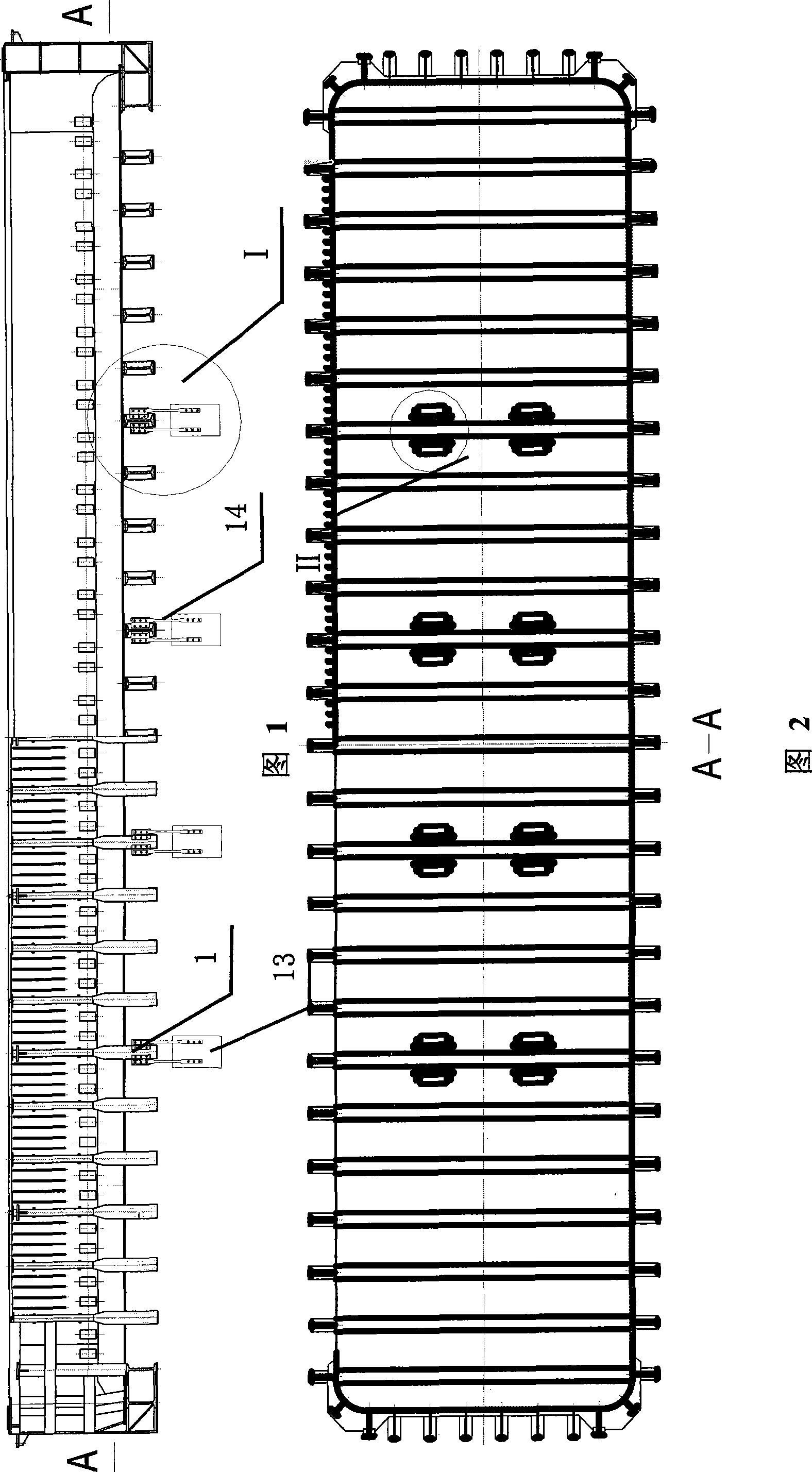

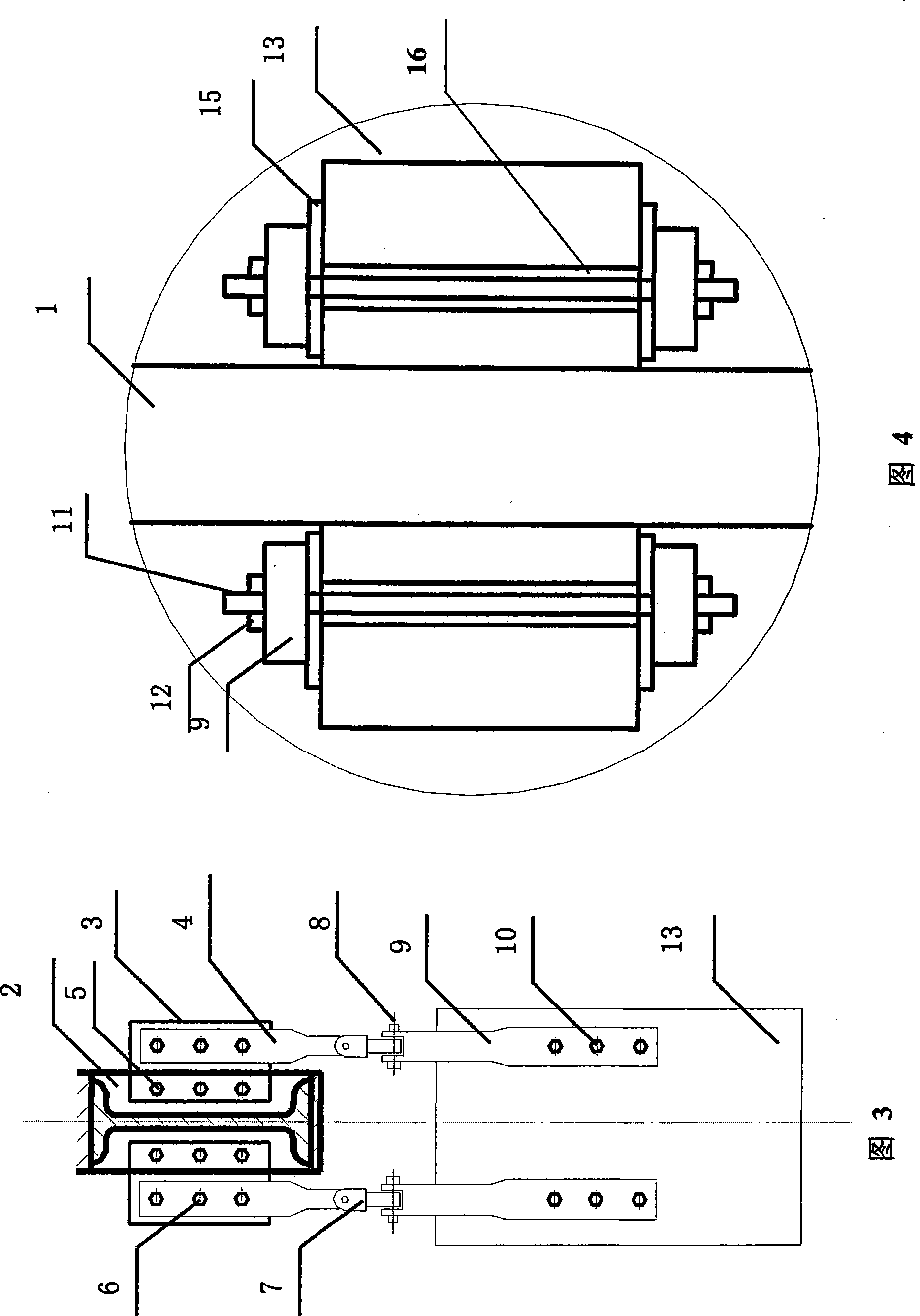

The invention relates to the field of centering mechanisms of cold rolling finished product machine set welding machines, in particular to a side guide centering device. According to the pressing plate type side guide centering device, a movable pressing plate mechanism comprises a lower layer pressing plate, an upper layer support plate and a drive device. The edges of the lower layer pressing plate and the upper layer support plate are supported and connected through connection rods. The parts where the connection rods make contact with the lower layer pressing plate and / or the upper layer support plate are provided with slide grooves. The connection rods slide in the slide grooves freely. A deformation sensor is arranged in the middle between the lower layer pressing plate and the upper layer support plate. The lower layer pressing plate and the upper layer support plate are driven by the drive device to move synchronously to press strip steel. A controller controls and is connected with a stepping motor and the deformation sensor which are in a centering drive mechanism. According to the pressing plate type side guide centering device, the strip steel is prevented from humping deformation, and when the strip steel humps, a side guide plate can be controlled to stop running through a signal of the deformation sensor, so that the centering accuracy and effectiveness in the process in which thin strip steel is centered through the centering device are effectively improved, and the welding efficiency of the welding machines is improved and stabilized.

Owner:BAOSHAN IRON & STEEL CO LTD

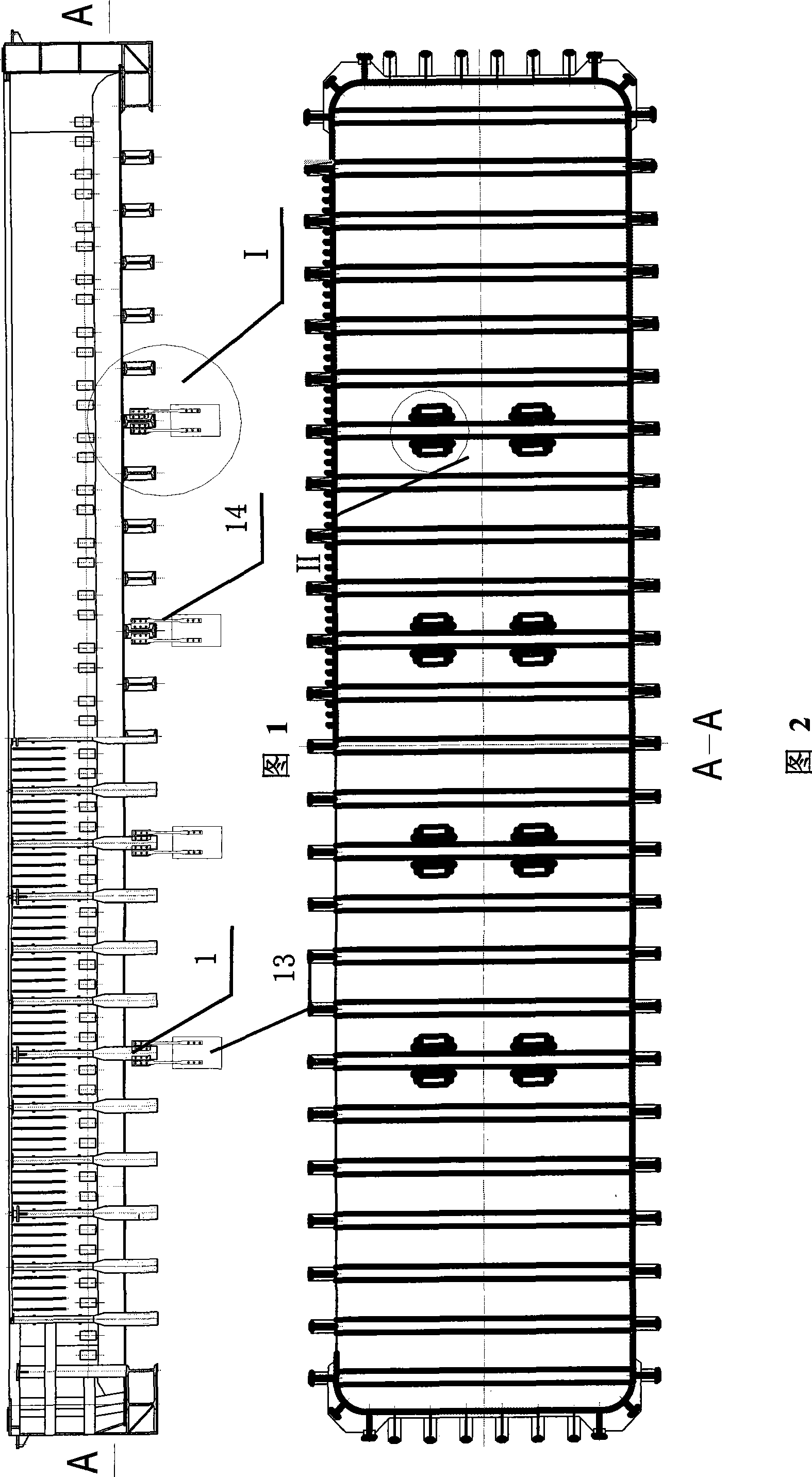

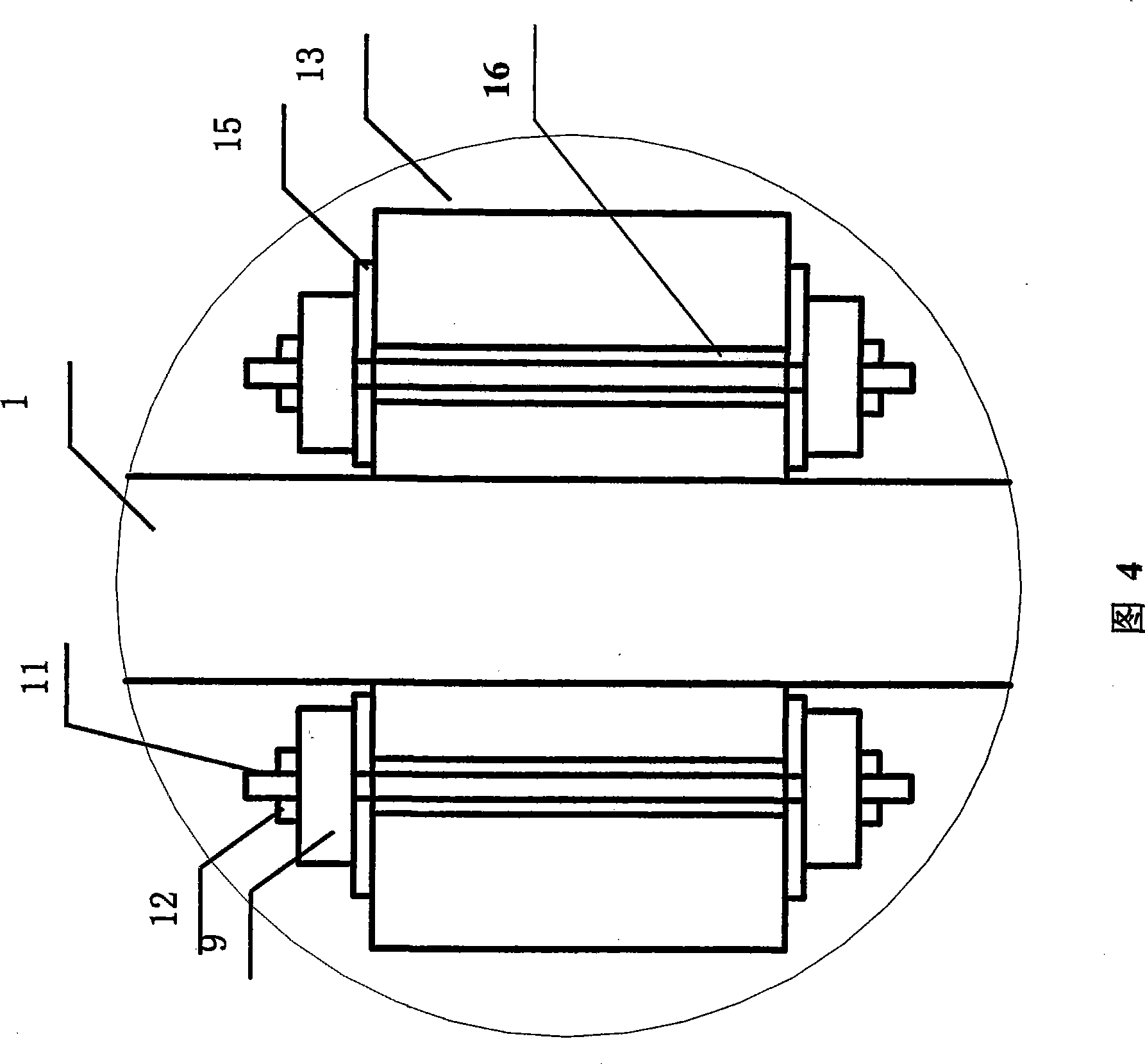

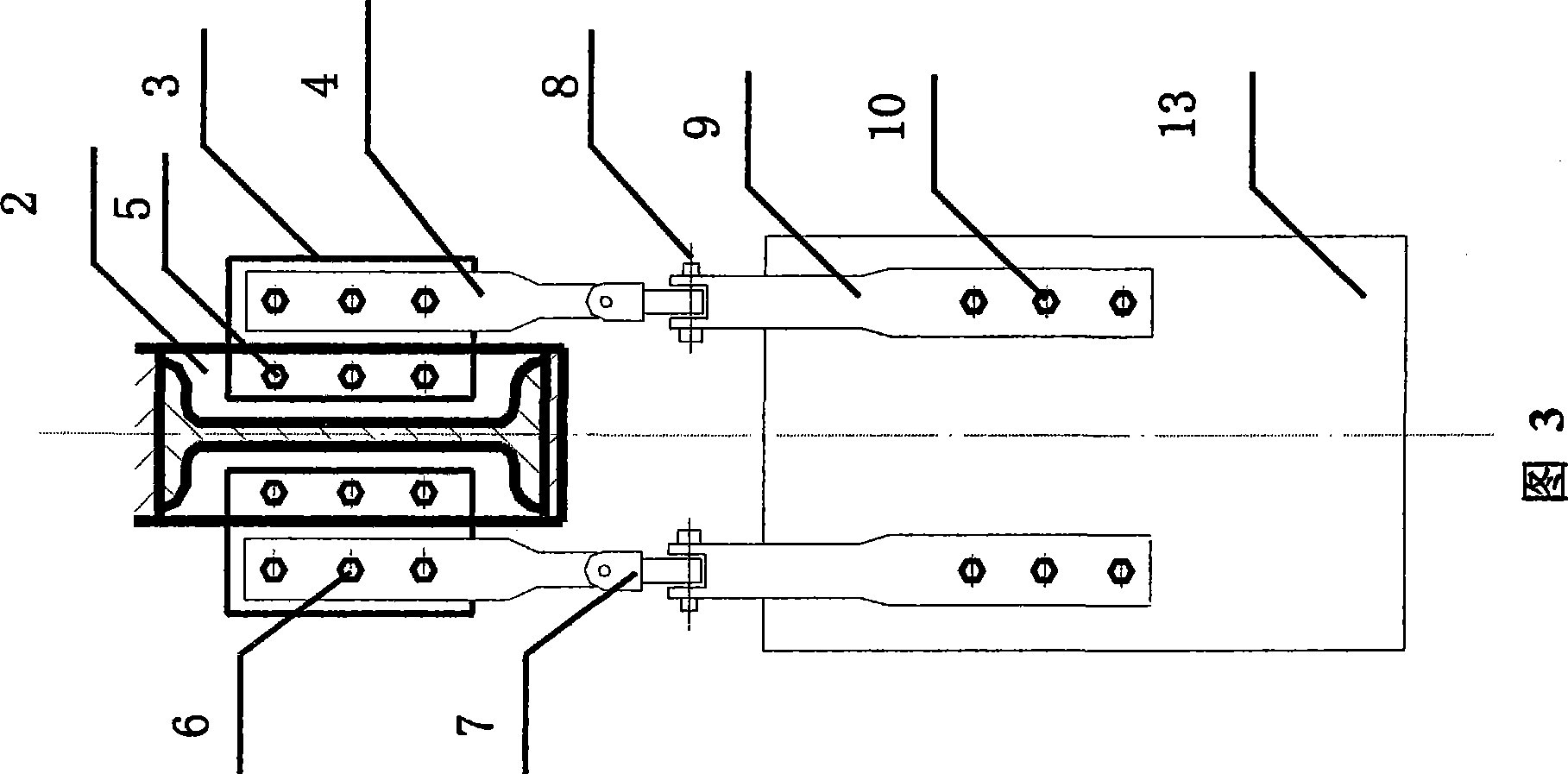

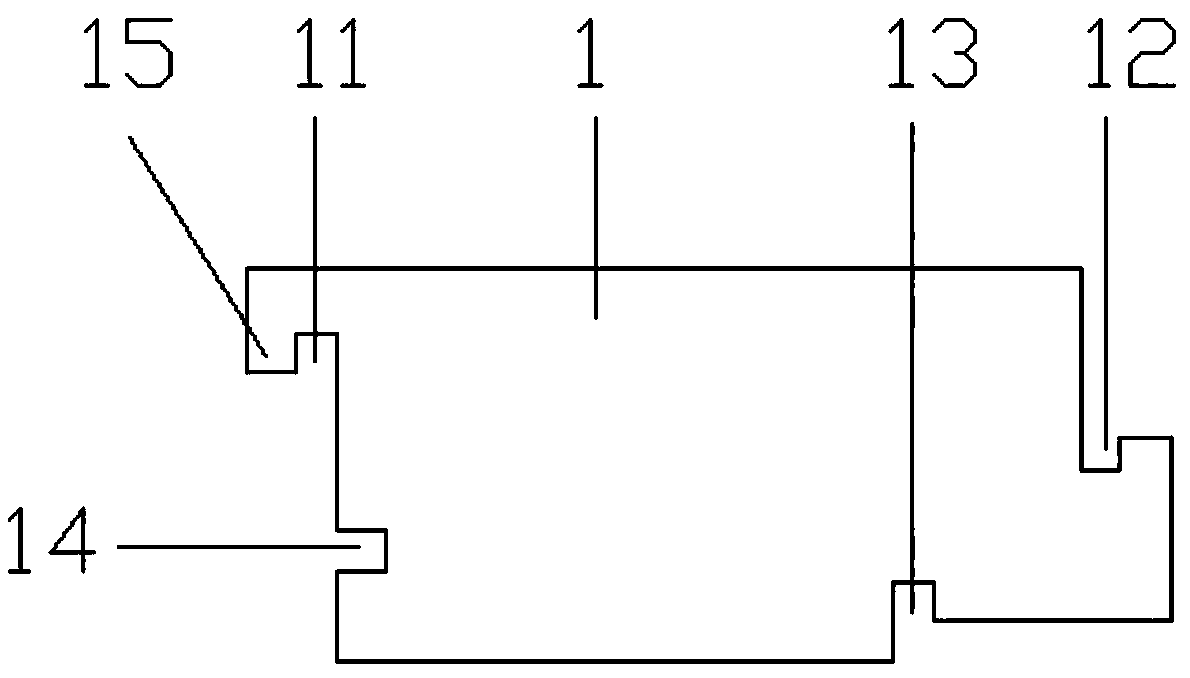

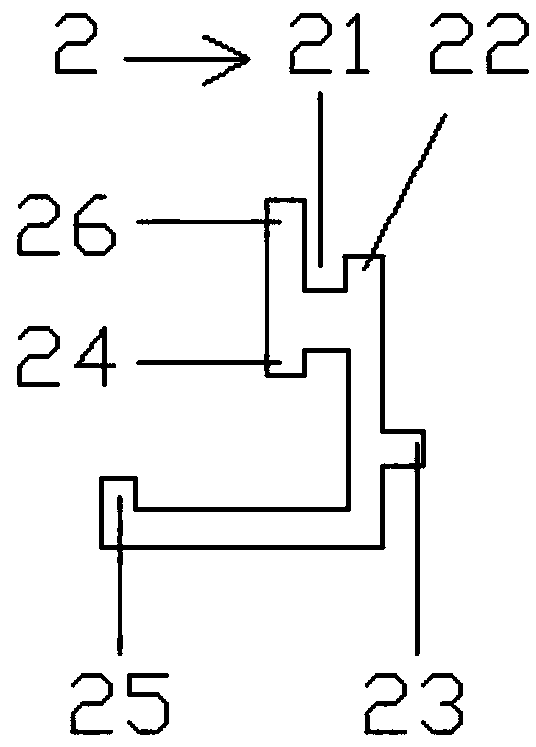

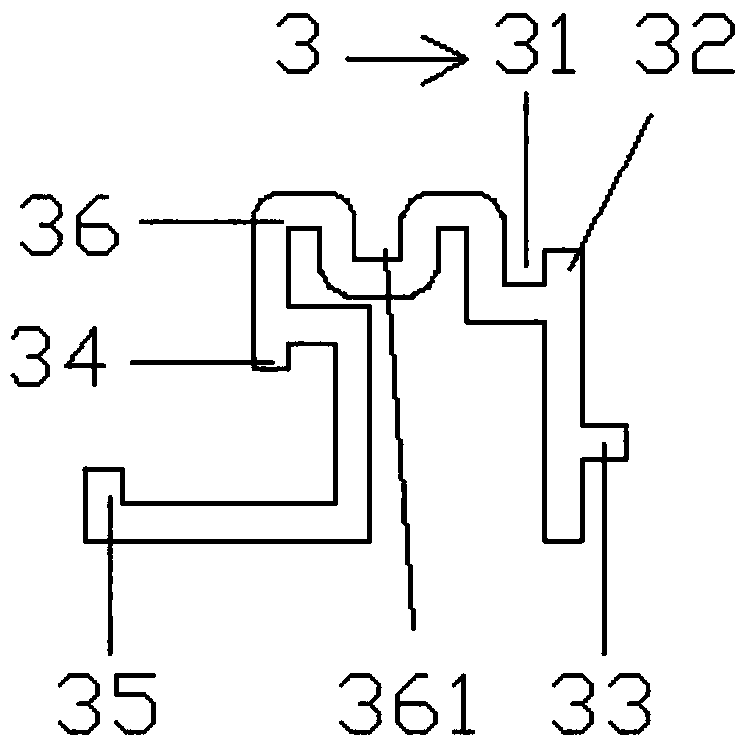

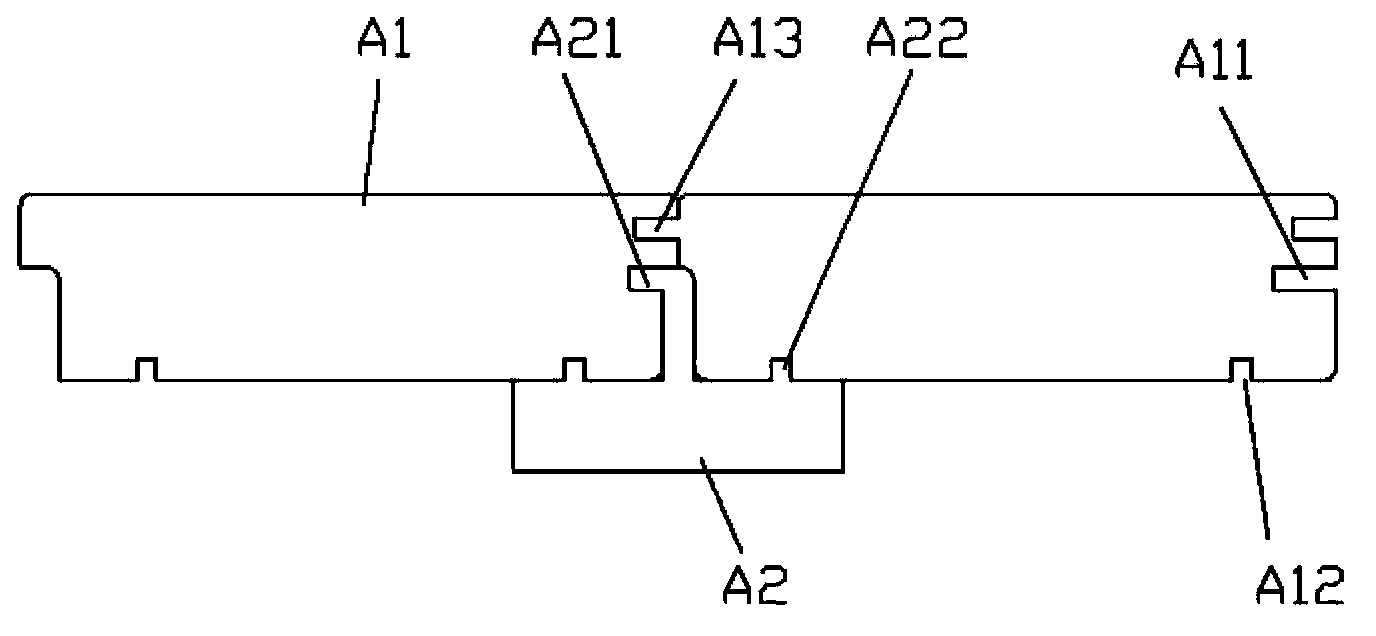

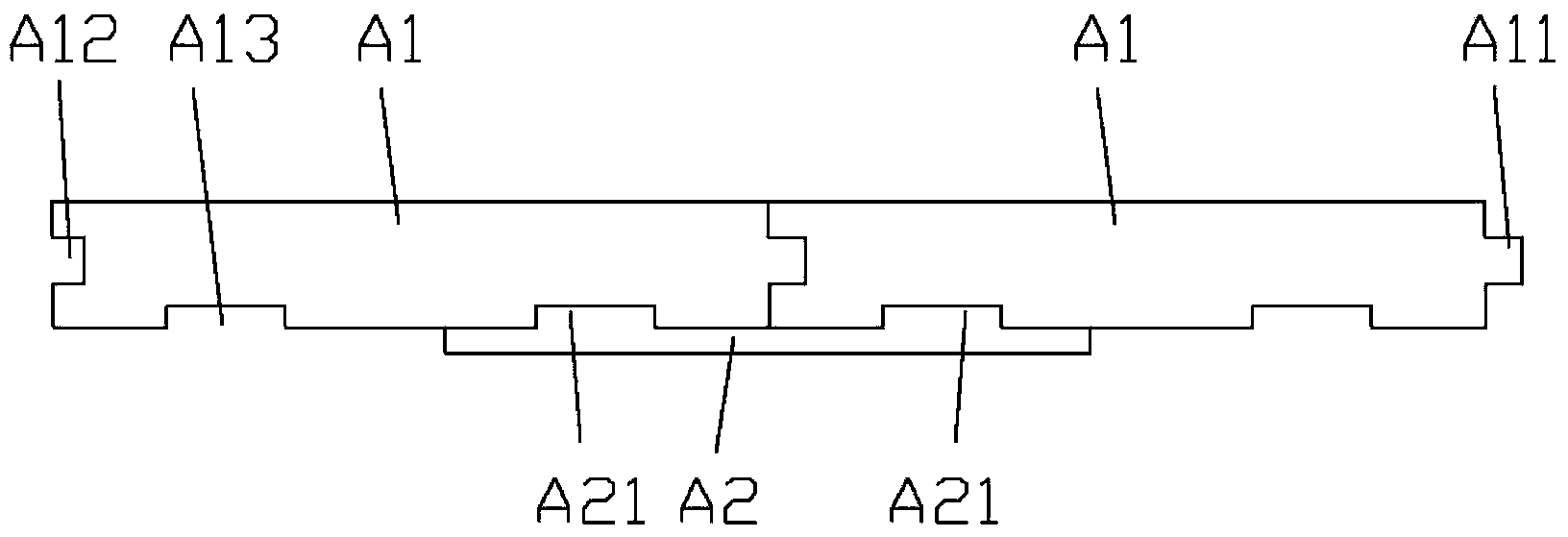

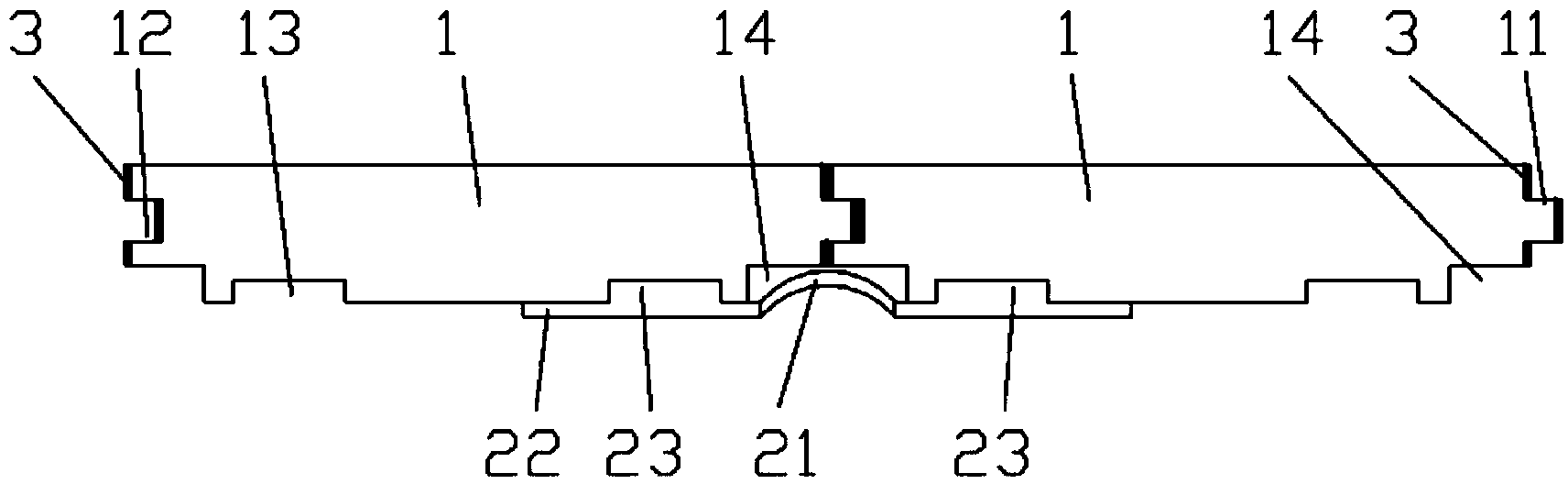

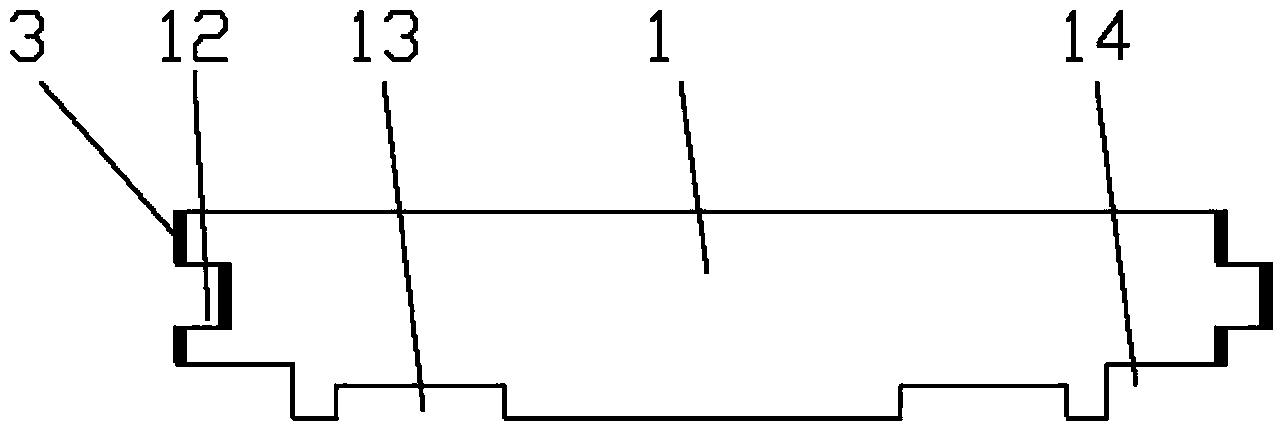

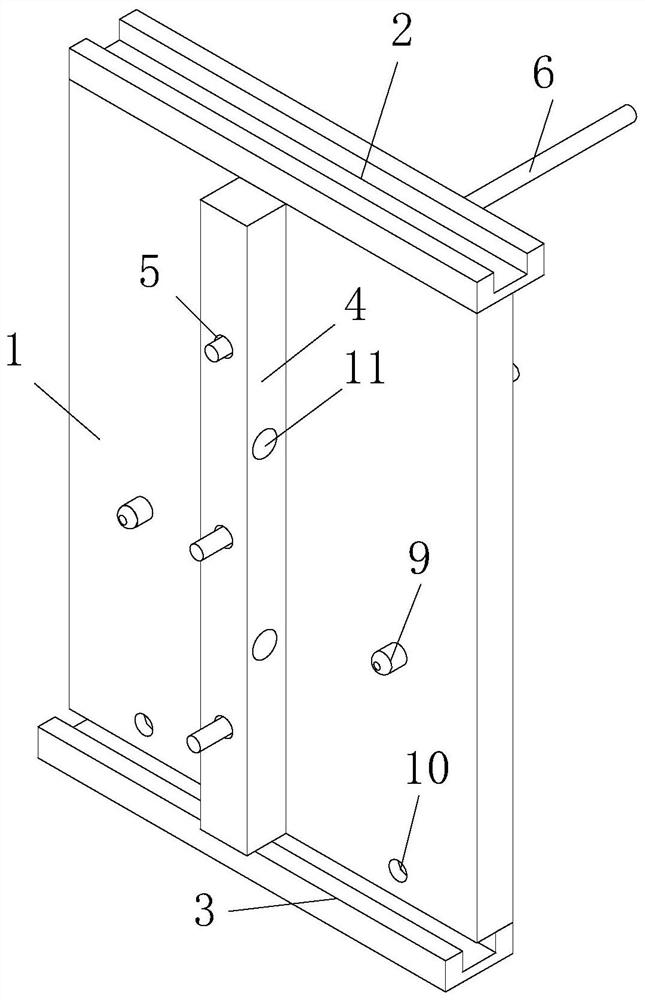

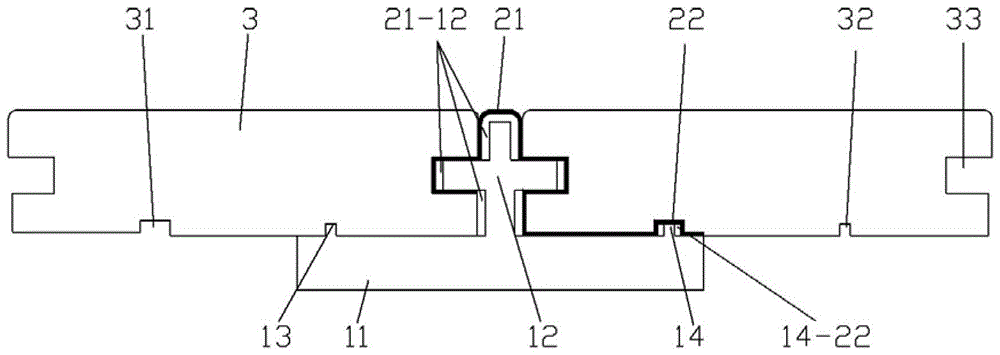

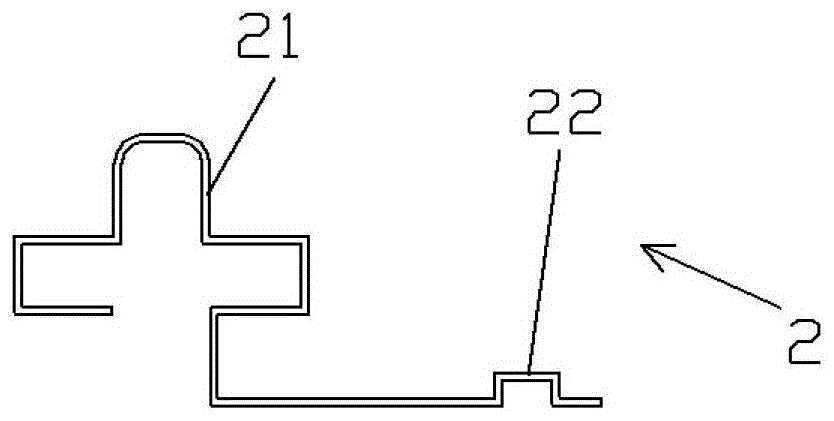

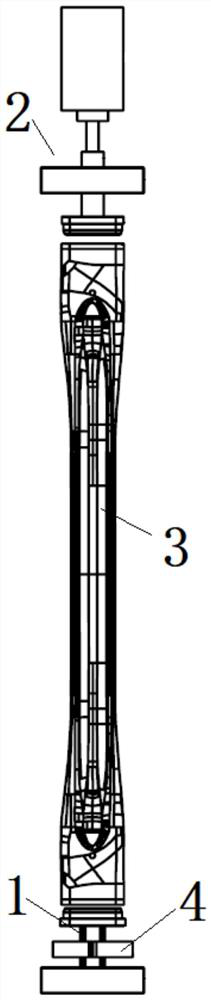

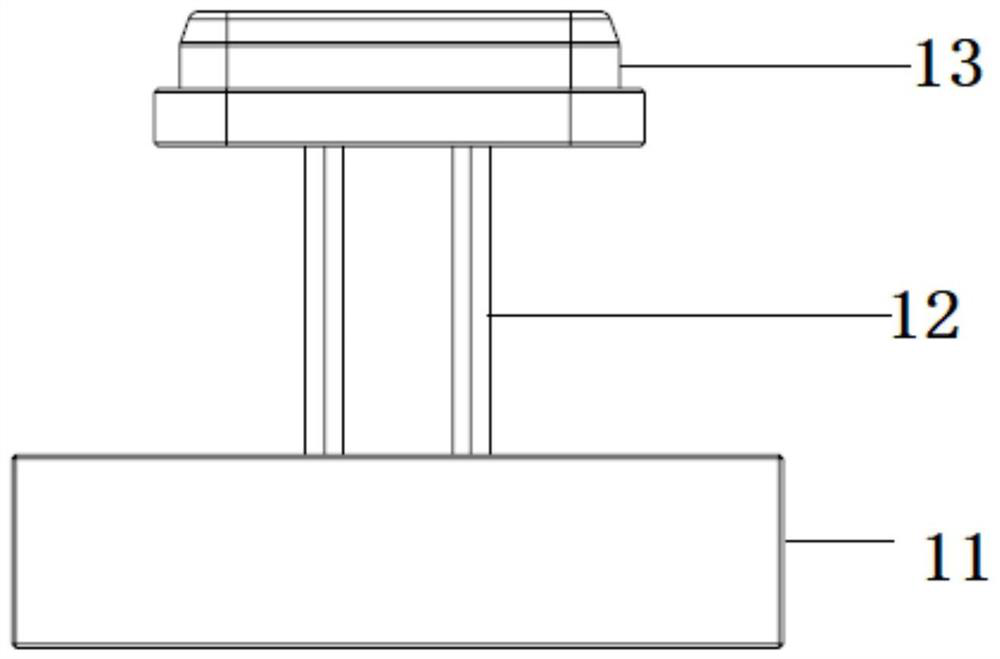

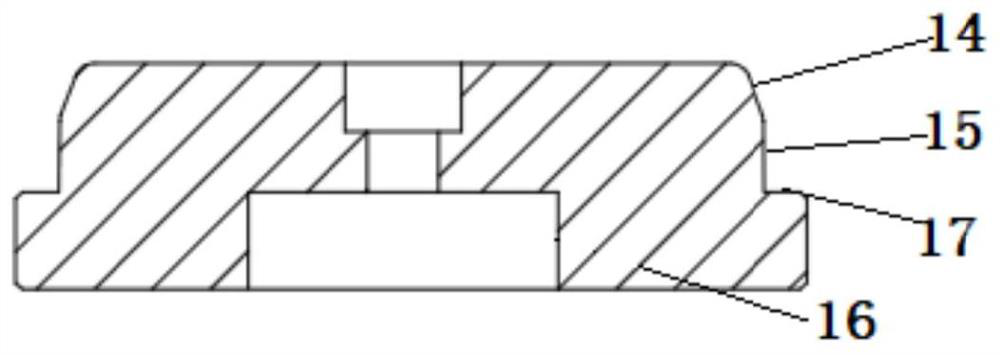

Method for preventing bottom of aluminum cell from upwarping and structure thereof

ActiveCN101440501APrevent arching deformationAvoid it happening againArchitectural engineeringCathode

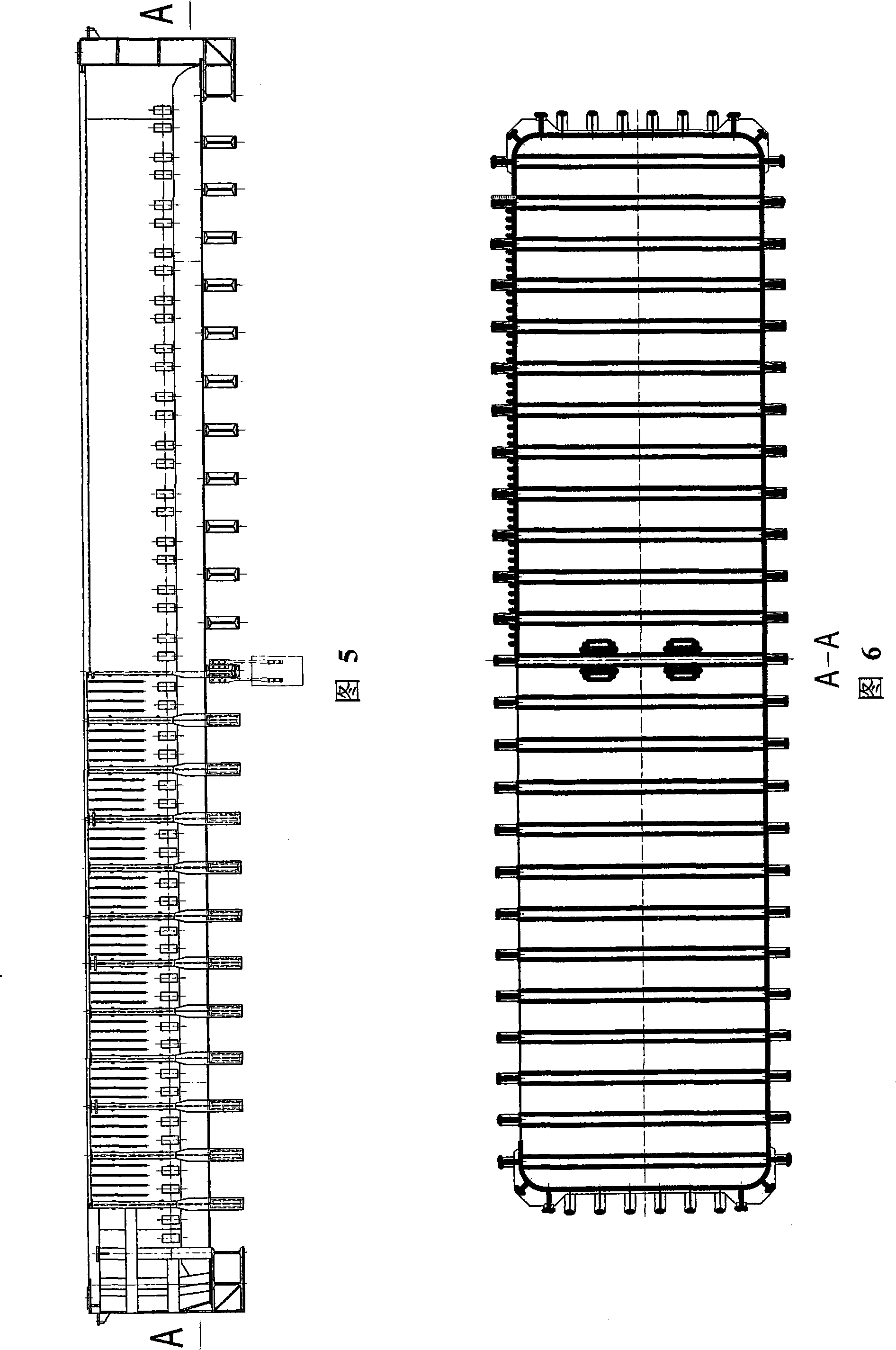

The invention discloses a method for preventing the bottom of an aluminum electrobath from upwarpping and a structure thereof and in particular relates to a method for preventing the bottom of the aluminum electrobath from upwarpping in the roasting startup process and a structure thereof. The structure comprises: the bottom of the aluminum electrobath is connected with a connecting mechanism (14); one end of the connecting mechanism (14) is connected with a cradle rack (1) on the underside of the aluminum electrobath; and the other end of the connecting mechanism (14) is fixed on a supporting pillar (13) of the electrobath. The method can solve the problem that the bottom of the aluminum electrobath is upwarpped and deformed in the roasting startup process, can prevent producing the crack of cathode and is convenient to produce and operate. The structure has a simple structure, easy realization in operation, obvious effect and wide market prospect.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

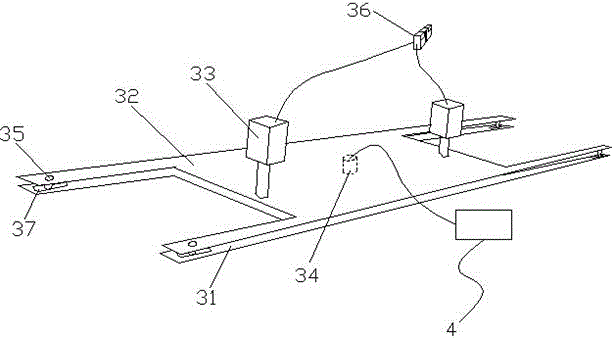

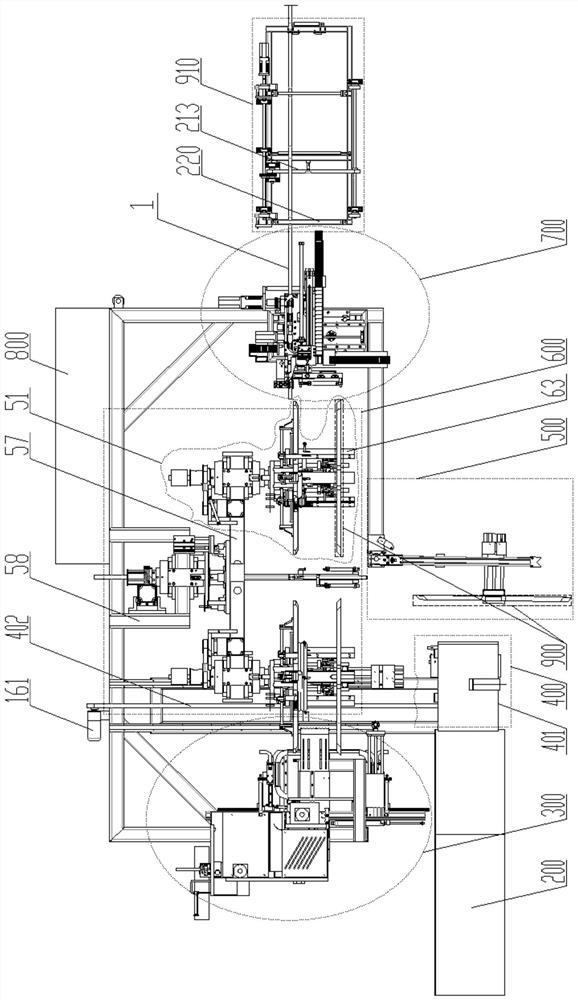

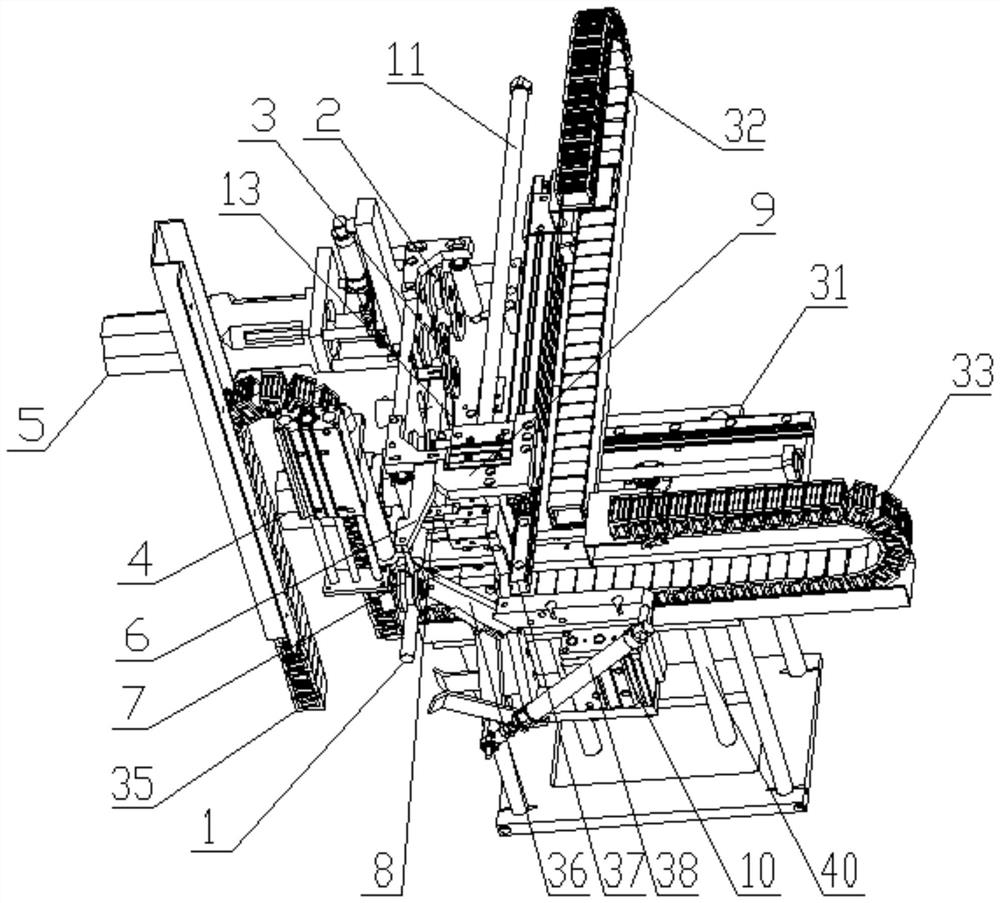

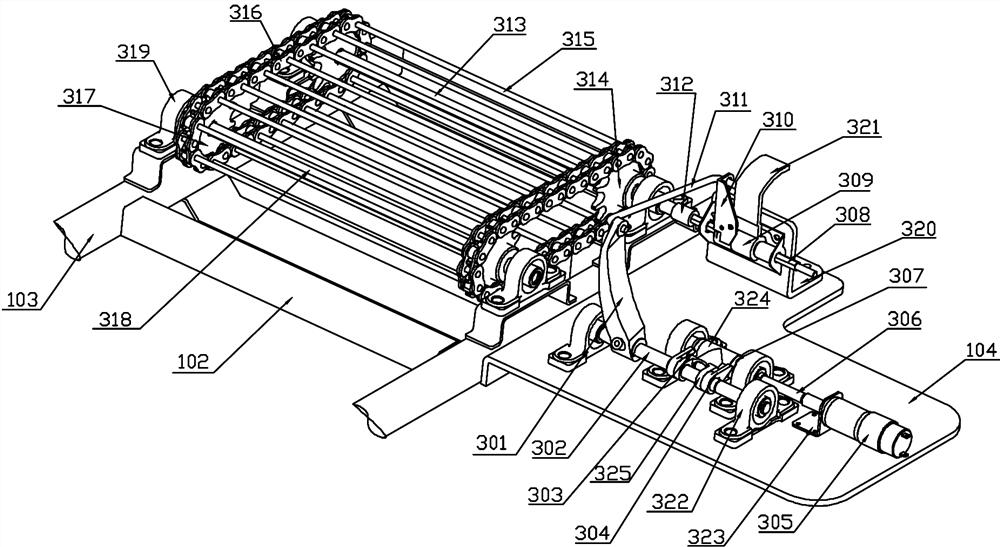

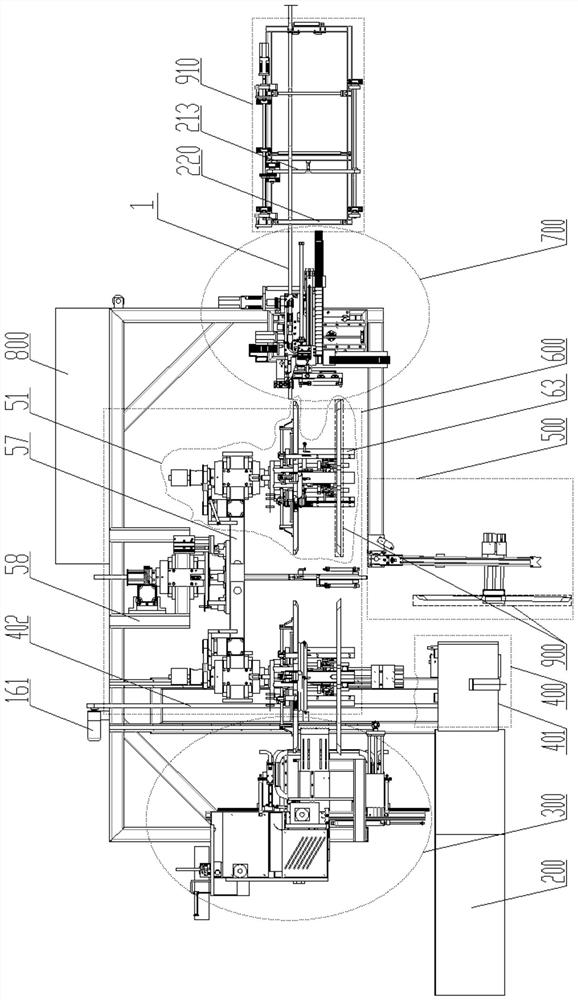

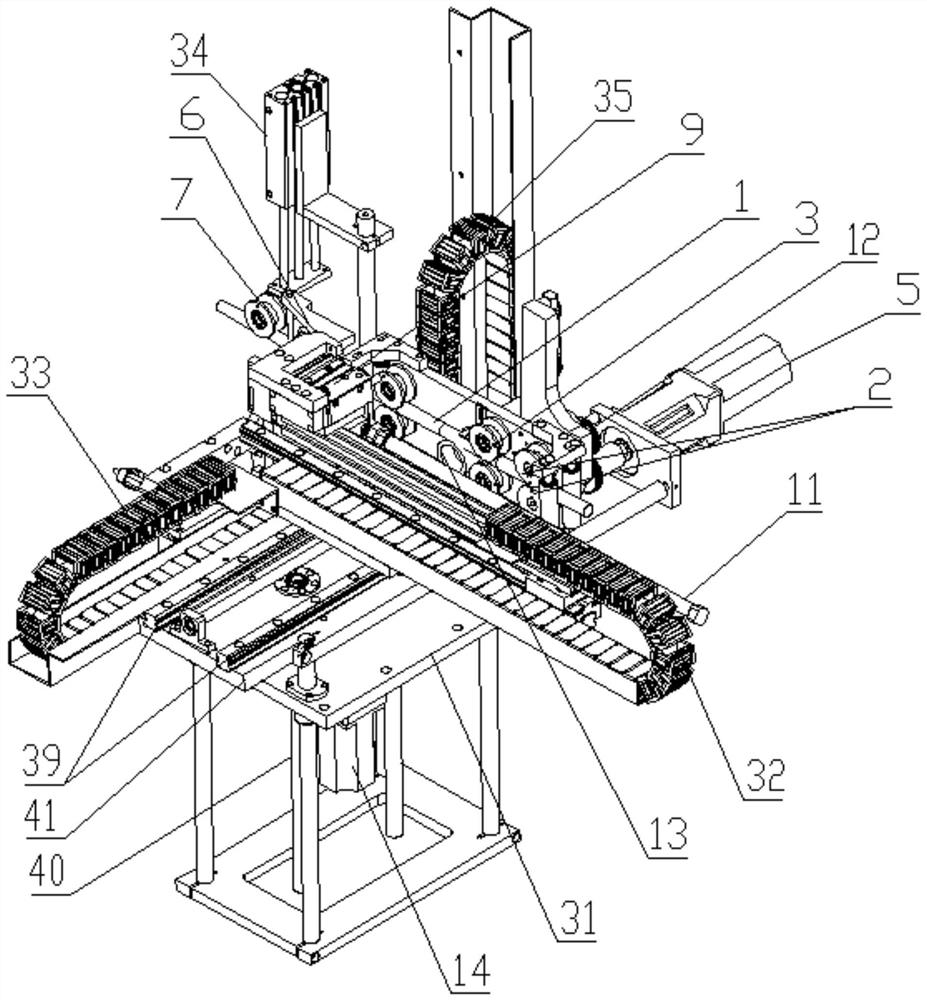

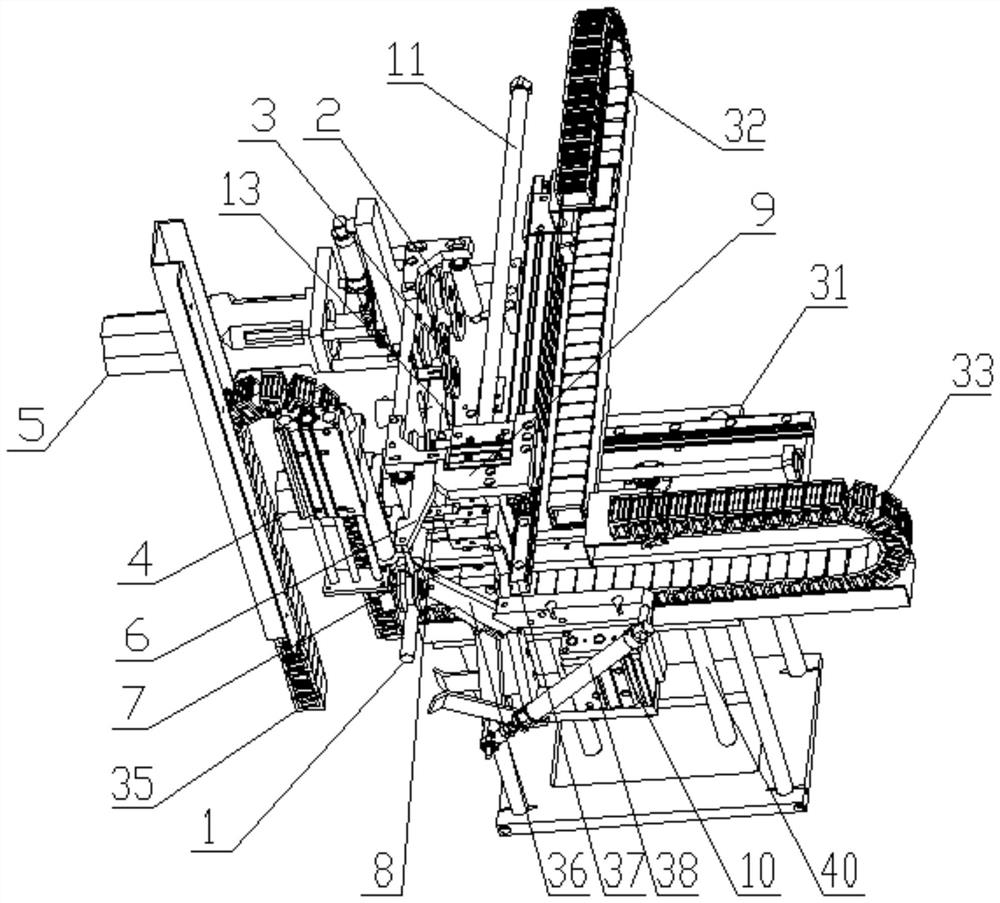

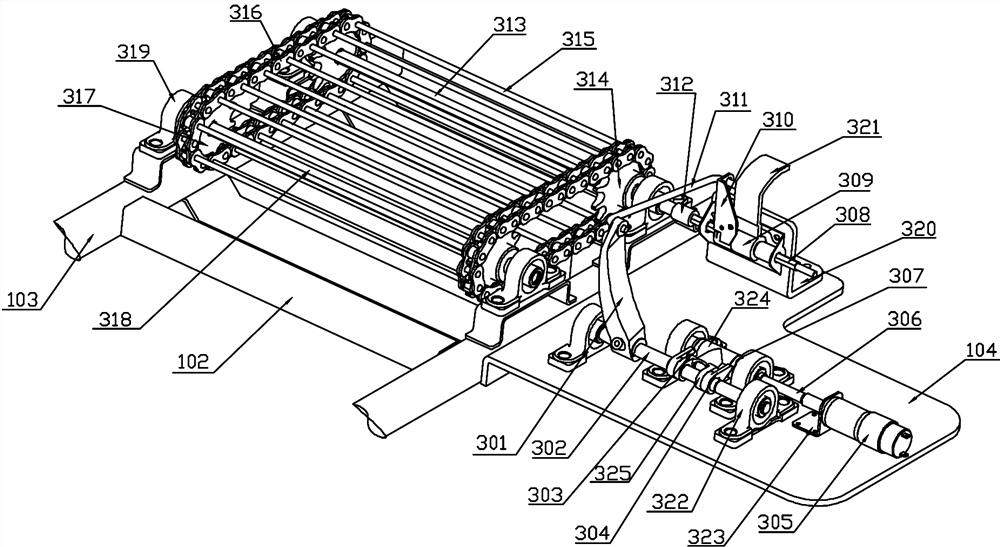

Pipe winding and bundling device

ActiveCN112298713AAdjustable winding radiusEasy to adjust winding radiusFilament handlingBundling machine detailsProduction linePipe

The invention provides a pipe winding and bundling device. The pipe winding and bundling device comprises a feeding mechanism, a winding mechanism, a bundling mechanism, a material returning mechanismand a grabbing mechanism, wherein the feeding mechanism is used for conveying pipes; the winding mechanism is used for winding the pipes; the bundling mechanism is used for bundling pipe discs; the material returning mechanism is used for unloading the pipe discs; the grabbing mechanism is used for disassembling and assembling winding part flanges; the feeding mechanism is used for conveying thefront ends of the pipes to winding parts of the winding mechanism to be fixed, then the pipes are wound into the pipe discs through rotation of the winding parts; the grabbing mechanism is used for removing the winding part flanges and then bundling the pipe discs through the bundling mechanism; and the material returning mechanism is used for unloading the bound pipe discs and then arranging thewinding part flanges on the winding parts in a reset mode through the grabbing mechanism. The pipe winding and bundling device can adapt to a high-speed pipe production line, the winding and bundlingefficiency of 10-40 m / min can be achieved, the manual workload can be greatly reduced in the winding and bundling process, and one person can operate multiple winding and bundling devices; compared with an existing pipe production line, the pipe winding and bundling device is higher in universality; and the winding and bundling device is adjustable in winding radius, and is suitable for winding and bundling pipes of various specifications.

Owner:重庆市齐垚机电设备有限公司 +1

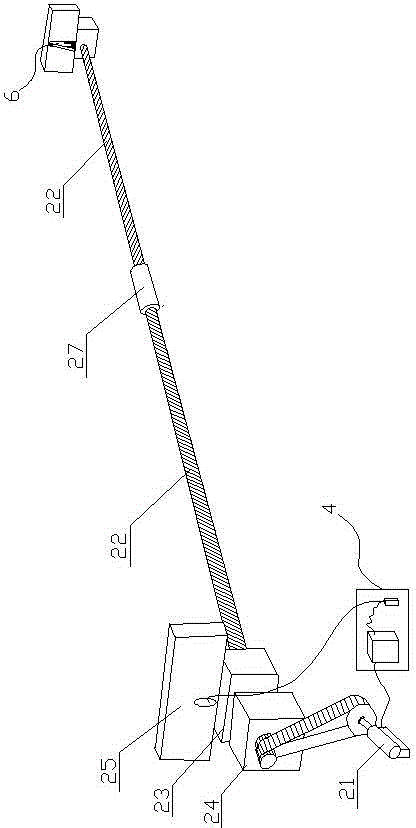

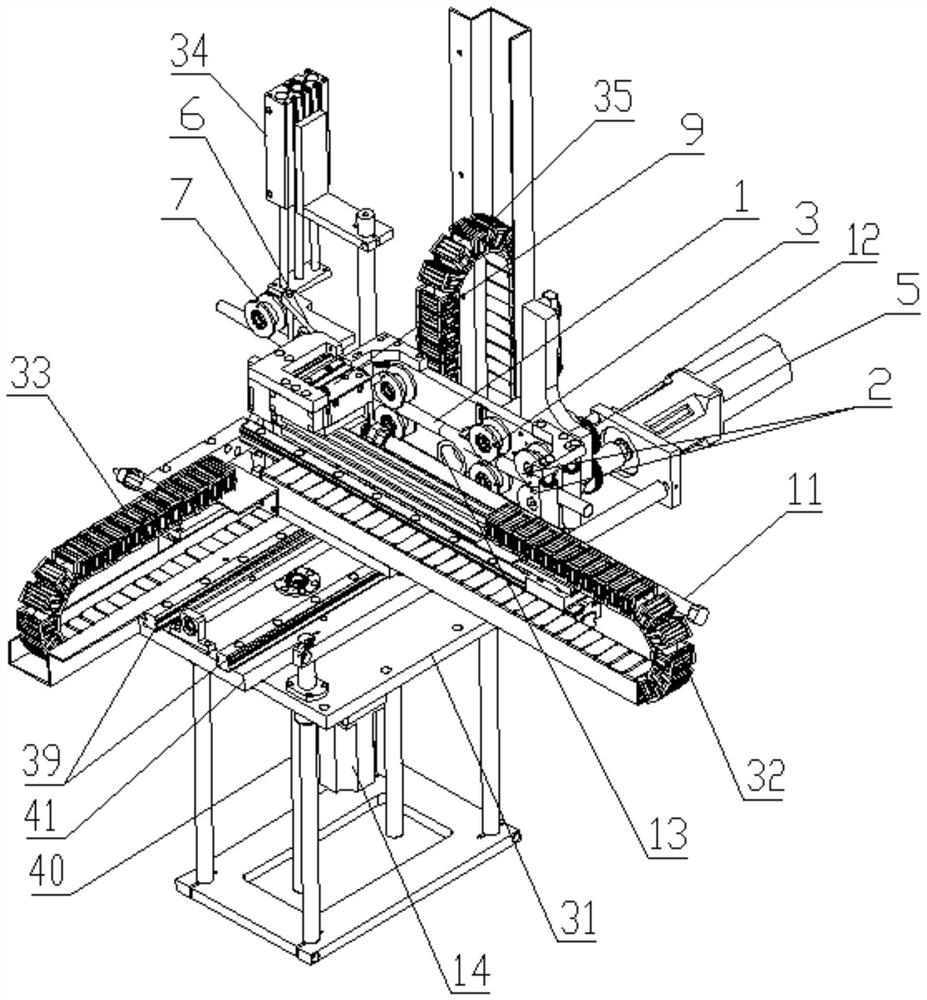

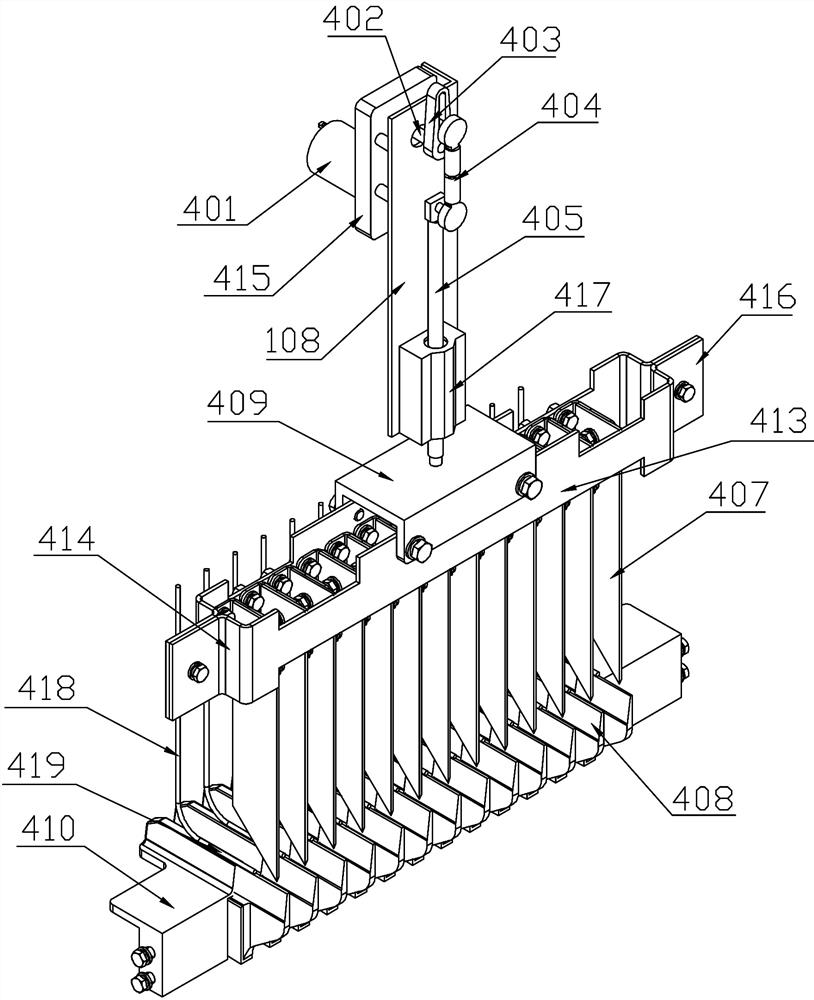

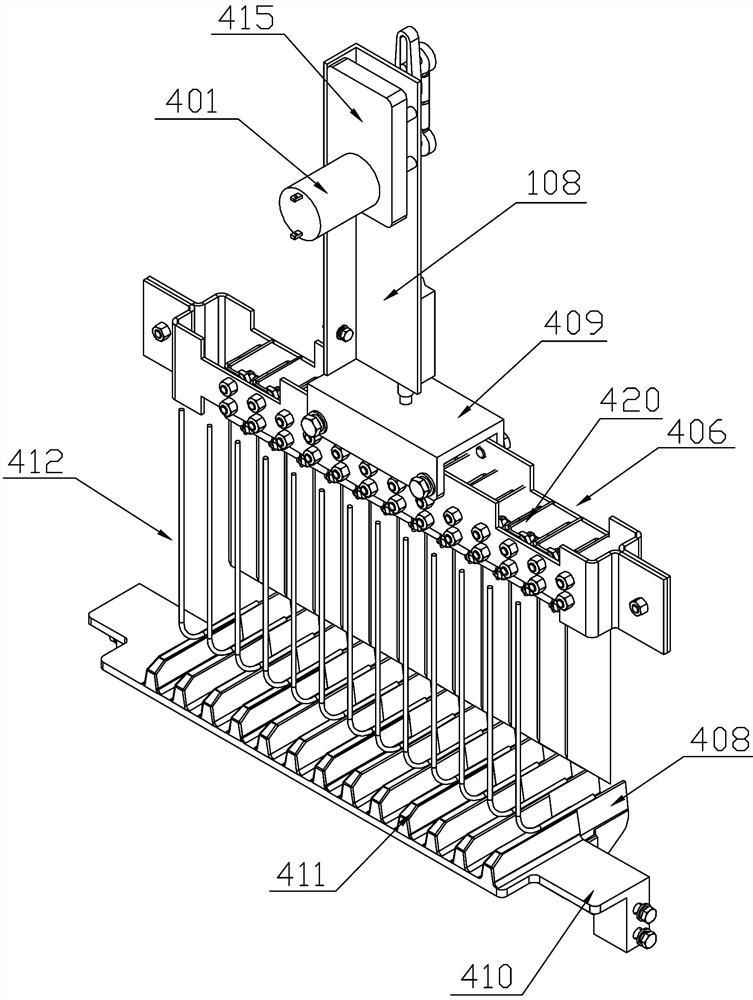

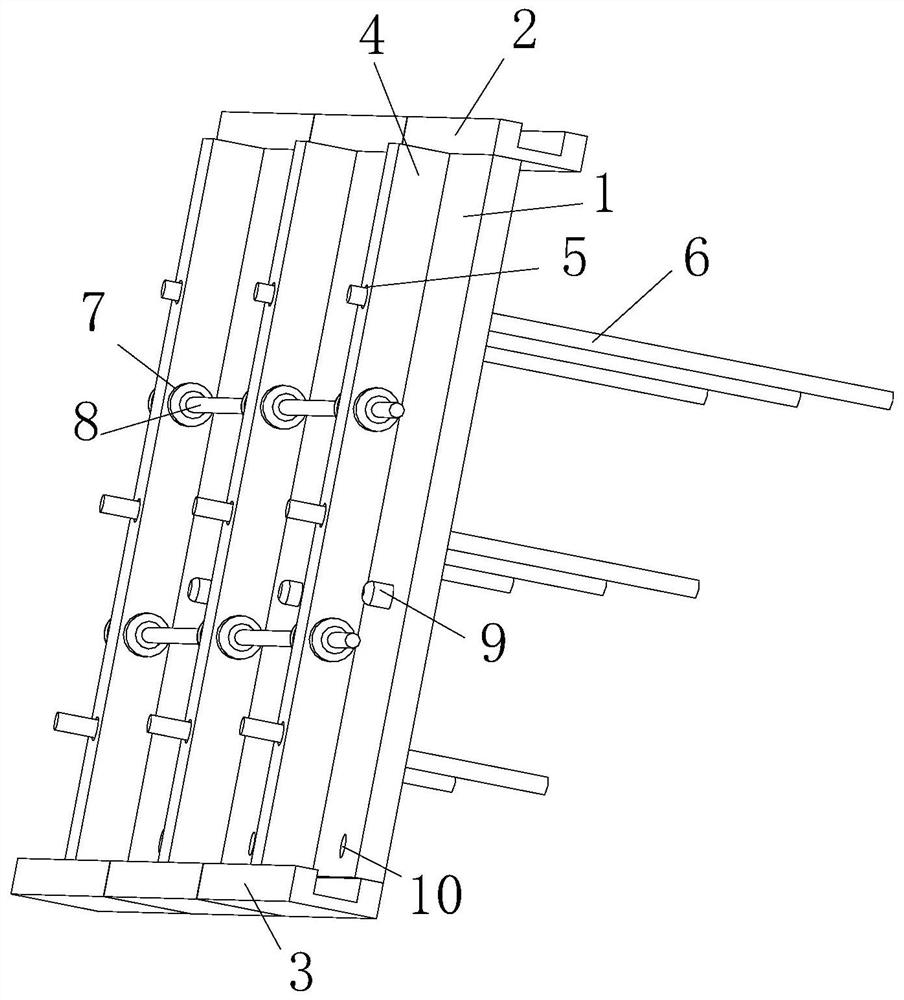

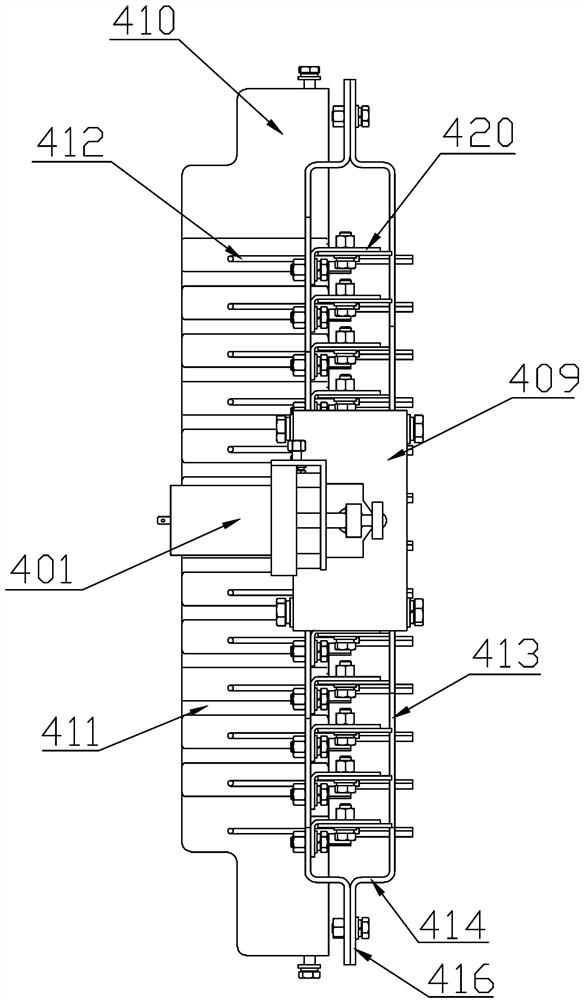

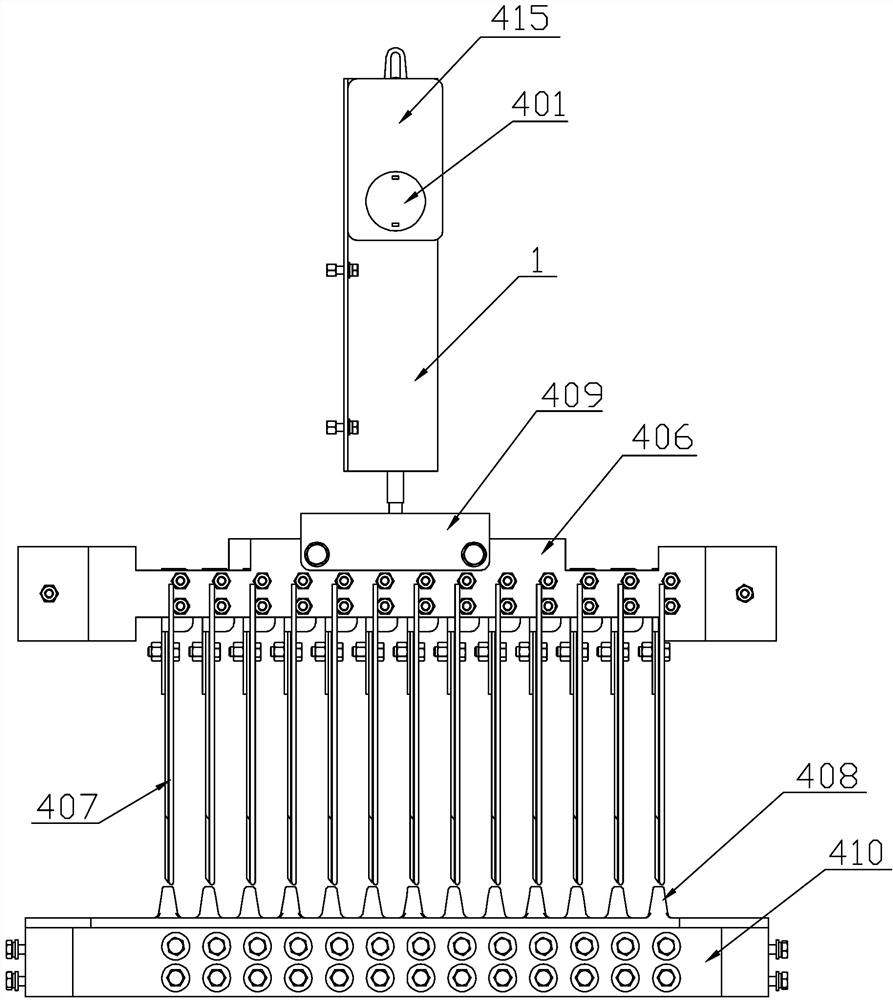

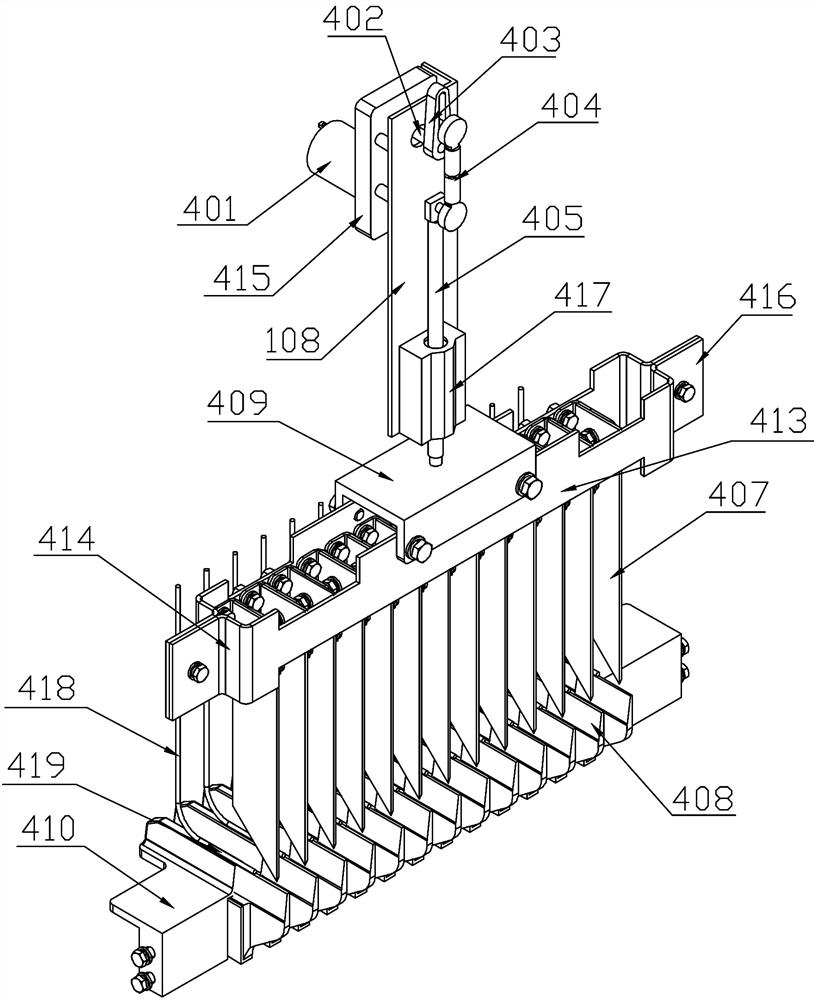

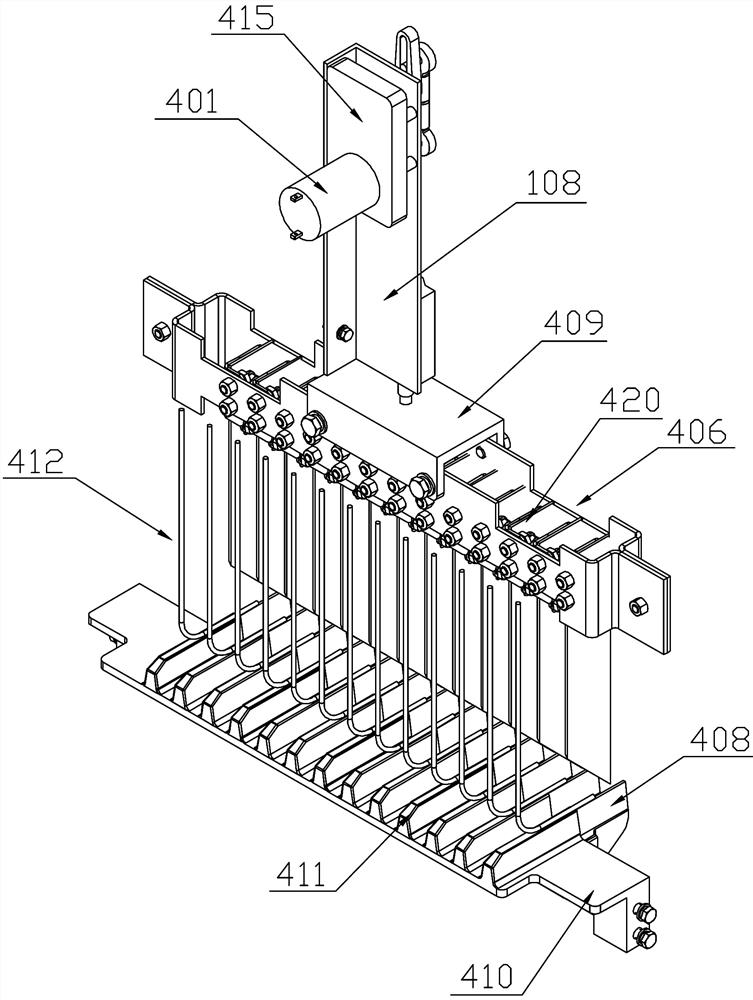

Whole-row accurate seedling transferring and taking mechanism suitable for degradable material seedling trays

ActiveCN112703865APrevent arching deformationQuality improvementTransplantingAgricultural engineeringStructural engineering

The invention discloses a whole-row accurate seedling transferring and taking mechanism suitable for degradable material seedling trays. The mechanism comprises a rack, a seedling box, an accurate seedling transferring mechanism and an accurate seedling taking mechanism, the seedling box is arranged at one end of the rack, and the accurate seedling taking mechanism is arranged at the other end of the rack; the accurate seedling transferring mechanism is arranged on the rack and located between the seedling box and the accurate seedling taking mechanism, the accurate seedling taking mechanism comprises a seedling taking driving motor, a movable cutter mounting plate, one or more movable cutters, a fixed cutter mounting base and one or more fixed cutters, and the movable cutter mounting plate is mounted on the rack and forms a vertical moving pair with the rack; and the seedling taking driving motor is installed on the rack and used for driving the movable cutter mounting plate to vertically move on the rack, the movable cutters are installed on the movable cutter mounting plate, the fixed cutter mounting base is installed on the rack, and the movable cutters are matched with the fixed cutters along with vertical movement of the movable cutter mounting plate to slit and convey seedlings to seedling trays on the fixed cutters. According to the whole-row accurate seedling transferring and taking mechanism, the seedling taking quality is improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

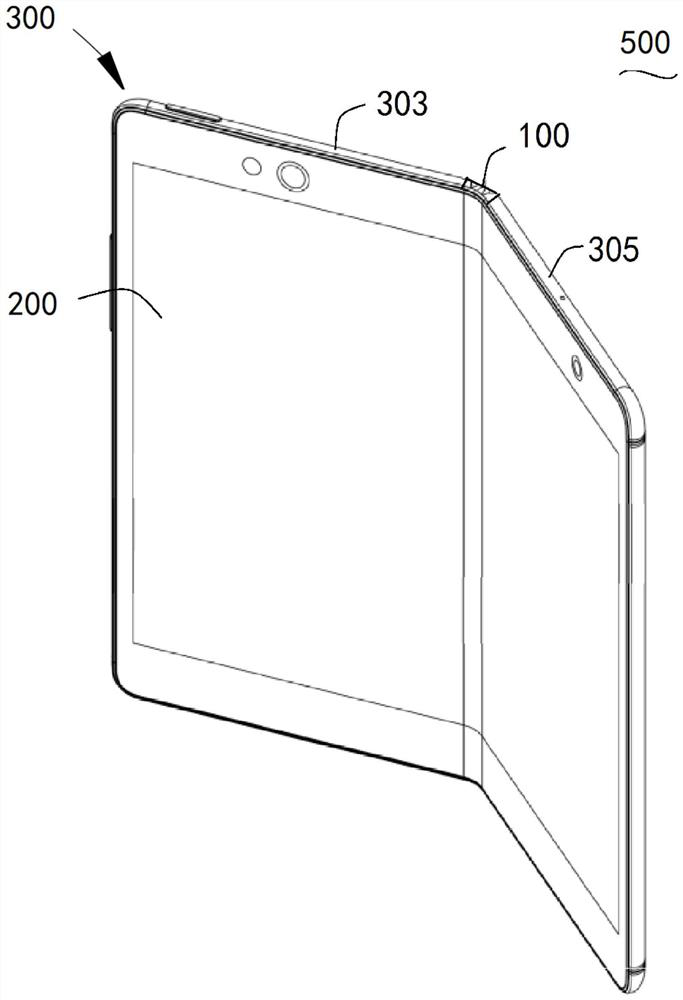

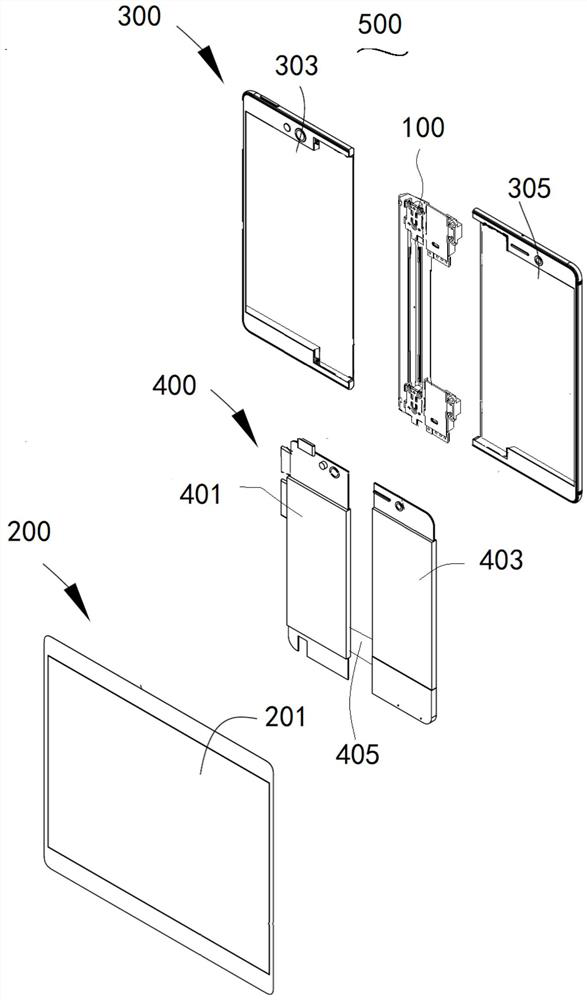

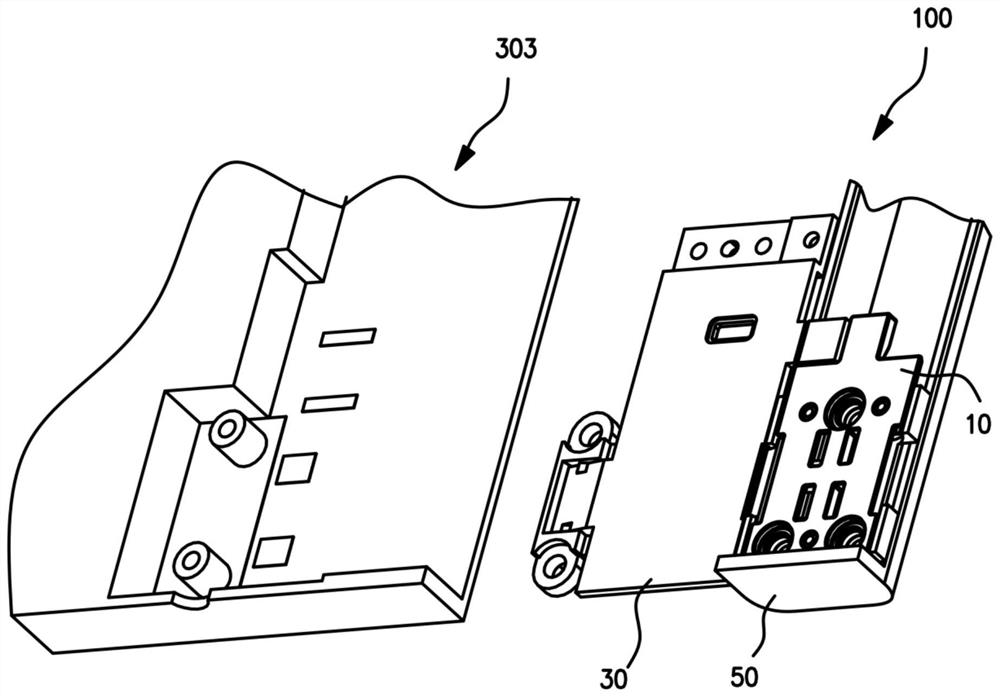

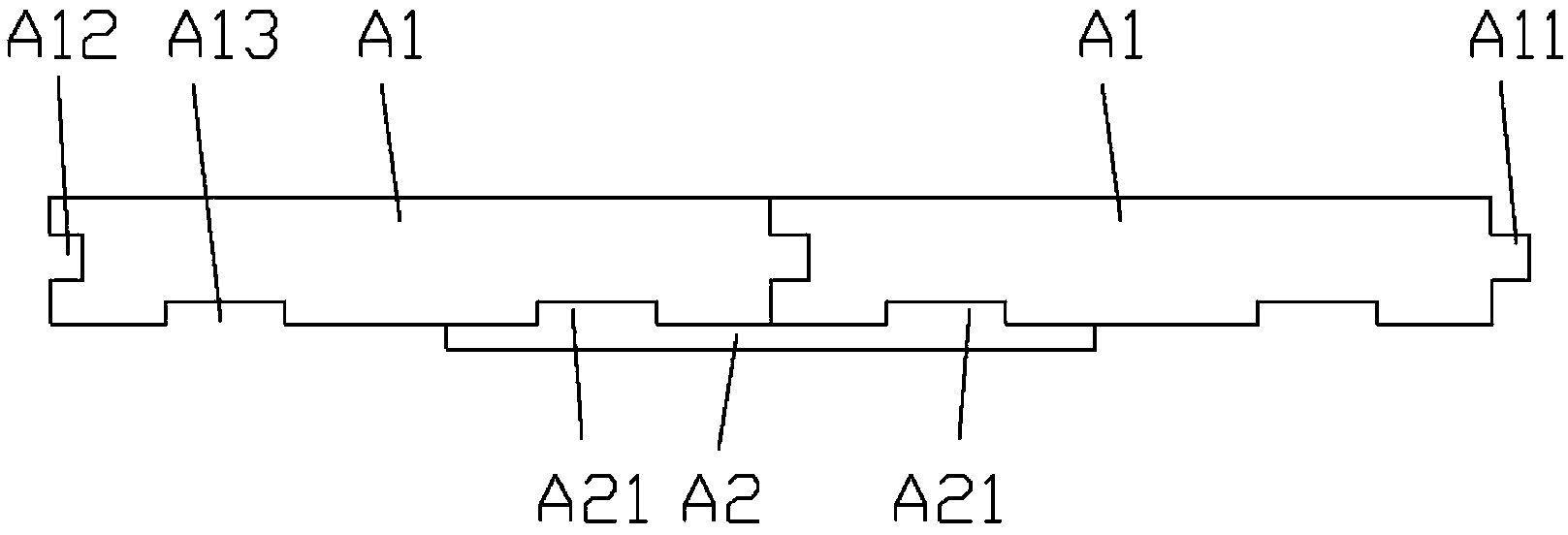

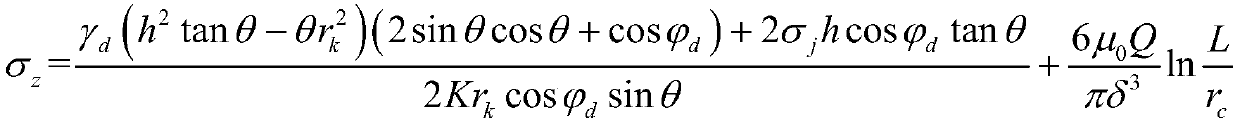

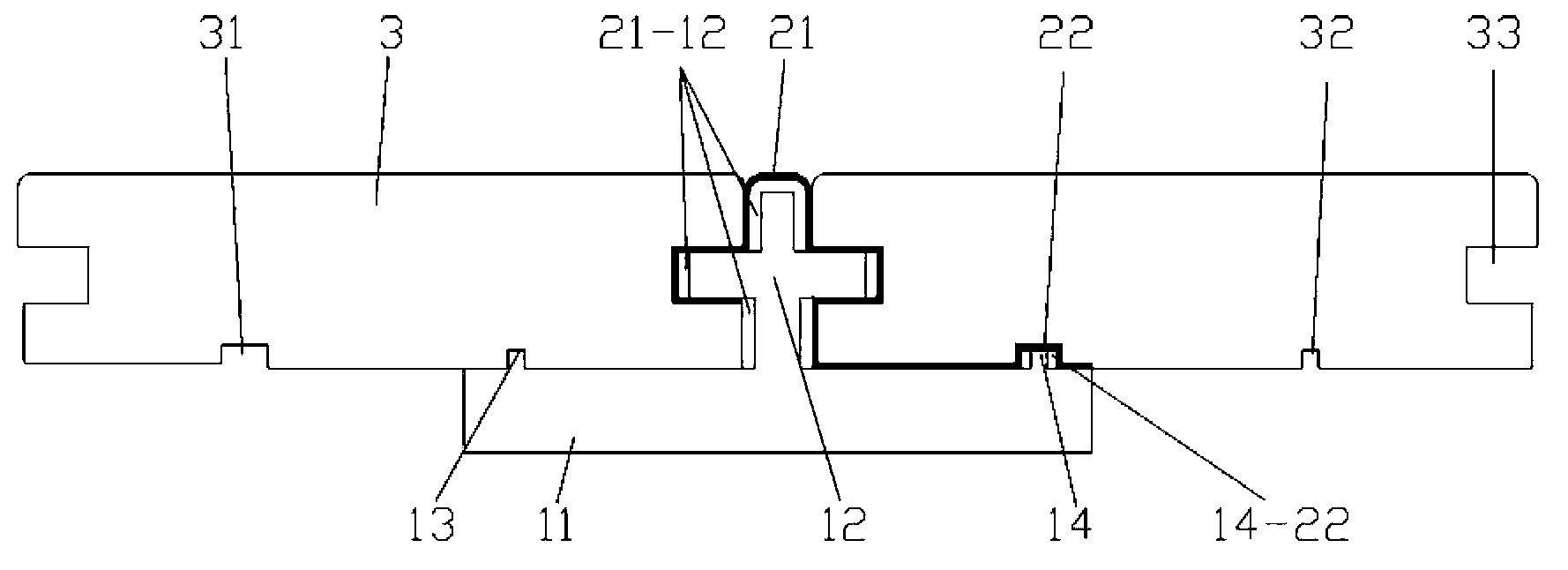

Rotating shaft mechanism and foldable electronic equipment

ActiveCN114205430APrevent arching deformationAvoid the tendency to bulgeDetails for portable computersTelephone set constructionsEngineeringMechanical engineering

The invention relates to electronic equipment and a rotating shaft mechanism thereof. The electronic equipment comprises a first shell, a second shell and a foldable screen. The rotating shaft mechanism comprises a base and a rotating assembly which are rotatably connected with each other. The rotating assembly comprises a support, a linkage piece and a guide piece. The support and the base are arranged at an interval, and the linkage piece is arranged between the base and the support. The linkage piece comprises a body and a driving part arranged on the body; one end of the body is rotatably connected to the base, and the other end of the body is slidably connected to the support. The guide piece is rotatably connected to the bracket; the guiding piece is provided with a sliding groove, and the driving part is at least partially contained in the sliding groove. When the base and the rotating assembly rotate relatively, the driving part slides in the sliding groove so as to drive the guiding piece to rotate relative to the support. According to the rotating shaft mechanism, the foldable screen can be protected when the foldable screen is folded, and damage caused by irregular deformation of folding of the foldable screen is avoided.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

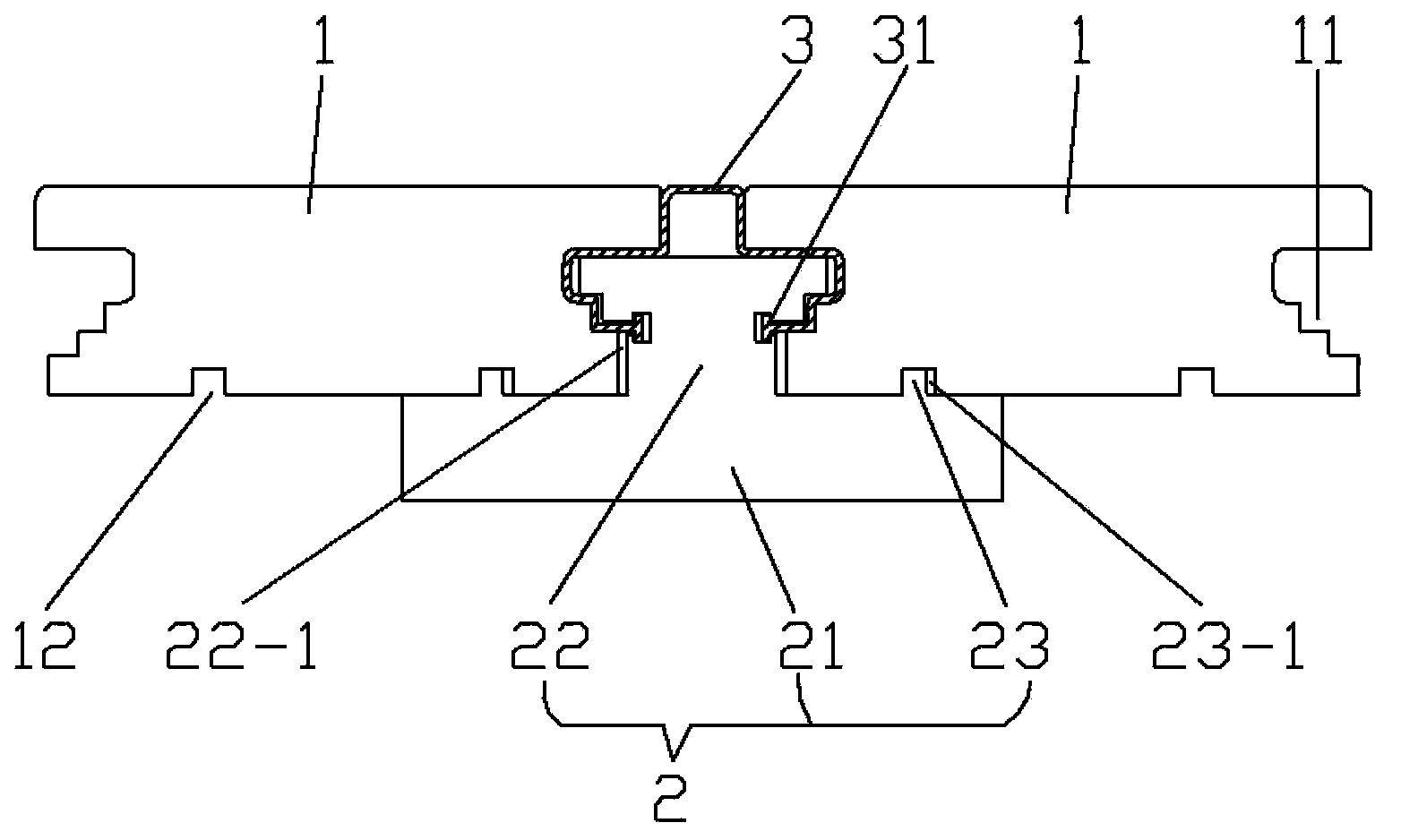

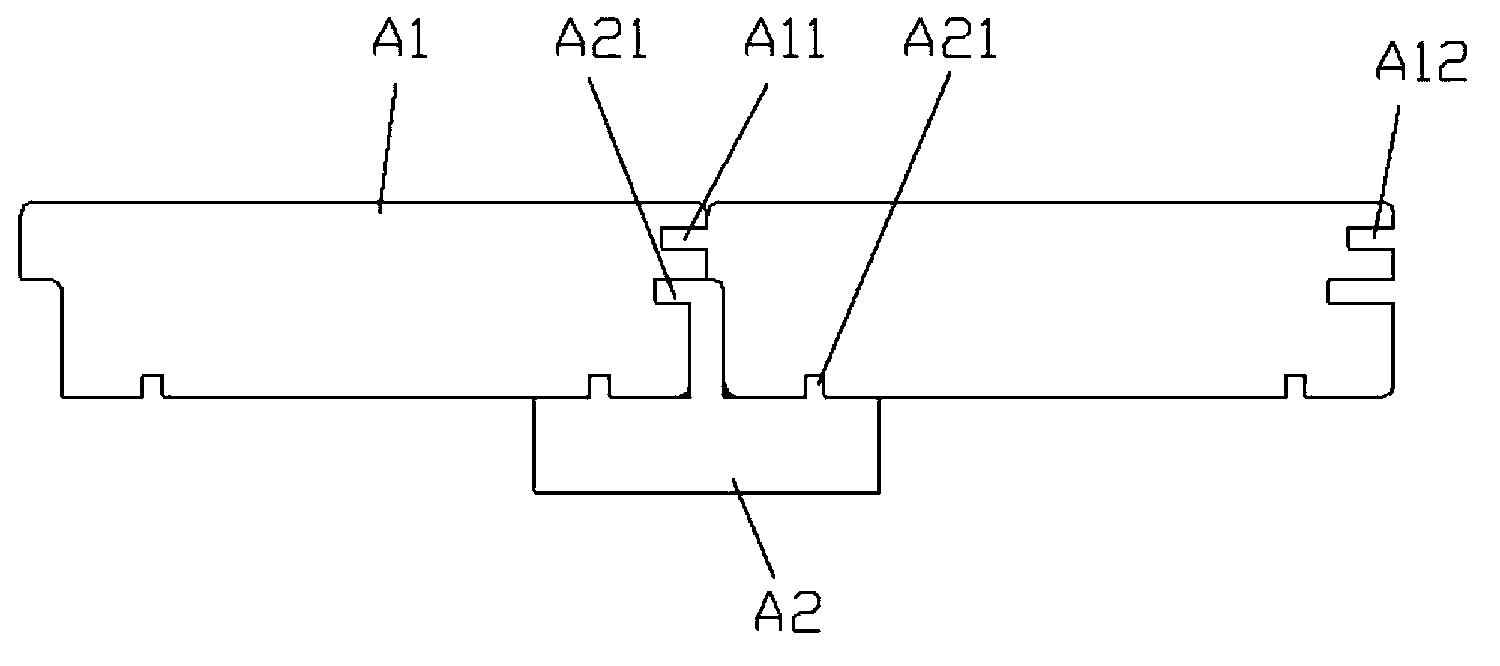

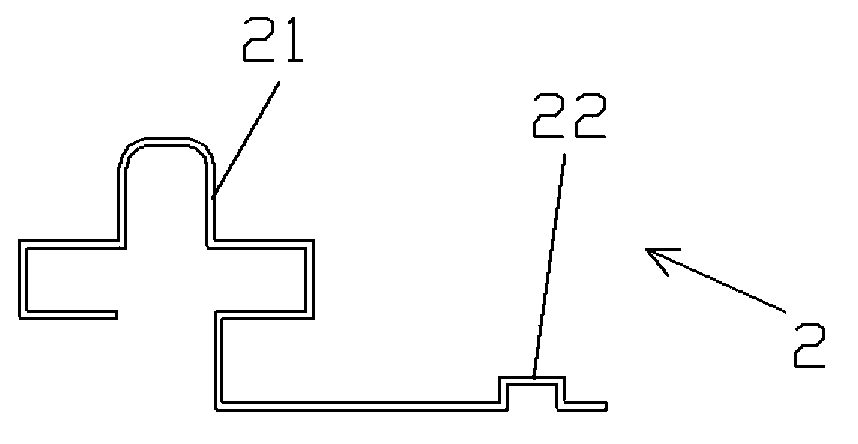

Wood-plastic floor

The invention discloses a wood-plastic floor, which comprises wood board blocks and a keel, wherein a horizontal insertion tenon, a horizontal rabbet and an undersurface rabbet are formed on each wood board block; the horizontal insertion tenon on one wood board block is inserted into a horizontal rabbet of the other adjacent wood board block; two joint bars are formed on a square block to form the keel; the two joint bars are inserted into two bottom rabbets of two adjacent wood board blocks respectively; the upper surfaces and the right surfaces of the two wood board blocks are coated with elastic plastic layers; the left surface, the right inner surface and the left inner surface of the bottom rabbet are coated with elastic plastic layers; the keel is made of wood or aluminum alloy. The wood-plastic floor has the advantages that the wood board blocks can be efficiently prevented from bulging and deformation, and meanwhile, the wood board blocks are coated with plastic, so that luxury and visual effects of the floor are enhanced.

Owner:苏州燕泥地热地板科技有限公司

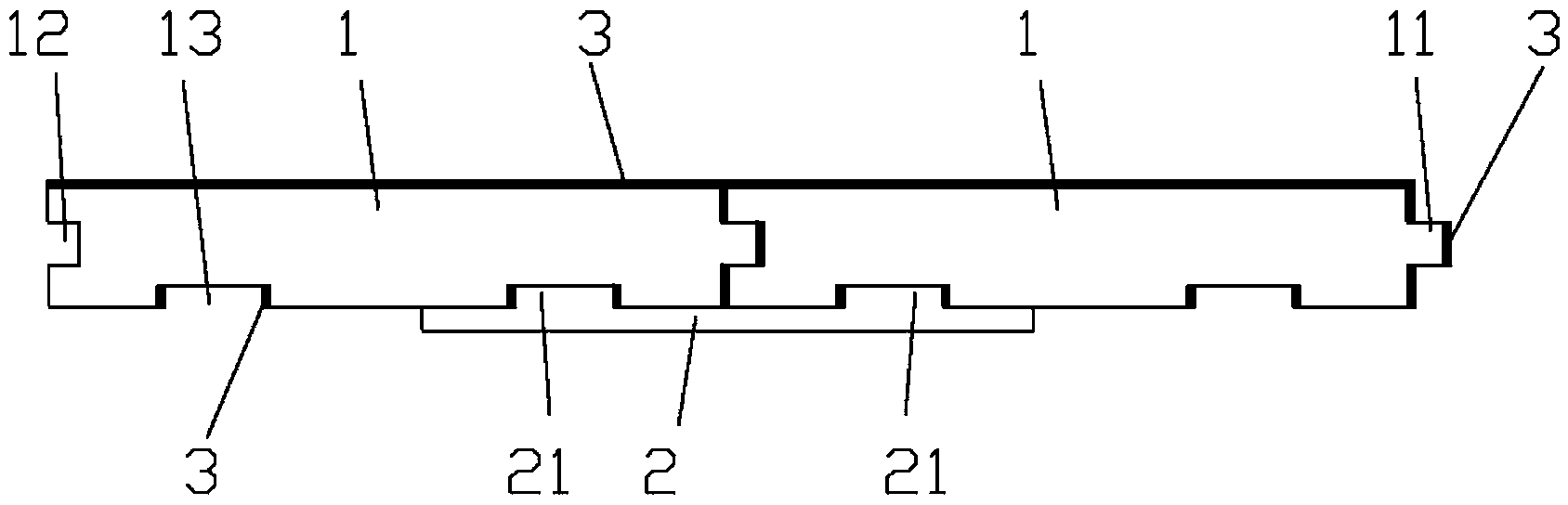

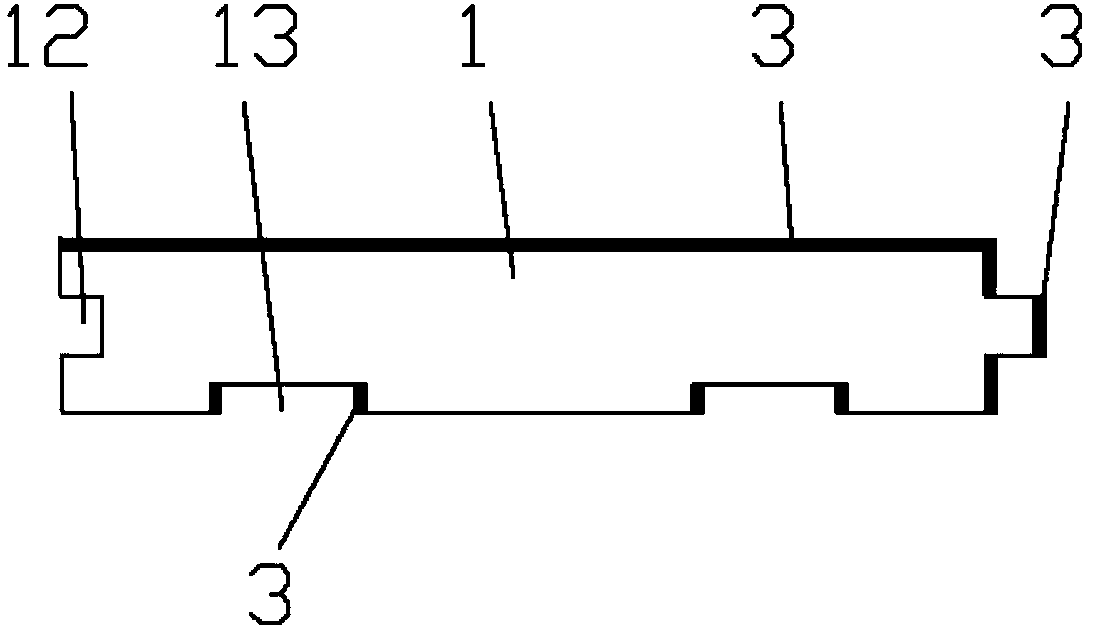

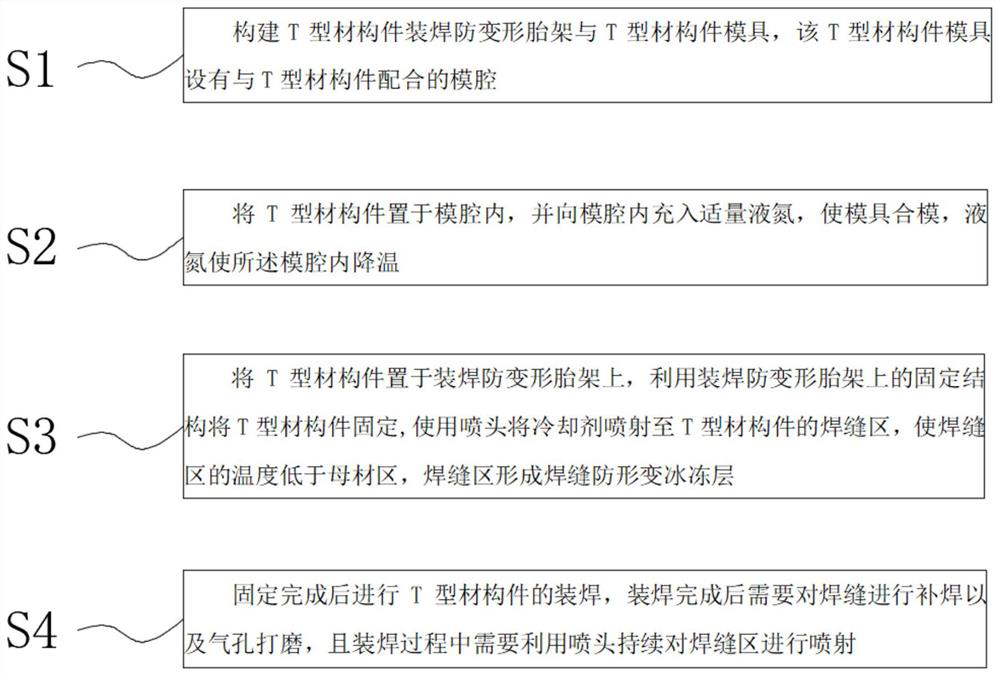

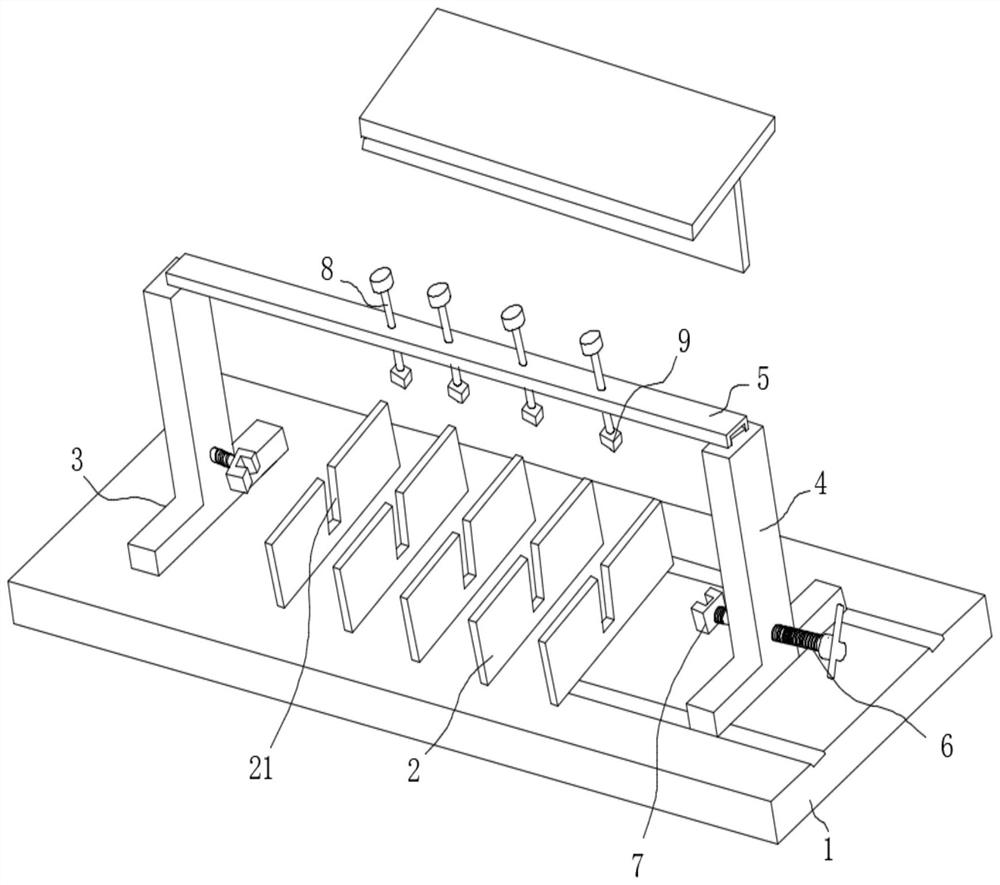

Ship T-shaped profile anti-deformation machining process

InactiveCN112008203AGuarantee the quality of welding processImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

The invention belongs to the field of ship T-shaped profile machining, and particularly discloses a ship T-shaped profile anti-deformation machining process. The ship T-shaped profile anti-deformationmachining process comprises the following steps that a T-shaped profile component assembling and welding anti-deformation jig frame and a T-shaped profile component mold are built, and the T-shaped profile component mold is provided with a mold cavity matched with a T-shaped profile component; the T-shaped profile component is placed in the mold cavity, the mold cavity is filled with a proper amount of liquid nitrogen, the mold is assembled, and the interior of the mold cavity is cooled by the liquid nitrogen; the T-shaped profile component is placed on the assembling and welding anti-deformation jig frame, the T-shaped profile component is fixed through a fixing structure on the assembling and welding anti-deformation jig frame, a cooling agent is sprayed to a weld joint area of the T-shaped profile component through a spray head, the temperature of the weld joint area is lower than that of a base metal area, and a weld joint anti-deformation freezing layer is formed in the weld joint area; and after fixing is completed, assembling and welding of the T-shaped profile component are conducted, and after assembling and welding are completed, repair welding and air hole grinding needto be conducted on weld joints. The machining process is free of deformation, and the working efficiency of shipbuilding can be greatly improved.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

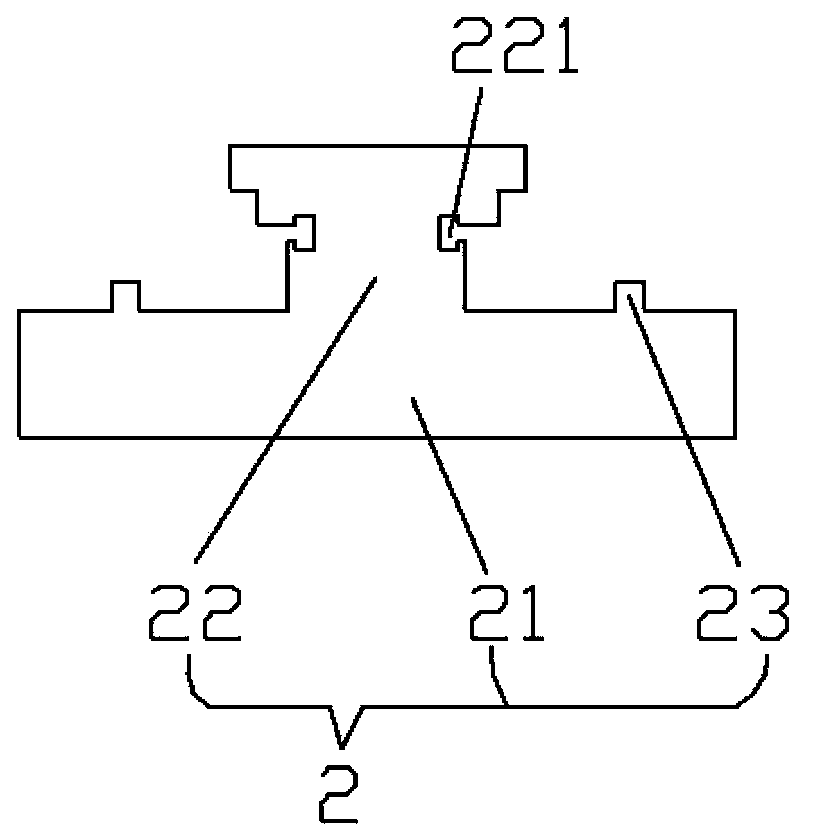

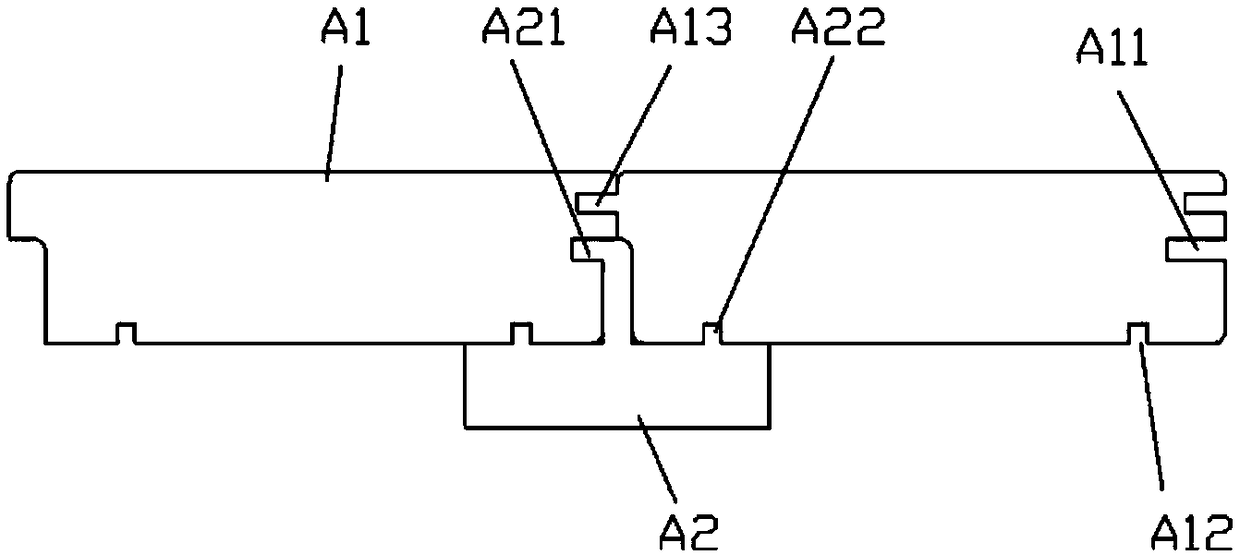

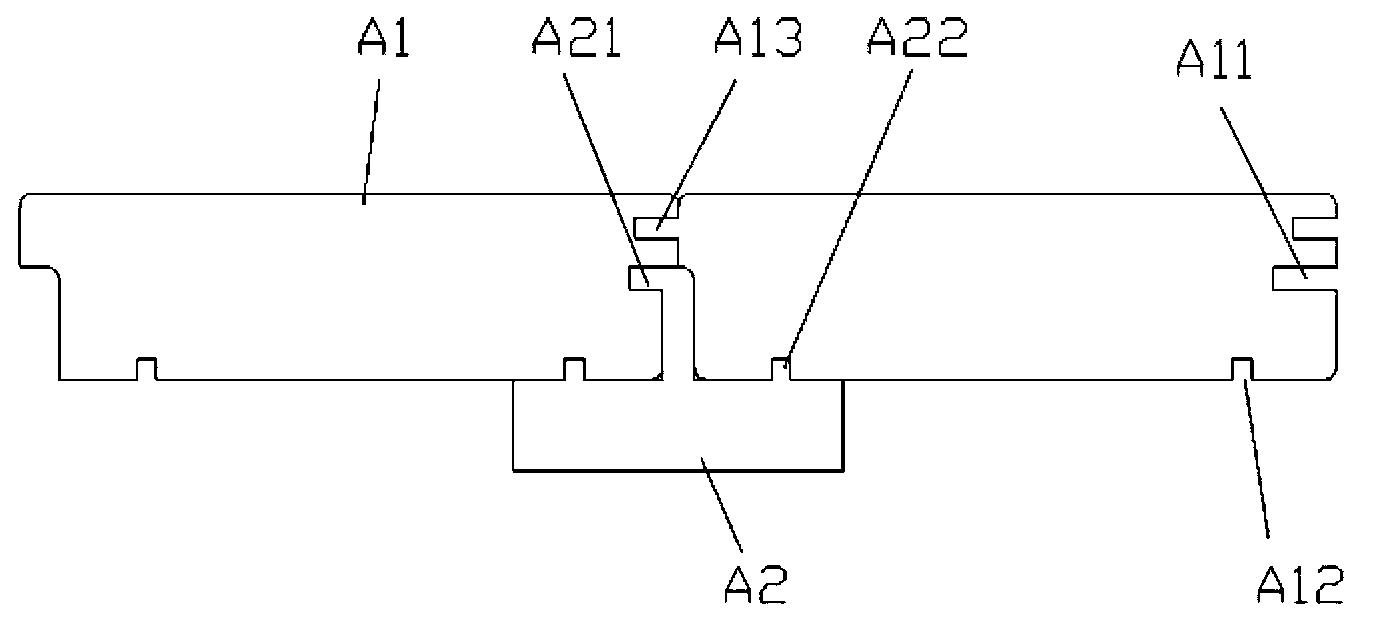

Floor capable of being provided with various kinds of keels

The invention relates to a floor capable of being provided with various kinds of keels. A plank left vertical insertion tenon, a plank left vertical insertion groove and a plank horizontal insertion groove are formed in the left edge of a plank, a plank right vertical insertion groove is formed in the right edge of the plank, and a bottom insertion groove is formed in the bottom of the plank; a first keel decoration strip, a first keel vertical insertion groove and a first keel right vertical insertion tenon are formed in the upper portion of a first keel from left to right in sequence, a first keel horizontal insertion tenon is formed in the middle of the first keel, a first bottom vertical insertion tenon extends to the lower portion of the first keel, a first keel left vertical insertion tenon is formed in the lower portion of the first keel decoration strip of the first keel, and the first keel is an aluminium alloy solid body; the plank can be installed by adopting various kinds of keels, and the first keel has good heat conduction performance and is low in production cost; the second keel has good elasticity, and through the second keel, the plank can be prevented from arching and deforming.

Owner:李新发

Double-keel decorative plate

A double-keel decorative plate comprises two neighboring wood blocks. A keel is composed of a T-shaped main rib and auxiliary ribs, which are formed on a square block; the main rib and the auxiliary ribs are inserted inside a main rib slot and auxiliary rib slots in the wood blocks in a matched mode; keel slots are formed in the T-shaped main rib; an elastic keel is a hollow elastic body, and elastic keel tenons are formed on the opening-type bottom edge of the elastic keel and inserted inside the keel slots; main rib transverse gaps and auxiliary rib gaps are retained between the main rib and the wood blocks as well as the auxiliary rib gaps and the wood blocks; the top end surface of the elastic keel is exposed out of the surfaces of the wood blocks, and the two neighboring wood blocks are pressed onto the elastic keel. The double-keel decorative plate can effectively avoid arching and deformation of the wood blocks and guarantee that contraction gaps seen from the surfaces of the wood blocks is relatively small.

Owner:湖州龙扣木业有限公司

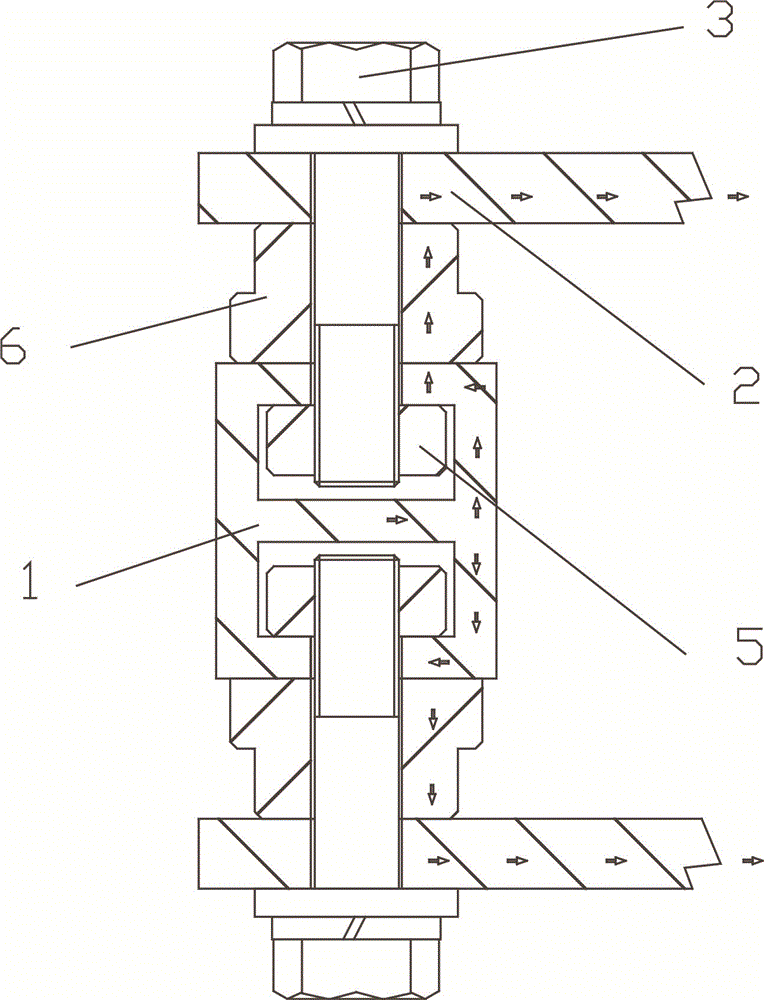

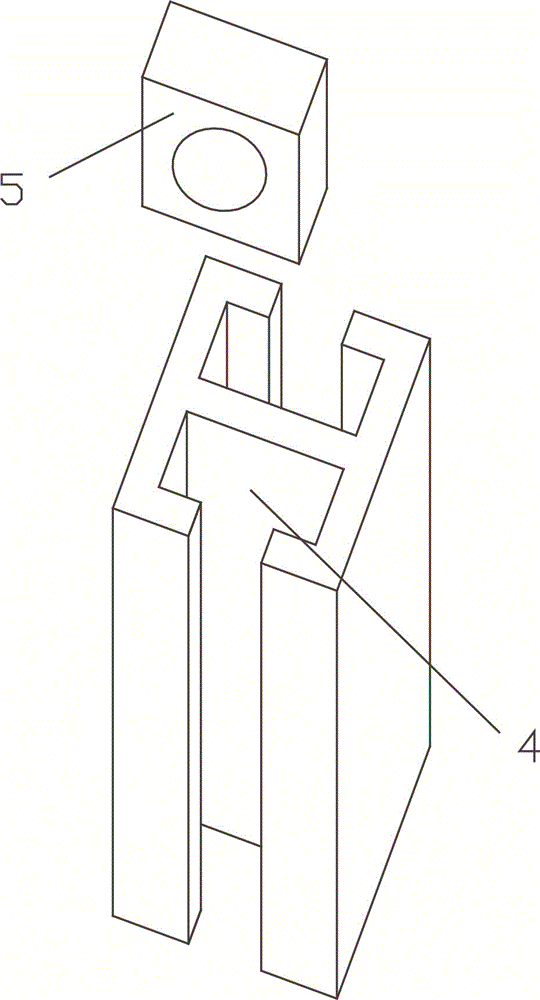

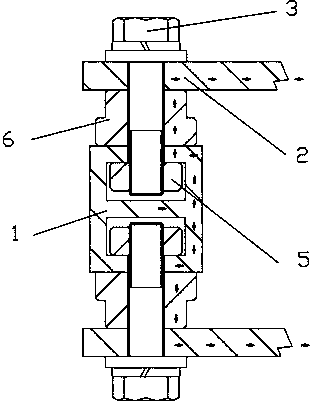

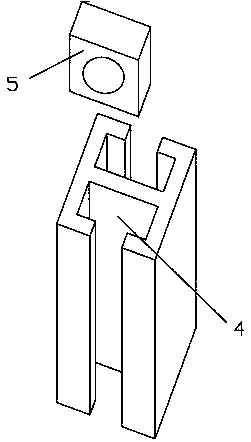

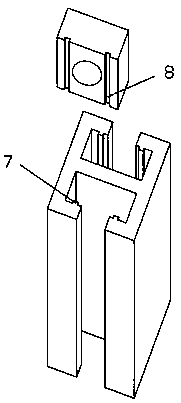

Copper bar connecting structure

ActiveCN104682212ASave installation spaceRealize economic benefitsBus-bar/wiring layoutsCooling bus-bar installationsCopperMaterials science

The invention discloses a copper bar connecting structure. The copper bar connecting structure comprises an input copper bar, an output copper bar and bolts, wherein the input copper bar and the output copper bar are arranged in a crossed manner, the cross section of the input copper bar is I-shaped, long grooves are formed in the two sides of the input copper bar, nuts are arranged in the long grooves, and a conductive pad is arranged between the input copper bar and the output copper bar; after sequentially penetrating through the output copper bar and the conductive pad, the bolts are fixed on the nuts in the long grooves; the cross sections of the long grooves are in a shape like the Chinese character tu, and raised lines are arranged on the inner surfaces of the open ends of the long grooves; grooves are formed in the surfaces of single sides of the nuts, and the raised lines are clamped in the grooves. The copper bar connecting structure has the advantages that the input copper bar is designed to be I-shaped, and the nuts can slide in the long grooves, so that the output copper bar can be fixed in any position in the long grooves without punching holes; current flows in from the input copper bar, flows across the conductive pad and then flows out from the output copper bar.

Owner:宁波双龙电器有限公司

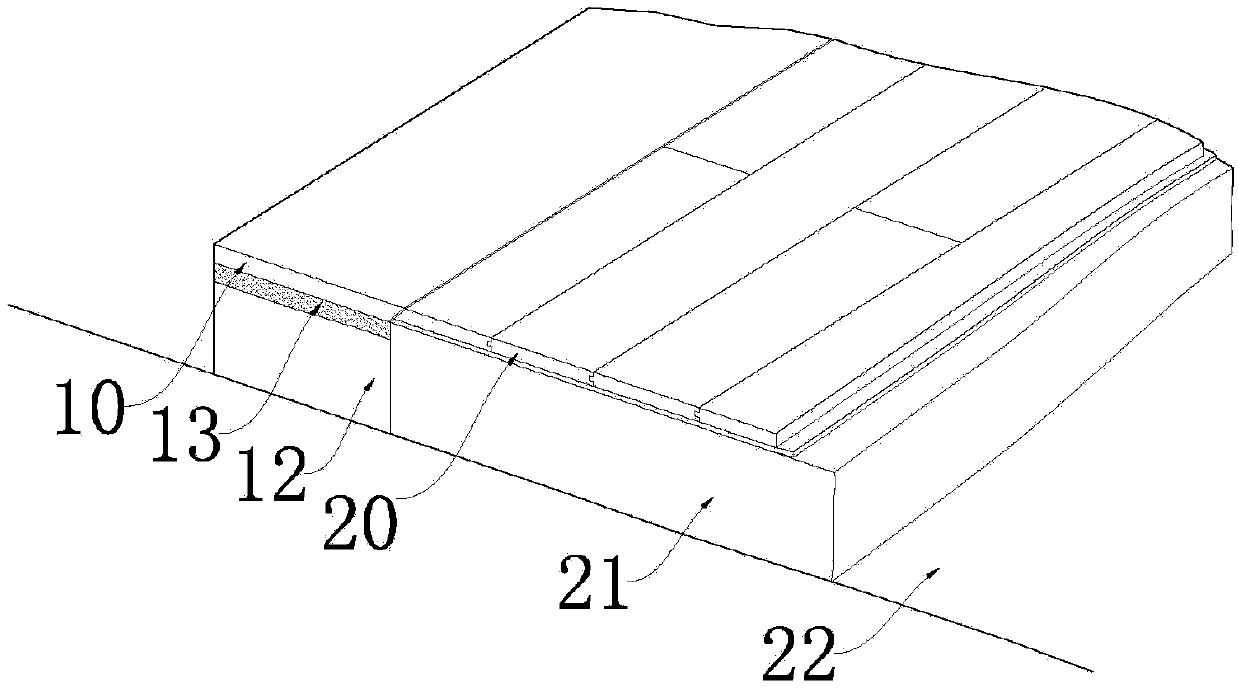

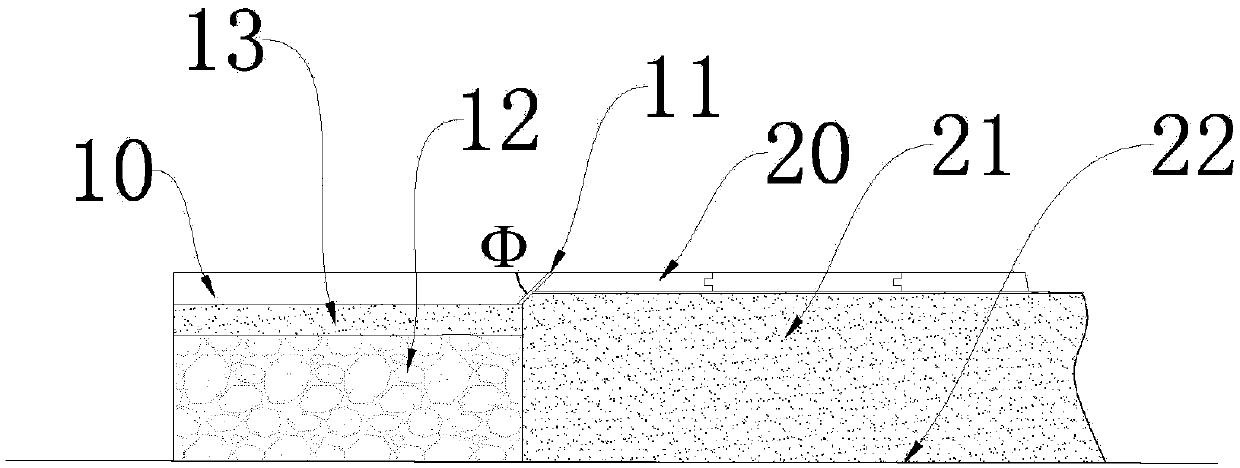

Threshold and floor closed-up part and manufacturing technique thereof

InactiveCN107905497APrevent arching deformationAvoid accumulationBuilding constructionsWater leakageMasking tape

The invention relates to a decoration technique, in particular to a threshold and floor closed-up part and a manufacturing technique thereof. The contact face of a threshold and a floor is an obliqueface, and an included angle phi of the oblique face and the horizontal face is 40-60 degrees. A telescopic seam is reserved at the connecting position of threshold stone and the floor, the width of the telescopic seam is 1.5-2 mm, and the telescopic seam is filled and leveled up with a sealant. According to the threshold and floor closed-up part and the manufacturing technique thereof, the contactface of the threshold stone and the floor is ground into the oblique face, and the stability after the threshold stone and the floor are laid is improved; meanwhile, the telescopic seam is reserved at the contact position of the threshold stone and the floor, so that a space is reserved for thermal expansion and contraction deformation of the floor, and the situation that the floor deforms in anarched mode and thus beauty is affected is prevented; and masking tapes are stuck to the two sides of the telescopic seam, the telescopic seam is filled and leveled up with the sealant, and dust is prevented from being accumulated. According to the threshold and floor closed-up part, the connecting seam is beautiful and firm, passage is easy, and the potential hazards of deformation and water leakage are avoided after long-term use.

Owner:SHANGHAI JUTONG DECORATION GRP

Floor with heat emitting, heat guiding and heat insulating function and transverse inserted connection function

PendingCN108952068APrevent arching deformationReduce gapCovering/liningsLighting and heating apparatusKeelEngineering

A floor with a heat emitting, heat guiding and heat insulating function and a transverse inserted connection function comprises a wood board block and a keel. According to the keel of the structure, transverse auxiliary ribs are formed on the left side and the right side of a main rib respectively, the lower surface of each auxiliary rib is an inclined surface, the inner side of each inclined surface extends to form a hook-shaped tenon, the two auxiliary ribs are connected together through an elastic piece, and a heating cable is placed in each auxiliary rib; a main rib insertion groove, auxiliary insertion grooves and hook-shaped tenon insertion grooves are formed in the wood board block, the main rib, the auxiliary ribs and the hook-shaped tenons are inserted in the main rib insertion groove, the auxiliary insertion grooves and the hook-shaped tenon insertion grooves respectively, the main rib is vertical, the auxiliary ribs are transverse and straight, and the hook-shaped tenons arestraight. The floor can prevent the wood board block from arching deformation and has the heat emitting, heat guiding and heat insulating function and the horizontal oppositely inserted installationfunction.

Owner:李新发

Arch camber prevention floor made of elastic materials

InactiveCN103452289APrevent arching deformationReduce gapResiliently-mounted floorsKeelElastic plastic

The invention provides an arch camber prevention floor made of elastic materials. The arch camber prevention floor comprises wood board blocks and keels, wherein a transverse inserted tenon, a transverse slot, bottom surface slots and bottom surface accommodating grooves are formed in each wood board block; the transverse inserted tenon on each wood board block is inserted into the transverse slot of the other wood board block adjacent to the wood board block in a sleeved manner; each keel is made of arc-shaped elastic pieces, square blocks and inserted ribs; the square blocks are welded and fixed on two sides of each arc-shaped elastic piece; the inserted ribs are formed on the square blocks; two inserted ribs are respectively inserted into the bottom surface slots formed in two adjacent wood board blocks in the sleeved manner; the arc-shaped elastic pieces are placed in the bottom surface accommodating grooves of each wood board block; the left surface and the right surface of each wood board block are coated with elastic plastic layers. The arch camber prevention floor provided by the invention can effectively prevent arch camber and deformation of the wood board blocks, and reduce the clearance between each two adjacent wood board blocks.

Owner:苏州燕泥地热地板科技有限公司

A grouting repair method for regenerating concealed karst at the subgrade base of existing ballastless track

ActiveCN108930265BSolving Grouting Repair ProblemsPrevent arching deformationRailway tracksSoil preservationHigh densityTrackway

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Method for laying moisture-proof and anti-arching deformation of floor

The invention discloses a method for laying floor moisture-proof and anti-arching deformation, which comprises the following steps: S1, cleaning dust on the ground; S2, scraping polyurethane on the ground to form a polyurethane layer, laying a floor on the polyurethane layer, and reserving a first expansion joint between the floor close to the wall surface and the wall surface. According to the laying method provided by the invention, a layer of polyurethane is firstly scraped, and then a floor is laid on the polyurethane layer; and because the polyurethane can firmly bond the ground to the floor, the moisture of the ground is completely isolated from the floor, and the floor is prevented from being damped and arched and deformed due to the moisture of the ground.

Owner:舍奢(武汉)家居有限公司

Safety supporting structure for civil engineering foundation pit supporting

InactiveCN112177014AReduce collapseImprove structural strengthExcavationsSoil preservationResidual deformationPre stress

The invention relates to the technical field of foundation pit supporting, and particularly relates to a safety supporting structure for civil engineering foundation pit supporting. The safety supporting structure comprises a plurality of supporting plates, wherein upper channel steel extending towards one side of a slope body is fixedly arranged at the upper ends of the supporting plates, lower channel steel extending towards the side away from the slope body is fixedly arranged at the lower ends of the supporting plates, openings of the upper channel steel and the lower channel steel are upward, and drainage grooves used for drainage are formed in the upper ends and the lower ends of the supporting plates; and vertically-arranged reinforcing ribs are arranged in the middles of the left sides of the supporting plates, and first holes are formed in the reinforcing ribs. According to the safety supporting structure, the supporting plates, the reinforcing ribs and steel wire ropes are arranged so that the overall structural stability of the supporting plates can be improved, the vibration energy can be consumed, the damping effect can be achieved, and therefore the situation that residual deformation of prestressed anchor rods is caused due to position deviation of the supporting plates can be avoided, the constraint of the prestressed anchor rods on the slope body can be guaranteed, and the risk of instability and collapse of the slope body can be reduced.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

A high-efficiency seedling picking mechanism suitable for growing seedlings with degradable materials

ActiveCN112703866BPrevent arching deformationQuality improvementTransplantingStructural engineeringDrive motor

The invention discloses a high-efficiency seedling picking mechanism suitable for seedling raising trays made of degradable materials, which includes a frame, a seedling picking drive motor, a moving knife mounting plate, more than one moving knife, a fixed knife mounting seat and more than one fixed knife. The moving knife mounting plate is installed on the frame and forms a vertical movement pair with the frame. The drive motor for picking seedlings is installed on the frame to drive the moving knife mounting plate to move vertically on the frame. The moving knife is mounted on the moving knife mounting plate And move up and down with the vertical movement of the moving knife mounting plate. The fixed knife mounting seat is installed on the frame and all the fixed knives are parallel to each other. The fixed knife is installed on the fixed knife mounting seat, and the fixed knife is located directly below the moving knife. In the state of use, the seedling tray passes through the fixed knife, and the movable knife moves up and down to cooperate with the fixed knife to cut the seedling tray into multiple rows. The present invention adopts the up and down movement of the movable knife and cooperates with the fixed knife to cut the seedling tray, and the seedling tray is forced downward to avoid arching deformation due to the action of tangential force and improve the quality of seedling picking.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Anti-cambering floor

Owner:湖州龙扣木业有限公司

Copper bar connecting structure production method

InactiveCN108039596APrevent arching deformationSave installation spaceCoupling contact membersClamped/spring connectionsCopper

The invention discloses a copper bar connecting structure comprising an input copper bar, an output copper bar and a bolt, wherein the input copper bar and the output copper bar are arranged in a crossed manner, the cross section of the input copper bar is in an I shape, long grooves are formed in the two sides of the input copper bar, and nuts are arranged in the long grooves, a conductive cushion block is arranged between the input copper bar and the output copper bar, the bolt penetrates through the output copper bar and the conductive cushion block in sequence, and then is fixed on the nuts in the long grooves, the cross section of each long groove is in a convex shape, a convex strip is arranged on the inner surface of the opening end of the long groove, and a groove is formed in thesingle side surface of each nut, and the convex strip is clamped into the groove. The method has the advantages that the input copper bar is designed into an I shape, the nuts can slide in the long grooves, so that the output copper bar can be fixed at any position in the long grooves, hole punching is not needed, the current flows from the input copper bar, passes through the conductive cushion block and then flows out of the output copper bar.

Owner:黄样忠

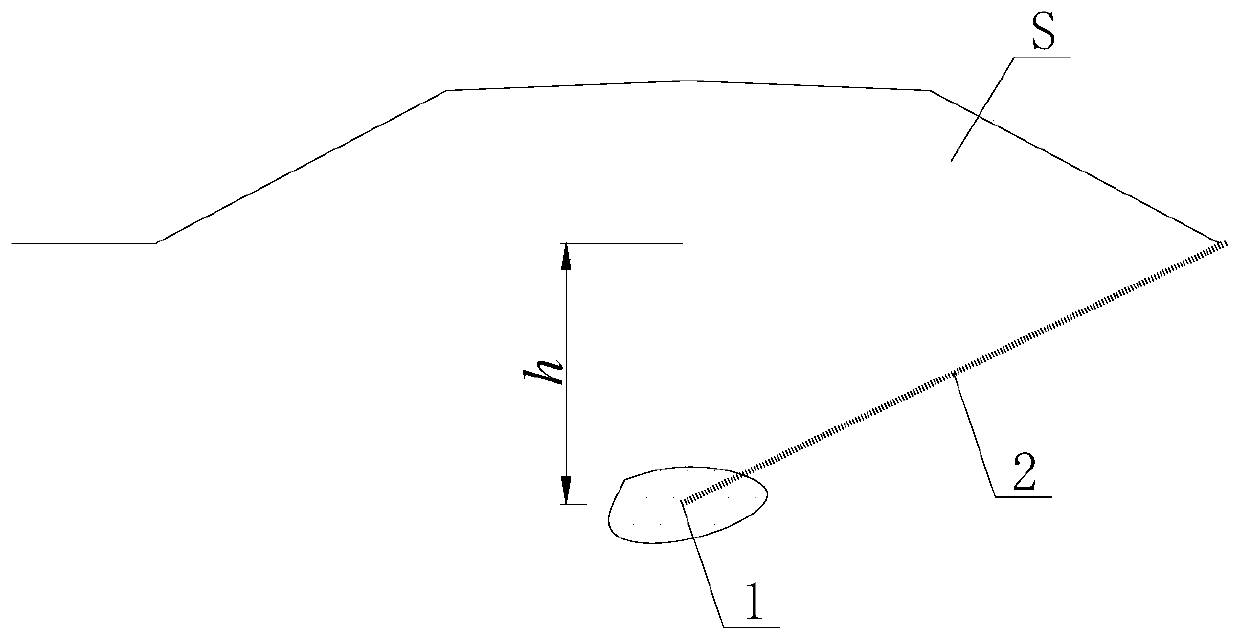

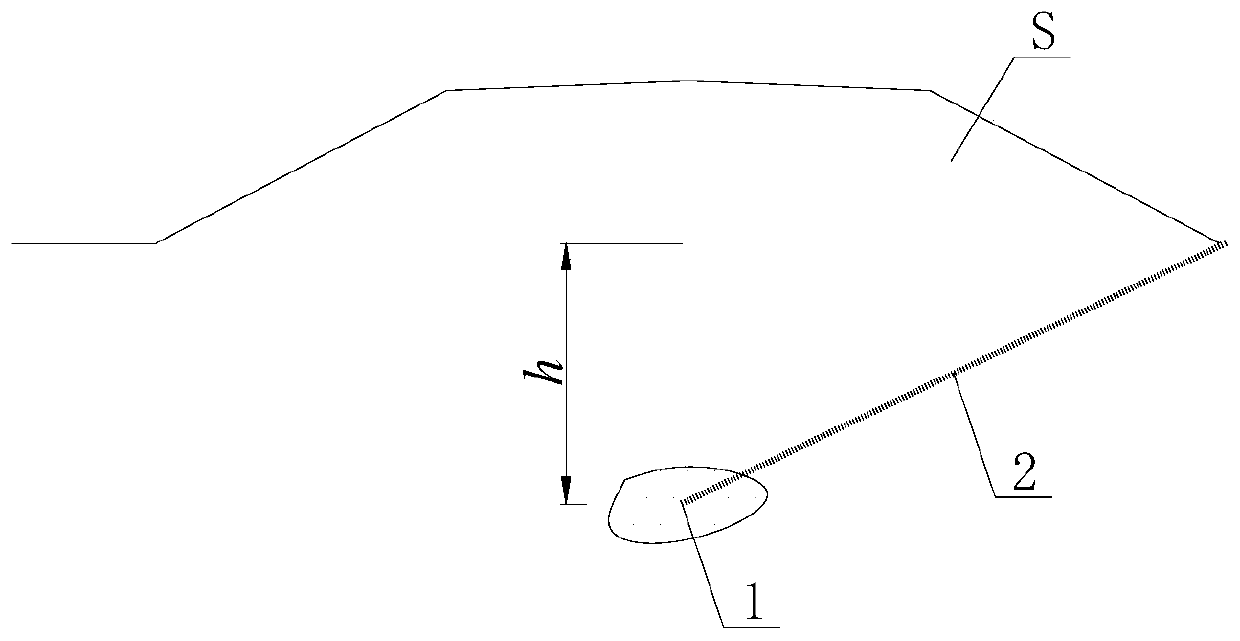

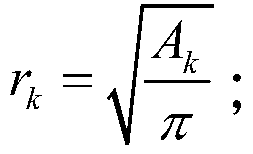

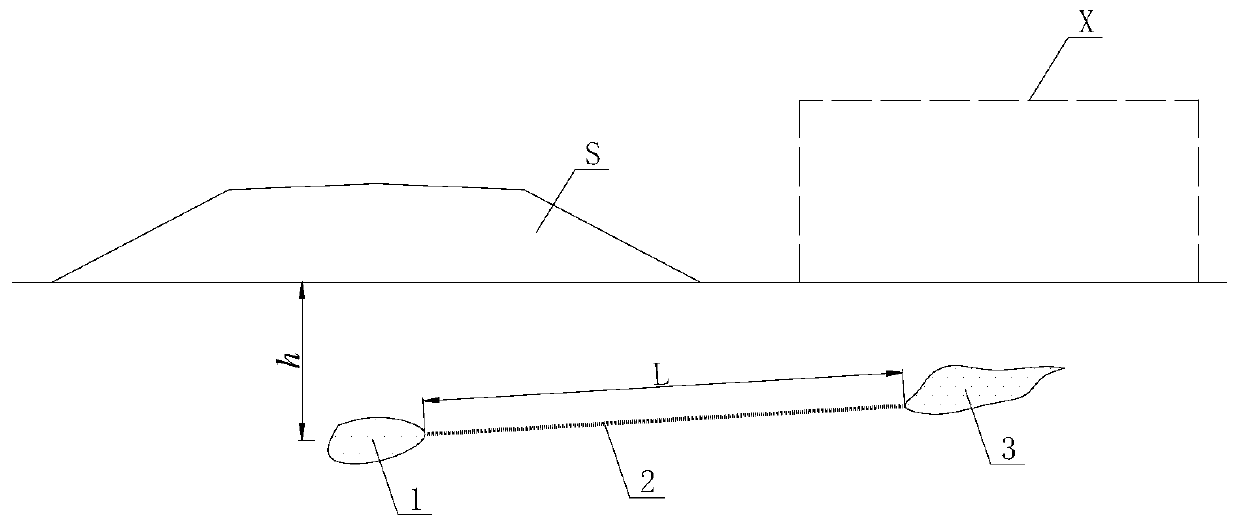

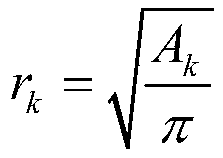

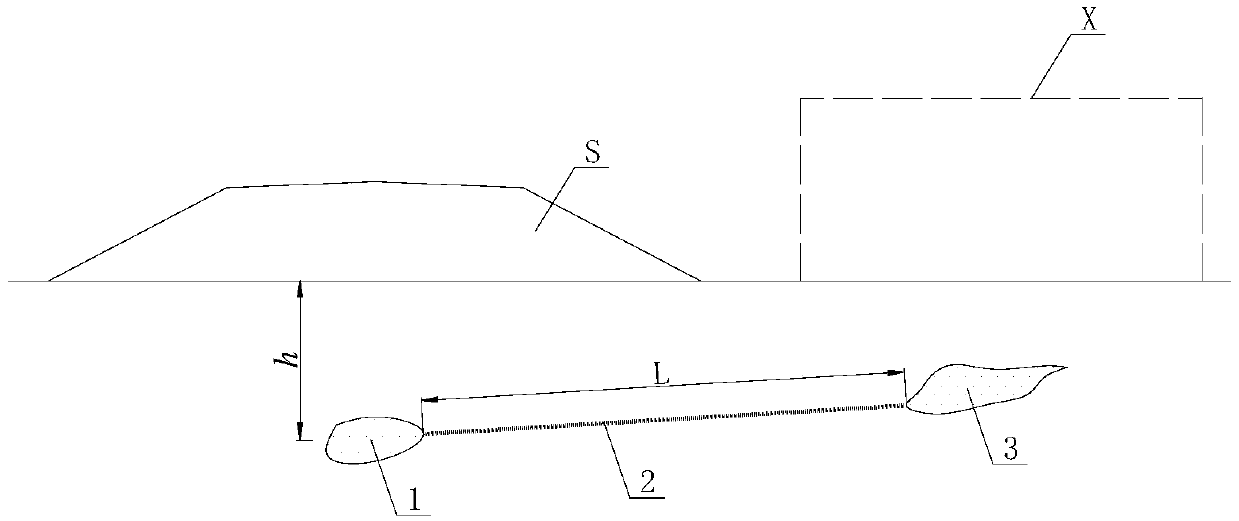

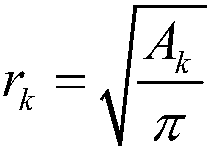

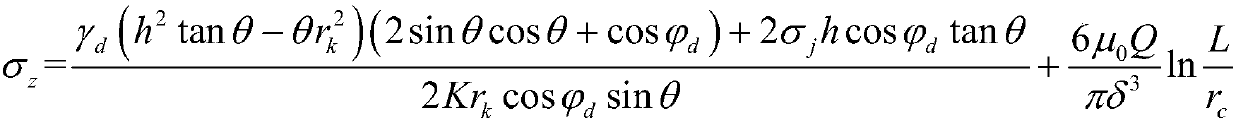

A karst grouting reinforcement method adjacent to the existing ballastless track subgrade

ActiveCN109056731BPrevent arching deformationSolve the problem of karst grouting reinforcementRoadwaysFoundation engineeringHigh densityTrackway

The invention discloses a karst grouting reinforcement method near an existing ballastless track roadbed; and the newly built building substrate karst grouting reinforcement near the existing ballastless track roadbed is scientifically and reasonably performed to effectively prevent the upwarp deformation of the ballastless track roadbed. The method comprises the following steps: (1) related parameters are determined through data collection or a high-density electrical method or a ground penetrating radar or an earthquake reflecting method or electromagnetic wave CT; (2) the weight gamma d andthe internal friction angle FORMULA of a substrate karst top covering layer of the existing roadbed are determined through scene investigation or data collection or drilling sampling or indoor geotechnical tests; (3) the grouting pressure omega z of the newly built building substrate karst is determined through calculation; and (4) the newly built building substrate is drilled to a karst distribution area; and the grouting reinforcement is performed according to the grouting pressure not higher than the grouting pressure omega z determined in the step (3).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Wound lithium ion battery and preparation method thereof

PendingCN113889673AReserve internal expansion spaceControl deformation archingFinal product manufactureSecondary cells servicing/maintenanceElectrical batteryCell fabrication

The invention discloses a preparation method of a wound lithium ion battery. The method comprises the following steps of: coating at least one of a battery positive electrode sheet, a battery negative electrode sheet and a diaphragm with an easy-to-remove substance solution, and removing the easy-to-remove substance after winding. The invention further discloses the wound lithium ion battery prepared according to the preparation method, wherein the internal expansion space of the battery can be reserved in the wound lithium ion battery, so that deformation and arching of the battery are controlled, and deformation and arching in the battery manufacturing and using process are solved. According to the invention, the easy-to-remove substance in the method is cheap, the cost is low, the process is simple, and rapid industrialization can be achieved.

Owner:福建省致格新能源电池科技有限公司 +1

Granite decorative panels

ActiveCN104153532BReduce weightEasy to carryCovering/liningsFire proofingSurface mountingCement board

The invention discloses a granite decorative board, which comprises a decorative board body, connecting grooves are arranged on both sides of the decorative board body, a vermiculite board is arranged near the connecting groove on the decorative board body, the vermiculite board is vertically installed on the decorative board body, and the vermiculite There are two stone slabs, a coating layer is connected between the two vermiculite slabs, and an insulation board is installed on the lower surface of the coating layer. The thickness of the insulation board is greater than the thickness of the coating layer. There is a foamed cement slab, and the foamed cement slab is flexibly connected to the main body of the decorative board, and a steel connecting column is installed between the foamed cement slab and the decorative board body, there are two steel connecting columns, and the top of the steel connecting column Extends within the insulation board. The granite decorative board is light in weight, easy to carry, has good fireproof performance, can avoid brittle cracking at the same time, and can effectively prevent the plate from arching and deformation, ensuring that the shrinkage joint gap of the plate is small, the overall is more reasonable, and the decorative effect is more obvious .

Owner:广东满大装饰工程有限公司

A kind of equipment and method for one-time forming bamboo frame by using bamboo strips

ActiveCN107363960BImprove stabilityQuality improvementCane mechanical workingWood working apparatusEngineeringMechanical engineering

The invention relates to equipment for forming a bamboo box at one time with bamboo canes and a method. The problems that multiple bamboo canes cannot be smoothly closed to form a bamboo box easily through existing equipment and quality of the formed bamboo box is low can be solved. The equipment comprises a fixed mold, a plurality of movable molds, a pressing roller mechanism and a cutting mechanism. The multiple movable molds are distributed around the fixed mold at intervals. A pressing roller of the pressing roller mechanism can abut against the periphery of the fixed mold and further can move along the periphery of the fixed mold. The cutting mechanism is located at the joint of the moving start end and the moving tail end of the pressing roller mechanism. A cutter of the cutting mechanism can cut and trim the start ends and the tail ends of the multiple layers of the bamboo canes. By improving the equipment and the corresponding method, the multiple layers of the bamboo canes can be smoothly closed to form the bamboo box, and meanwhile the product quality of the bamboo box can be improved.

Owner:FUJIAN SHUANGYI BAMBOO DEV CO LTD

Method for preventing bottom of aluminum cell from upwarping and structure thereof

ActiveCN101440501BPrevent arching deformationAvoid it happening againArchitectural engineeringCathode

The invention discloses a method for preventing the bottom of an aluminum electrobath from upwarpping and a structure thereof and in particular relates to a method for preventing the bottom of the aluminum electrobath from upwarpping in the roasting startup process and a structure thereof. The structure comprises: the bottom of the aluminum electrobath is connected with a connecting mechanism (14); one end of the connecting mechanism (14) is connected with a cradle rack (1) on the underside of the aluminum electrobath; and the other end of the connecting mechanism (14) is fixed on a supporting pillar (13) of the electrobath. The method can solve the problem that the bottom of the aluminum electrobath is upwarpped and deformed in the roasting startup process, can prevent producing the crack of cathode and is convenient to produce and operate. The structure has a simple structure, easy realization in operation, obvious effect and wide market prospect.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

A pipe winding and binding device

ActiveCN112298713BAdjustable winding radiusEasy to adjust winding radiusFilament handlingBundling machine detailsControl engineeringEngineering

Owner:重庆市齐垚机电设备有限公司 +1

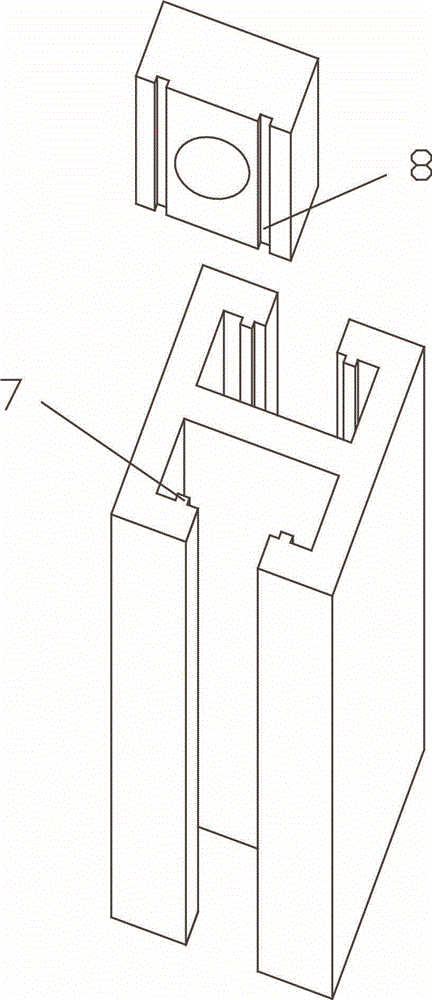

Clamping device for high-frequency heat treatment process and method

ActiveCN113278773AReduce torqueReduce torsional deformationFurnace typesIncreasing energy efficiencyEngineeringTorsional deformation

The invention provides a clamping device for a high-frequency heat treatment process. The device comprises a lower positioning assembly and an upper positioning assembly which are arranged in a vertical direction, wherein the lower end of a to-be-treated part in a length direction is placed on the lower positioning assembly, the upper positioning assembly can adjust a fixing position in the vertical direction to clamp the upper end of the part, and an induction coil can move in the vertical direction to penetrate through the two ends of the part. The device has the advantages that the part is supported through the lower positioning assembly, and the upper positioning assembly is matched with the upper end of the part to enable the part to be kept vertical, so that the part does not bear too large pressure, arching deformation of the part is prevented, the part is not subjected to the effect of torsional force or pressure in a circumferential direction, and the torsional deformation of the part is reduced; and the induction coil can penetrate through the whole part, so that the part is integrally quenched, and the whole part can be subjected to heat treatment.

Owner:保隆沙士基达(安徽)液压成型有限公司

Combined double-keel decorative board

The invention relates to a combined double-keel decorative board. A right additional rib and a left additional rib are located on the two sides of a main rib respectively; a hollow sleeving part is arranged at the upper part of an upper keel; an upper keel right additional rib chase mortise extends transversely from the hollow sleeving part; the right additional rib is arranged in the upper keel right additional rib chase mortise; the upper keel right additional rib chase mortise is inserted and sleeved into a matched right additional rib groove in a board block; the left additional rib is inserted and sleeved into a matched left additional rib inserting groove in the board block; the main rib is sleeved with the hollow sleeving part; the hollow sleeving part is inserted and sleeved into a matched main rib inserting groove in the board block; an additional bar transverse clearance less than 1mm exists between the right additional rib and the upper keel right additional rib chase mortise; and a main rib transverse clearance less than 1mm exists between the hollow sleeving part and the main rib. According to the board, the board block can be effectively prevented from arch camber deformation, and visible contraction joint gaps on the surface of the board block can be smaller.

Owner:李新发

A whole-row precise transfer and picking mechanism suitable for seedling trays made of degradable materials

ActiveCN112703865BPrevent arching deformationQuality improvementTransplantingAgricultural engineeringElectric machinery

The invention discloses an entire row of precise seedling transfer and fetching mechanism suitable for degradable material seedling raising trays. The seedling mechanism is set at the other end of the frame, and the precise seedling transfer mechanism is set on the frame and is located between the seedling box and the precise seedling picking mechanism. The knife, the fixed knife mounting seat and one or more fixed knives, the moving knife mounting plate is installed on the frame and forms a vertical moving pair with the frame, and the seedling drive motor is installed on the frame to drive the moving knife mounting plate on the frame. Move vertically, the movable knife is installed on the movable knife mounting plate, the fixed knife mounting seat is installed on the frame, and the vertical movement of the movable knife with the movable knife mounting plate cooperates with the fixed knife to slit and transport to the seedling tray on the fixed knife. The invention improves the quality of the seedlings.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Karst grouting reinforcement method near existing ballastless track roadbed

ActiveCN109056731APrevent arching deformationSolve the problem of karst grouting reinforcementRoadwaysFoundation engineeringGeomorphologyHigh density

The invention discloses a karst grouting reinforcement method near an existing ballastless track roadbed; and the newly built building substrate karst grouting reinforcement near the existing ballastless track roadbed is scientifically and reasonably performed to effectively prevent the upwarp deformation of the ballastless track roadbed. The method comprises the following steps: (1) related parameters are determined through data collection or a high-density electrical method or a ground penetrating radar or an earthquake reflecting method or electromagnetic wave CT; (2) the weight gamma d andthe internal friction angle FORMULA of a substrate karst top covering layer of the existing roadbed are determined through scene investigation or data collection or drilling sampling or indoor geotechnical tests; (3) the grouting pressure omega z of the newly built building substrate karst is determined through calculation; and (4) the newly built building substrate is drilled to a karst distribution area; and the grouting reinforcement is performed according to the grouting pressure not higher than the grouting pressure omega z determined in the step (3).

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com