A whole-row precise transfer and picking mechanism suitable for seedling trays made of degradable materials

A seedling tray and precise technology, applied in the field of the whole row of precise transfer and picking mechanism, can solve the problems of easy arching and deformation of the seedling tray, affecting the quality of picking seedlings, etc., and achieve the effect of improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

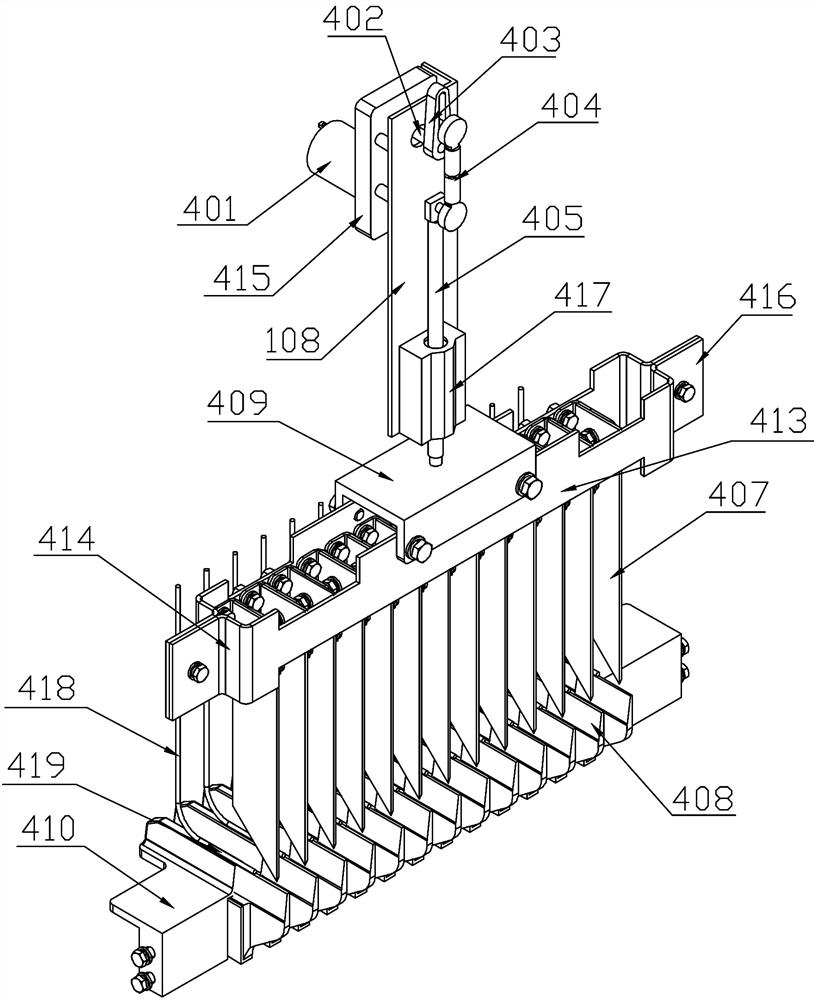

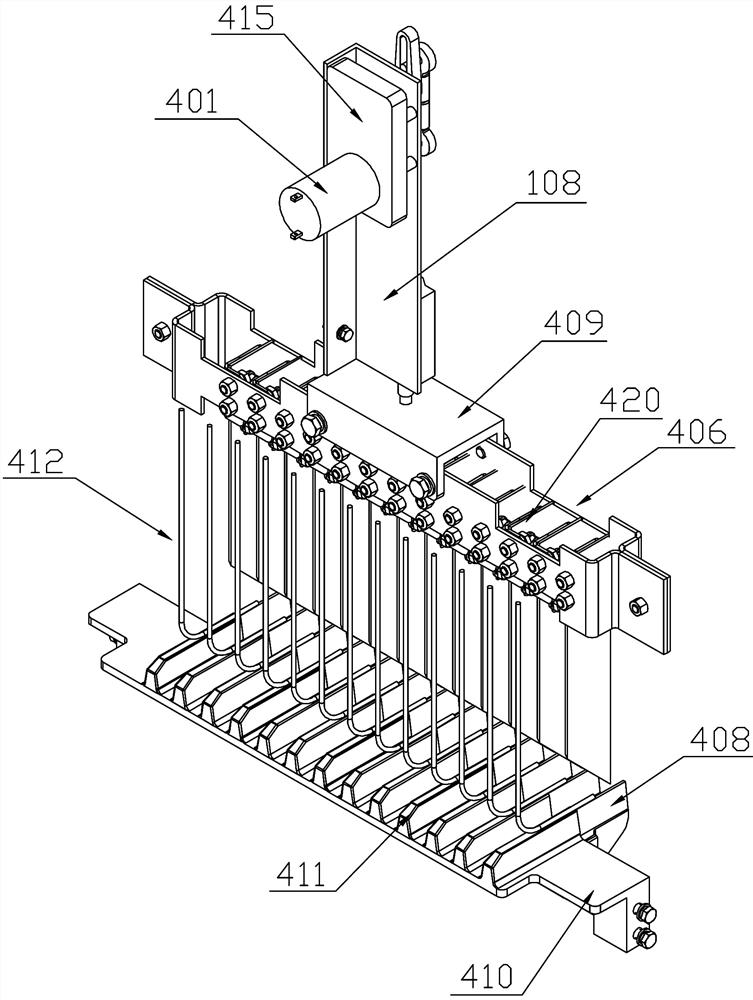

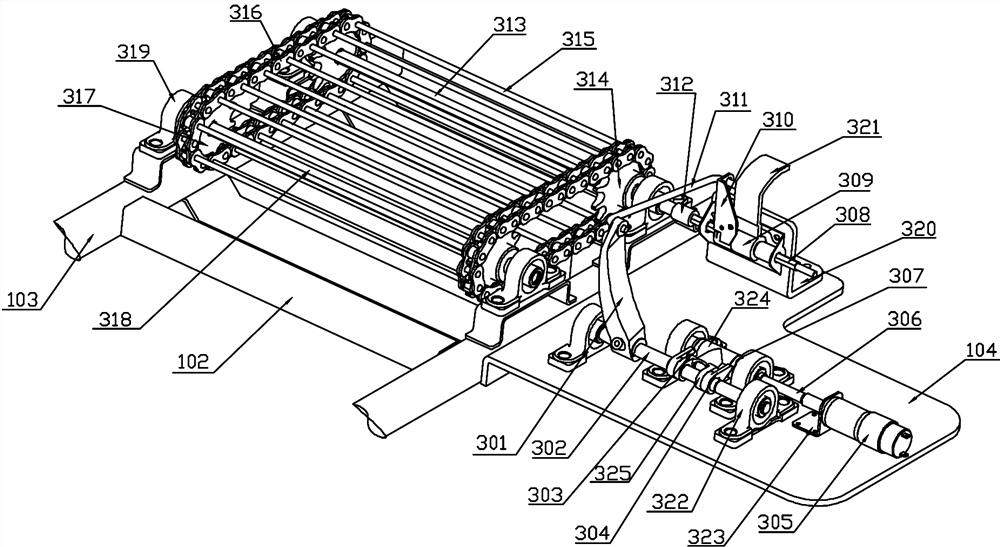

[0028] Such as Figure 1 to Figure 5 The whole row of precise seedling transfer and retrieval mechanism suitable for degradable seedling trays shown includes a frame 1, a seedling box 2, a precise seedling transfer mechanism 3 and a precise seedling retrieval mechanism 4, and the seedling box 2 is set at one end of the frame 1 For placing seedling trays, the precise seedling picking mechanism 4 is set on the other end of the frame 1 for cutting the seedling trays, and the precise seedling transfer mechanism 3 is set on the frame 1 and is located between the seedling box 2 and the precise seedling picking mechanism 4 , for transporting the seedling tray on the seedling box 2 to the precise seedling picking mechanism 4 .

[0029]Frame 1 among the present invention comprises four support columns 101, three horizontally arranged transverse support bars 102, two horizontally arranged longitudinal support bars 103, a support plate 104 and a seedling-taking mechanism support, and two...

Embodiment 2

[0045] This embodiment is a further improvement made on the basis of Embodiment 1. Compared with Embodiment 1, this embodiment is provided with a seedling pulling mechanism 5 on the frame 1 away from the end of the seedling box 2, and the seedling pulling mechanism 5 Comprise seedling pulling driving motor 501, pulling seedling driving shaft 502 and a plurality of seedling pulling discs 503, the two ends of pulling seedling driving shaft 502 adopt bearings to rotate respectively and be arranged on two supporting vertical plates 105, one end of pulling seedling driving shaft 502 is connected with The seedling driving motor 501 is connected, and the seedling driving motor 501 drives the relative support vertical plate 105 to rotate. The seedling driving motor 501 in the present invention is detachably mounted on one of the supporting vertical plates 105 using bolts. The seedling disc 503 A plurality of shifting teeth 504 are evenly arranged along the circumferential direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com