Threshold and floor closed-up part and manufacturing technique thereof

A technology for floors and thresholds, applied in the field of thresholds and floor closings and their production processes, can solve the problems of inclination of threshold stones, rough edges, and warped heads, and achieve the effects of avoiding dust accumulation, beautiful joints, and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

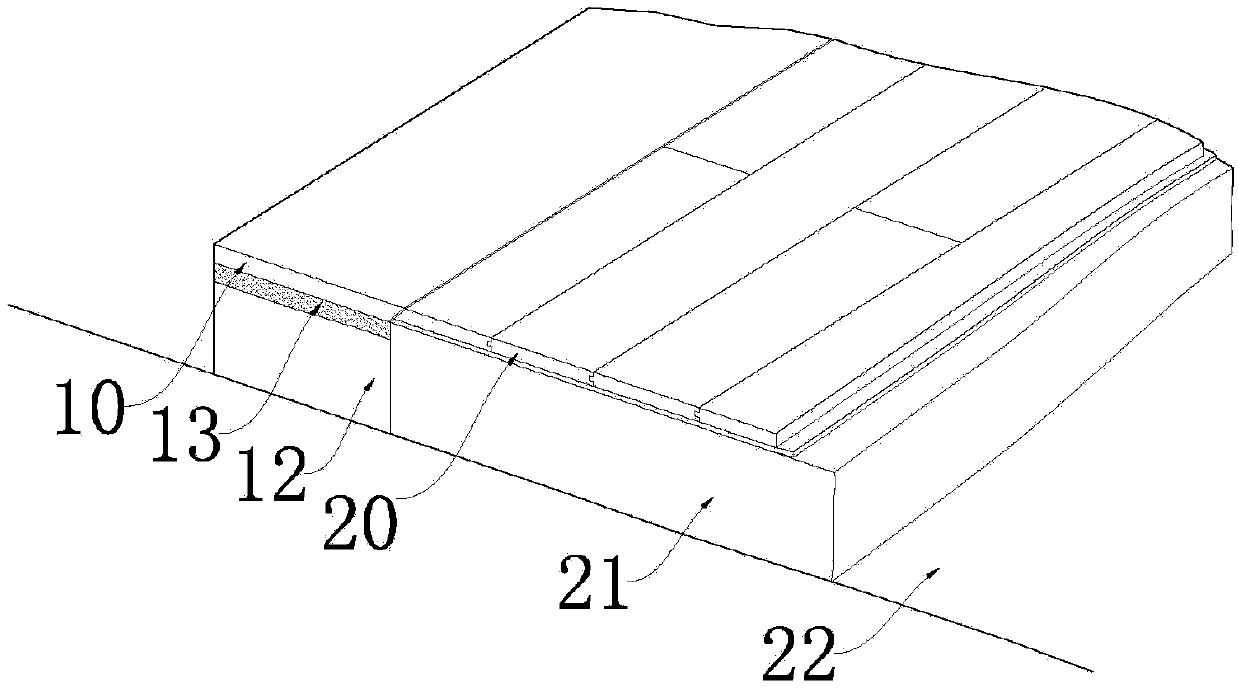

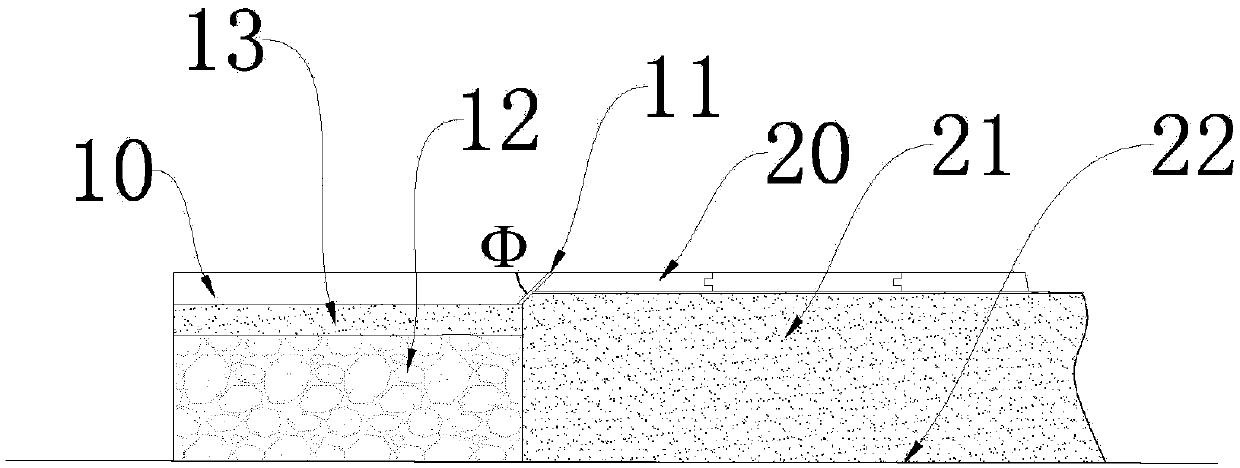

[0029] refer to figure 1 , the threshold of the present invention is closed with the floor, the threshold is a dry and wet area to separate the threshold, the wet area is the kitchen, bathroom, balcony and other areas, the dry area is the living room or room, and a partition made of plain concrete is laid below the threshold stone 10. The dam 12, the floor 20 is a composite floor, and the concrete leveling layer 21 is laid directly below. The contact surface between the threshold stone 10 and the floor 20 is an inclined plane, and the included angle Φ between the inclined plane and the horizontal plane is 45 degrees. For the consideration of waterproofing, the angle between the slope and the side of the floor is an obtuse angle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com