Arch camber prevention floor made of elastic materials

An elastic material and floor technology, applied in elastic floors, floors, buildings, etc., can solve problems such as arching deformation and large gaps of wood blocks, and achieve the effect of preventing arching deformation and reducing gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

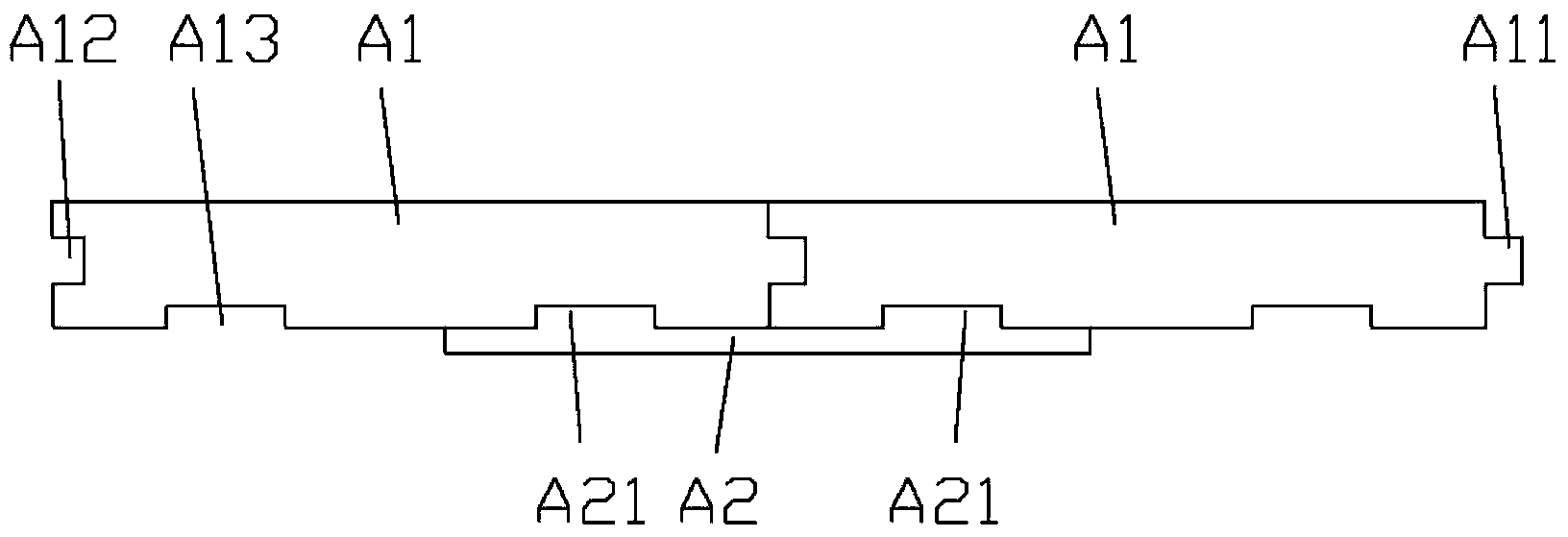

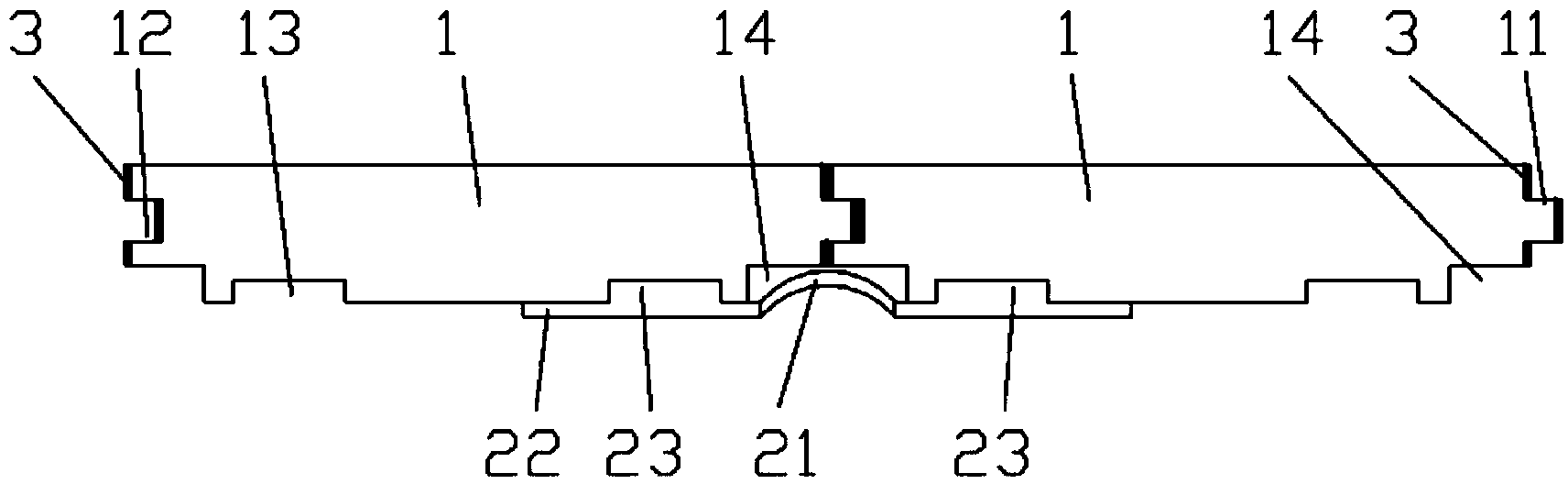

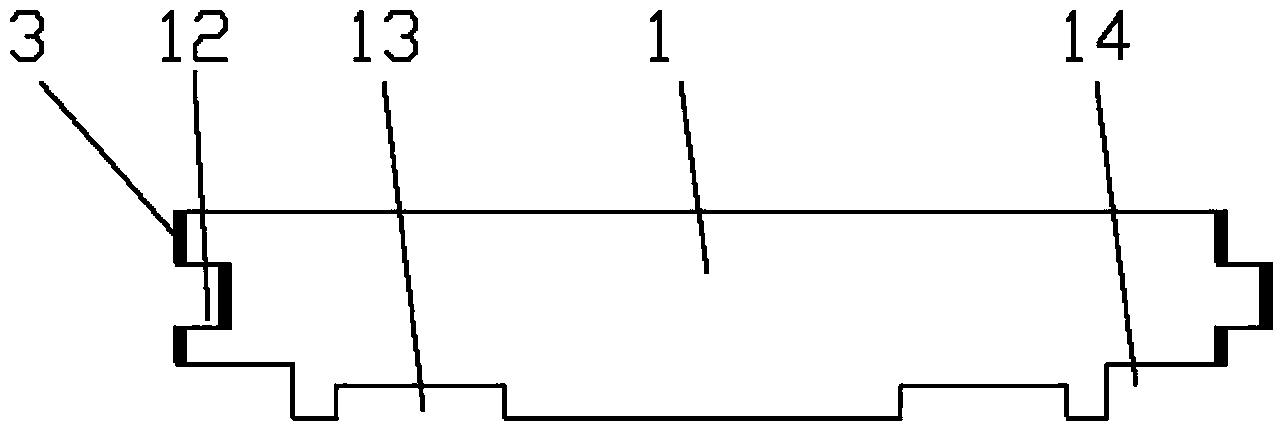

[0014] Example: see Figures 2 to 4 As shown, an anti-arching floor using elastic materials includes a wooden board 1 and a keel 2. The wooden board 1 is formed with a horizontal tenon 11, a horizontal slot 12, a bottom slot 13 and a bottom receiving groove 14. The wooden board The horizontal tenon 11 on 1 is inserted into the horizontal slot 12 of another adjacent wooden board 1, the keel 2 is composed of arc-shaped shrapnel 21, square block 22, and ribs 23, and the two sides of the arc-shaped shrapnel 21 are respectively The square block 22 is welded and fixed, and the square block 22 is formed with inserting ribs 23. The two inserting ribs 23 are respectively inserted into the two bottom slots 13 on the two adjacent wooden boards 1, and the arc-shaped shrapnel 21 is placed In the bottom receiving groove 14 of the wooden board 1 , the left surface and the right surface of the wooden board 1 are coated with an elastic plastic layer 3 .

[0015] Each keel 2 has at least two a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com