Combined double keel decorative board

A combined and decorative panel technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of wood panel arching deformation, large shrinkage gaps, large transverse stress, etc., and achieve the effect of preventing arching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

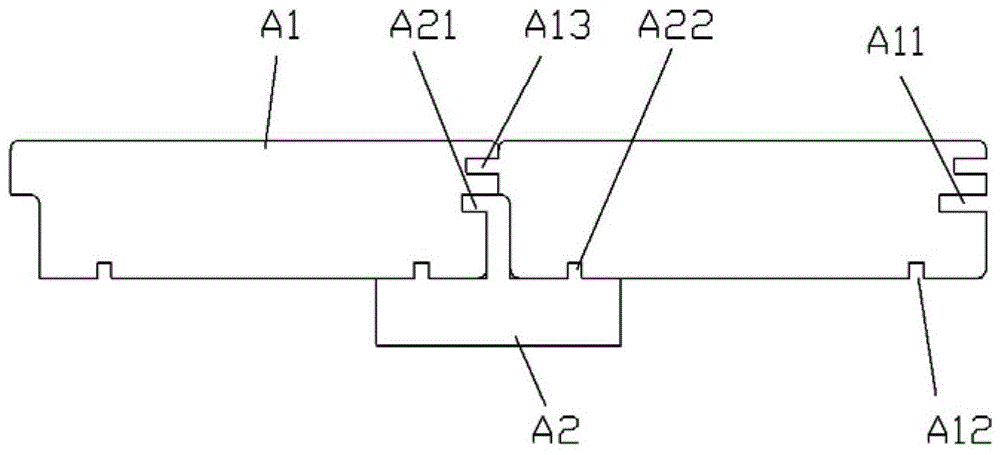

Examples

Embodiment 2

[0029] Example 2, see Figure 5 As shown, the positions of the right auxiliary rib 14 and the right auxiliary rib groove tenon 22 of the upper keel are exchanged. All the other are with embodiment 1.

Embodiment 3

[0030] Example 3, see Image 6 , 7 As shown, the hollow fitting part 21 extends laterally with the groove tenon 23 of the right auxiliary reinforcement of the second upper keel, and the groove tenon 23 of the right auxiliary reinforcement of the second upper keel is inserted into the matching slot on the wooden board 3 . All the other are with embodiment 2. Image 6 with Figure 7 The difference is that the position of the second upper keel right auxiliary rib groove tenon 23 is different.

Embodiment 4

[0031] Example 4, see Figure 8 As shown, the fitting portion 21 is formed with an oblique tenon 24 whose upper surface is inclined, and the oblique tenon 24 is inserted into the matching oblique groove 34 on the wooden board 3 . All the other are with embodiment 1.

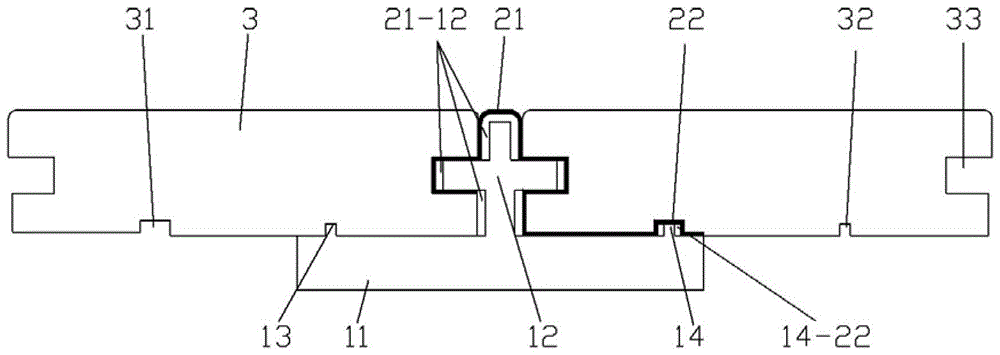

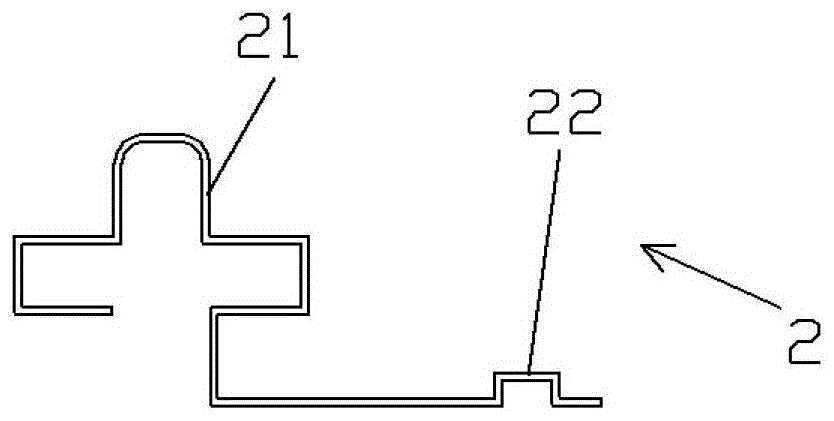

[0032] Working principle: When the two adjacent wooden boards 3 swell, the transverse stress between the two adjacent wooden boards 3 is effectively eliminated due to the elasticity of the upper keel 2, so that the wooden boards will not cause arching deformation , There is a transverse gap 21-12 between the hollow fitting part 21 and the main rib 12 which is not less than 1mm. The transverse gap 21-12 of the main reinforcement and the lateral gap 14-22 of the auxiliary reinforcement are to give space for deformation of the wooden board 3 and the upper keel 2 .

[0033] When the wooden board shrinks, the elastic upper keel 2 will return to its original shape, thus ensuring that the shrinkage gap seen on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com