Pressing plate type side guide centering device

A centering device and pressing plate technology, which is applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to accurately control the centering thrust of side guides and easy damage to the edge of the strip, and achieve improved The accuracy and effectiveness of centering, and the effect of stabilizing welding efficiency and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

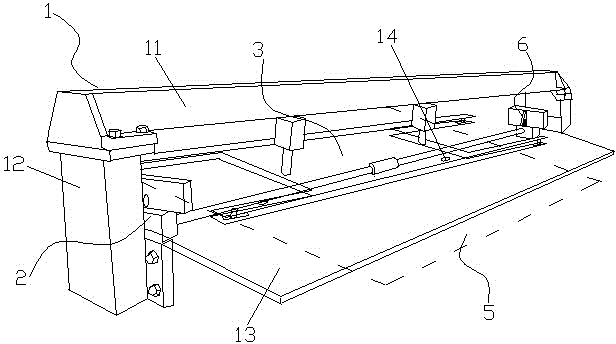

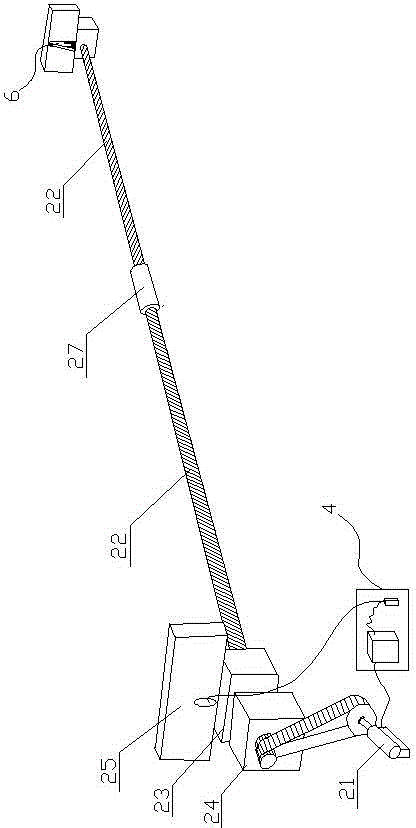

[0020] Such as figure 1 As shown, a pressure plate type side guide centering device includes a supporting frame structure 1 and a centering drive mechanism 2, and the centering drive mechanism 2 pushes the side edge of the strip steel 5 to be centered on the supporting surface of the supporting frame structure 1 , the support frame structure 1 is also provided with a mobile platen mechanism 3, the support frame structure 1 used in the embodiment of the present invention includes an upper support frame 11, a lower load-bearing frame 12 and a plane guide frame 13, and the plane guide frame 13 As a guide surface, a pair of limit position detection switches 14 are arranged on the plane guide frame 13 , the drive device 33 is installed on the upper support frame 11 , and the centering drive mechanism 2 is installed on the lower load-bearing frame 12 .

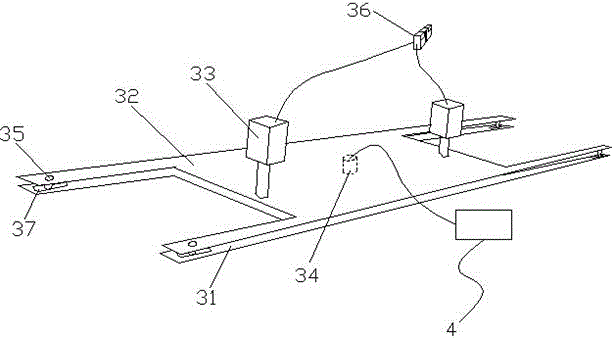

[0021] Such as figure 2 As shown, the moving platen mechanism 3 includes a lower laminate 31, an upper support plate 32 and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com