A kind of equipment and method for one-time forming bamboo frame by using bamboo strips

A disposable, bamboo strip technology, applied in the direction of mechanical equipment, manufacturing tools, wood processing appliances, etc., to improve stability and product quality, avoid local warping or arching deformation, and improve the quality of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, achieved purpose and effects of the present invention in detail, the following will be further described in detail in conjunction with the embodiments and accompanying drawings.

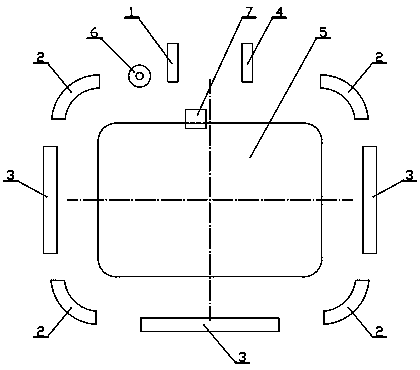

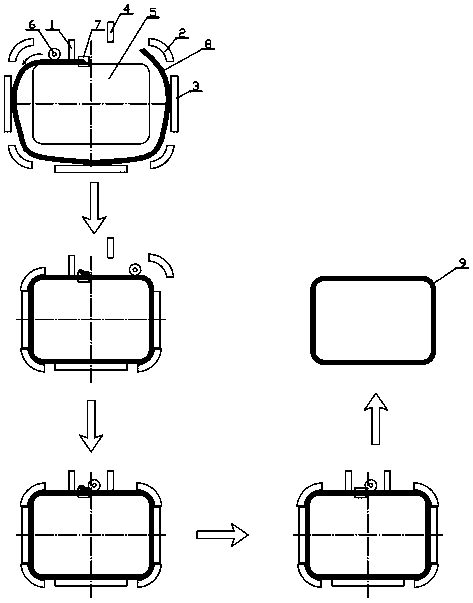

[0021] Such as figure 1 Shown, a kind of equipment that utilizes bamboo strips to form a bamboo frame at one time, the equipment includes a fixed mold, several movable molds, a pressing wheel mechanism and a cutting mechanism. The plurality of movable molds include a starting movable mold 1, an arc movable mold 2, a linear movable mold 3 and an end movable mold 4. Several movable mold intervals are distributed around the fixed mold 5 . The moving molds are respectively driven by the power mechanism to move.

[0022] The pinch wheel 6 of described pinch wheel mechanism can lean against the outer periphery of fixed mold, and can move along fixed mold 5 outer peripheries, so that the multi-layer bamboo strips of fixed mold 5 outer peripheries are grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com