Pipe winding and bundling device

A technology for bundling devices and pipes, which is applied in the directions of bundling objects, packaging/bundling items, and parts of bundling machinery, etc., can solve the problems of low degree of automation, backlog of pipes, and large workload, so as to reduce manual workload and stabilize The effect of draining and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

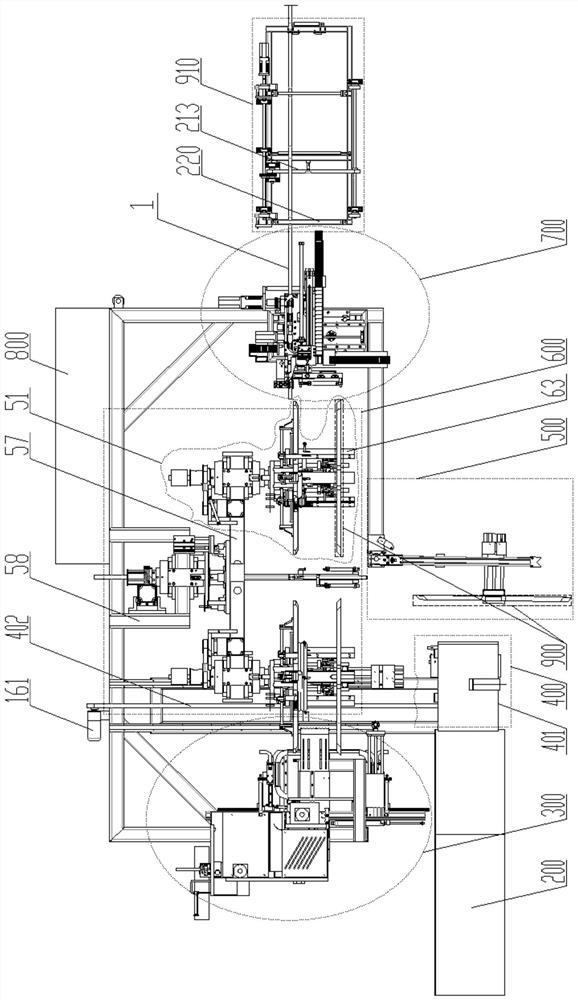

[0032] A pipe rewinding and binding device, see Figure 1 to Figure 20 .

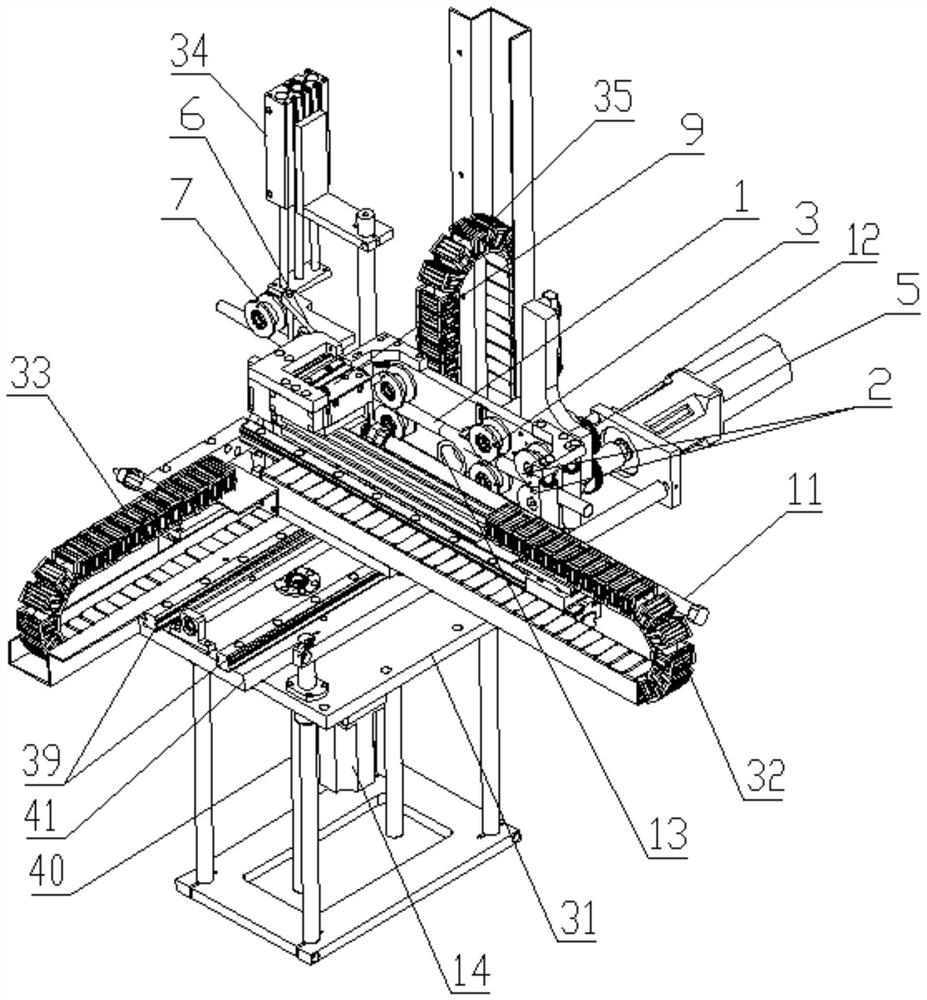

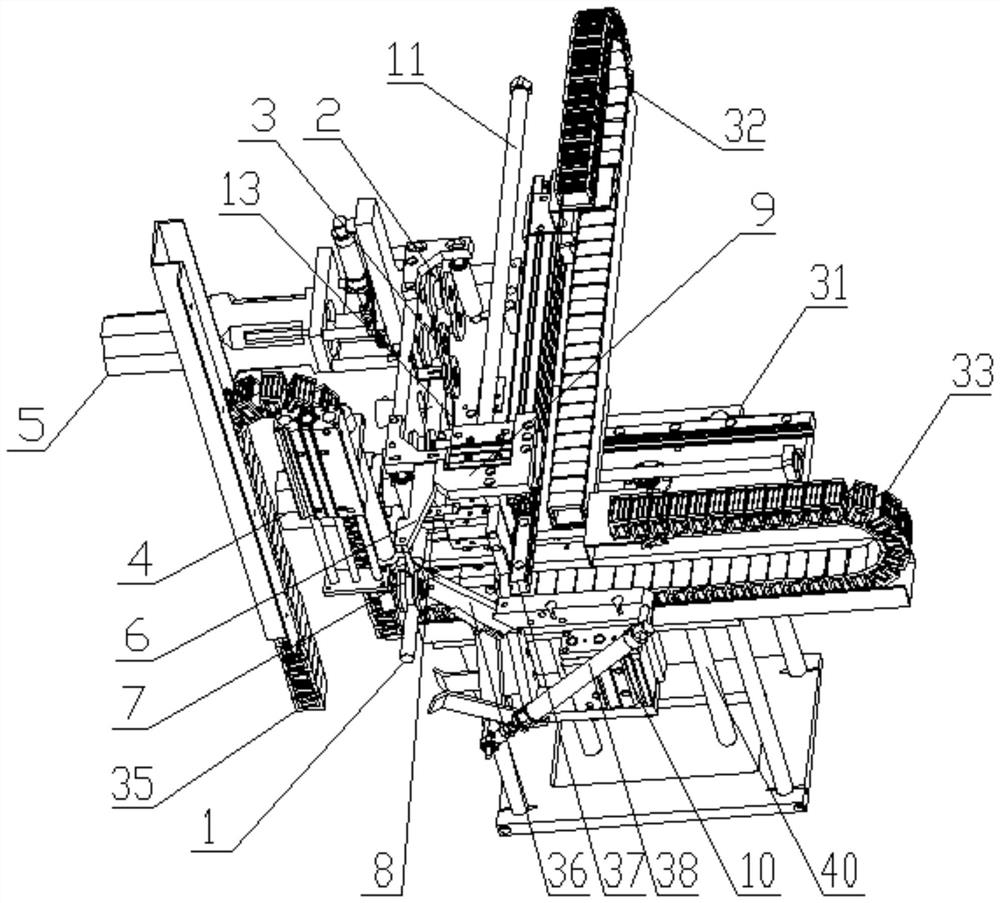

[0033] Such as figure 1 As shown, the device includes a feeding mechanism 700 for conveying pipes, a winding mechanism 600 for winding pipes, a binding mechanism 300 for bundling pipe coils (pipe coils refer to pipes after winding is completed), Based on the unloading mechanism 400 for removing the pipe coil and the grasping mechanism 500 for disassembling the sidewall 900 of the rewinding part, the feeding mechanism 700 sends the front end of the pipe to the rewinding part 63 of the rewinding mechanism 600 and fixes it through the rewinding part. The roll part 63 rotates to coil the pipe material into a tube coil. The grabbing mechanism 500 removes the sidewall 900 of the winding part and binds the tube coil through the binding mechanism 300. 500 reset and install the rewinding portion rib 900 on the rewinding portion 63;

[0034] Wherein, the feeding mechanism 700 includes a base plate 31, a feed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com