Copper bar connecting structure production method

A connection structure, copper bar technology, applied in the direction of clamping/spring connection, contact parts, etc., can solve the problems of current flow line changes, time-consuming and labor-intensive, etc., to achieve fast heat dissipation, economic benefits, and large heat dissipation area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

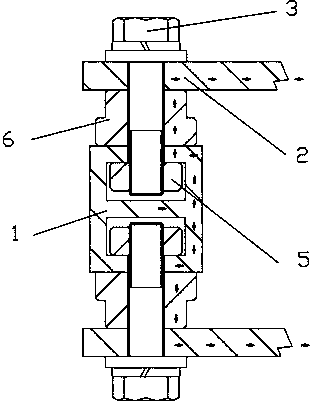

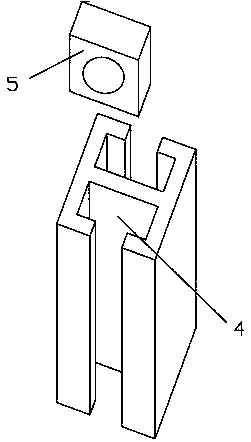

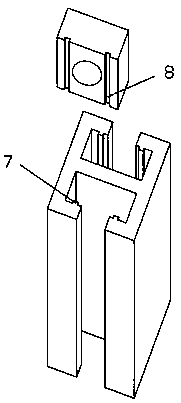

[0014] As shown in Figure 1 to Figure 3, the copper bar connection structure includes input copper bar 1, output copper bar 2 and bolt 3, the input copper bar and output copper bar are set in a cross, and the cross section of the input copper bar is "I" , there are long grooves 4 on both sides, and nuts 5 are arranged in the long grooves. The nuts can be hexagonal nuts or square nuts. The nuts can be moved to a designated position to fix the output copper bar without drilling and will not change the flow trace of the current. The surface of the nut on the side that is against the input copper bar is flat, which can increase the contact area. A conductive pad 6 is set between the input copper bar and the output copper bar. The upper and lower surfaces of the conductive pad are flat, and the bolts pass through the output in turn. After the copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com