A karst grouting reinforcement method adjacent to the existing ballastless track subgrade

A technology for grouting reinforcement and roadbed, applied in the direction of roads, roads, infrastructure engineering, etc., can solve the problems of the upper arch deformation of the covering layer, the aggravation of track irregularity, threatening the safe operation of high-speed trains, etc., to avoid the upper arch deformation, Easy to implement and clear process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

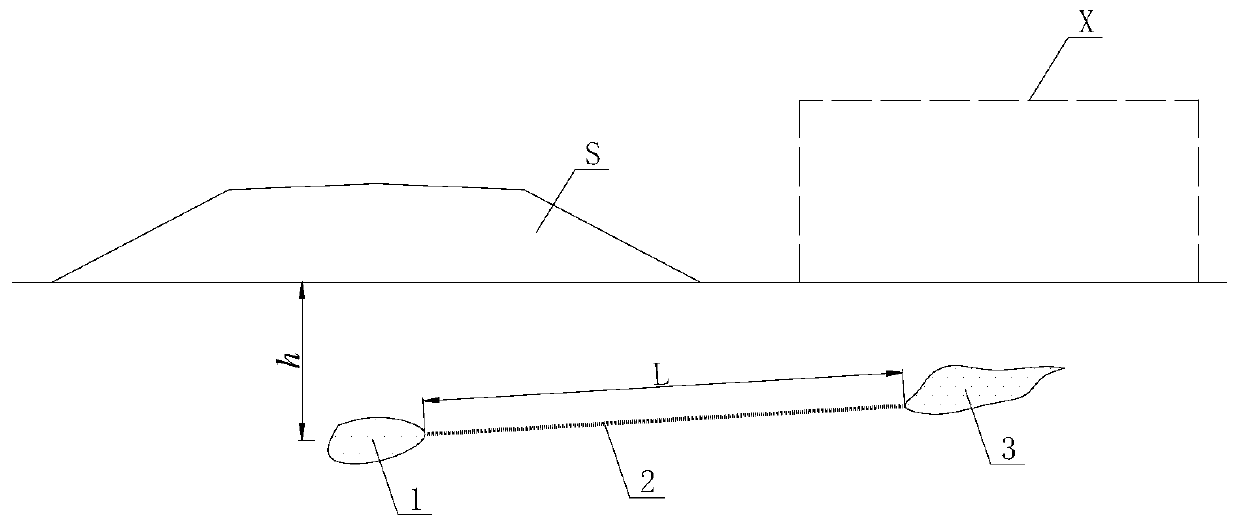

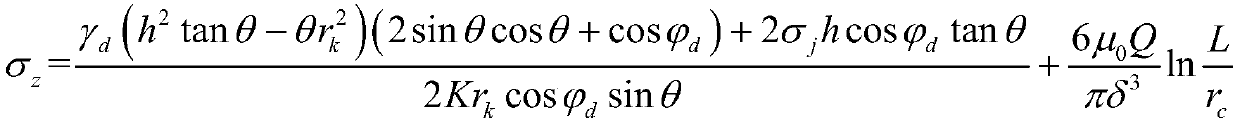

[0036] refer to figure 1 A ballastless track high-speed railway embankment was built in a karst area, and the embankment was filled with a height of 1.6m. There may be hidden karst at the base of the existing ballastless track embankment S. Now a new building needs to be built next to the embankment, and the base of the building is explored. In the karst development area, it is planned to use grouting for karst reinforcement, and the amount of grouting Q is 100m 3 , r c The radius of the grouting pipe is 0.025m. The initial kinematic viscosity of slurry μ 0 for 10 -6 kpa.

[0037] In order to prevent the existing ballastless track subgrade S from being arched due to karst grouting reinforcement, the method of the present invention is used to determine the grouting reinforcement method for the newly built building X base karst 3 adjacent to the existing ballastless track subgrade S, and the specific steps are as follows:

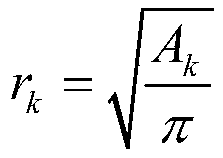

[0038] 1. Determine the vertical distance h from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com