A grouting repair method for regenerating concealed karst at the subgrade base of existing ballastless track

A karst and track technology, applied in the field of geotechnical engineering, can solve the problems of aggravated track irregularity, upper arch deformation, regenerated hidden karst collapse, etc., and achieves the effect of convenient implementation, clear process, and avoiding upper arch deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

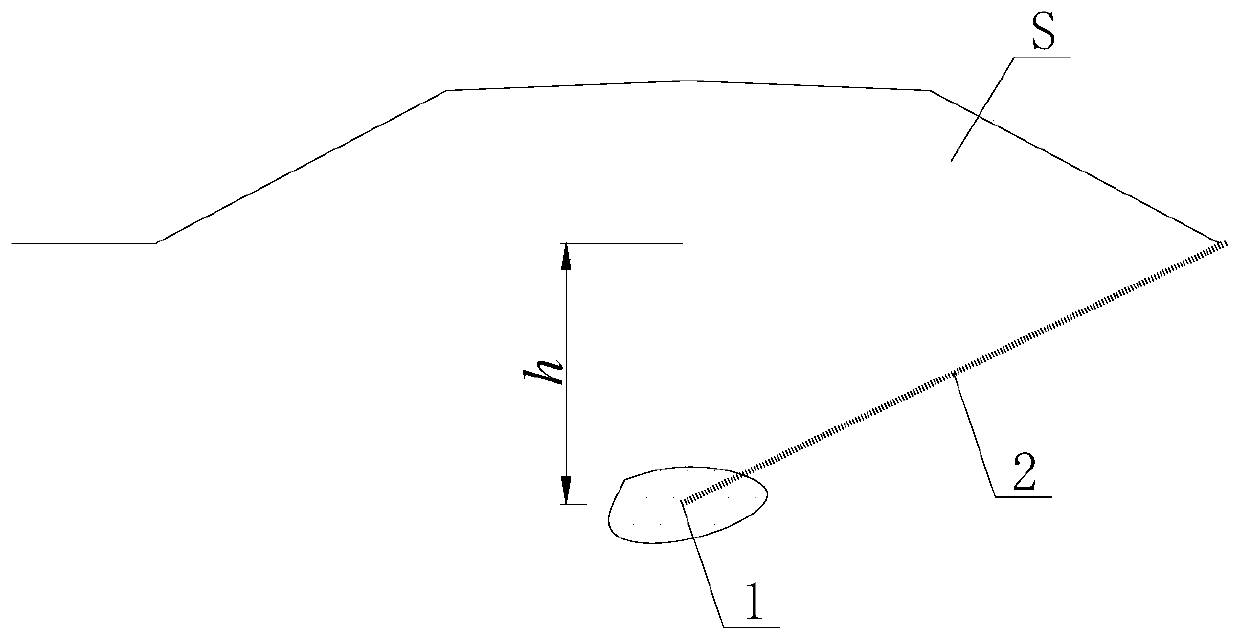

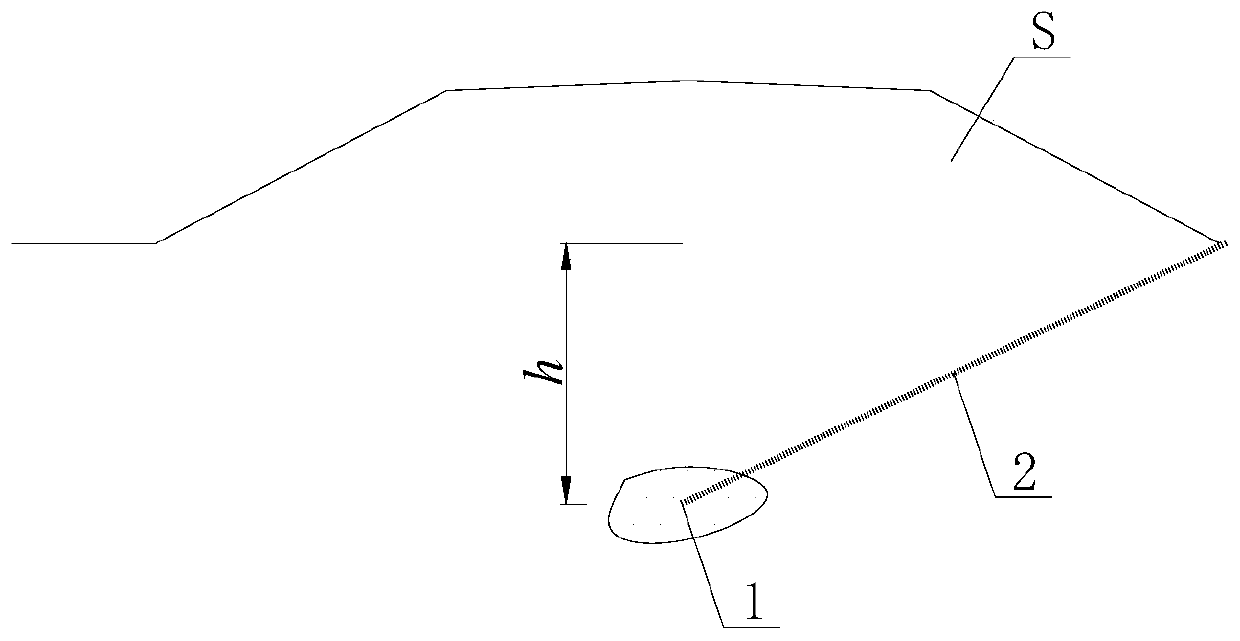

[0032] refer to figure 1 A ballastless track high-speed railway subgrade was built in a karst area, and the subgrade was filled to a height of 2.0m. The soluble rock at the S base of the existing ballastless track subgrade formed a regenerated concealed karst 1 under the action of water erosion and dissolution, and grouting was required to repair the regenerated concealed Karst 1 foundation.

[0033] In order to avoid karst grouting causing the existing ballastless track subgrade S to produce arching deformation, the method of the present invention is used to determine the grouting repair method of the regenerated concealed karst 1 of the existing ballastless track subgrade S base, and the specific steps are as follows:

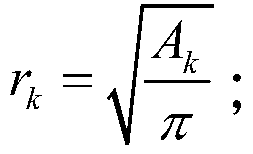

[0034] 1. Determine the vertical distance h from the base of the existing ballastless track subgrade S to the center of the regenerated concealed karst 1 as 4.5m by high-density electrical method or ground penetrating radar or seismic reflection method or ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com