Low-cost production process for Q355C steel plate

A production process, low-cost technology, applied in the field of steel plates, can solve the problems of difficult to achieve low-cost production and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Steel type: Q355C; billet thickness 250mm; rolled product specification: 16mm; quantity: 8 pieces, 80.20t in total.

[0035] 1. Melting composition: C=0.17%, Si=0.30%, Mn=1.45%, P=0.015%, S=0.012%, Alt=0.025%;

[0036] The slab has a good low-magnification structure, with H content of 2.5ppm, T[O]: 20ppm, and N content of 44ppm.

[0037] 2. Soaking temperature: 1200°C; rough rolling start temperature: 1130°C; finish rolling start temperature: 950°C; final rolling temperature 840°C; ACC final cooling temperature 680°C.

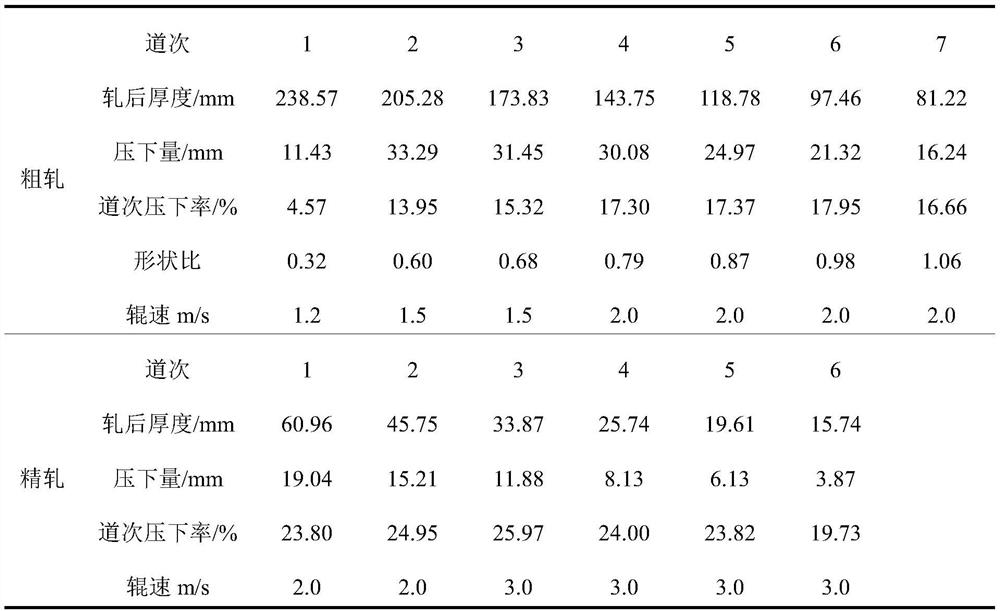

[0038] 3. The distribution of rough and finish rolling passes is 7 / 7, the intermediate billet is 80mm, and the compression ratio of the intermediate billet is 5. The specific parameters are shown in Table 1.

[0039] Table 1 Embodiment 1 rolling pass situation

[0040]

[0041] 4. After the steel plate is rolled, it goes off-line for stack cooling, and the off-line temperature is 250°C.

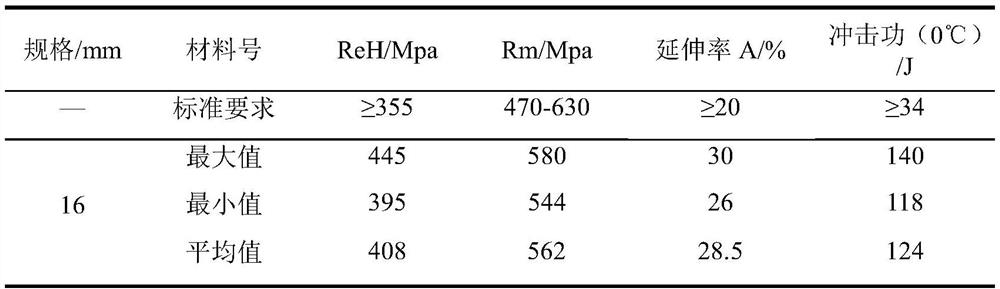

[0042] 5. After the steel plate stack is cooled to room temp...

Embodiment 2

[0047] Steel type: Q355C; slab thickness 250mm; rolled product specification: 30mm; quantity: 7 pieces, 85.23t in total.

[0048]1. Melting composition: C=0.15%, Si=0.35%, Mn=1.51%, P=0.018%, S=0.010%, Alt=0.025%;

[0049] The low-magnification structure of the slab is good, the H content is 2.5ppm, T[O]: 22ppm; the N content is 49ppm.

[0050] 2. Soaking temperature: 1180°C; rough rolling start temperature: 1100°C; finish rolling start temperature: 910°C; final rolling temperature 840°C; ACC final cooling temperature 650°C.

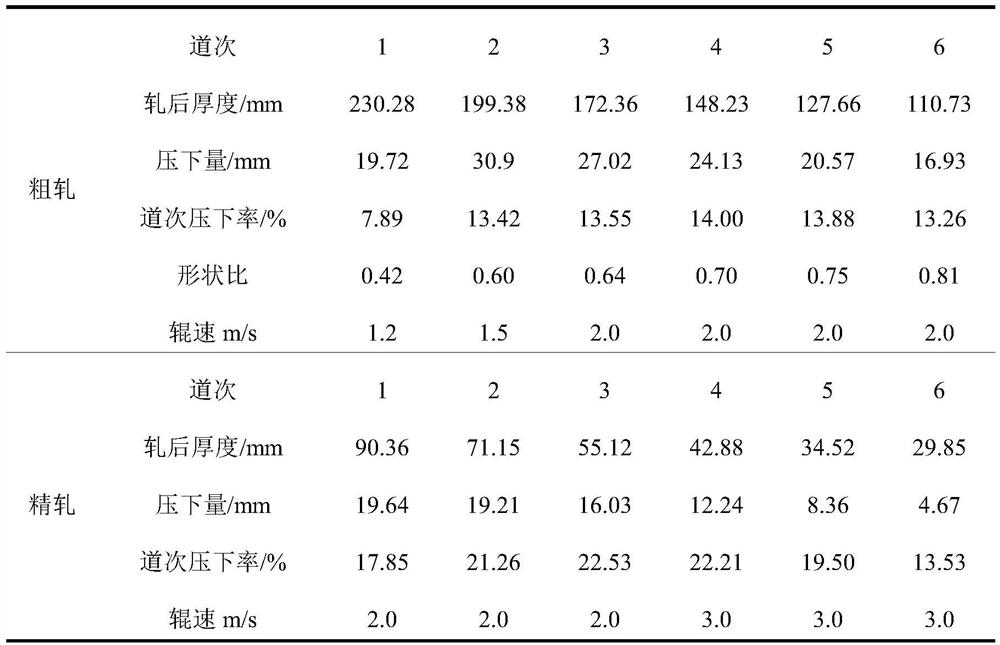

[0051] 3. The distribution of rough and finish rolling passes is 7 / 7, the intermediate billet is 110mm, and the intermediate billet compression ratio is 3.7. The specific parameters are shown in Table 3.

[0052] Table 3 Example 2 rolling pass situation

[0053]

[0054] 4. After the steel plate is rolled, it goes off-line for stack cooling, and the off-line temperature is 280°C.

[0055] 5. After the steel plate stack is cooled to room temperature...

Embodiment 3

[0060] Steel type: Q355C; slab thickness 250mm; rolled product specification: 50mm; quantity: 6 pieces, 78.72t in total.

[0061] 1. Melting composition: C=0.18%, Si=0.32%, Mn=1.56%, P=0.017%, S=0.008%, Alt=0.030%;

[0062] The low-magnification structure of the slab is good, the H content is 1.8ppm, T[O]: 20ppm; the N content is 46ppm.

[0063] 2. Soaking temperature: 1160°C; rough rolling start temperature: 1090°C; finish rolling start temperature: 870°C; final rolling temperature 850°C; ACC final cooling temperature 630°C.

[0064] 3. The distribution of rough and finish rolling passes is 5 / 7, the intermediate billet is 150 mm, and the compression ratio of the intermediate billet is 3. The specific parameters are shown in Table 5.

[0065] Table 5 Embodiment 3 rolling pass situation

[0066]

[0067] 4. After the steel plate is rolled, it goes off-line for stack cooling, and the off-line temperature is 310°C.

[0068] 5. After the steel plate stack is cooled to room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com