Medium-frequency induction quenching process in heavy-duty rack with super modulus

A technology of induction hardening and rack, which is applied in the field of heat treatment, can solve problems such as the inability to eliminate the adverse effects of rack tooth roots, quenching cracks and deformation, and achieve the effects of avoiding quenching cracking and delayed cracking, improving stress state, and satisfying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

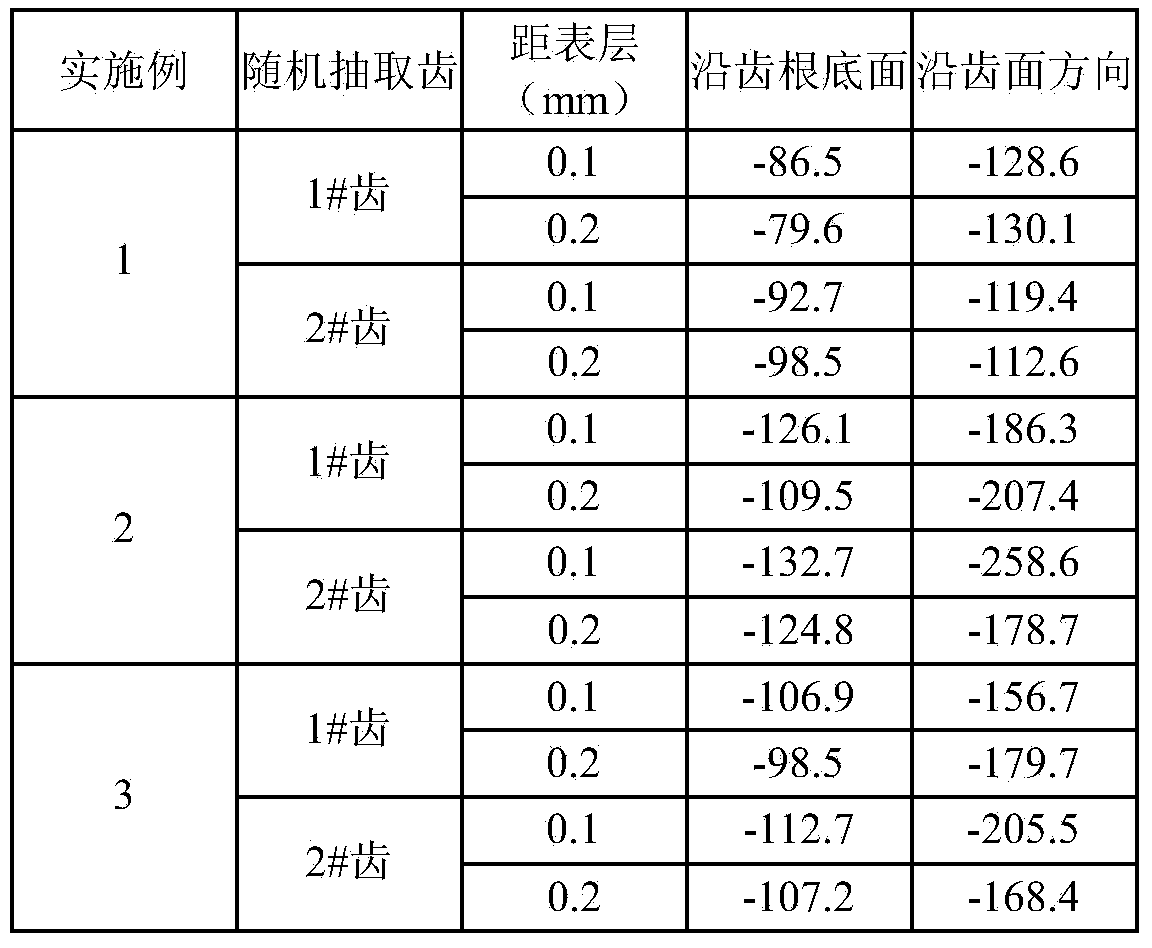

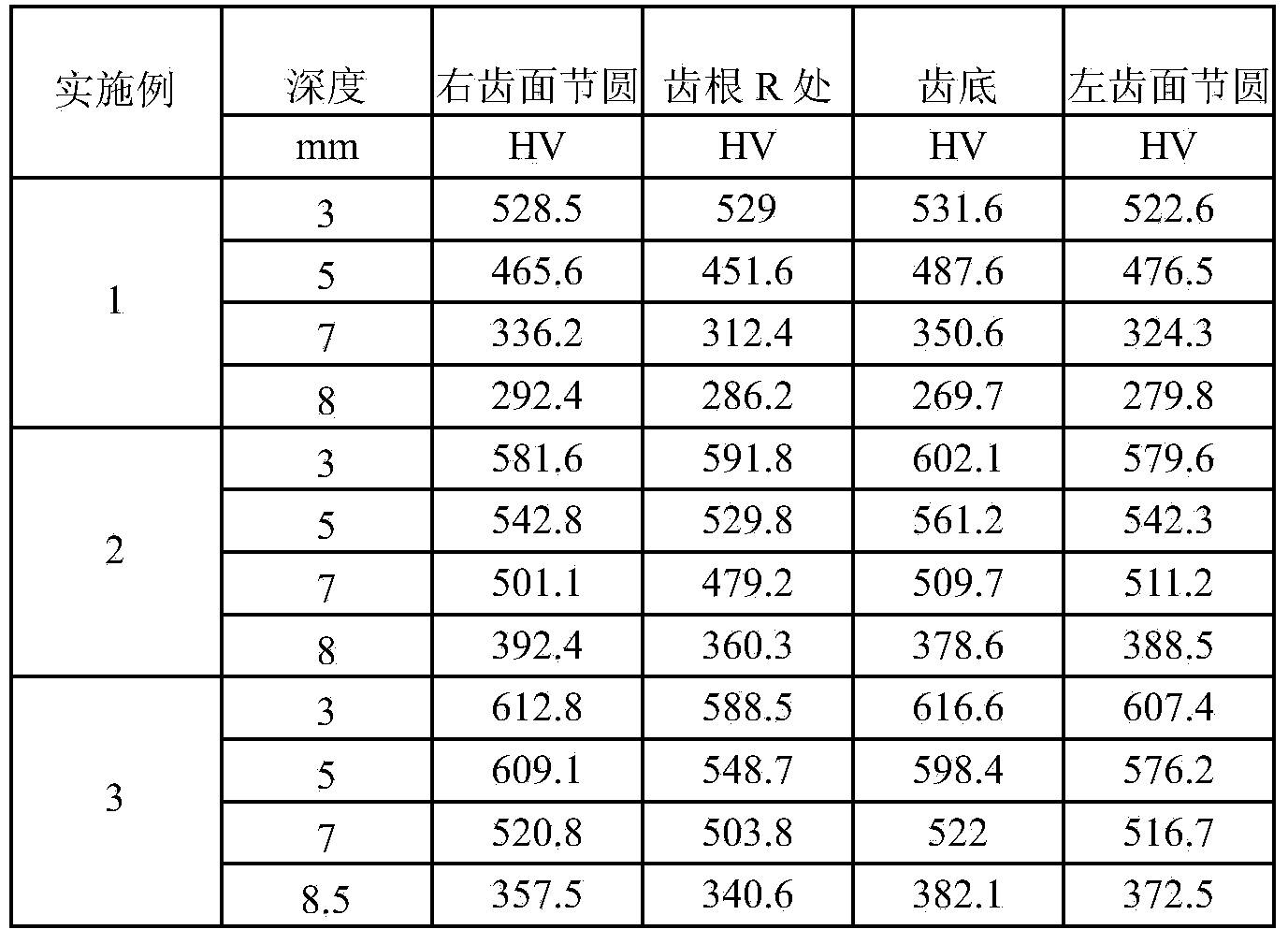

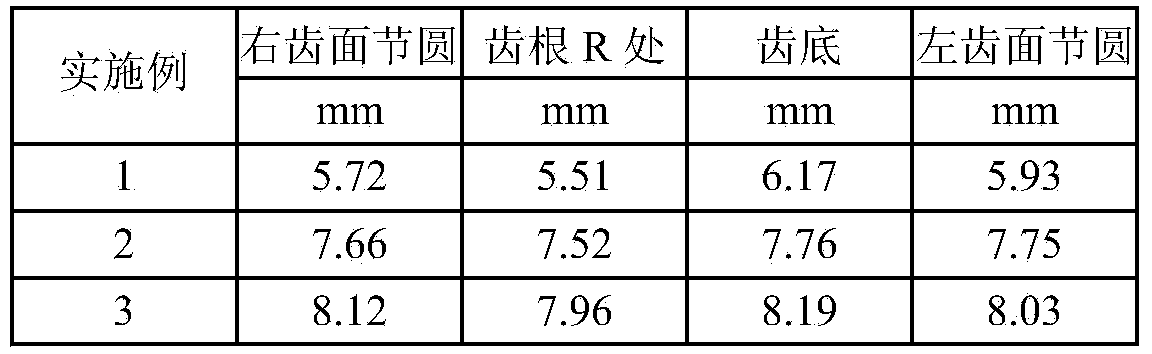

[0043] In a factory, an engineering test was carried out according to the quenching process design of the present invention. The sample racks are all castings, made of G35CrNiMo6-6 material, the rack modulus is 66.667mm, the tooth height is 141mm, and the tooth width is 810mm. Containing 24 teeth, the depth of the hardened layer is required to be ≥ 5mm, and the surface hardness ≥ HV520. Before quenching, quench and temper according to the DIN EN 10293-2005 steel casting material standard according to the existing process.

[0044] Before quenching, the two racks are connected back to back through the connecting tool, so that the two racks form a whole, and the teeth of the two racks are symmetrically distributed on both sides. The connecting tool adopts the applicant's patent number ZL 201120545825.3, the tooling described in the utility model patent of the invention titled super-large modulus rack table quenching and anti-deformation tooling.

[0045] Before implementation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com