Thermal treatment method of cam shaft

A heat treatment method and camshaft technology, applied in heat treatment furnaces, heat treatment equipment, process efficiency improvement, etc., can solve the problems of uneven quenching hardness, uneven depth of hardened layer, inconsistent heat transfer speed, increased production cost, etc., and achieve fatigue strength And the service life is improved, the depth of the hardened layer is uniform and reasonable, and the metallographic structure is uniform and reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Ultrasonic frequency induction heating and quenching

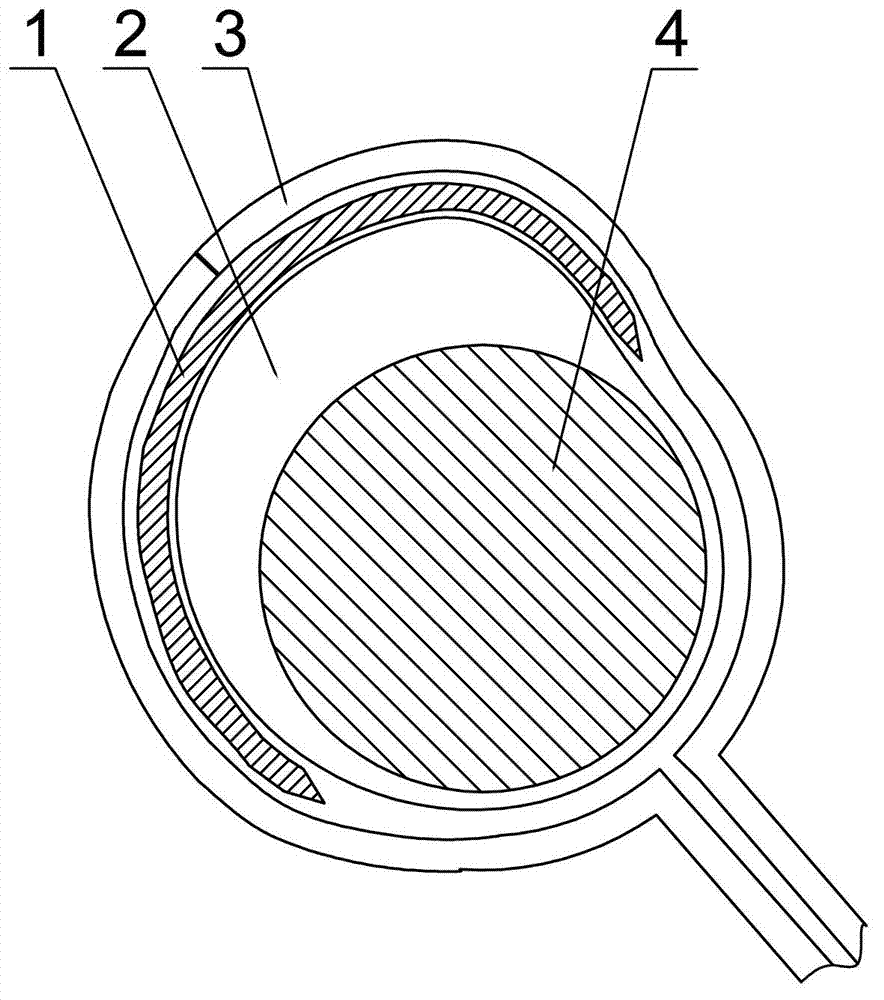

[0021] Install the camshaft 4 on the quenching machine tool, set the induction coil 3 of the super-audio frequency induction heating device on the outside of the cam 2, and place a shielding plate 1 (material Q235 steel) between the cam lift part and the induction coil 3, Use the above-mentioned supersonic frequency as the heating power supply, and then perform the heating and quenching operation in the following order:

[0022] a. Preheating, under the conditions of voltage 360V and current 175A, preheat for 35s;

[0023] b. Stop heating after the preheating is completed, then remove the shielding plate 1, stop heating for 6 seconds, and continue heating for 9 seconds under the conditions of voltage 415V and current 210A;

[0024] c. Cooling, using polyvinyl alcohol aqueous solution with a mass concentration of 1.2% as the quenching medium, the injection pressure is gradually reduced from 0.15Mpa to 0.05Mpa, c...

Embodiment 2

[0029] (1) Ultrasonic frequency induction heating and quenching

[0030] Camshaft 4 will be installed on the quenching lathe according to embodiment 1, then carry out heating and quenching operation in the following order:

[0031] a. Preheating, under the conditions of voltage 460V and current 220A, preheat for 42s;

[0032] b. Stop heating after the preheating is completed, then remove the shielding plate 1, stop heating for 7 seconds, and continue heating for 12 seconds under the conditions of voltage 480V and current 235A;

[0033] c. Cooling, using polyvinyl alcohol aqueous solution with a mass concentration of 1.8% as the quenching medium, the injection pressure is gradually reduced from 0.2Mpa to 0.05Mpa, controlled by a servo hydraulic valve, the spray cooling pressure is continuously adjustable, first fast and then slow, spray The time of quenching medium is 170s.

[0034] (2) Tempering

[0035] Put the quenched camshaft 4 into a hot air circulation furnace whose t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com