Normalizing method for forging waste heat of steel

A technology of forging waste heat and normalizing, applied in the field of warm normalizing, can solve the problems of high cost, mixed crystals, large energy consumption, etc., and achieve the effect of prolonging the service life, preventing quenching cracks and reducing the amount of distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

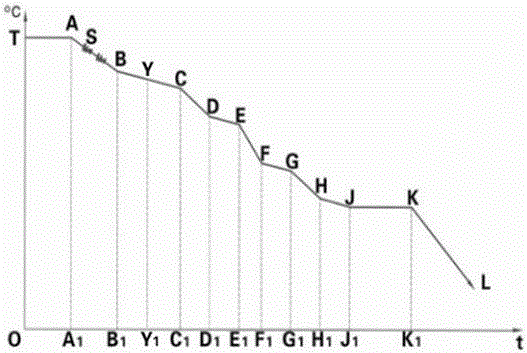

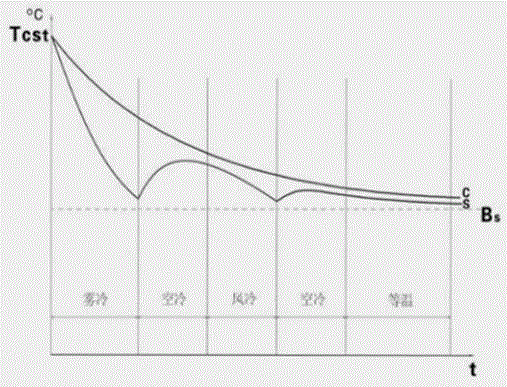

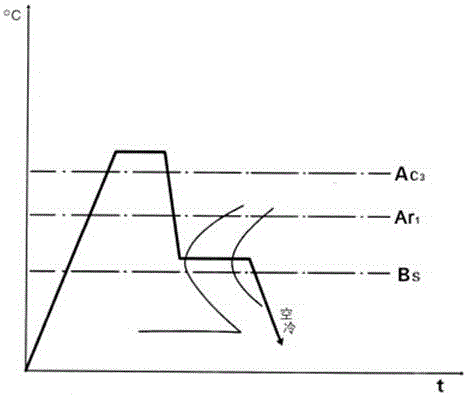

[0122] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0123] Deformation degree:

[0124] From the point of view of metallurgy, above the recrystallization temperature, the plastic deformation process that does not cause work hardening is called thermal deformation processing. This is based on whether the metal undergoes work hardening after deformation processing; in fact, the metal also undergoes hardening during thermal deformation, but because the temperature of thermal deformation is much higher than the recrystallization temperature, the hardening caused by deformation is quickly eliminated simultaneously. Eliminated by the recrystallization process that occurs.

[0125] The degree of deformation is calculated by the following formula:

[0126] ϵ = H 0 - H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com