Anti-cracking machining method of small axial surface carburizing and hardening stepped shaft with end face provided with groove

A technology of carburizing, quenching, and processing methods, which is applied in the field of mechanical processing, and can solve problems such as easy cracks in steps, and achieve the effects of avoiding quenching cracks, reducing production costs, and reducing tissue stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

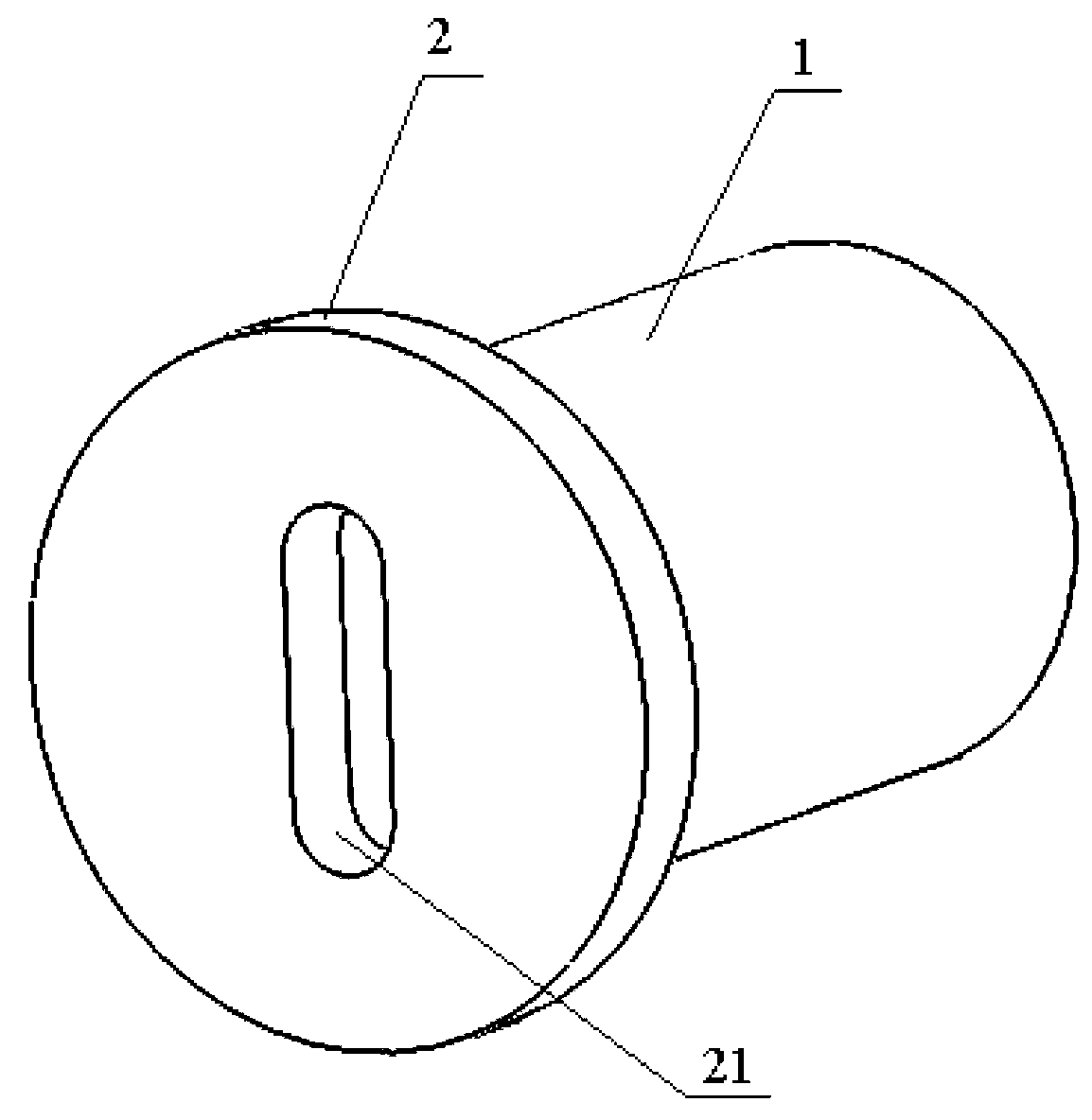

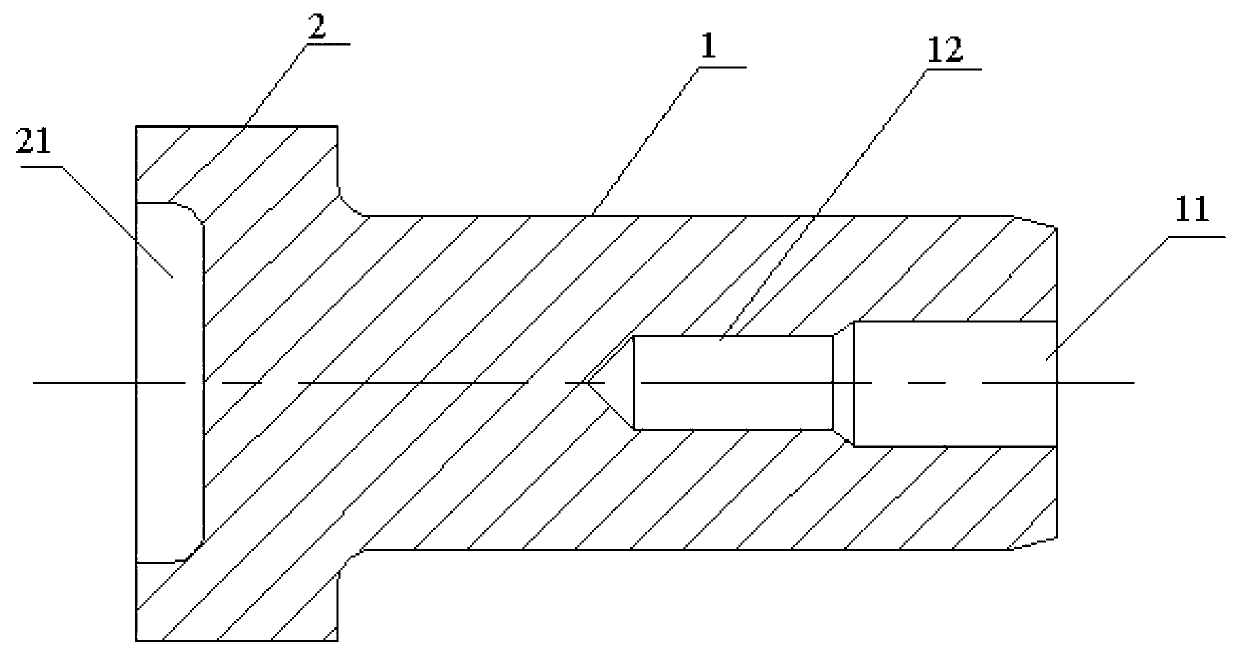

[0027] The anti-cracking processing method of the small shaft surface carburized and quenched stepped shaft with grooves on the end surface. In this embodiment, the stepped shaft to be manufactured is as follows figure 1 and figure 2 As shown, the stepped shaft includes two shaft segments: a thinner shaft segment A and a thicker shaft segment B, where the shaft segment A and the shaft segment B are connected to form a step. Among them, the length of shaft section A is required to be 55.295 mm to 55.3 mm, the total length of the shaft is required to be 59.9 mm to 60.1 mm, and the length of shaft section B is jointly limited by the total length of the shaft and the length of shaft section A. The diameter of shaft section A is required to be 35.959mm to 35.975mm, and the diameter of shaft section B is required to be 48.8mm to 49mm. The outer end surface of the shaft section A requires a center hole 11 of φ14×15, and a threaded hole 12 with a specification of M12×35 is required ...

Embodiment 2~5

[0039] The size of the protective steps and the effect after quenching in Examples 2-5 are as follows: (except for the different protective steps, the rest of the process parameters are the same)

[0040]

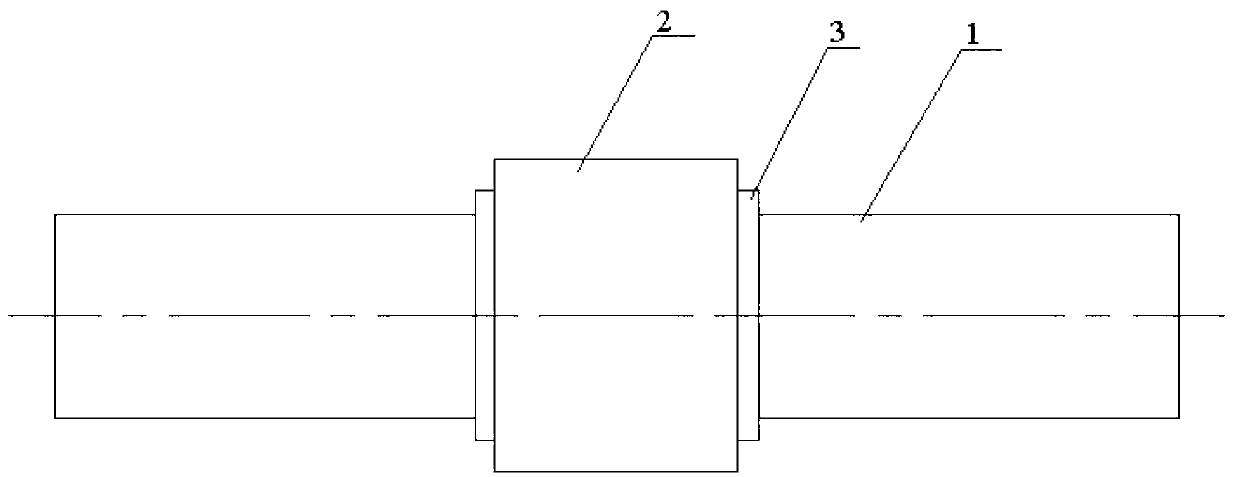

[0041] It can be seen from the above table that the setting of the protective step can effectively prevent the occurrence of cracks on the end face of the step and improve the qualified rate of finished products; when the width and height of the protective step are 0.7 to 1 times the depth of the carburized layer, it can Form a relatively shallow carburized layer with low carbon content, so that the root of the step still has a certain hardness and wear resistance after quenching; when the width and height of the protective step are 1 to 3 times the depth of the carburized layer At the same time, there will be no carburized layer at the root of the step, so the stress is small, the possibility of cracks is low, and the product qualification rate is high; in production, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com