Heat treatment process for high-hardenability Martensitic stainless steel for moving blades

A martensitic stainless steel and high hardenability technology, which is applied in the heat treatment process of martensitic stainless steel and the heat treatment process of high hardenability martensitic stainless steel, can solve the problems of low product qualification rate and reduce structural stress. , The effect of reducing volume expansion and reducing tissue stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further described in detail by means of examples.

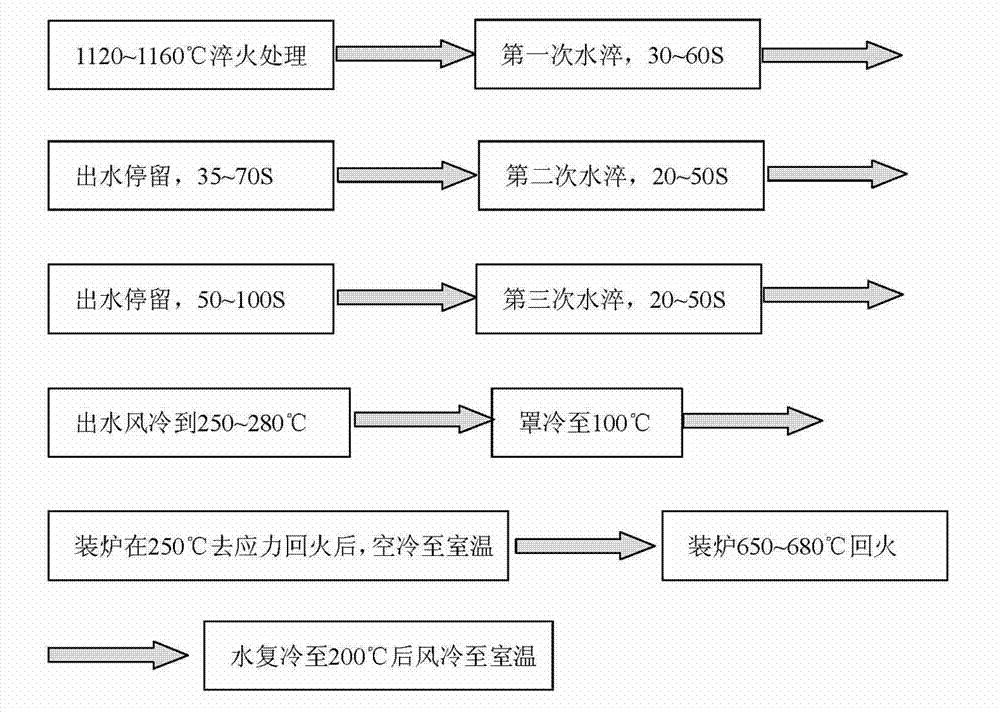

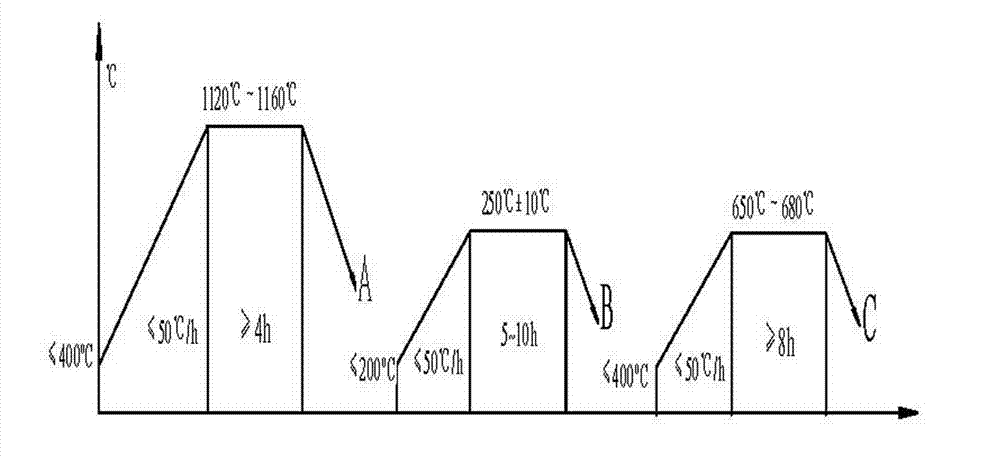

[0017] attached figure 1 The specific technological process for the heat treatment of the high-hardenability martensitic stainless steel for moving blades according to the present invention has the following steps.

[0018] (1) After forging, the workpiece is air-cooled to 50-90°C and installed in a furnace, and then heated to 1120-1160°C (furnace temperature lower than 400°C) after 1-2 hours of uniform temperature for quenching treatment.

[0019] (2) After 8-10 hours of heat preservation, the first water quenching time is 30-60S, the effluent residence time is 35-70S, the second water quenching time is 20-50S, the effluent residence time is 50-100S, and the third The secondary water quenching time is 20-50S, and air-cooled after the water is discharged.

[0020] (3) Use a blower to blow the workpiece, and the workpiece rotates at the same time. After 30 to 50 minutes, the workpie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com