Treatment method for improving tensile property qualification rate of steel plate

A processing method and a technology of tensile properties, which are applied in the field of processing to improve the pass rate of steel plate tensile properties, can solve the problems of long rerolling cycle, long production cycle of thick steel plates, and affecting product delivery time, etc., and achieve an increase in pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

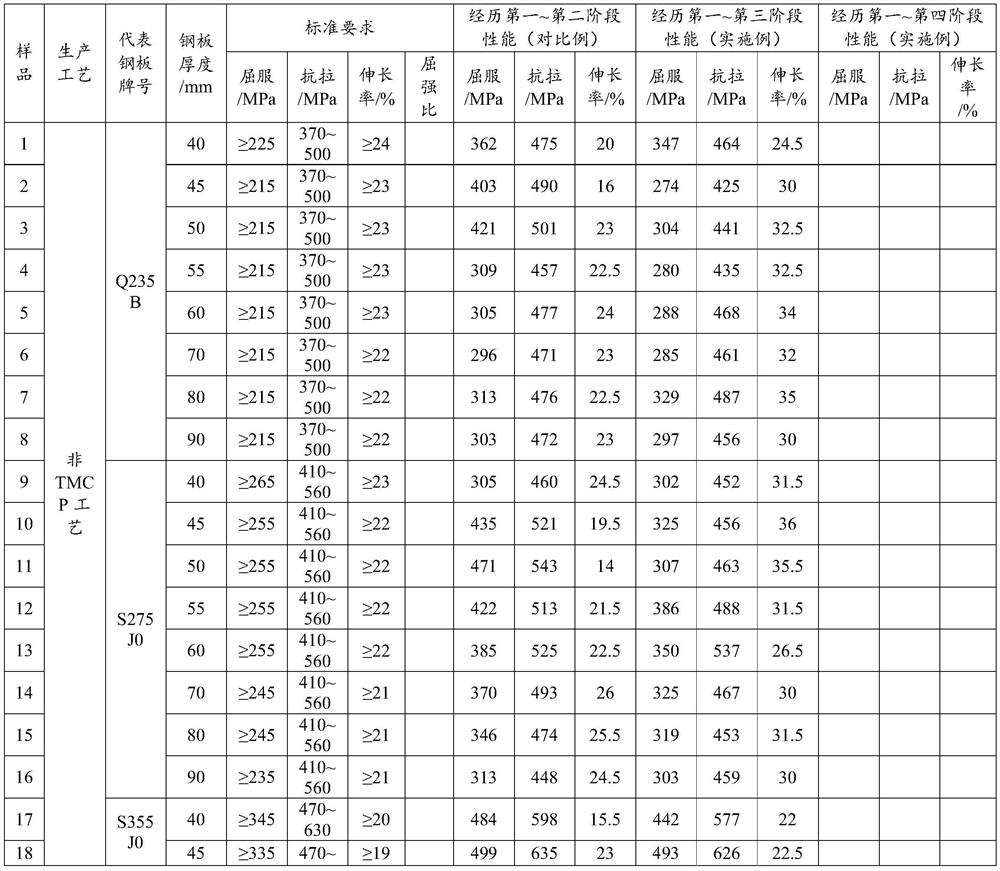

Examples

Embodiment

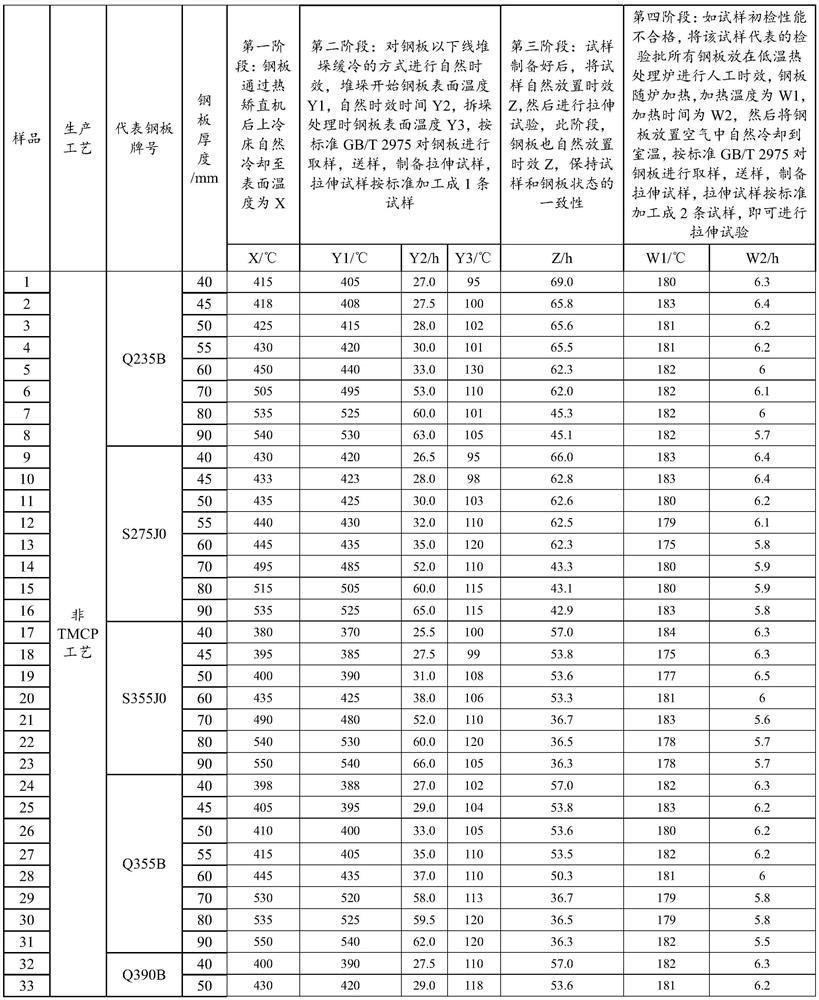

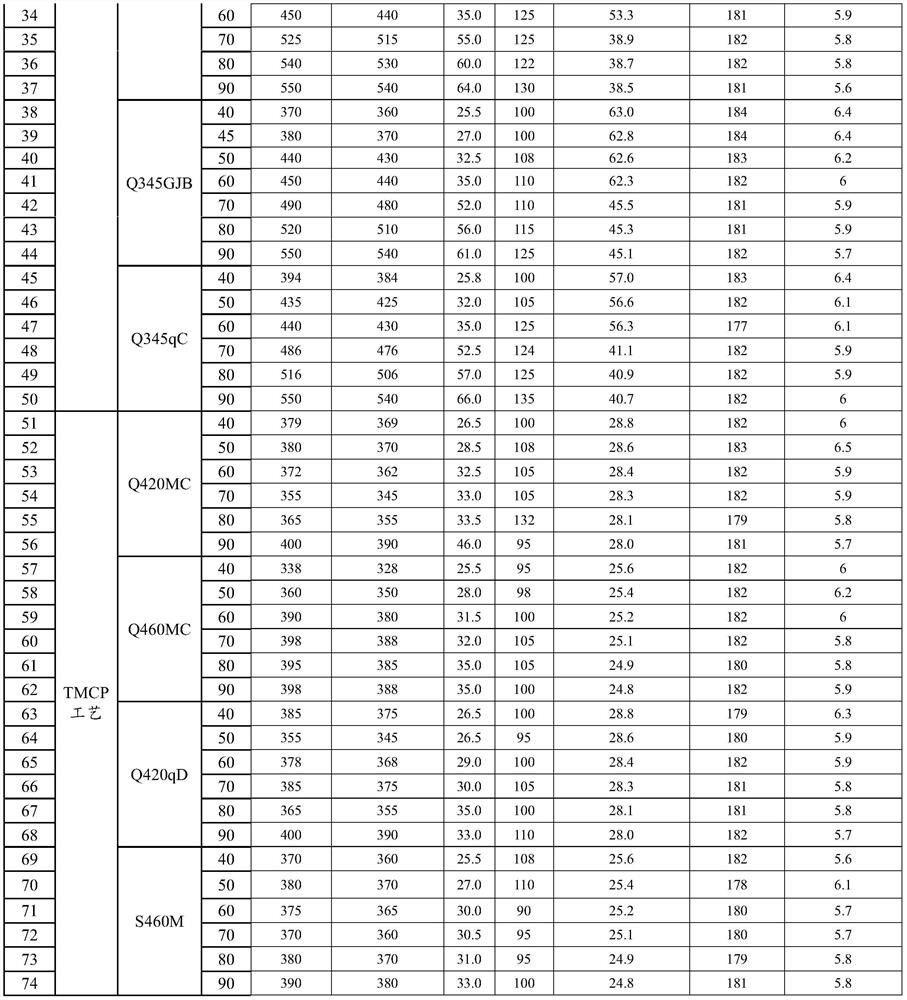

[0090] Table 1 is the specific steps of the processing method for improving the steel plate tensile property qualified rate:

[0091] Table 1 Treatment methods for improving the qualified rate of steel plate tensile properties

[0092]

[0093]

[0094] It should be noted that in the above Table 1, each type of steel plate does not have to be processed through the above four stages. For the data in the comparative example, only the first stage and the second stage are processed, and after the processing is completed, the tensile properties of the sample are directly detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com