Production processing method for edge-digging scissors made of Cr12Mo1V1

A technology of cr12mo1v1 and processing method, applied in the field of cutting edge shears made of cold work die steel Cr12Mo1V1, can solve the problems of improper selection of heat treatment and tempering temperature, damage to internal stress balance, large amount of retained austenite, etc. Acceptance rate, grinding stress relief, tissue stress relief and thermal stress relief effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

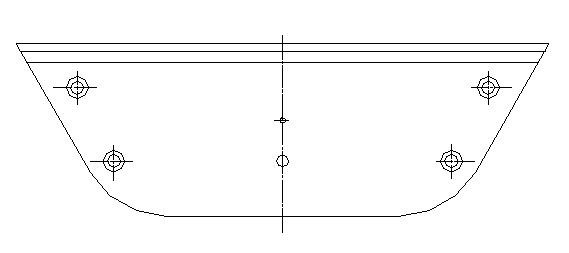

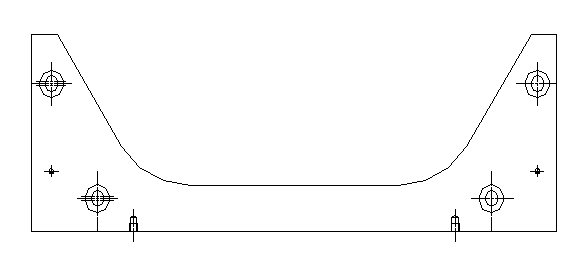

Image

Examples

Embodiment Construction

[0008] The production and processing method of the material Cr12Mo1V1 digging shears of the present invention, the specific steps are as follows: (1) Isothermal spheroidizing annealing of the forging: heat the forging at 850~870°C for about 4 hours, then cool it to 730~750°C for 5~ After 6 hours, it is cooled to below 500°C with the furnace and air-cooled, and its hardness is less than HB260. (2) Rough milling, flaw detection, component detection. (3) Stress relief and tempering: the workpiece is kept at 600°C for about 5 hours, then cooled to 500°C with the furnace and air-cooled; fine milling to the size before quenching. (4) Quenching and tempering: Heating before quenching adopts three stages of temperature rise: 550°C for 120 minutes, 850°C for 120 minutes, 1010°C for 110 minutes; then out of the furnace for oil quenching, the oil temperature must be kept at 60 Between -80°C, cool down to below 150°C, and after the oil is air-cooled to room temperature, immediately perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com