Heat treatment process of stone cutting saw blade

A stone cutting and saw blade technology, applied in the field of stone cutting saw blade heat treatment technology, can solve the problems of stone cutting saw blade matrix performance cannot be guaranteed, toughness, wear resistance, lack of performance, etc., to improve life and mechanical properties. The effect of improved performance, wear resistance and tool life, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 The heat treatment process of the stone cutting saw blade

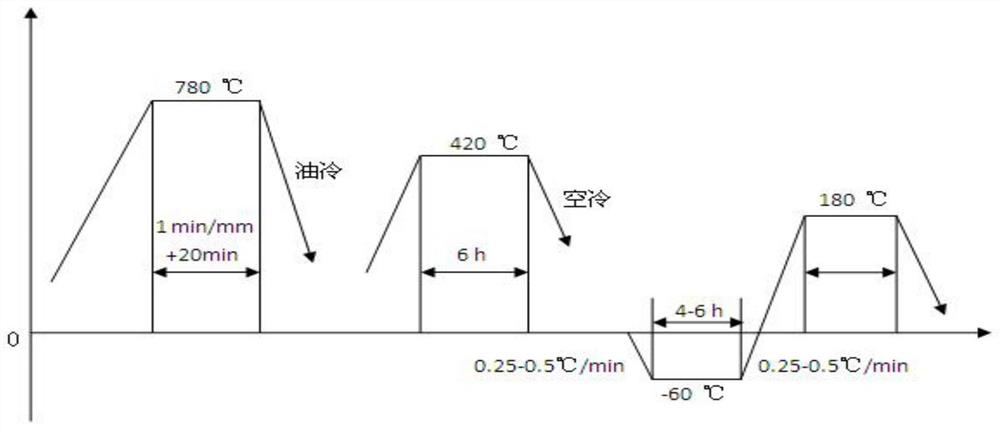

[0034] The steps are as follows (such as figure 1 shown):

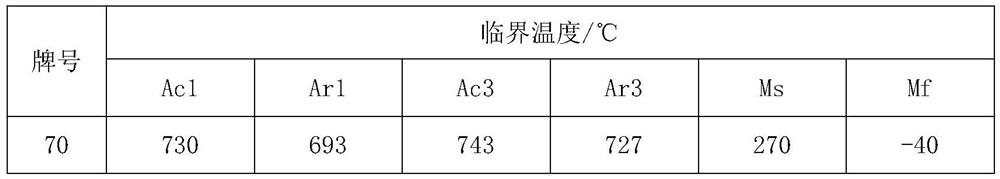

[0035] (1) Cutting, forging, and preheating treatment: hoist the 70 spring steel saw blade equipped with fixtures on the hanger for hanging and burning, put it into the well-type gas protection furnace, and drip protection (drip methanol protection, 60 drops / min), heating uniformly without oxidation, heating at 100°C / h to the optimum quenching heating temperature of 780°C (Ac1+50°C);

[0036] (2) Heat preservation: the heat preservation time is calculated as 1min / mm, plus 20min / furnace, and it is baked out after being thoroughly baked;

[0037] (3) Oil quenching: the quenching temperature is selected at Curie point 768°C and then quenched after loss of magnetism. The purpose is to refine austenite, control the grade of austenite grains, and hinder the growth of grains; evenly heat, and the oil temperature is controlled at 80 Within ℃, ...

Embodiment 2

[0044] Embodiment 2 Traditional 65Mn thermal processing technology

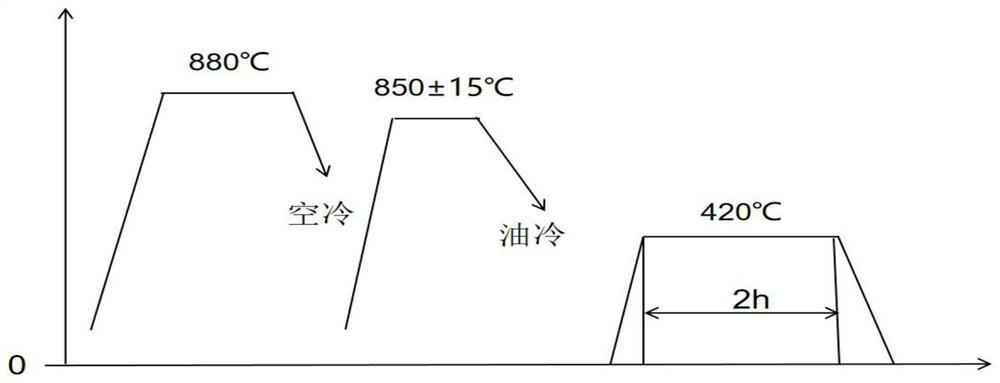

[0045] The steps are as follows (such as figure 2 shown):

[0046] Normalizing: Normalizing temperature 880℃;

[0047] Oil quenching: the quenching temperature is 850°C±15°C, the oil temperature is controlled within 80°C, the spreader comes out of the furnace, puts oil into it, moves it into the quenching press, pressurizes and cools down to room temperature;

[0048] Tempering at medium temperature: control the tempering temperature at 420°C and temper for 2 hours.

[0049] According to the traditional technique (Example 2) and the technique of the present invention (Example 1), four kinds of stone saw blades were trial-manufactured respectively. After testing and comparison, the performance was improved, and the qualified rate was increased by 80%. As we all know, the blade should have sufficient strength and hardness to maintain the wear resistance of the blade. After setting tempering and cryogenic tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com